Superalloy steels are a class of high-performance materials renowned for their exceptional strength, resistance to high temperatures, and corrosion resistance. These remarkable properties make them indispensable in numerous critical applications where conventional steels simply fall short. This blog post delves into the fascinating world of superalloy steels, exploring their unique characteristics and diverse applications across various industries.

1. Aerospace: Reaching for the Sky with Superalloy Steel

The aerospace industry is arguably the most demanding environment for materials, requiring components to withstand extreme temperatures, pressures, and corrosive environments. Superalloys are the backbone of many crucial aerospace components. In jet engines, for example, turbine blades and disks operate at temperatures exceeding 1000°C (1832°F). Superalloys like nickel-based alloys (Inconel, Waspaloy) and cobalt-based alloys (L605, Stellite) provide the necessary high-temperature strength and creep resistance to ensure engine efficiency and longevity. These alloys also exhibit excellent resistance to oxidation and hot corrosion, crucial for prolonged operation in harsh environments. Beyond jet engines, superalloys are used in other critical aerospace components such as afterburners, exhaust nozzles, and airframe structures, ensuring safety and performance at extreme altitudes and speeds.

2. Power Generation: Fueling Progress with Enhanced Durability

The power generation sector relies heavily on superalloy steels for their exceptional resistance to high temperatures and corrosion. In gas turbines used for electricity generation, superalloys are vital for components operating under intense heat and pressure. These alloys’ resistance to creep and fatigue ensures the reliable and long-term operation of power plants. Similarly, in fossil fuel power plants, superalloys find applications in boiler components, superheaters, and reheater tubes, where they withstand high temperatures and aggressive environments. The increasing demand for efficient and reliable power generation continues to drive innovation and the development of new, even more resilient superalloys.

3. Chemical Processing: Withstanding Harsh Environments

The chemical processing industry faces unique challenges, with many processes involving highly corrosive chemicals and extreme temperatures. Superalloy steels provide the necessary resistance to these harsh conditions. In reactors, heat exchangers, and piping systems, superalloys protect against chemical attack and ensure the safe and efficient operation of chemical plants. Their resistance to various acids, alkalis, and other corrosive agents makes them invaluable in handling a wide range of chemicals, preventing costly downtime and environmental hazards. The specific superalloy selected depends on the chemical environment, with some alloys showing superior resistance to specific corrosive agents.

4. Automotive Industry: Enhancing Performance and Efficiency

While not as prevalent as in aerospace or power generation, superalloy steels are finding increasing applications in the automotive industry, particularly in high-performance vehicles. Their high strength-to-weight ratio allows for lighter and more fuel-efficient engines. Turbocharger components, exhaust manifolds, and valves benefit from the high-temperature strength and corrosion resistance of superalloys. As the demand for more efficient and powerful engines grows, the use of superalloys in the automotive sector is expected to increase significantly.

5. Medical Implants: Biocompatibility and Strength Combined

A less widely known application of superalloys is in the field of medical implants. Certain superalloys, particularly those with excellent biocompatibility, are used in the manufacture of orthopedic implants, such as hip and knee replacements. Their high strength and wear resistance ensure the longevity and reliability of these critical implants. The biocompatibility aspect is crucial, as it ensures that the implant does not cause adverse reactions within the body. Research continues to explore the potential of superalloys in other biomedical applications, driven by the need for durable and biocompatible materials.

In conclusion, superalloy steels represent a crucial class of materials, pushing the boundaries of performance in demanding applications across various industries. Their unique combination of high-temperature strength, corrosion resistance, and durability makes them indispensable for ensuring safety, efficiency, and longevity in critical systems worldwide.

SEO Tags:

- Superalloy steel

- Superalloy applications

- High-temperature alloys

- Nickel-based superalloys

- Corrosion-resistant alloys

Ring shank nails are a crucial element in many wooden structures, offering superior holding power compared to common nails. This comprehensive guide delves into the world of ring shank nails, exploring their unique features, applications, and installation best practices. Understanding their properties is key to building strong, durable, and safe wooden structures.

Understanding Ring Shank Nail Design and Functionality

Unlike smooth shank nails, ring shank nails feature a series of rings or barbs along their shaft. These rings significantly increase the nail’s surface area in contact with the wood. This increased surface area creates a much stronger frictional grip, resisting withdrawal forces far more effectively. The rings also help prevent the nail from spinning during hammering, ensuring a straight, secure drive. The size and spacing of the rings can vary depending on the nail’s diameter and intended application. Larger rings and closer spacing generally provide superior holding power, particularly in softer woods where the nail might otherwise pull out easily.

Applications of Ring Shank Nails in Wooden Structures

The superior holding power of ring shank nails makes them ideal for a wide range of applications in wooden construction. They are frequently used in:

- Framing: Securing wall studs, roof rafters, and floor joists. The increased holding power is crucial for resisting the stresses and loads these structural members experience.

- Decking: Attaching decking boards to joists. Ring shank nails provide excellent resistance to the shear forces created by foot traffic and the expansion and contraction of the wood.

- Siding: Securing wooden siding to framing. Their superior holding power ensures the siding remains securely fastened, even in high-wind conditions.

- Sheathing: Attaching plywood or OSB sheathing to framing. This application benefits from the increased resistance to pulling out, ensuring a stable surface for exterior cladding.

- Furniture Making: While not as common as in construction, ring shank nails can be used in furniture construction where strength and holding power are paramount. Often used in concealed joints or where strength is critical.

Advantages of Using Ring Shank Nails

The advantages of using ring shank nails over common nails are substantial:

- Increased Holding Power: This is the primary benefit, offering superior resistance to withdrawal forces.

- Improved Shear Resistance: The rings prevent slippage under lateral loads.

- Reduced Nail Pops: The increased grip minimizes the risk of nails popping out of the wood over time.

- Enhanced Durability: Structures built with ring shank nails are generally more durable and resistant to damage.

- Better Joint Strength: Provides stronger and more reliable joints in various wood applications.

Disadvantages and Considerations When Using Ring Shank Nails

While offering significant advantages, ring shank nails also have some drawbacks:

- Higher Cost: Ring shank nails are generally more expensive than common nails.

- Potential for Wood Splitting: The increased holding power can sometimes lead to wood splitting if not driven correctly, especially in hardwoods or when using larger-diameter nails.

- More Difficult to Remove: Their superior grip makes them more difficult to remove if necessary.

- Less Suitable for Fine Work: Their larger size and aggressive grip can be less suitable for fine woodworking applications where a less noticeable fastener is required.

Proper pre-drilling can mitigate the risk of wood splitting, especially in harder woods.

Proper Installation Techniques for Ring Shank Nails

To maximize the benefits of ring shank nails, proper installation techniques are crucial:

- Pre-drilling: Pre-drilling pilot holes, especially in hardwoods, is highly recommended to prevent wood splitting. The pilot hole should be slightly smaller than the nail’s shank diameter.

- Angle of Drive: Drive the nails straight to ensure maximum holding power. Avoid angled driving unless specifically required by the design.

- Hammering Technique: Use a hammer with a smooth face to avoid damaging the nail head or the surrounding wood. Apply steady, even pressure during hammering.

- Nail Spacing: Follow recommended nail spacing guidelines for the specific application to ensure adequate strength and prevent over-driving.

- Nail Type Selection: Choose the appropriate nail size and type (e.g., galvanized for exterior use) based on the wood species, application, and environmental conditions.

By understanding the properties and proper application of ring shank nails, builders and DIY enthusiasts can create stronger, more durable wooden structures. Remember to always prioritize safety and follow best practices for nail installation.

Tags: ring shank nails, wooden construction, construction nails, framing nails, decking nails, DIY

body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

img {

max-width: 100%;

height: auto;

display: block;

margin: 20px auto;

}

Cold drawn hexagonal bars are a highly versatile and robust material used extensively in various industries. Their unique hexagonal shape and superior mechanical properties make them ideal for a wide range of applications, from automotive components to construction materials. This comprehensive guide delves into the intricacies of cold drawn hexagonal bars, exploring their manufacturing process, properties, applications, advantages, and selection criteria.

The Manufacturing Process of Cold Drawn Hexagonal Bars

The creation of cold drawn hexagonal bars begins with hot-rolled steel bars. These bars are initially shaped into a round profile. The subsequent cold drawing process is crucial in determining the final quality and characteristics of the bar. This process involves pulling the heated round bar through a series of successively smaller hexagonal dies. The dies are precisely engineered to ensure the accurate shaping and dimensional tolerances of the final product. The cold drawing process significantly enhances the material’s strength and surface finish. This is due to the work hardening that occurs during the drawing process, which increases the yield strength and tensile strength of the steel. The process also improves the surface quality, resulting in a smoother, more precise finish compared to hot-rolled bars. Lubrication is critical during cold drawing to minimize friction and prevent surface defects. The final product undergoes rigorous quality control checks to ensure it meets the specified dimensions and mechanical properties.

Mechanical Properties and Material Grades

Cold drawn hexagonal bars are available in a variety of steel grades, each offering specific mechanical properties. Common grades include low carbon steel, medium carbon steel, and alloy steels. The choice of grade depends largely on the intended application. Low carbon steel grades are suitable for applications requiring good formability and weldability, while medium and high carbon steel grades offer increased strength and hardness. Alloy steels provide enhanced properties such as corrosion resistance and high temperature strength. Key mechanical properties to consider include tensile strength, yield strength, elongation, and hardness. These properties are significantly improved compared to hot-rolled equivalents, resulting in a stronger and more durable final product. Detailed specifications for each grade are typically available from the manufacturer.

Diverse Applications Across Industries

The versatility of cold drawn hexagonal bars makes them suitable for a vast array of applications across diverse industries. In the automotive industry, they are used in the manufacturing of various components, including axles, shafts, and connecting rods. The construction industry utilizes these bars for reinforcing structures and creating custom-designed components. The manufacturing industry uses them in machinery parts, tools, and fixtures. Other applications include the production of hydraulic cylinders, fasteners, and various specialized components. The precise dimensions and superior surface finish make them ideal for applications requiring close tolerances and high-quality finishes.

Advantages of Using Cold Drawn Hexagonal Bars

Several key advantages make cold drawn hexagonal bars a preferred choice over other materials: Firstly, their superior strength and hardness compared to hot-rolled counterparts offer enhanced durability and longevity. Secondly, the precise dimensions and surface finish reduce the need for secondary machining, saving time and costs. Thirdly, the improved surface quality reduces the likelihood of surface defects, leading to better fatigue resistance. Fourthly, the availability of various steel grades caters to a wide range of application requirements. Finally, their consistent quality and reliability ensure predictable performance in demanding applications.

Selecting the Right Cold Drawn Hexagonal Bar: A Guide

Selecting the appropriate cold drawn hexagonal bar requires careful consideration of several factors. The most crucial factor is the intended application and the required mechanical properties. The specific steel grade should be chosen based on the application’s demands for strength, hardness, ductility, and other properties. Dimensional tolerances are another critical consideration, especially for applications requiring precise fitting and assembly. Surface finish requirements also play a significant role; certain applications may necessitate a smoother surface finish than others. Finally, cost-effectiveness should be factored in, balancing the material cost with the overall project cost and the potential for reduced machining costs.

Choosing the right cold drawn hexagonal bar ensures optimal performance and longevity in your project. By understanding the manufacturing process, material properties, and application requirements, you can make an informed decision that meets your specific needs.

Steel, the backbone of modern infrastructure and countless products, doesn’t simply appear. Its creation relies on a complex interplay of raw materials, each playing a crucial role in determining the final product’s quality and properties. Understanding these sources is key to appreciating the steel industry’s intricacies and its impact on the global economy.

1. Iron Ore: The Foundation of Steel

Iron ore is undoubtedly the most important raw material in steelmaking. This naturally occurring rock contains iron oxides, primarily hematite (Fe₂O₃) and magnetite (Fe₃O₄), along with various impurities like silica, alumina, and manganese. The iron content in commercially viable ore typically ranges from 30% to 65%, with higher concentrations being more economically attractive. Different types of iron ore deposits exist, including banded iron formations (BIFs), which are ancient sedimentary rocks, and lateritic deposits, formed through weathering processes in tropical climates. The extraction of iron ore involves mining, often through open-pit or underground methods, followed by crushing, grinding, and beneficiation to increase the iron content and remove unwanted impurities. Major iron ore producers include Australia, Brazil, China, India, and Russia, contributing significantly to the global steel supply chain.

2. Scrap Metal: A Sustainable Steel Ingredient

Scrap metal, encompassing discarded steel and iron products, plays a vital role in modern steel production. It’s a crucial secondary raw material, offering a sustainable and cost-effective alternative to relying solely on iron ore. Scrap metal sources are diverse, including industrial scrap from manufacturing processes, automotive scrap, construction and demolition debris, and even household appliances. The quality and composition of scrap metal vary widely, influencing its suitability for different steelmaking processes. Electric arc furnaces (EAFs), a prominent steelmaking technology, heavily rely on scrap metal as their primary raw material, significantly reducing the energy consumption and carbon emissions compared to traditional blast furnaces. The efficient collection, processing, and recycling of scrap metal are essential for environmental sustainability and resource management within the steel industry.

3. Coking Coal: Fueling the Blast Furnace

While not a direct component of steel itself, coking coal is indispensable in traditional blast furnace steelmaking. This high-quality coal, after undergoing a coking process, transforms into coke, a porous carbon fuel. Coke’s role is multifaceted: it acts as a fuel, providing the heat necessary to reduce iron oxides in the ore, and as a reducing agent, facilitating the chemical reaction that converts iron oxides into metallic iron. The quality of coking coal, particularly its low sulfur and ash content, is crucial for producing high-quality steel. Major coking coal reserves are concentrated in Australia, the United States, and Russia, making these countries significant players in the global steel industry’s supply chain. The increasing focus on reducing carbon emissions is pushing the steel industry to explore alternative fuels and technologies to reduce its reliance on coking coal.

4. Fluxing Materials: Refining the Steel

Fluxing materials, such as limestone and dolomite, are added during steelmaking to remove impurities and control the chemical composition of the molten steel. These materials react with silica and other impurities in the iron ore, forming slag—a molten waste product that floats on top of the molten steel. Slag removal is essential for producing clean steel with the desired properties. The choice of fluxing materials depends on the specific composition of the iron ore and the desired steel grade. The careful control of fluxing materials is critical for optimizing the steelmaking process and ensuring the quality of the final product. The sustainable sourcing and management of fluxing materials are also becoming increasingly important considerations for the environmentally conscious steel industry.

5. Alloying Elements: Tailoring Steel Properties

Alloying elements, such as manganese, chromium, nickel, molybdenum, and vanadium, are added to molten steel to enhance its specific properties. These elements are introduced in controlled quantities to modify the steel’s strength, hardness, ductility, corrosion resistance, and other characteristics. The precise combination and proportion of alloying elements determine the final steel grade, tailoring it for specific applications, from construction and automotive components to medical implants and aerospace parts. The sourcing of these alloying elements, many of which are derived from specific ores or recycled materials, is another critical aspect of the steel supply chain. The demand for specialized steel grades continues to drive innovation in alloying technology and the efficient sourcing of these essential components.

In conclusion, the production of steel is a complex process dependent on a diverse range of raw materials. From the foundational iron ore to the carefully selected alloying elements, each component contributes to the final product’s quality and characteristics. Understanding the origins and significance of these raw materials is crucial for appreciating the intricacies of the steel industry and its ongoing efforts towards sustainability and innovation.

SEO Tags:

Steel raw materials, Iron ore, Scrap metal recycling, Coking coal, Alloying elements

Wind turbines, the silent giants of renewable energy, rely on a complex interplay of engineering marvels to harness the power of the wind. While the blades themselves capture the kinetic energy, their efficient and reliable operation hinges critically on the robust support systems that hold them in place. These systems, often overlooked, are crucial for the longevity, performance, and safety of the entire turbine. This post delves into the fascinating world of wind turbine blade support systems, exploring their design, materials, maintenance challenges, and future innovations.

1. The Anatomy of a Blade Support System: A Closer Look

A wind turbine blade support system isn’t a single component but rather a sophisticated network of parts working in concert. The primary function is to securely attach the blade to the rotor hub, allowing for controlled rotation while withstanding immense forces – both from the wind itself and from the centrifugal forces generated during operation. Key components include:

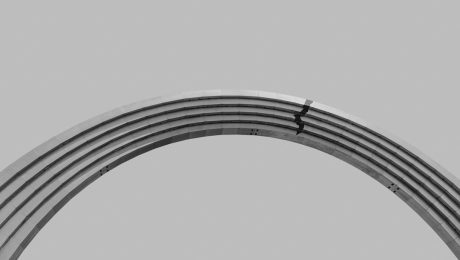

- Pitch Bearing: This crucial element allows the blade to rotate around its longitudinal axis, enabling pitch control (adjusting the blade angle to optimize energy capture or feather the blade during high winds or shutdown). These bearings are typically designed to withstand high loads and operate reliably in harsh environmental conditions.

- Blade Root Connection: This is the physical interface between the blade and the hub. It often involves a complex arrangement of bolts, flanges, and potentially composite materials to ensure a strong and fatigue-resistant connection. The design must accommodate thermal expansion and contraction, as well as the bending and torsional stresses experienced by the blade.

- Hub Assembly: The hub acts as the central connection point for all three blades. It’s a robust structure designed to distribute the loads evenly and provide a stable platform for the rotating assembly. The hub design must account for the weight of the blades, the aerodynamic forces, and the stresses from centrifugal forces.

- Safety Mechanisms: Redundant safety mechanisms are integrated to protect the turbine from catastrophic failure. These can include shear pins, overload protection systems, and backup support structures that prevent blade detachment in the event of extreme loading conditions.

2. Materials Science in Blade Support: Strength and Durability

The choice of materials for blade support systems is critical, as these components must endure extreme stresses and environmental conditions for decades. High-strength steels, advanced composites (like carbon fiber reinforced polymers), and specialized alloys are commonly used. The selection depends on factors such as cost, weight, fatigue resistance, and corrosion resistance. Advanced composites offer a compelling combination of high strength-to-weight ratio and fatigue resistance, making them increasingly popular in modern designs. However, their cost and manufacturing complexity remain considerations.

3. Maintenance and Inspection: Ensuring Operational Reliability

Regular maintenance and inspection are paramount for ensuring the long-term reliability and safety of wind turbine blade support systems. This typically involves visual inspections, non-destructive testing (NDT) techniques (such as ultrasonic testing and radiography) to detect internal flaws, and regular lubrication of bearings. Advanced monitoring systems, incorporating sensors and data analytics, are increasingly used to track the health of the support system and predict potential failures, enabling proactive maintenance and reducing downtime.

4. Technological Advancements: Shaping the Future of Support Systems

Ongoing research and development are constantly pushing the boundaries of wind turbine blade support system technology. This includes exploring new materials with even higher strength-to-weight ratios, developing more sophisticated monitoring and diagnostic systems, and designing more robust and efficient bearing systems. Additive manufacturing (3D printing) offers the potential to create highly customized and optimized support structures, while advancements in artificial intelligence and machine learning are enabling predictive maintenance strategies that minimize downtime and maximize the operational lifespan of turbines.

5. The Impact of Blade Size and Design on Support Systems

The ever-increasing size of wind turbine blades presents significant challenges for support system design. Larger blades generate greater aerodynamic loads and centrifugal forces, demanding more robust and sophisticated support structures. The design of the blade itself also influences the support system requirements. For example, blades with complex aerodynamic profiles may necessitate more sophisticated pitch control mechanisms and bearing systems. Furthermore, the material composition of the blade (e.g., composite vs. traditional materials) influences the design of the root connection and the overall support system architecture.

In conclusion, wind turbine blade support systems are far more than just simple connections; they are crucial engineering components that underpin the efficiency, reliability, and safety of wind energy generation. Ongoing innovation in materials science, monitoring technologies, and design methodologies will continue to enhance their performance and contribute to the growth of sustainable energy solutions.

SEO Tags: Wind turbine blades, blade support systems, wind turbine maintenance, wind turbine technology, renewable energy

Twisted square wire, with its unique texture and strength, offers a surprising array of applications beyond its initial perception. From intricate jewelry designs to robust structural elements, this versatile material has earned its place in various industries and crafting pursuits. This comprehensive guide delves into the diverse uses of twisted square wire, providing you with a deeper understanding of its potential.

1. Crafting and Jewelry Making: Unleashing Artistic Expression

Twisted square wire’s distinct appearance makes it a favorite among crafters and jewelry makers. Its angular profile adds a modern, geometric touch to designs, contrasting beautifully with smoother, rounder wires. The twisting introduces an interesting textural element, enhancing the overall aesthetic appeal. This wire is ideal for creating:

- Unique earrings and pendants: The wire’s strength allows for intricate shapes and designs that hold their form well. It can be easily bent and shaped using pliers, enabling complex patterns and customized pieces.

- Bracelets and bangles: Twisted square wire can be wrapped, woven, or soldered to create sturdy and stylish bracelets. The wire’s texture provides a comfortable grip, preventing slippage.

- Sculptural wire art: Larger gauge twisted square wire can be used to construct three-dimensional sculptures. Its rigidity lends itself well to maintaining complex forms.

- Wire wrapping for gemstones: The wire’s angular profile provides excellent grip, securely holding gemstones in place without the need for excessive adhesive.

The choice of metal, such as copper, silver, or brass, further expands the creative possibilities, allowing for a wide range of finishes and colors.

2. Construction and Industrial Applications: Strength and Durability

Beyond the artistic realm, twisted square wire finds its place in construction and industrial settings. Its strength and durability make it suitable for applications requiring resilience and longevity. Examples include:

- Reinforcement in concrete: Twisted square wire, especially in galvanized steel, can be used as reinforcement in concrete structures, enhancing their tensile strength and resistance to cracking.

- Wire fencing and cages: Its robust nature makes it suitable for creating strong and secure fences, cages, and enclosures for various purposes.

- Support structures in horticulture: Twisted square wire can be used to create support structures for climbing plants, offering a sturdy framework for growth.

- Industrial binding and fastening: The wire’s strength allows it to be used for binding materials together, securing packages, or creating durable fasteners.

The choice of metal will depend on the specific application, with galvanized steel being a common choice for outdoor and high-stress environments due to its corrosion resistance.

3. Home Décor and DIY Projects: Adding a Touch of Industrial Chic

Twisted square wire’s unique aesthetic lends itself well to home décor and DIY projects. Its industrial feel adds a touch of modern sophistication to various designs. This includes:

- Creating unique wall art: Twisted square wire can be shaped and formed into abstract designs, creating striking wall art pieces.

- Building decorative shelves: The wire’s strength makes it suitable for constructing sturdy and stylish shelves, particularly in minimalist or industrial-style interiors.

- Making candle holders and lanterns: The wire can be bent and shaped to create interesting and unique candle holders and lanterns, adding a touch of rustic charm.

- Crafting plant hangers and pot stands: Twisted square wire can be used to create attractive and functional plant hangers and pot stands, adding a touch of industrial style to indoor gardens.

The possibilities are vast, limited only by creativity and imagination. Experimentation with different wire gauges and finishes can lead to unique and personalized home décor items.

4. Choosing the Right Gauge and Material: Considerations for Specific Applications

Selecting the appropriate gauge and material of twisted square wire is crucial for achieving optimal results. The gauge refers to the thickness of the wire, with lower gauges indicating thicker wires. Thicker wires are stronger and more suitable for structural applications, while thinner wires are better suited for delicate crafting projects. The material selection depends on the intended use and desired aesthetic:

- Steel: Offers high strength and durability, ideal for construction and industrial applications. Galvanized steel provides additional corrosion resistance.

- Copper: Provides excellent conductivity and is often used in electrical applications. It also offers a pleasing aesthetic for crafting projects.

- Brass: Offers a golden hue and good corrosion resistance, making it popular for decorative purposes.

- Aluminum: Lightweight and corrosion-resistant, suitable for certain crafting and decorative applications.

Careful consideration of these factors ensures that the chosen wire is appropriate for the intended application, maximizing its performance and longevity.

5. Safety Precautions When Working with Twisted Square Wire

While twisted square wire is a versatile material, it’s essential to take necessary safety precautions when working with it, especially with thicker gauges. Sharp edges and potential for injury necessitate careful handling:

- Wear protective gloves: This will protect your hands from cuts and abrasions.

- Use appropriate tools: Employ wire cutters, pliers, and other tools designed for working with metal wire to avoid injury.

- Wear eye protection: This will protect your eyes from flying debris or sharp pieces of wire.

- Work in a well-ventilated area: When working with certain metals, especially when soldering or using chemicals, ensure proper ventilation to prevent inhalation of harmful fumes.

- Dispose of wire scraps responsibly: Recycle or dispose of wire scraps according to local regulations.

Prioritizing safety ensures a pleasant and injury-free crafting or construction experience.

Twisted square wire, with its unique properties and versatile applications, truly deserves a place in your crafting arsenal or construction toolbox. Its strength, durability, and aesthetic appeal make it a material worth exploring for a wide range of projects.

Tags: twisted square wire, square wire uses, wire crafting, metal wire, construction wire

In today’s competitive market, delivering high-quality products is paramount. The pursuit of zero-defect production, while seemingly unattainable, is a powerful goal that drives continuous improvement and significant business benefits. This isn’t about achieving literal perfection – it’s about striving for excellence, minimizing defects, and establishing a culture of quality throughout your organization. This post will explore the key elements involved in achieving this ambitious yet rewarding objective.

Understanding the Zero-Defect Philosophy

The zero-defect philosophy isn’t just about catching defects at the end of the production line; it’s a proactive approach that emphasizes preventing defects from occurring in the first place. It’s a fundamental shift from reactive quality control to preventative quality management. This involves a holistic approach, impacting every stage of production, from design and procurement to manufacturing and delivery. It requires a commitment from every employee, fostering a culture of responsibility and ownership for quality. Adopting this philosophy necessitates a deep understanding of potential failure points and implementing robust processes to mitigate risks. This includes rigorous testing, meticulous documentation, and a continuous feedback loop to identify and address potential issues.

Implementing Preventative Measures: The Foundation of Zero-Defect Production

Preventative measures are the cornerstone of achieving zero-defect goals. This involves identifying potential sources of defects early in the process, often during the design phase. Techniques like Failure Mode and Effects Analysis (FMEA) help anticipate potential problems and implement solutions before they cause defects. Robust design principles ensure that the product is inherently less prone to defects. Investing in high-quality materials and equipment also plays a significant role. Regular maintenance and calibration of machinery prevent breakdowns and inconsistent output. Furthermore, providing thorough training to employees ensures they possess the skills and knowledge to perform their tasks correctly, minimizing human error.

Strengthening Quality Control Processes: Catching Defects Early

Even with the best preventative measures, some defects might slip through. This is why robust quality control processes are essential. Statistical Process Control (SPC) techniques allow for continuous monitoring of production processes, identifying deviations from established standards and allowing for timely intervention. Regular inspections at different stages of production help catch defects early, minimizing the cost and effort required for rectification. Implementing check points and using quality control tools like control charts and Pareto charts helps to identify the root causes of defects and prioritize corrective actions. Furthermore, regular audits ensure compliance with quality standards and identify areas for improvement.

Embracing Continuous Improvement: The Kaizen Approach

Zero-defect production is not a destination but a journey. Continuous improvement is crucial for sustaining progress and adapting to evolving needs. The Kaizen philosophy, emphasizing small, incremental improvements, is highly effective in achieving this. Regularly reviewing processes, analyzing data, and soliciting feedback from employees are key components of this approach. Implementing lean manufacturing principles, such as eliminating waste and streamlining processes, further enhances efficiency and reduces the potential for defects. Regularly updating and refining standard operating procedures (SOPs) based on lessons learned ensures that processes remain optimal and prevent future defects.

Measuring Success and Tracking Progress: Key Performance Indicators (KPIs)

To effectively pursue zero-defect production, it is crucial to track progress using relevant KPIs. These metrics provide valuable insights into the effectiveness of implemented strategies and highlight areas requiring attention. Key indicators include defect rate, defect per million opportunities (DPMO), customer returns, and customer satisfaction scores. Regularly monitoring these KPIs allows for timely adjustments to processes and strategies, ensuring that the organization remains on track towards its zero-defect goals. Data analysis helps identify trends and patterns, providing a clear picture of the overall performance and pinpointing specific areas for improvement. Using dashboards to visualize this data makes it easily accessible to all stakeholders.

Achieving zero-defect production requires a long-term commitment, a culture of continuous improvement, and a relentless focus on quality at every level of the organization. While the ultimate goal might seem elusive, the journey itself brings significant benefits, including increased customer satisfaction, reduced costs, improved efficiency, and a stronger competitive edge.

SEO Tags:

Zero-Defect Production, Quality Control, Lean Manufacturing, Six Sigma, Continuous Improvement

The global steel trade is a complex network of transactions involving significant financial commitments. Securing payment is paramount for both buyers and sellers. Letters of Credit (L/C), a crucial payment mechanism, mitigate risks and provide a framework for trust in this high-stakes industry. This comprehensive guide will unravel the intricacies of payment terms in the steel trade, focusing on the use of Letters of Credit.

What are Letters of Credit (L/C) in Steel Trade?

A Letter of Credit (L/C) is a financial instrument issued by a buyer’s bank (issuing bank) promising payment to the seller (beneficiary) upon fulfillment of specific conditions. In the steel trade, these conditions typically involve the presentation of shipping documents proving that the agreed-upon quantity and quality of steel have been shipped. The L/C acts as a guarantee, offering the seller greater security than other payment methods like open account or documentary collections. The issuing bank’s commitment significantly reduces the seller’s credit risk, especially when dealing with international buyers.

Different types of L/Cs exist, each with varying degrees of risk and complexity. Irrevocable L/Cs are the most common in steel trade, meaning the commitment cannot be cancelled without the agreement of all parties. Confirmed L/Cs offer even greater security, as a second bank (confirming bank) adds its guarantee to the issuing bank’s promise. This is especially beneficial when dealing with buyers in countries with potentially unstable financial systems.

Key Components of an L/C for Steel Transactions

A well-drafted L/C is crucial for a smooth transaction. Essential components include:

- Applicant (Buyer): The party requesting the L/C.

- Beneficiary (Seller): The steel supplier receiving the payment.

- Issuing Bank: The bank issuing the L/C on behalf of the buyer.

- Advising Bank (Optional): A bank that informs the beneficiary about the L/C.

- Confirming Bank (Optional): A bank that adds its guarantee to the L/C.

- Amount: The total value of the steel shipment.

- Expiry Date: The deadline for presenting the required documents.

- Shipping Documents: These are crucial and typically include commercial invoice, packing list, bill of lading, certificate of origin, and potentially quality certificates specific to the steel grade.

- Incoterms: These define the responsibilities of the buyer and seller regarding delivery and shipping costs (e.g., FOB, CIF, CFR).

Any discrepancies in these documents can lead to delays or rejection of the L/C, highlighting the importance of meticulous attention to detail.

Navigating Incoterms and Their Impact on L/Cs

Incoterms (International Commercial Terms) are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. The choice of Incoterms significantly impacts the documents required for the L/C and the associated costs and risks. For example, under FOB (Free On Board), the seller’s responsibility ends once the goods are loaded onto the vessel, while under CIF (Cost, Insurance, and Freight), the seller is responsible for shipping costs and insurance until the goods arrive at the port of destination. The L/C must clearly reflect the chosen Incoterms to avoid confusion and disputes.

Careful consideration of Incoterms is crucial to allocate responsibilities and costs effectively. Mismatches between Incoterms and the L/C stipulations can lead to delays and potential financial losses for both parties. Understanding the nuances of each Incoterm is essential for negotiating and executing steel trade transactions smoothly.

Potential Challenges and Risks Associated with L/Cs

While L/Cs offer significant security, they are not without potential challenges. Discrepancies in the presented documents are a common cause of delays. Even minor inconsistencies can lead to the L/C being rejected, potentially resulting in financial losses and strained relationships. Careful document preparation and review are therefore critical. Furthermore, the process itself can be complex and time-consuming, requiring expertise in international trade finance.

Another risk is the potential for fraud. Buyers may attempt to obtain goods without paying, or sellers may present fraudulent documents. Due diligence and robust verification processes are essential to mitigate these risks. Engaging experienced professionals in international trade and finance can minimize these potential pitfalls.

Best Practices for Utilizing L/Cs in Steel Trade

To maximize the benefits and minimize the risks associated with L/Cs in steel trade, consider these best practices:

- Clear Communication: Establish clear and concise communication between all parties involved, ensuring a shared understanding of the terms and conditions.

- Experienced Professionals: Seek advice from experienced professionals in international trade and finance to navigate the complexities of L/Cs.

- Thorough Document Review: Carefully review all documents, ensuring accuracy and consistency with the L/C terms.

- Due Diligence: Conduct thorough due diligence on both the buyer and the issuing bank to assess their creditworthiness.

- Regular Monitoring: Monitor the progress of the L/C throughout the transaction to identify and address any potential issues promptly.

By following these best practices, businesses can leverage the security and efficiency of L/Cs to navigate the complexities of the global steel trade successfully.

Conclusion: Letters of Credit provide a vital mechanism for secure payment in the international steel trade. Understanding the intricacies of L/Cs, Incoterms, and potential challenges is critical for both buyers and sellers to mitigate risks and ensure smooth transactions. By employing best practices and seeking expert advice, businesses can leverage this powerful tool to build trust and enhance their success in the global steel market.

body {

font-family: sans-serif;

line-height: 1.6;

margin: 20px;

}

h1, h2 {

color: #333;

}

img {

max-width: 100%;

height: auto;

display: block;

margin: 20px auto;

}

Steel, the backbone of countless industries, requires precise and efficient cutting techniques for its various applications. From intricate automotive parts to robust construction beams, the method used to cut steel significantly impacts the final product’s quality, cost, and production speed. This comprehensive guide explores the diverse world of steel cutting technologies, examining their strengths, weaknesses, and ideal applications.

1. Oxy-Fuel Cutting: The Classic Flame Approach

Oxy-fuel cutting, a time-tested method, utilizes a high-velocity jet of oxygen to cut through steel. The process begins by preheating the steel with a flame mixture of oxygen and fuel gas (typically acetylene or propane). Once the steel reaches its ignition temperature, a pure oxygen jet is introduced, rapidly oxidizing the metal and creating a molten slag that is blown away by the jet’s force. Oxy-fuel cutting is relatively inexpensive and portable, making it suitable for on-site work and thicker steel plates. However, it’s less precise than other methods and leaves a wider heat-affected zone (HAZ), potentially compromising the material’s properties.

2. Plasma Cutting: Harnessing the Power of Ionized Gas

Plasma cutting employs a high-velocity jet of superheated, ionized gas (plasma) to melt and cut through the steel. The plasma arc’s extremely high temperature allows for faster cutting speeds and greater precision compared to oxy-fuel cutting. Plasma cutting is effective on a wider range of steel thicknesses and produces a narrower HAZ. It’s commonly used in industrial settings for its efficiency and ability to handle various steel grades. However, it requires a more sophisticated setup and is generally more expensive than oxy-fuel cutting.

3. Laser Cutting: Precision and Versatility in a Single Beam

Laser cutting utilizes a highly focused beam of light to melt and vaporize the steel, achieving exceptional precision and intricate cutting patterns. The non-contact nature of laser cutting minimizes material deformation and produces clean, burr-free edges. It’s highly versatile, capable of cutting various steel types and thicknesses, and often integrated into automated manufacturing processes. While laser cutting offers superior accuracy and speed, it’s typically more expensive than other thermal cutting methods, particularly for thicker steel.

4. Waterjet Cutting: The Gentle Giant of Steel Cutting

Waterjet cutting uses a high-pressure jet of water, often mixed with an abrasive material like garnet, to cut through steel. This method is incredibly versatile, capable of cutting almost any material, including hardened steel, without generating significant heat. The absence of a heat-affected zone preserves the material’s properties and makes it ideal for delicate or heat-sensitive applications. Waterjet cutting is slower than thermal methods but offers superior precision and minimal material waste. The high-pressure equipment is a considerable investment.

5. Shearing: A Powerful Force for Straight Cuts

Shearing is a mechanical cutting process that uses a powerful press to cut relatively thin sheets of steel along a straight line. Two sharp blades forcefully compress the steel, causing it to fracture along the cutting line. Shearing is highly efficient for mass production of standardized parts and is capable of extremely high cutting speeds. However, it’s limited to straight cuts and relatively thin steel sheets. The resulting edges may require further finishing depending on the application’s precision requirements.

Choosing the right steel cutting technology depends on several factors, including the steel’s thickness, desired precision, material properties, production volume, and budget. Each method has its own strengths and weaknesses, and understanding these differences is crucial for selecting the optimal approach for any given application.

Choosing the Right Technology

The selection of the appropriate steel cutting technology is a critical decision influenced by several factors. These include the thickness of the steel, the required precision of the cut, the type of steel being cut (its hardness and alloy composition), the desired production volume, and the overall budget. Careful consideration of these factors ensures optimal efficiency and cost-effectiveness.

For example, oxy-fuel cutting is suitable for thicker materials and on-site work where portability is important, while laser cutting is ideal for intricate designs and high-precision applications. Waterjet cutting provides a heat-free solution for delicate materials or those susceptible to heat damage. Shearing is the most efficient choice for mass production of thin sheet steel parts requiring straight cuts.

The future of steel cutting likely involves further advancements in laser and waterjet technologies, pushing the boundaries of precision, speed, and material versatility. The ongoing development of automation and intelligent control systems will further enhance the efficiency and capabilities of these cutting-edge processes.

Tags: steel cutting, laser cutting, plasma cutting, waterjet cutting, oxy-fuel cutting

body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

The oil and gas industry relies heavily on efficient and reliable well construction. Central to this process are casing and tubing – two distinct but interconnected systems crucial for drilling, completing, and producing hydrocarbons. This comprehensive guide will delve into the intricacies of casing and tubing, exploring their functions, types, materials, and installation processes.

The Vital Role of Casing in Well Construction

Casing is a series of steel pipes cemented into the wellbore during drilling. Its primary function is to provide structural integrity and stability to the well. Think of it as the skeleton of the well, protecting against wellbore collapse, preventing the influx of unwanted fluids (like water or gas from different formations), and isolating different geological zones. Casing strings are installed in concentric layers, each with a specific diameter and grade of steel chosen to withstand the pressure and stress at that particular depth. The process of running and cementing casing is a complex and critical operation, requiring precision and expertise.

Different types of casing serve different purposes. Surface casing protects the upper portions of the wellbore, while intermediate and production casing protect deeper sections. The choice of casing type and grade depends on factors like well depth, formation pressure, and the presence of unstable formations. Proper casing design and installation are paramount to preventing costly blowouts and environmental damage.

Tubing: The Pathway for Hydrocarbon Production

Once the well is cased and cemented, tubing is installed. Unlike casing, which is primarily a structural element, tubing serves as the conduit for the production of hydrocarbons (oil and gas). It’s a smaller diameter pipe that runs from the bottom of the well to the surface, allowing the produced fluids to flow upwards. Tubing strings are typically made of high-strength steel and are designed to withstand the pressures and temperatures encountered during production.

Various types of tubing exist, including production tubing, workover tubing, and completion tubing. Production tubing is the primary conduit for hydrocarbon flow. Workover tubing is used during well intervention operations, while completion tubing is used in specialized completion designs. The selection of tubing depends on factors such as well productivity, fluid properties, and anticipated production conditions.

Materials and Grades: Ensuring Durability and Performance

Both casing and tubing are primarily made of steel, but the specific grade and properties vary depending on the application. High-strength low-alloy (HSLA) steels are commonly used, offering a balance of strength and ductility. Other materials, such as corrosion-resistant alloys (CRAs) like stainless steel or duplex stainless steel, are used in environments with corrosive fluids or high temperatures. The selection of materials is crucial in ensuring the long-term integrity and performance of the well.

The grade of steel is indicated by a designation that reflects its yield strength and other mechanical properties. Higher grade steels are stronger and more resistant to deformation, but also more expensive. The selection of the appropriate grade is a critical engineering decision, balancing cost and performance requirements.

Cementing: The Key to Well Integrity

Cementing is the process of filling the annulus (the space between the casing and the wellbore) with cement. This crucial step provides several vital functions: it provides zonal isolation, preventing fluid migration between different formations; it provides structural support to the casing, preventing its collapse; and it enhances wellbore stability. Proper cementing practices are essential for preventing wellbore instability, blowouts, and environmental contamination. The cement slurry’s properties, such as density and setting time, are carefully selected based on the well conditions.

Various cementing techniques exist, including conventional cementing, lightweight cementing, and foamed cementing, each optimized for specific well conditions and challenges. Successful cementing requires a precise understanding of the well’s geological characteristics and fluid properties.

Installation and Maintenance: Ensuring Operational Efficiency

The installation of casing and tubing is a complex and highly specialized operation, often involving specialized equipment and skilled personnel. The process involves running the pipes into the wellbore, cementing the casing, and then running the tubing. Regular inspections and maintenance are crucial to ensure the long-term integrity of the casing and tubing strings. This includes monitoring for corrosion, erosion, and other forms of degradation.

Well intervention techniques, such as workovers and repairs, are sometimes necessary to address issues with casing or tubing. These interventions can involve replacing damaged sections, performing repairs, or installing additional equipment. Advanced technologies, such as downhole tools and logging techniques, play a vital role in monitoring well integrity and identifying potential problems.

In conclusion, casing and tubing are essential components in oil and gas well construction and production. Understanding their functions, materials, and installation processes is crucial for safe, efficient, and environmentally responsible operations. The continuous advancement in materials science and well construction techniques ensures the ongoing improvement of these critical well components.

Tags: oil and gas, casing, tubing, well construction, drilling, cementing, well integrity