In the ever-evolving landscape of construction, prefabricated steel structures are emerging as a dominant force, revolutionizing how we design, build, and inhabit spaces. Their inherent strength, versatility, and efficiency are transforming industries, from commercial and industrial projects to residential developments and even disaster relief efforts. This comprehensive guide delves into the world of prefabricated steel structures, exploring their advantages, design intricacies, diverse applications, cost-effectiveness, and future prospects.

The Unmatched Advantages of Prefabricated Steel Structures

Prefabricated steel structures offer a compelling array of advantages over traditional construction methods. Their inherent strength-to-weight ratio allows for the creation of larger, more open spaces with minimal support structures. This translates to increased usable floor area and reduced material costs. Furthermore, steel’s durability ensures longevity and resistance to various environmental factors, including fire, pests, and weathering. The precision manufacturing process minimizes on-site errors and waste, leading to faster construction timelines and reduced labor costs. The modular nature of prefabricated steel components also simplifies transportation and assembly, making them ideal for challenging or remote locations.

The Design Process: From Blueprint to Built Environment

The design process for prefabricated steel structures is highly meticulous and collaborative. It begins with detailed architectural and engineering plans, taking into account factors such as load-bearing capacity, seismic considerations, and specific client requirements. Advanced Computer-Aided Design (CAD) software plays a crucial role in creating accurate 3D models and optimizing structural components for efficient fabrication. This digital approach allows for precise pre-fabrication, minimizing on-site adjustments and ensuring a seamless assembly process. Rigorous quality control measures are implemented at each stage, from material selection to component manufacturing, guaranteeing the structural integrity and safety of the final product. Detailed shop drawings are produced to guide the fabrication and erection process, providing clear instructions for the construction crew.

Diverse Applications: Where Steel Structures Shine

The versatility of prefabricated steel structures makes them suitable for a wide range of applications. In the commercial sector, they are frequently used for warehouses, factories, retail spaces, and office buildings. Their ability to span large areas without internal columns creates flexible and adaptable spaces. The industrial sector benefits from their robust construction, making them ideal for heavy machinery and hazardous environments. Prefabricated steel structures also find applications in residential construction, offering cost-effective and customizable housing solutions, especially in areas prone to natural disasters. Furthermore, they are utilized in the construction of bridges, stadiums, and other large-scale infrastructure projects, demonstrating their adaptability and scalability.

Cost-Effectiveness: Balancing Quality and Budget

While the initial investment in prefabricated steel structures might seem higher than traditional methods, the long-term cost-effectiveness is undeniable. Faster construction times translate to reduced labor costs and project completion delays. The minimized waste and precision manufacturing process lead to significant material savings. Furthermore, the durability and longevity of steel structures reduce the need for frequent repairs and maintenance, leading to lower operational costs over the building’s lifespan. The off-site fabrication minimizes disruptions to the surrounding environment, further contributing to cost savings.

The Future of Prefabricated Steel Structures: Innovation and Sustainability

The future of prefabricated steel structures is bright, driven by continuous innovations in design, materials, and manufacturing processes. The integration of sustainable practices, such as the use of recycled steel and energy-efficient design features, is becoming increasingly important. Advancements in robotics and automation are streamlining the fabrication process, further enhancing efficiency and precision. The development of new steel alloys with improved strength and durability is expanding the possibilities for even more complex and ambitious projects. The ongoing research into sustainable construction methods ensures that prefabricated steel structures will continue to play a vital role in shaping the built environment of tomorrow.

Tags: prefabricated steel structures, steel buildings, modular construction, prefabricated steel buildings, steel structure design

The combination of steel’s inherent strength and carbon fiber’s exceptional lightness and stiffness creates a material marvel: carbon fiber-coated steel pipes. This innovative technology is revolutionizing various industries, offering unparalleled performance and efficiency. This blog post delves deep into the world of carbon fiber-coated steel pipes, exploring their properties, applications, manufacturing processes, advantages, and future potential.

1. Enhanced Mechanical Properties: A Symphony of Strength and Lightness

The core advantage of carbon fiber-coated steel pipes lies in the synergistic combination of materials. Steel provides the foundational strength and durability, resisting high pressures and impacts. The carbon fiber coating, on the other hand, significantly enhances stiffness, reduces weight, and improves fatigue resistance. This results in pipes that are stronger, lighter, and more resilient than traditional steel pipes alone. The carbon fiber layer acts as a protective shield, mitigating corrosion and extending the lifespan of the steel core. The precise properties achieved depend heavily on the type and layering of the carbon fiber, the type of steel used, and the bonding techniques employed during manufacturing. For example, using high-modulus carbon fiber results in exceptionally stiff pipes, while using a more flexible variety might prioritize impact resistance.

2. Manufacturing Processes: Precision Engineering for Superior Performance

Creating carbon fiber-coated steel pipes requires a sophisticated manufacturing process that ensures a strong and consistent bond between the steel core and the carbon fiber layer. Several methods exist, each with its own advantages and disadvantages. One common approach involves the application of a prepreg (pre-impregnated) carbon fiber sheet onto the cleaned and prepared steel pipe. This is then cured in an autoclave under controlled temperature and pressure, resulting in a tightly bonded composite structure. Another method involves filament winding, where continuous carbon fiber strands are precisely wound onto the steel pipe, creating a customized layer thickness and orientation. The choice of manufacturing process depends on factors such as the desired pipe diameter, length, and the required mechanical properties. Quality control is paramount throughout the process to ensure consistent performance and prevent defects.

3. Diverse Applications: From Energy to Aerospace

The unique properties of carbon fiber-coated steel pipes have opened up a wide range of applications across diverse industries. In the energy sector, these pipes are used for transporting oil and gas under high pressure, reducing weight and improving efficiency in pipelines. Their corrosion resistance makes them ideal for harsh environments, extending their operational lifespan. In the aerospace industry, they find use in aircraft structures and other applications where a high strength-to-weight ratio is critical. The automotive industry is also exploring their use in high-performance vehicles, particularly in areas requiring lightweight yet strong components. Furthermore, their application extends to infrastructure projects, such as bridges and buildings, where they can contribute to improved structural integrity and reduced weight.

4. Advantages Over Traditional Steel Pipes: A Comprehensive Comparison

Compared to traditional steel pipes, carbon fiber-coated steel pipes offer several key advantages. Firstly, their significantly improved strength-to-weight ratio leads to reduced transportation and installation costs. Secondly, their enhanced corrosion resistance extends their lifespan, reducing maintenance and replacement costs. Thirdly, the increased stiffness improves their resistance to buckling and vibrations, crucial in applications involving high pressures or dynamic loads. Fourthly, the carbon fiber coating can contribute to improved thermal insulation, potentially reducing energy loss in applications like pipelines. Finally, the potential for customization through different carbon fiber types and layering enables engineers to tailor the pipes to specific application requirements, optimizing performance and cost-effectiveness.

5. Future Trends and Innovations: Pushing the Boundaries of Material Science

The field of carbon fiber-coated steel pipes is constantly evolving, with ongoing research and development focused on improving manufacturing processes, exploring new materials, and expanding applications. Researchers are investigating advanced bonding techniques to further enhance the strength and durability of the composite structure. The use of advanced carbon fiber materials with enhanced properties, such as graphene-enhanced carbon fiber, is also being explored to further improve performance. Furthermore, the development of more efficient and cost-effective manufacturing processes is crucial for broader adoption of this technology across various industries. The future likely holds even lighter, stronger, and more versatile carbon fiber-coated steel pipes, contributing to advancements in various technological sectors.

In conclusion, carbon fiber-coated steel pipes represent a significant advancement in material science, offering a compelling combination of strength, lightness, and durability. Their diverse applications and ongoing innovations promise to shape the future of numerous industries, paving the way for lighter, stronger, and more efficient structures and systems.

body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

h1 {

font-size: 2.5em;

}

h2 {

font-size: 2em;

}

h3 {

font-size: 1.5em;

}

Steel is a ubiquitous material in modern civil engineering, forming the backbone of countless structures from skyscrapers to bridges. A strong understanding of steel design, fabrication, and construction is therefore paramount for any aspiring or practicing civil engineer. This comprehensive guide explores the essential aspects of steel training for civil engineers, highlighting key areas of knowledge and expertise.

Understanding Steel Design Principles

Steel design isn’t simply about selecting the right size beam; it’s a complex interplay of structural analysis, material properties, and relevant design codes. Training in this area should cover topics like:

- Stress-Strain Relationships: Grasping the elastic and plastic behavior of steel under load is crucial for accurate design. This includes understanding yield strength, ultimate tensile strength, and the concept of ductility.

- Load Paths and Analysis: Engineers must be proficient in analyzing structural loads (dead loads, live loads, wind loads, seismic loads) and determining the resulting stresses and deflections within steel members. Methods like Finite Element Analysis (FEA) are increasingly important.

- Design Codes and Standards: Familiarity with relevant codes like AISC (American Institute of Steel Construction) and Eurocode 3 is essential. These codes provide detailed design requirements and safety factors.

- Connection Design: The design of connections (e.g., welds, bolts) is critical to the overall structural integrity. Understanding different connection types, their strengths, and limitations is crucial.

- Stability and Buckling: Steel members can fail due to buckling under compressive loads. Training should cover methods for assessing and mitigating buckling risks.

Steel Fabrication Processes and Techniques

A civil engineer needs a practical understanding of how steel structures are fabricated. This involves knowledge of various processes and techniques:

- Cutting and Shaping: This includes methods like flame cutting, plasma cutting, laser cutting, and cold forming, each with its own advantages and limitations.

- Welding: Different welding techniques (e.g., SMAW, GMAW, FCAW) have varying strengths and applications. Understanding weld quality, inspection, and non-destructive testing (NDT) is vital.

- Bolting and Fastening: Proper bolting procedures and the selection of appropriate fasteners are crucial for ensuring structural integrity. This also includes understanding different bolt types and their applications.

- Surface Treatments: Protecting steel from corrosion is essential. Training should cover different surface treatments like painting, galvanizing, and other protective coatings.

- Quality Control and Assurance: Understanding quality control procedures throughout the fabrication process is necessary to ensure compliance with design specifications and safety standards.

Steel Construction Methods and Practices

On-site construction requires a detailed understanding of safe and efficient practices:

- Erection Techniques: This includes understanding different methods of lifting, placing, and assembling steel members, ensuring safety and efficiency.

- Temporary Supports and Bracing: Temporary supports are crucial during construction to maintain stability and prevent collapse. Understanding the design and implementation of these supports is essential.

- Safety Procedures: Steel construction sites are inherently hazardous. Training must emphasize safety procedures, including fall protection, proper lifting techniques, and hazard identification.

- Site Management and Coordination: Effective site management and coordination between different trades are crucial for timely and efficient construction.

- Inspection and Quality Control: Regular inspection during construction is necessary to ensure that the structure is being built according to the design specifications and safety standards.

Advanced Steel Design Concepts

Beyond the fundamentals, advanced training can delve into specialized areas:

- Seismic Design: Designing steel structures to withstand seismic activity requires specialized knowledge of seismic loads and design techniques.

- Finite Element Analysis (FEA): FEA software is widely used for complex structural analysis. Proficiency in FEA is highly valuable for advanced steel design.

- Cold-Formed Steel Design: Cold-formed steel sections have unique design considerations compared to hot-rolled sections.

- Composite Steel-Concrete Structures: Combining steel and concrete can create efficient and high-performance structures.

- Sustainability in Steel Design: Understanding the environmental impact of steel and exploring sustainable design practices is increasingly important.

Finding the Right Steel Training Programs

Numerous institutions and organizations offer steel training programs for civil engineers. Look for programs accredited by relevant professional bodies and offering a blend of theoretical knowledge and practical experience. Consider factors like the program’s curriculum, instructors’ expertise, and the availability of hands-on training opportunities. Online courses, workshops, and professional development programs can supplement formal education and keep your skills current.

Investing in comprehensive steel training is a crucial step in advancing your career as a civil engineer. The demand for skilled professionals in this field remains high, and a strong understanding of steel design and construction will set you apart in a competitive market.

Tags: Steel training, Civil engineering, Steel design, Steel construction, Steel fabrication

High-pressure systems are integral to numerous industries, from chemical processing and oil and gas to power generation and pharmaceuticals. While offering significant advantages in efficiency and productivity, they also present substantial safety risks. A catastrophic failure can lead to devastating consequences, including serious injuries, fatalities, environmental damage, and significant economic losses. This comprehensive guide explores the crucial safety considerations involved in designing, operating, and maintaining high-pressure systems.

1. Design and Engineering for Safety in High-Pressure Systems

The foundation of a safe high-pressure system lies in its design. Careful consideration must be given to material selection, pressure vessel design, and component integrity. Materials must possess sufficient strength and resistance to corrosion and fatigue at the anticipated operating pressures and temperatures. Pressure vessels should be designed according to recognized industry codes and standards (e.g., ASME Boiler and Pressure Vessel Code), incorporating features such as pressure relief devices, safety interlocks, and robust pressure monitoring systems. Finite element analysis (FEA) is often employed to simulate stress and strain under various operating conditions, identifying potential weak points and optimizing the design for maximum safety.

Furthermore, the design process should incorporate redundancy and fail-safe mechanisms. This means designing the system to withstand component failure without causing a catastrophic event. For instance, multiple pressure relief valves can be installed, ensuring that even if one fails, others are available to prevent overpressurization. Regular inspections and testing are crucial throughout the design phase to validate the system’s performance and ensure it meets the required safety standards.

2. Implementing Robust Operational Procedures

Safe operation of a high-pressure system requires well-defined and strictly adhered-to procedures. These procedures should cover all aspects of operation, from startup and shutdown to normal operation and emergency response. Operators should receive thorough training on the system’s functionality, potential hazards, and emergency procedures. This training should include hands-on experience with the equipment and regular refresher courses to ensure knowledge remains up-to-date. Clear communication protocols are essential, especially during emergency situations. Operators should be equipped with the necessary personal protective equipment (PPE) and understand the procedures for handling leaks, spills, and other potential incidents.

Regular monitoring of pressure, temperature, and other critical parameters is crucial. Automated monitoring systems with alarms and shut-down mechanisms can help prevent accidents. Operators should be trained to interpret the data from these systems and respond appropriately to any deviations from normal operating conditions. A comprehensive system of logs and records should be maintained to track operational parameters, maintenance activities, and any incidents that occur.

3. Comprehensive Maintenance and Inspection Strategies

Regular maintenance and inspection are vital for ensuring the continued safety and reliability of high-pressure systems. A preventative maintenance program should be implemented, including scheduled inspections, repairs, and replacements of components as needed. This program should be based on risk assessments and industry best practices. Inspections should include visual checks for signs of wear, corrosion, or damage, as well as non-destructive testing (NDT) methods such as ultrasonic testing and radiographic inspection to detect internal flaws. Maintenance records should be meticulously maintained to track the history of the system and identify any recurring problems.

The frequency of inspections and maintenance should be determined based on the criticality of the system and the operating conditions. High-risk systems may require more frequent inspections and maintenance than those with lower risks. Competent and qualified personnel should conduct all maintenance and inspection activities, adhering to strict safety protocols. Any repairs or modifications to the system should be documented and approved by the appropriate authorities.

4. Emergency Response Planning and Preparedness

Despite the best preventative measures, accidents can still occur. A comprehensive emergency response plan is essential to minimize the consequences of any unforeseen events. This plan should include procedures for handling leaks, spills, fires, and other potential emergencies. It should also outline the roles and responsibilities of personnel during an emergency, including evacuation procedures and communication protocols. Emergency response training should be provided to all personnel who may be involved in responding to an incident.

The emergency response plan should be regularly reviewed and updated to reflect any changes in the system or operating procedures. Emergency equipment, such as fire extinguishers, spill containment materials, and personal protective equipment, should be readily available and regularly inspected. Regular drills should be conducted to ensure that personnel are familiar with the emergency procedures and can respond effectively in a real-world scenario. Communication with local emergency services is also crucial and should be established beforehand.

5. Risk Assessment and Mitigation in High-Pressure Systems

A thorough risk assessment is a fundamental step in ensuring the safety of high-pressure systems. This involves identifying potential hazards, analyzing their likelihood and severity, and implementing appropriate control measures. Hazard identification can be achieved through a variety of methods, including HAZOP (Hazard and Operability) studies, fault tree analysis, and what-if checklists. Once hazards are identified, their likelihood and severity should be assessed, allowing for prioritization of risk mitigation strategies.

Risk mitigation strategies can include engineering controls, administrative controls, and personal protective equipment. Engineering controls involve modifying the system design to reduce the likelihood or severity of hazards. Administrative controls include implementing safe operating procedures, training programs, and emergency response plans. Personal protective equipment (PPE) provides a last line of defense for personnel working with high-pressure systems. The effectiveness of risk mitigation strategies should be regularly reviewed and updated as needed. Continuous improvement is key to maintaining a safe working environment.

By carefully considering these safety aspects throughout the lifecycle of a high-pressure system – from design and engineering to operation, maintenance, and emergency response – industries can significantly reduce the risks associated with these powerful and essential technologies.

SEO Tags:

high-pressure systems safety, pressure vessel safety, pipeline safety, process safety management, risk assessment high pressure

Equal angle bars, also known as angle irons or simply angles, are versatile structural components found in countless applications across various industries. Their simple yet robust design, characterized by two equal legs meeting at a right angle, makes them incredibly adaptable and cost-effective. This comprehensive guide will delve into the world of equal angle bars, exploring their properties, manufacturing processes, diverse applications, advantages, and important considerations for their effective utilization.

Understanding the Properties of Equal Angle Bars

Equal angle bars are typically manufactured from steel, although other materials like aluminum or stainless steel can be used depending on the specific application requirements. The key characteristic is the equal length of the two legs, which provides symmetrical strength and simplifies design calculations. Key properties to consider include:

- Material Strength: The tensile and yield strength of the steel used directly impacts the load-bearing capacity of the angle bar. Higher strength grades are chosen for applications requiring greater structural integrity.

- Dimensional Accuracy: Precise dimensions are crucial for proper fitting and assembly. Manufacturers adhere to strict tolerances to ensure consistent quality and reliable performance.

- Surface Finish: The surface finish can range from hot-rolled (rough) to hot-dipped galvanized (corrosion-resistant) or even powder-coated for enhanced aesthetics and durability.

- Weight and Density: The weight of the angle bar is a significant factor in transportation and construction costs. Engineers often optimize designs to minimize weight without compromising strength.

Manufacturing Processes of Equal Angle Bars

The manufacturing process for equal angle bars typically involves hot rolling of steel billets. This high-temperature process shapes the steel into the desired angle profile. Subsequent steps may include:

- Cutting to Length: The hot-rolled angles are cut to precise lengths using automated sawing or shearing equipment.

- Surface Treatment: Depending on the application, the angles may undergo galvanization, painting, or powder coating to enhance corrosion resistance and aesthetics.

- Quality Control: Rigorous quality control measures are implemented throughout the manufacturing process to ensure dimensional accuracy, material properties, and surface finish meet specified standards.

Precision machining may be required for certain applications demanding tighter tolerances or specific surface finishes.

Diverse Applications of Equal Angle Bars in Construction and Industry

The versatility of equal angle bars makes them indispensable in a wide range of applications, including:

- Structural Support: Used extensively in building frameworks, bridges, and other structures to provide support and stability.

- Reinforcement: Often used to reinforce weaker sections of structures or to strengthen existing components.

- Framing: Forms the basis for framing in various structures, from simple shelving units to complex industrial machinery.

- Machinery Components: Used in the construction of machinery and equipment, providing support and rigidity.

- Automotive Industry: Used in various automotive components, providing structural support and strength.

- Fabrication: Serve as a base material for custom fabrication of various parts and components.

Advantages of Using Equal Angle Bars

The popularity of equal angle bars stems from several key advantages:

- High Strength-to-Weight Ratio: Equal angle bars offer excellent strength relative to their weight, making them efficient for load-bearing applications.

- Cost-Effectiveness: Generally, they are a relatively inexpensive structural material compared to other options.

- Ease of Fabrication: They are easily welded, bolted, or riveted, simplifying assembly and construction processes.

- Versatility: Their simple design allows them to be used in a wide range of applications and configurations.

- Readily Available: Equal angle bars are widely available from various steel suppliers, ensuring easy procurement.

Considerations for Optimal Use of Equal Angle Bars

While equal angle bars offer numerous advantages, certain considerations are essential for optimal use:

- Load Capacity: Proper engineering calculations are crucial to ensure the selected angle bar can handle the anticipated loads.

- Corrosion Protection: In outdoor or corrosive environments, appropriate corrosion protection measures (galvanization, painting) are necessary.

- Connection Methods: The chosen connection method (welding, bolting, riveting) should be appropriate for the application and load requirements.

- Material Selection: The choice of material (steel grade, aluminum, etc.) depends on the specific application requirements and environmental conditions.

- Safety Precautions: Appropriate safety measures should be followed during handling, cutting, and welding of equal angle bars.

In conclusion, equal angle bars represent a fundamental yet powerful element in structural engineering and various industrial applications. Understanding their properties, manufacturing, and optimal usage is key to leveraging their full potential for robust and cost-effective solutions.

Tags: equal angle bar, angle iron, steel angle, structural steel, construction materials

body {

font-family: sans-serif;

line-height: 1.6;

margin: 20px;

}

h1, h2, h3 {

color: #333;

}

img {

max-width: 100%;

height: auto;

display: block;

margin: 20px auto;

}

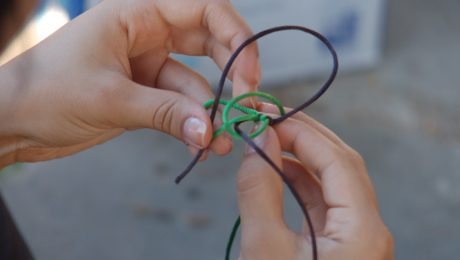

Twisted square wire, with its unique strength and aesthetic appeal, offers a surprisingly wide range of applications. Its distinctive square shape and twisted construction provide a robust yet visually interesting material perfect for both artistic endeavors and industrial needs. This post delves into the diverse world of twisted square wire uses, exploring its potential across various fields.

1. Crafting and Jewelry Making: Unleashing Artistic Expression

Twisted square wire’s unique texture and strength make it a favorite among crafters and jewelry makers. Its square profile provides a bold contrast to round wire, adding a modern and edgy touch to designs. The twisted nature lends itself beautifully to intricate patterns and textures. It’s ideal for:

- Wire wrapping: The firm structure of twisted square wire holds its shape well, making it perfect for wrapping gemstones, beads, and other components in jewelry pieces. The square profile provides a secure grip.

- Sculptural wire work: Its strength allows for the creation of complex three-dimensional forms, from delicate filigree to bold, statement pieces. The twisted texture adds visual interest and depth.

- Earring and bracelet making: The wire’s durability ensures that finished jewelry pieces can withstand daily wear. The unique look makes it a stand-out choice for contemporary designs.

- Mixed media art: Twisted square wire can be incorporated into a variety of mixed media projects, including wall art, sculptures, and decorative objects. Its texture and color can be effectively combined with other materials.

2. Industrial Applications: Strength and Durability in Action

Beyond the artistic realm, twisted square wire finds its place in various industrial applications where strength and durability are paramount. Its resistance to bending and twisting makes it suitable for demanding environments. Some key industrial uses include:

- Reinforcement in composites: The wire’s strength contributes to the overall structural integrity of composite materials, enhancing their tensile strength and resistance to damage.

- Brush making: Twisted square wire, particularly in heavier gauges, is used in the creation of industrial brushes designed for heavy-duty cleaning and scrubbing applications.

- Fence construction: In some specialized fencing applications, twisted square wire can provide a strong and durable framework, especially in situations where increased resistance to bending or twisting is required.

- Basket weaving (heavy-duty): While often associated with lighter materials, twisted square wire can be used to create exceptionally strong and durable baskets for carrying heavy loads.

3. Choosing the Right Gauge and Material: Understanding the Specifications

Twisted square wire is available in a variety of gauges and materials, each suited to different applications. Understanding these specifications is crucial for selecting the right wire for your project. Gauge refers to the thickness of the wire, with lower gauges indicating thicker wire. Common materials include:

- Steel: Offers high strength and durability, ideal for industrial applications and heavier crafting projects.

- Aluminum: Lighter and more malleable than steel, suitable for crafting projects where flexibility is needed.

- Copper: Offers excellent conductivity and is often used in electrical applications or projects requiring specific conductive properties.

- Brass: A corrosion-resistant option with a pleasing golden color, often used in decorative applications.

4. Safety Precautions When Working with Twisted Square Wire

While versatile, twisted square wire requires careful handling. Sharp edges and potential for injuries necessitate precautions. Always use appropriate safety gear, including:

- Gloves: Protect your hands from cuts and scrapes.

- Safety glasses: Prevent eye injuries from flying debris during cutting or shaping.

- Cutters designed for wire: Using the correct tools ensures clean cuts and minimizes the risk of injury.

- Work in a well-ventilated area: Especially important when working with certain metal alloys or coatings.

5. Sourcing and Inspiration: Finding Twisted Square Wire and Project Ideas

Twisted square wire can be sourced from various online retailers and craft supply stores. Searching for “twisted square wire,” “square wire,” or “artisan wire” will yield a variety of results. For inspiration, explore online platforms like Pinterest, Etsy, and Instagram, searching for hashtags such as #twistedsquarewire, #wirewrapping, #wiresculpture, and #wirejewelry. Numerous tutorials and project ideas are available to help you unlock the creative potential of this versatile material.

With its unique properties and broad range of applications, twisted square wire offers endless possibilities for both artistic expression and practical problem-solving. Experiment with different gauges, materials, and techniques to discover the full potential of this remarkable material.

Tags: twisted square wire, square wire, wire crafting, jewelry making, industrial wire, wire art, metal wire

Pipe bending and straightening are crucial processes in various industries, from construction and manufacturing to plumbing and oil and gas. Achieving precise bends and straight sections is essential for functionality, aesthetics, and structural integrity. This comprehensive guide explores the diverse methods, tools, and considerations involved in mastering these techniques.

1. Understanding Pipe Bending Techniques

Several techniques exist for bending pipes, each suited to different pipe materials, diameters, and desired bend radii. The choice of method significantly impacts the quality and efficiency of the process. Common methods include:

- Manual Bending: This involves using hand tools like pipe benders, which are suitable for smaller diameter pipes and simpler bends. These tools often utilize a hinged mechanism and require significant manual force. The process is relatively slow but allows for precise control over the bend angle.

- Hydraulic Bending: Hydraulic pipe benders utilize hydraulic pressure to bend pipes, enabling the efficient bending of larger diameter pipes and achieving tighter radii. They offer greater precision and speed compared to manual methods, making them ideal for high-volume applications. Different types of hydraulic benders exist, including those using a ram to push the pipe against a die or those employing a rotating mechanism.

- Rotary Draw Bending: This advanced technique involves rotating the pipe while simultaneously pulling it through a die. This method is particularly effective for bending thin-walled pipes with minimal distortion or wrinkling. It’s widely used in industries requiring precise bends, such as aerospace and automotive manufacturing.

- Roll Bending: This method uses three rollers to bend the pipe gradually. The rollers are adjusted to control the bend radius and angle. Roll bending is suitable for bending long lengths of pipe and creating complex curves.

The selection of the appropriate bending technique depends on several factors, including the pipe material (steel, copper, aluminum, etc.), diameter, wall thickness, desired bend radius, and the required level of precision.

2. Essential Tools and Equipment for Pipe Bending

The tools required vary depending on the chosen bending technique. However, some common tools include:

- Pipe Benders (Manual and Hydraulic): These are the core tools for bending pipes, offering varying levels of capacity and precision.

- Dies and Formers: These are used to shape the pipe during bending, ensuring consistent bend radii and preventing damage.

- Measuring Tools: Accurate measurement is crucial for precise bending. This includes tape measures, protractors, and angle finders.

- Support Structures: Stable support is necessary to prevent pipe deformation during bending. This may involve using workbenches, stands, or specialized fixtures.

- Lubricants: Lubricants help reduce friction during bending, preventing damage to the pipe and ensuring smoother bends.

- Safety Gear: Appropriate safety gear, including gloves, eye protection, and hearing protection, is essential to prevent injuries during the bending process.

Investing in high-quality tools is crucial for achieving accurate and consistent results. Regular maintenance of these tools is also essential to ensure their longevity and performance.

3. Addressing Pipe Straightening Challenges

Pipes can become bent or misaligned during transportation, handling, or installation. Straightening bent pipes requires careful consideration to avoid further damage. Methods for straightening include:

- Manual Straightening: For minor bends, manual straightening using hammers and mallets may suffice. This requires careful application of force to avoid creating new bends or kinks.

- Hydraulic Straightening: For more significant bends, hydraulic presses or specialized straightening machines can be employed. These machines offer greater control and force, allowing for more effective straightening.

- Thermal Straightening: In some cases, controlled heating can be used to straighten pipes. This method involves carefully heating the bent section to allow for expansion and then gradually cooling it while applying corrective force.

The choice of straightening method depends on the severity of the bend, the pipe material, and the desired level of straightness. It’s crucial to avoid excessive force, which can lead to pipe damage or failure.

4. Material Considerations in Pipe Bending and Straightening

The material of the pipe significantly influences the bending and straightening process. Different materials have varying levels of ductility and strength, affecting their susceptibility to bending and straightening techniques. For example:

- Steel: Steel pipes require more force to bend and are prone to cracking if bent too sharply. Careful selection of bending techniques and the use of appropriate lubricants are essential.

- Copper: Copper pipes are more ductile than steel and can be bent more easily. However, excessive bending can lead to work hardening, reducing their flexibility.

- Aluminum: Aluminum pipes are lightweight and relatively easy to bend, but they are also susceptible to kinking if not handled carefully.

Understanding the material properties is crucial for selecting the appropriate bending and straightening techniques to avoid damage and ensure the integrity of the pipe.

5. Safety Precautions During Pipe Bending and Straightening

Safety should always be the top priority when working with pipe bending and straightening equipment. Essential safety precautions include:

- Proper Training: Operators should receive adequate training on the safe operation of all equipment.

- Use of Safety Gear: Always wear appropriate safety gear, including gloves, eye protection, hearing protection, and steel-toed boots.

- Machine Guards: Ensure all machine guards are in place and functioning correctly.

- Safe Work Practices: Follow established safe work practices and procedures.

- Regular Maintenance: Regularly inspect and maintain all equipment to prevent malfunctions.

By adhering to these safety precautions, you can minimize the risk of accidents and injuries during pipe bending and straightening operations.

By understanding the various techniques, tools, and safety precautions, you can effectively bend and straighten pipes, ensuring accuracy, efficiency, and safety in your projects.

Tags: pipe bending, pipe straightening, hydraulic bending, manual bending, pipe bending techniques, pipe bending tools, safety in pipe bending

In today’s rapidly evolving business landscape, organizations that embrace continuous improvement are the ones that thrive. A culture of continuous improvement, often referred to as Kaizen, isn’t just a buzzword; it’s a fundamental shift in mindset and operational approach that fosters innovation, efficiency, and sustainable growth. This post delves into the key elements of building and sustaining a thriving continuous improvement culture within your organization.

1. Defining and Communicating the “Why” of Continuous Improvement

Before embarking on any continuous improvement initiative, it’s crucial to clearly define the “why.” Why is continuous improvement important for your organization? What are the specific goals you aim to achieve? This “why” needs to be more than just increased efficiency or cost savings; it needs to resonate with employees on a personal level. Connect the improvement efforts to the overall organizational mission and vision. Clearly communicate this vision to every team member, highlighting how their contributions directly impact the bigger picture. This clarity fosters buy-in and encourages active participation. Use compelling storytelling and real-life examples to demonstrate the positive impact of previous improvement initiatives. Regularly reinforce the “why” through company-wide communications, team meetings, and leadership messaging.

2. Empowering Employees: Fostering a Growth Mindset

A successful continuous improvement culture hinges on employee empowerment. Create an environment where employees feel comfortable identifying problems, suggesting solutions, and taking ownership of improvement projects. This requires a shift from a blame culture to a learning culture. Encourage open communication, constructive feedback, and risk-taking. Provide employees with the necessary training, resources, and tools to implement their ideas. Establish clear processes for submitting improvement suggestions, ensuring that all suggestions are reviewed and considered. Recognize and reward employees for their contributions, both big and small. Celebrate successes and learn from failures, fostering a culture of continuous learning and development. Implement systems for knowledge sharing, allowing employees to learn from each other’s experiences.

3. Implementing Practical Continuous Improvement Tools and Techniques

While a positive mindset is crucial, a continuous improvement culture also requires practical tools and techniques. Lean methodologies, such as Kaizen events, 5S, and Value Stream Mapping, are valuable tools for identifying and eliminating waste. Six Sigma methodologies offer a structured approach to process improvement, focusing on reducing variation and defects. Data-driven decision-making is paramount; implement systems for collecting, analyzing, and interpreting data to track progress and identify areas for improvement. Regularly review key performance indicators (KPIs) to monitor the effectiveness of improvement initiatives. Utilize project management methodologies to manage improvement projects effectively, ensuring timely completion and measurable results.

4. Overcoming Challenges: Addressing Resistance to Change

Implementing a continuous improvement culture isn’t without its challenges. Resistance to change is a common hurdle. Addressing this requires proactive communication, transparency, and empathy. Involve employees in the change process from the outset, allowing them to voice their concerns and contribute to solutions. Provide adequate training and support to help employees adapt to new processes and technologies. Acknowledge and address any anxieties or fears related to the change. Recognize that change takes time; celebrate small wins along the way to build momentum and maintain motivation. Continuously monitor employee feedback and adjust your approach as needed. Leadership buy-in is crucial; leaders must champion the initiative and model the desired behaviors.

5. Measuring Success and Sustaining the Culture

Measuring the success of your continuous improvement efforts is vital for demonstrating the value of the initiative and sustaining momentum. Establish clear metrics and KPIs to track progress against your goals. Regularly review the data to identify areas where improvements are needed. Celebrate successes and share best practices across the organization. Regularly assess employee engagement and satisfaction levels to ensure that the culture is thriving. Continuously refine your approach based on feedback and data. Invest in ongoing training and development to equip employees with the skills and knowledge they need to continue driving improvement. Make continuous improvement an integral part of your organization’s culture, not just a temporary initiative.

By focusing on these key elements, you can cultivate a thriving continuous improvement culture that fosters innovation, efficiency, and sustainable growth. Remember, continuous improvement is a journey, not a destination. Embrace the process, learn from your experiences, and celebrate your successes along the way.

SEO Tags:

- Continuous Improvement

- Kaizen

- Lean Management

- Process Improvement

- Organizational Culture

The pursuit of zero-defect production is a noble goal, often perceived as an unattainable ideal. However, while achieving absolute perfection might be elusive, striving for it significantly improves product quality, reduces waste, and enhances customer satisfaction. This blog post delves into the strategies and methodologies required to effectively pursue zero-defect production goals.

Understanding the Zero-Defect Philosophy

Zero-defect manufacturing isn’t about eliminating every single imperfection. Instead, it’s a mindset – a commitment to continuous improvement and a relentless pursuit of minimizing defects to a level that’s virtually undetectable to the end-user. It’s about building a culture of quality where every employee takes ownership of the quality of their work and actively contributes to defect prevention. This philosophy requires a holistic approach, integrating quality considerations into every stage of the production process, from design and procurement to manufacturing and delivery.

This shift from reactive quality control (finding and fixing defects after they occur) to proactive defect prevention is crucial. It emphasizes identifying and eliminating the root causes of defects before they even arise. This proactive approach leads to significant cost savings in the long run by reducing rework, scrap, and warranty claims.

Implementing Robust Quality Control Systems

A robust quality control system is the backbone of any zero-defect initiative. This goes beyond simple inspection at the end of the production line. Effective quality control necessitates implementing a multi-layered approach that incorporates:

- Statistical Process Control (SPC): SPC uses statistical methods to monitor and control processes, identifying variations and preventing defects before they become widespread.

- Total Quality Management (TQM): TQM is a holistic approach that integrates quality into every aspect of the organization, fostering a culture of continuous improvement and employee empowerment.

- Six Sigma Methodology: Six Sigma is a data-driven methodology that aims to reduce variation and improve process capability, leading to a significant reduction in defects.

- Regular Audits and Inspections: Regular audits and inspections at various stages of the production process help identify potential problems early on and prevent them from escalating.

The choice of specific quality control tools will depend on the nature of the production process and the type of defects being addressed. However, the overarching principle remains the same: proactive identification and prevention of defects.

Investing in Employee Training and Empowerment

Employees are the heart of any production process, and their skills and commitment are crucial for achieving zero-defect goals. Investing in comprehensive training programs that focus on quality awareness, process understanding, and problem-solving skills is paramount. This training should not be a one-time event, but an ongoing process of continuous learning and development.

Furthermore, empowering employees to take ownership of quality is essential. This means giving them the authority and resources to identify and address quality issues without excessive layers of bureaucracy. Creating a culture of open communication and feedback is vital for encouraging employees to report potential problems and contribute to solutions.

Leveraging Technology for Enhanced Quality

Technology plays a significant role in achieving zero-defect production goals. Automation, robotics, and advanced data analytics can significantly improve process consistency and reduce human error. Examples include:

- Automated Inspection Systems: These systems can quickly and accurately detect defects, often with greater precision than human inspectors.

- Predictive Maintenance: Using data analytics to predict equipment failures and schedule maintenance proactively prevents production downtime and reduces the likelihood of defects.

- Real-time Data Monitoring: Monitoring key process parameters in real-time allows for immediate intervention if deviations from established norms are detected.

- Advanced Quality Management Software: Software solutions can streamline quality control processes, track defects, and provide valuable insights for continuous improvement.

The integration of technology should be carefully planned and implemented to ensure seamless integration with existing systems and processes.

Continuous Improvement and Kaizen Culture

Achieving zero-defect production is not a destination but a journey. Continuous improvement should be embedded in the company’s culture. The Kaizen philosophy, which emphasizes incremental improvements and continuous learning, is particularly well-suited for this purpose. Regularly reviewing processes, identifying areas for improvement, and implementing changes based on data and feedback is crucial for maintaining momentum and achieving ongoing progress.

This involves fostering a culture where employees are encouraged to suggest improvements, and where feedback is actively solicited and incorporated into decision-making. Regular brainstorming sessions, process mapping, and root cause analysis can all contribute to identifying areas for improvement and driving continuous progress towards the zero-defect goal.

In conclusion, while achieving perfect zero-defect production might be theoretically impossible, the pursuit of it drives significant improvements in quality, efficiency, and customer satisfaction. By implementing robust quality control systems, investing in employee training, leveraging technology, and fostering a culture of continuous improvement, businesses can significantly reduce defects and move closer to their zero-defect goals.

Tags: zero-defect production, quality control, lean manufacturing, six sigma, kaizen

For decades, galvanized pipes have been a mainstay in plumbing systems worldwide. Their robust construction and inherent durability make them a reliable choice for both residential and commercial applications. But what exactly makes galvanized pipes stand out from other piping materials? Let’s delve into the compelling advantages that solidify their position as a top contender in the plumbing world.

Unmatched Durability and Strength: The Foundation of Galvanized Pipes

Galvanized pipes are manufactured from steel, a material renowned for its exceptional strength and resilience. This inherent strength allows galvanized pipes to withstand high water pressure and resist damage from impacts and vibrations, making them ideal for various applications, from underground water mains to high-rise building plumbing systems. Their robust nature ensures long-term performance, minimizing the risk of leaks and failures associated with weaker materials like plastic or copper in demanding situations.

Superior Corrosion Resistance: Protecting Against the Elements

The defining characteristic of galvanized pipes is their zinc coating. This zinc layer acts as a sacrificial anode, protecting the underlying steel from rust and corrosion. When exposed to moisture and oxygen, the zinc reacts preferentially, corroding instead of the steel. This process significantly extends the lifespan of the pipes, preventing costly replacements and repairs often associated with unprotected steel pipes. The effectiveness of the zinc coating is particularly crucial in environments with high humidity, soil acidity, or aggressive water chemistry.

Long Lifespan and Cost-Effectiveness: A Smart Investment

The combination of strength and corrosion resistance translates into an exceptionally long lifespan for galvanized pipes. While the exact lifespan depends on factors like water quality and soil conditions, galvanized pipes can easily last for 50 years or more, significantly exceeding the lifespan of many alternative piping materials. This longevity makes them a cost-effective choice in the long run, minimizing the need for frequent replacements and reducing overall plumbing maintenance costs. The initial investment in galvanized pipes is often offset by their extended lifespan and reduced repair needs.

Easy Installation and Maintenance: Streamlining Your Plumbing Project

Galvanized pipes are relatively easy to install, thanks to their robust construction and standard threading. Experienced plumbers are familiar with working with galvanized pipes, making installation efficient and straightforward. While they may require specialized tools for cutting and threading, the overall installation process is generally less complex compared to some other piping systems. Furthermore, their durability translates to less frequent maintenance, further simplifying long-term ownership.

Applications Versatility: From Homes to Industries

The versatility of galvanized pipes is another key advantage. They are suitable for a wide array of applications, including residential plumbing, industrial piping systems, irrigation systems, and even gas lines (though specific regulations must be followed). Their strength and corrosion resistance make them well-suited for both above-ground and underground installations, catering to diverse plumbing needs. This adaptability makes galvanized pipes a practical and reliable solution across various sectors.

In conclusion, galvanized pipes offer a compelling combination of strength, durability, corrosion resistance, and cost-effectiveness. Their long lifespan, ease of installation, and versatility make them a practical and reliable choice for a wide range of plumbing applications. While other materials have their advantages, the enduring performance and value proposition of galvanized pipes remain unmatched for many projects.

SEO-Friendly Tags:

- galvanized steel pipes

- galvanized pipe lifespan

- corrosion resistant pipes

- durable plumbing pipes

- best plumbing pipes