Boiler tubes are the unsung heroes of countless industrial processes and power generation facilities. These seemingly simple components are crucial for efficient and safe heat transfer, forming the backbone of steam generation. This comprehensive guide delves into the technology and use of boiler tubes, exploring their materials, manufacturing processes, applications, maintenance, and future trends.

The Materials Science Behind Boiler Tubes

The choice of material for boiler tubes is paramount, dictated by factors such as operating pressure, temperature, and the type of fluid being heated. Common materials include:

- Carbon Steel: Cost-effective for low-pressure applications, but susceptible to corrosion and scaling.

- Alloy Steel: Offers enhanced strength and resistance to creep and corrosion at higher temperatures and pressures. Specific alloy compositions are tailored to meet demanding operating conditions.

- Stainless Steel: Exhibits superior corrosion resistance, making it ideal for applications involving aggressive chemicals or high-purity steam.

- Non-Ferrous Metals: Materials like copper and copper alloys are employed in specialized applications where corrosion resistance is critical, although they are generally less robust than steel.

The selection process involves careful consideration of material properties, cost, and the specific requirements of the boiler system. Advanced materials like advanced high-strength steels and superalloys are increasingly used in high-efficiency power plants to withstand extreme conditions.

Manufacturing Processes: From Raw Material to Finished Product

The manufacturing process for boiler tubes is a precise and demanding undertaking. It typically involves several steps:

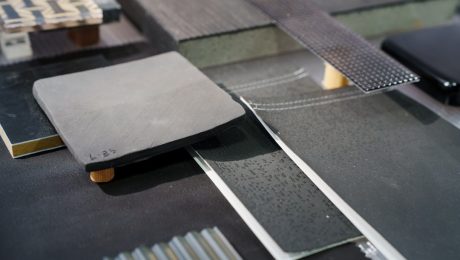

- Raw Material Selection and Preparation: Careful selection of raw materials with appropriate chemical composition and metallurgical properties is crucial.

- Tube Making: Various techniques are used, including seamless rolling, electric resistance welding (ERW), and submerged arc welding (SAW). Seamless tubes offer superior strength and resistance to fatigue.

- Heat Treatment: Heat treatment processes like annealing and tempering are employed to enhance the mechanical properties of the tubes, improving their strength, ductility, and resistance to creep.

- Surface Finishing: Surface treatments like pickling, polishing, and coating can improve corrosion resistance and reduce friction.

- Quality Control: Rigorous quality control measures are implemented throughout the manufacturing process to ensure that the tubes meet stringent specifications.

Advanced manufacturing techniques, such as precision forging and advanced welding processes, are continuously being developed to produce even higher-quality boiler tubes capable of withstanding increasingly demanding operating conditions.

Diverse Applications Across Industries

Boiler tubes find widespread applications in various industries, including:

- Power Generation: In thermal power plants, boiler tubes are essential components in steam generators, responsible for transferring heat from the combustion process to water, producing high-pressure steam to drive turbines.

- Industrial Processes: Boiler tubes are used in various industrial processes requiring steam, such as heating, sterilization, and chemical processing. Examples include refineries, chemical plants, and food processing facilities.

- Heating Systems: In district heating systems and large-scale building heating systems, boiler tubes are utilized to transfer heat from a central boiler to individual buildings or zones.

- Waste Heat Recovery: Boiler tubes can be used to recover waste heat from industrial processes, improving energy efficiency and reducing environmental impact.

The specific type and design of boiler tubes used depend on the application’s operating parameters and the nature of the heat transfer fluid. Specialized designs are available for various applications, ensuring optimal performance and longevity.

Maintenance and Inspection: Ensuring Operational Integrity

Regular maintenance and inspection of boiler tubes are crucial for ensuring safe and efficient operation. This includes:

- Visual Inspection: Regular visual inspections can detect signs of corrosion, erosion, or damage.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing (UT), radiographic testing (RT), and eddy current testing (ECT) are used to detect internal flaws and defects.

- Chemical Cleaning: Periodic chemical cleaning removes scale and deposits that can reduce heat transfer efficiency and lead to corrosion.

- Tube Replacement: Damaged or worn-out tubes should be promptly replaced to prevent catastrophic failures.

A comprehensive maintenance program, incorporating regular inspections and preventative measures, is essential for maximizing the lifespan and performance of boiler tubes and ensuring the safe and reliable operation of the boiler system. Implementing a robust predictive maintenance strategy using data analytics can further enhance boiler tube lifespan and reliability.

Future Trends in Boiler Tube Technology

Ongoing research and development are focused on improving the performance and durability of boiler tubes. Key trends include:

- Advanced Materials: The development of advanced materials with enhanced strength, corrosion resistance, and creep resistance at higher temperatures is a key focus.

- Improved Manufacturing Processes: Advanced manufacturing techniques are being developed to produce higher-quality tubes with improved dimensional accuracy and consistency.

- Enhanced Coatings and Surface Treatments: New coatings and surface treatments are being developed to further improve corrosion resistance and reduce friction.

- Digital Twin Technology: Digital twin technology is being used to model and simulate the behavior of boiler tubes under various operating conditions, enabling improved design and maintenance strategies.

- Sustainable Materials: Research is being conducted on the use of more sustainable materials and manufacturing processes to reduce the environmental impact of boiler tube production.

These advancements will lead to more efficient, reliable, and environmentally friendly boiler systems in the future.

Tags: boiler tubes, boiler tube technology, boiler tube materials, boiler maintenance, steam generation

The steel industry, a cornerstone of global infrastructure and manufacturing, is undergoing a significant digital transformation. One key element driving this change is the emergence of sophisticated B2B matching platforms specifically designed to connect buyers and sellers of steel products efficiently and effectively. These platforms are revolutionizing how businesses source, procure, and distribute steel, streamlining operations and boosting profitability. This comprehensive guide explores the intricacies of these platforms and their impact on the steel industry.

1. Streamlining Steel Procurement: How Matching Platforms Improve Efficiency

Traditional steel procurement methods often involve lengthy searches, multiple intermediaries, and complex negotiations. B2B matching platforms drastically reduce these inefficiencies. By leveraging advanced algorithms and data analytics, these platforms create a centralized marketplace where buyers can easily find suppliers based on specific criteria such as steel grade, quantity, location, and delivery timeframe. This streamlined approach drastically reduces the time and resources spent on sourcing, allowing businesses to focus on core operations. Furthermore, the transparency offered by these platforms ensures fair pricing and prevents hidden costs, leading to significant cost savings.

Many platforms incorporate features like real-time inventory tracking, allowing buyers to see available stock and plan accordingly. This reduces the risk of delays caused by material shortages and improves supply chain predictability. Automated communication tools within the platform facilitate seamless interaction between buyers and sellers, minimizing misunderstandings and accelerating the procurement process. The overall result is a more agile and responsive procurement process, contributing to improved operational efficiency and reduced lead times.

2. Expanding Market Reach: Connecting Global Steel Buyers and Sellers

The global nature of the steel industry presents unique challenges in connecting buyers and sellers across geographical boundaries. Steel B2B matching platforms overcome these challenges by providing a single, unified marketplace accessible to businesses worldwide. This expanded reach allows smaller steel producers to access a larger customer base, while larger buyers can diversify their supplier network and access a wider variety of steel grades and products.

These platforms often include features that facilitate international trade, such as multi-language support, international payment gateways, and compliance with relevant trade regulations. This simplifies the complexities of international transactions, making it easier for businesses to engage in global trade and expand their market reach. The increased competition fostered by these platforms also leads to more competitive pricing and improved product quality, benefiting both buyers and sellers.

3. Enhancing Transparency and Trust: Building Confidence in Steel Transactions

Trust and transparency are crucial elements in any B2B transaction, especially in the steel industry where the value of materials can be significant. Steel B2B matching platforms address these concerns by providing a secure and transparent environment for buyers and sellers to interact. Platforms often incorporate features like verified supplier profiles, buyer reviews, and secure payment processing systems to build confidence and minimize the risk of fraud.

The ability to track transactions and access historical data provides increased transparency and accountability. This allows businesses to monitor the performance of their suppliers and make informed decisions based on real-time data. The platform’s centralized nature also helps reduce disputes and ensures fair and equitable transactions, fostering trust and collaboration within the steel industry ecosystem.

4. Data-Driven Insights: Leveraging Analytics for Strategic Decision-Making

Modern steel B2B matching platforms go beyond simply connecting buyers and sellers. Many platforms utilize advanced data analytics to provide valuable insights into market trends, pricing patterns, and supply chain dynamics. This data can be used to inform strategic decision-making, optimize procurement strategies, and identify new business opportunities.

For instance, platforms can generate reports on steel price fluctuations, allowing buyers to anticipate changes and negotiate favorable contracts. They can also track supplier performance metrics, helping buyers identify reliable and efficient suppliers. This data-driven approach empowers businesses to make more informed decisions, improve their competitive advantage, and maximize profitability.

5. The Future of Steel B2B Matching Platforms: Innovation and Integration

The future of steel B2B matching platforms is likely to be characterized by increased innovation and integration. We can expect to see further advancements in artificial intelligence (AI) and machine learning (ML) to enhance the platform’s ability to match buyers and sellers, predict market trends, and optimize supply chains. Integration with other enterprise resource planning (ERP) systems and supply chain management (SCM) tools will further streamline operations and improve data flow.

The adoption of blockchain technology could enhance transparency and security, ensuring the authenticity and traceability of steel products. The continued development of these platforms will undoubtedly contribute to a more efficient, transparent, and sustainable steel industry, driving growth and innovation for years to come.

In conclusion, steel B2B matching platforms are transforming the way businesses operate within the steel industry. By streamlining procurement, expanding market reach, enhancing transparency, providing data-driven insights, and fostering innovation, these platforms are creating a more efficient, competitive, and sustainable ecosystem for all stakeholders. Their continued evolution promises to further revolutionize the steel industry, ushering in a new era of efficiency and profitability.

Tags: Steel B2B, Steel Marketplace, Steel Procurement, Steel Supply Chain, Steel Industry Technology

The steel industry is a cornerstone of global infrastructure, but its traditional practices have a significant environmental footprint. The urgent need to mitigate climate change and resource depletion demands a radical shift towards sustainable steel supply chains. This means rethinking every stage of the process, from raw material extraction to product end-of-life, integrating environmental and social responsibility into every decision.

1. Minimizing Carbon Emissions in Steel Production

Steel production is notoriously carbon-intensive, primarily due to the energy-intensive blast furnace process. A significant portion of global CO2 emissions stems from this process, relying heavily on coking coal. To mitigate this, several strategies are being implemented:

- Hydrogen-based steelmaking: Replacing coking coal with hydrogen as a reducing agent significantly reduces carbon emissions. While still in its developmental stages, hydrogen steelmaking holds immense promise for decarbonizing the industry. Research and investment in this area are crucial for its widespread adoption.

- Electric Arc Furnaces (EAFs): EAFs utilize scrap steel as their primary raw material, significantly reducing the need for iron ore and coking coal. This process is considerably more energy-efficient and generates fewer emissions than blast furnaces. Increasing the use of EAFs is a key strategy for immediate emission reductions.

- Carbon Capture, Utilization, and Storage (CCUS): CCUS technologies capture CO2 emissions from steel plants and either utilize them in other industrial processes or store them underground. While still relatively expensive, CCUS offers a viable pathway to reduce emissions from existing blast furnaces in the short to medium term.

- Energy efficiency improvements: Optimizing energy consumption throughout the steelmaking process, through technological advancements and process improvements, can significantly reduce the overall carbon footprint.

2. Responsible Sourcing of Raw Materials

The environmental and social impacts of raw material extraction must be considered throughout the supply chain. Sustainable steel production requires responsible sourcing of iron ore, coal, and other raw materials. This involves:

- Minimizing deforestation and habitat loss: Ensuring that iron ore mining operations do not contribute to deforestation or habitat destruction is critical. This requires careful site selection, responsible land management, and adherence to strict environmental regulations.

- Reducing water consumption: Steel production is water-intensive. Implementing water-efficient technologies and practices is crucial to minimize the environmental impact of water usage.

- Sustainable mining practices: Adopting responsible mining practices, including minimizing waste generation, reclamation of mined areas, and biodiversity protection, is essential for environmental sustainability.

- Traceability and transparency: Establishing transparent and traceable supply chains enables better monitoring of environmental and social performance throughout the raw material sourcing process.

3. Embracing the Circular Economy in Steel

The circular economy model focuses on minimizing waste and maximizing resource utilization. In the context of steel, this involves:

- Increased scrap metal recycling: Recycling steel scrap is significantly less energy-intensive than producing steel from raw materials. Promoting and incentivizing steel scrap recycling is crucial for reducing the industry’s environmental impact.

- Product design for recyclability: Designing steel products with recyclability in mind simplifies the recycling process and improves the quality of recycled steel.

- Developing closed-loop systems: Creating closed-loop systems where steel products are designed for easy disassembly and recycling, minimizing waste and maximizing resource recovery.

- Extended Producer Responsibility (EPR): Implementing EPR schemes holds producers accountable for the end-of-life management of their steel products, incentivizing sustainable design and recycling.

4. Enhancing Supply Chain Transparency and Traceability

Building trust and ensuring accountability requires enhanced transparency and traceability throughout the steel supply chain. This involves:

- Blockchain technology: Utilizing blockchain technology to track the origin and movement of steel materials, ensuring transparency and preventing the use of conflict minerals or materials sourced from unsustainable practices.

- Data-driven monitoring: Implementing robust data collection and analysis systems to monitor environmental and social performance throughout the supply chain.

- Third-party certifications: Seeking independent certifications, such as those related to sustainable sourcing and responsible manufacturing, to verify the sustainability claims of steel producers and suppliers.

- Collaboration and information sharing: Fostering collaboration and information sharing among stakeholders throughout the supply chain to improve transparency and accountability.

5. Investing in Research and Development

Continuous innovation is crucial for achieving truly sustainable steel supply chains. This requires significant investment in research and development focused on:

- Developing more efficient and sustainable steelmaking processes: Research into new technologies and processes that minimize energy consumption and reduce emissions.

- Improving steel recycling technologies: Developing technologies that enhance the efficiency and effectiveness of steel recycling.

- Exploring alternative raw materials: Investigating the potential of alternative raw materials that are less environmentally damaging than traditional sources.

- Developing sustainable coatings and surface treatments: Researching sustainable alternatives to traditional coatings and surface treatments that can improve the durability and lifespan of steel products.

Creating truly sustainable steel supply chains requires a collaborative effort involving steel producers, suppliers, consumers, and policymakers. By adopting the strategies outlined above, the steel industry can significantly reduce its environmental impact and contribute to a more sustainable future.

Tags: Sustainable Steel, Green Steel, Circular Economy Steel, Steel Supply Chain Sustainability, Responsible Steel Sourcing

The global steel industry is a dynamic and interconnected landscape. For businesses involved in steel manufacturing, processing, trading, or technology, participating in international steel expos presents a unique opportunity to expand market reach, forge strategic partnerships, and stay ahead of the curve. This comprehensive guide will delve into the multifaceted benefits and considerations of attending these crucial events.

Networking: The Heart of International Steel Expos

International steel expos are unparalleled networking hubs. They bring together key players from across the globe – manufacturers, suppliers, distributors, investors, researchers, and government representatives. This concentrated environment allows for efficient and effective relationship building. You can connect with potential clients, identify new suppliers, explore joint ventures, and establish long-term collaborations. Actively participating in networking events, conferences, and even informal gatherings within the expo is crucial for maximizing your return on investment. Remember to prepare a concise and compelling elevator pitch to efficiently communicate your company’s value proposition.

Market Research and Trend Analysis: Gaining a Competitive Edge

Attending international steel expos provides invaluable market intelligence. By observing competitor strategies, analyzing the latest technologies showcased, and gauging market trends firsthand, you gain a significant competitive edge. Pay close attention to the types of steel products being displayed, the innovations being introduced, and the overall market sentiment. This hands-on research is far more effective than relying solely on secondary data. Take notes, collect brochures, and schedule meetings with industry analysts present at the expo to gather comprehensive market insights.

Showcasing Your Products and Services: Reaching a Global Audience

An international steel expo offers a powerful platform to showcase your company’s products and services to a global audience. A well-designed booth, complete with compelling visuals and engaging demonstrations, can attract significant attention. Consider offering interactive displays, product samples, and detailed technical information. This is an opportunity to build brand awareness, generate leads, and secure direct sales. Effective booth management and a proactive approach to engaging visitors are essential to maximizing your expo’s impact. Don’t forget the power of pre-show marketing to generate interest and schedule meetings before the event even begins.

Identifying Emerging Technologies and Innovations: Staying Ahead of the Curve

The steel industry is constantly evolving, with new technologies and innovations emerging at a rapid pace. International steel expos serve as a window into these advancements. By attending conferences, workshops, and demonstrations, you can stay informed about the latest developments in steel manufacturing, processing, and application. This understanding of emerging technologies allows you to make informed decisions about investments, process improvements, and product development, ensuring your company remains competitive in the long term. Engage with technology providers and researchers to learn about potential collaborations and licensing opportunities.

Strategic Partnerships and Joint Ventures: Expanding Your Global Reach

International steel expos facilitate the formation of strategic partnerships and joint ventures. By networking with companies from different regions and specializing in complementary areas, you can expand your global reach, access new markets, and leverage each other’s strengths. These collaborations can take various forms, from distribution agreements to joint research and development projects. The concentrated environment of an expo makes it easier to identify potential partners and initiate negotiations, leading to mutually beneficial collaborations that significantly boost your business’s growth.

Participating in international steel expos requires careful planning and execution. From securing booth space and designing engaging displays to networking effectively and following up on leads, each step plays a crucial role in maximizing your return on investment. However, the potential rewards – increased brand awareness, strategic partnerships, and valuable market insights – far outweigh the effort involved. By actively engaging with the expo’s opportunities, you can unlock significant global opportunities and propel your steel business to new heights.

SEO-Friendly Tags:

- Steel Expo

- International Steel Exhibition

- Global Steel Market

- Steel Industry Networking

- Steel Manufacturing Technology

ISO 9001:2015 is more than just a certification; it’s a framework for building a robust and efficient quality management system (QMS). This post delves into the practical application of ISO 9001, showcasing its impact on various aspects of an organization.

1. Establishing the Foundation: Defining Scope and Context

The journey to ISO 9001 compliance begins with a thorough understanding of your organization’s context. This involves identifying internal and external issues that can impact your ability to meet customer requirements and achieve your objectives. A clearly defined scope outlines the specific products, services, and processes covered by the QMS. This meticulous planning is crucial; it prevents scope creep and ensures the system remains focused and effective. Consider factors like your organization’s size, structure, and the complexity of your operations. Understanding your stakeholders – customers, suppliers, employees, and regulatory bodies – is equally important. Their needs and expectations must be incorporated into your QMS.

2. Process Mapping and Documentation: The Backbone of ISO 9001

Once the scope and context are defined, the next step involves mapping your key processes. This isn’t simply listing tasks; it’s about visualizing the flow of activities, identifying interdependencies, and pinpointing potential bottlenecks. Detailed process maps, supported by comprehensive documentation, are the backbone of your ISO 9001 implementation. This documentation includes standard operating procedures (SOPs), work instructions, forms, and records. The goal is to create a clear and consistent set of instructions that ensure everyone understands their roles and responsibilities. Proper documentation not only facilitates compliance but also improves efficiency and reduces errors.

3. Resource Management: Empowering Your Team for Success

Implementing a successful ISO 9001 QMS requires more than just processes and documentation; it demands the right resources. This includes human resources, infrastructure, and technological capabilities. Effective resource management involves identifying the skills and competencies needed within your organization and developing training programs to bridge any gaps. It also includes providing employees with the necessary tools, equipment, and technology to perform their tasks efficiently and effectively. Regular performance reviews and ongoing training are essential to maintain competency and ensure continuous improvement. Furthermore, maintaining and upgrading infrastructure is crucial for ensuring the smooth operation of your QMS.

4. Continuous Improvement: The Heart of the ISO 9001 Philosophy

ISO 9001 isn’t a static system; it’s a dynamic framework designed for continuous improvement. The Plan-Do-Check-Act (PDCA) cycle is central to this philosophy. This iterative process involves planning improvements, implementing them, checking their effectiveness, and then acting on the results. Regular internal audits, management reviews, and corrective and preventive actions (CAPA) are crucial tools for identifying areas for improvement. Analyzing data from various sources, such as customer feedback, internal audits, and performance indicators, provides valuable insights into areas needing attention. Continuous improvement isn’t just about fixing problems; it’s about proactively seeking ways to enhance efficiency, quality, and customer satisfaction.

5. Measuring Success: Key Performance Indicators (KPIs) and Metrics

Tracking your progress and demonstrating the effectiveness of your ISO 9001 QMS requires the use of Key Performance Indicators (KPIs) and other relevant metrics. These metrics should be aligned with your organizational objectives and provide a clear picture of your performance. Examples include customer satisfaction scores, defect rates, lead times, and on-time delivery rates. Regular monitoring of these KPIs enables you to identify trends, highlight areas of strength and weakness, and demonstrate the tangible benefits of your QMS. Data analysis is crucial for making informed decisions and driving continuous improvement. The data collected should be used to inform management decisions and to demonstrate the effectiveness of the implemented QMS to both internal and external stakeholders.

Implementing an ISO 9001 QMS is a journey, not a destination. It requires commitment, dedication, and a continuous focus on improvement. By embracing the principles outlined above, organizations can unlock operational excellence, enhance customer satisfaction, and achieve sustainable growth.

Tags: ISO 9001, Quality Management System, QMS, Continuous Improvement, ISO 9001 Implementation, PDCA Cycle

In the world of construction, manufacturing, and engineering, the safety and reliability of materials are paramount. Steel, a fundamental building block in countless applications, requires stringent quality control to ensure structural integrity and user safety. This is where CE certification comes in. This comprehensive guide explores the intricacies of CE-certified steel products, providing you with the knowledge to make informed decisions and prioritize safety in your projects.

What Does CE Certification Mean for Steel Products?

The CE marking (Conformité Européenne) is a mandatory conformity marking for products sold within the European Economic Area (EEA). It signifies that the steel product has met the essential requirements of relevant European Union (EU) directives and regulations. For steel, this means it has undergone rigorous testing and evaluation to prove its compliance with specific safety, health, and environmental protection standards. A CE-marked steel product assures buyers that the manufacturer has demonstrated conformity with these regulations, reducing risks associated with substandard materials.

The Rigorous Process of CE Certification for Steel

Achieving CE certification for steel products isn’t a simple process. It involves several key stages:

- Product Design and Specification: The manufacturer must meticulously design the steel product to meet the relevant EU directives and harmonized standards (EN standards). This includes specifying material properties, dimensions, and manufacturing processes.

- Testing and Evaluation: Independent testing laboratories conduct rigorous tests to verify that the steel product meets the specified requirements. These tests may include tensile strength, yield strength, elongation, impact resistance, and chemical composition analysis.

- Quality Management System (QMS): Manufacturers must implement and maintain a robust QMS, typically ISO 9001 certified, to ensure consistent production and quality control throughout the manufacturing process. This system is regularly audited to ensure compliance.

- Declaration of Conformity (DoC): Once testing and evaluation are complete and the QMS is audited, the manufacturer issues a DoC, a formal statement confirming the product’s compliance with the relevant EU directives and standards. This document is a crucial part of the certification process.

- CE Marking Application: Finally, the CE marking is affixed to the product, usually accompanied by the manufacturer’s identification number and other relevant information. This visible marking is the ultimate confirmation of compliance.

Benefits of Choosing CE-Certified Steel Products

Selecting CE-certified steel products offers numerous advantages:

- Enhanced Safety: The primary benefit is the assurance of safety. CE certification guarantees the product meets stringent safety standards, reducing the risk of structural failure and accidents.

- Improved Quality: The rigorous testing and quality control procedures ensure a consistently high-quality product, minimizing defects and enhancing reliability.

- Legal Compliance: Using CE-certified steel products ensures compliance with EU regulations, avoiding potential legal repercussions and penalties.

- Increased Confidence: Both manufacturers and end-users gain increased confidence in the product’s performance and longevity.

- Better Reputation: For businesses, using CE-certified steel enhances their reputation for quality and commitment to safety.

Applications of CE-Certified Steel Products

The versatility of steel makes CE-certified products applicable across a wide range of sectors:

- Construction: In building and construction, CE-certified steel is crucial for structural elements like beams, columns, and frameworks. Its reliability is essential for the safety and stability of buildings.

- Manufacturing: Various industries use CE-certified steel in machinery, equipment, and components, requiring high-strength and reliable materials.

- Automotive: The automotive industry utilizes CE-certified steel for car bodies, chassis, and other components, demanding both strength and lightweight properties.

- Infrastructure: Bridges, railways, and other infrastructure projects rely heavily on CE-certified steel for their durability and load-bearing capacity.

- Renewable Energy: The growing renewable energy sector uses CE-certified steel in wind turbine towers and solar panel structures.

Identifying Genuine CE Certification: Avoiding Counterfeits

Unfortunately, counterfeit CE markings exist. To ensure you’re purchasing genuine CE-certified steel, consider these points:

- Verify the Manufacturer: Check the manufacturer’s credentials and ensure they are reputable and have a history of compliance.

- Examine the Marking: The CE marking should be clearly visible and correctly formatted. Look for inconsistencies or poorly printed markings.

- Request Documentation: Ask for the Declaration of Conformity (DoC) and other relevant certification documents. Legitimate suppliers will readily provide these.

- Use Reputable Suppliers: Source your steel products from established and trusted suppliers with a proven track record of supplying certified materials.

- Independent Verification: In case of doubt, consider engaging an independent testing laboratory to verify the steel’s conformity to the claimed standards.

Choosing CE-certified steel products is an investment in safety, quality, and compliance. By understanding the certification process and how to identify genuine markings, you can ensure the reliability and integrity of your projects, ultimately contributing to a safer and more sustainable built environment.

Tags: CE certified steel, steel certification, European conformity, steel quality, construction steel

body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

h1 {

font-size: 2.5em;

}

h2 {

font-size: 2em;

}

h3 {

font-size: 1.5em;

}

code {

background-color: #f0f0f0;

padding: 2px 4px;

border-radius: 4px;

}

Steel frames are ubiquitous in modern construction, offering strength, flexibility, and speed of construction. Designing these frames, however, requires a deep understanding of structural engineering principles, material properties, and relevant building codes. This comprehensive guide delves into the key aspects of steel frame design, providing a solid foundation for engineers and students alike.

1. Understanding Load Determination and Analysis

Accurate load determination is paramount in steel frame design. This involves identifying all forces acting on the structure, including:

- Dead Loads: The weight of the structure itself (steel members, cladding, roofing).

- Live Loads: Variable loads such as occupancy loads (people, furniture), snow loads, and wind loads.

- Environmental Loads: Seismic loads (earthquakes), and thermal loads (temperature variations).

Once loads are determined, structural analysis techniques, such as finite element analysis (FEA) or simplified methods like portal frame analysis, are employed to calculate internal forces (axial forces, shear forces, bending moments) in each member. Software packages like ETABS, SAP2000, and RISA-3D are commonly used for this purpose. Understanding the distribution of these forces is crucial for selecting appropriate steel sections.

2. Steel Section Selection and Material Properties

Selecting the right steel section is crucial for both structural integrity and economic efficiency. Several factors influence this decision:

- Strength Requirements: The section must be able to resist the calculated internal forces without yielding or buckling.

- Stiffness Requirements: The section must provide sufficient stiffness to limit deflections and maintain serviceability.

- Cost Considerations: Optimizing the design to minimize the amount of steel used without compromising safety is essential.

- Availability: The chosen section should be readily available from local steel suppliers.

Steel material properties, such as yield strength (fy) and modulus of elasticity (E), are critical inputs in the design calculations. These properties are specified in relevant steel standards (e.g., ASTM A992).

3. Designing Steel Connections

Steel connections are critical elements that transfer forces between structural members. The design of connections must ensure sufficient strength and stiffness to resist the anticipated loads. Common connection types include:

- Bolted Connections: Relatively simple and economical, using high-strength bolts to transfer shear and moment.

- Welded Connections: Offer high strength and stiffness but require skilled welders and quality control.

- Moment Connections: Designed to transfer both shear and moment, providing greater rigidity to the frame.

- Pinned Connections: Transfer only shear forces, allowing for greater rotation at the joint.

Connection design involves detailed calculations to determine bolt sizes, weld sizes, and plate thicknesses, ensuring that the connection’s capacity exceeds the applied loads. Proper detailing is crucial to prevent premature failure.

4. Code Compliance and Design Standards

Steel frame design must adhere to relevant building codes and design standards to ensure public safety. These codes specify design loads, material properties, and design procedures. Examples include:

- AISC (American Institute of Steel Construction): Provides design specifications for structural steel buildings in North America.

- Eurocode 3: The European standard for the design of steel structures.

- AS/NZS 4600: Australian and New Zealand standard for the design of steel structures.

Understanding these codes is essential to ensure the designed frame meets the required safety and performance criteria. Designers must also consider local regulations and specific project requirements.

5. Detailing and Fabrication Considerations

Detailed drawings are crucial for the successful fabrication and erection of the steel frame. These drawings must clearly show:

- Member Sizes and Locations: Precise dimensions and locations of all steel members.

- Connection Details: Clear specifications of all bolted and welded connections, including bolt sizes, weld types, and plate thicknesses.

- Material Specifications: Details of the steel grade and other material properties.

- Fabrication Tolerances: Acceptable variations in dimensions and fabrication processes.

Collaboration with fabricators is essential to ensure that the design is feasible and cost-effective to construct. Consideration should be given to fabrication limitations and potential challenges during erection.

Designing steel frames is a complex process requiring expertise in structural analysis, material science, and building codes. By carefully considering the factors outlined above, engineers can design robust, efficient, and safe steel structures that meet the demands of modern construction.

SEO Tags:

- Steel Frame Design

- Structural Steel Design

- Steel Frame Analysis

- Steel Connections

- Steel Building Design

body { font-family: sans-serif; line-height: 1.6; }

h1, h2, h3 { color: #333; }

img { max-width: 100%; height: auto; display: block; margin: 20px auto; }

.gallery-item { display: inline-block; width: 30%; margin: 1%; }

@media (max-width: 768px) {

.gallery-item { width: 48%; }

}

@media (max-width: 480px) {

.gallery-item { width: 100%; }

}

Steel. A word that conjures images of strength, resilience, and enduring power. But its applications extend far beyond the simple image of a skyscraper or a bridge. This visual gallery explores the incredible versatility of steel, showcasing its transformative presence in various industries and facets of modern life. Prepare to be amazed by the sheer breadth of its capabilities!

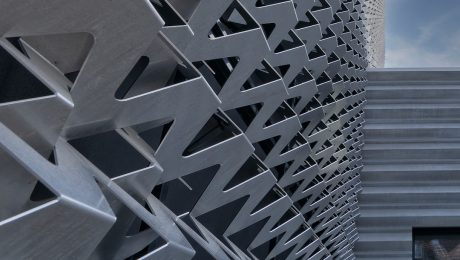

Sculpting the Skyline: Steel in Construction

Steel’s high tensile strength and malleability make it the undisputed king of the construction world. From towering skyscrapers that pierce the clouds to intricate architectural marvels, steel provides the backbone for some of humanity’s most ambitious building projects. Imagine the intricate framework of the Eiffel Tower, the robust support beams of a modern stadium, or the elegant curves of a contemporary museum – all made possible by steel’s unique properties. The images below showcase the sheer scale and artistry achievable with steel in construction.

The Industrial Backbone: Steel in Manufacturing

Beyond construction, steel forms the bedrock of countless manufacturing processes. From the heavy machinery used in factories to the intricate components of automobiles and appliances, steel’s durability and workability are essential. Consider the robust chassis of a car, the precision-engineered parts of a machine, or the durable casing of a washing machine – steel’s presence is undeniable. This section explores the diverse roles steel plays in shaping the products we use every day.

Beyond the Brute Strength: The Elegance of Stainless Steel

Stainless steel, an alloy of steel with chromium and other elements, adds a layer of sophistication to the already impressive capabilities of its base material. Its corrosion resistance makes it ideal for applications demanding hygiene and longevity. From surgical instruments and food processing equipment to sleek kitchen appliances and architectural accents, stainless steel’s elegance and practicality are unmatched. The images below showcase the refined beauty and diverse applications of this versatile material.

Reinforcing Resilience: Steel in Infrastructure

Steel’s role in infrastructure extends beyond buildings and manufacturing. It’s a vital component in railways, pipelines, and bridges, ensuring the safe and efficient movement of goods and people. Think of the robust railway tracks that crisscross continents, the durable pipelines transporting essential resources, and the supporting structures of massive bridges – all relying on steel’s strength and durability to withstand the test of time and environmental challenges.

The Art of Steel: Creative and Artistic Applications

Steel’s versatility extends beyond its purely functional applications. Artists and designers have long recognized its potential for creative expression. From intricate sculptures to modern art installations, steel’s malleability and strength allow for the creation of breathtaking pieces that challenge conventional notions of art and design. This section showcases the remarkable artistry achievable with this remarkable material.

This visual gallery only scratches the surface of steel’s vast and ever-expanding applications. Its remarkable properties continue to drive innovation and shape the world around us, making it a truly indispensable material for the modern age.

Tags: steel applications, steel uses, steel gallery, steel construction, stainless steel

“`

**Note:** Replace the placeholder image URLs (`placeholder-skyscraper.jpg`, etc.) with actual image URLs. You will need to provide your own images to make this HTML functional. The CSS is basic and can be expanded for a more visually appealing design.

In today’s competitive global market, maintaining high-quality production while adhering to stringent regulatory standards is paramount. ISO standards provide a framework for achieving this, offering a path to improved efficiency, reduced risks, and enhanced customer satisfaction. This comprehensive guide delves into the intricacies of ISO-compliant production processes, providing a practical blueprint for success.

1. Understanding the Relevance of ISO Standards in Production

ISO (International Organization for Standardization) develops and publishes international standards that cover a vast array of industries and processes. For manufacturing and production, specific ISO standards, such as ISO 9001 (Quality Management Systems), ISO 14001 (Environmental Management Systems), and ISO 45001 (Occupational Health and Safety Management Systems), are crucial. These standards provide a structured approach to managing various aspects of production, ensuring consistency, traceability, and continuous improvement. Adherence to these standards not only demonstrates a commitment to quality and safety but also opens doors to new markets and strengthens brand reputation. Companies certified to these standards often gain a competitive advantage, attracting clients who prioritize quality and responsible practices.

2. Implementing a Robust Quality Management System (QMS) – ISO 9001

ISO 9001 forms the cornerstone of many ISO-compliant production processes. A robust QMS, built upon the principles of ISO 9001, encompasses all aspects of production, from planning and design to delivery and post-production support. Key elements include: defining clear processes and procedures; establishing documented workflows; implementing regular internal audits; conducting management reviews; and consistently monitoring and measuring performance against predetermined targets. A well-defined QMS ensures that products and services consistently meet customer requirements and applicable regulatory standards. This involves meticulous documentation of all processes, clear roles and responsibilities, and a system for identifying and addressing non-conformances. Continual improvement is a core tenet of ISO 9001, driving ongoing refinement and optimization of processes.

3. Integrating Environmental Considerations – ISO 14001

ISO 14001 focuses on environmental management. For production processes, this translates to minimizing environmental impact throughout the lifecycle of a product. This includes reducing waste generation, conserving energy and resources, and managing emissions effectively. Implementation requires establishing environmental objectives and targets, identifying potential environmental aspects and impacts, and implementing control measures to mitigate risks. Regular environmental monitoring and auditing are essential to ensure compliance and identify areas for improvement. ISO 14001 promotes a proactive approach to environmental responsibility, fostering sustainable practices and contributing to a healthier planet. This can lead to cost savings through reduced waste and improved resource efficiency, as well as enhanced brand image and stakeholder trust.

4. Prioritizing Occupational Health and Safety – ISO 45001

ISO 45001 emphasizes the importance of workplace health and safety. In a production environment, this involves minimizing risks to employees’ physical and mental well-being. Implementation involves identifying hazards, assessing risks, and implementing control measures to eliminate or mitigate them. This includes providing appropriate training, personal protective equipment (PPE), and safe working procedures. Regular safety inspections, incident reporting, and investigation are crucial for identifying areas for improvement and preventing future accidents. ISO 45001 promotes a proactive and preventative approach to occupational health and safety, creating a safer and more productive work environment. This leads to reduced workplace accidents, improved employee morale, and increased productivity.

5. Maintaining Compliance and Continuous Improvement

Achieving ISO compliance is not a one-time event; it’s an ongoing process. Regular internal audits, management reviews, and external certifications are essential to maintain compliance and identify areas for improvement. The process should be integrated into the company culture, with all employees understanding their roles and responsibilities in maintaining the ISO standards. Continual improvement is a key principle of all ISO standards, encouraging organizations to constantly seek ways to enhance their processes and performance. This might involve adopting new technologies, improving training programs, or streamlining workflows. Regular monitoring of key performance indicators (KPIs) is crucial to track progress and identify areas needing attention. By embracing continuous improvement, organizations can ensure the long-term effectiveness of their ISO-compliant production processes.

By implementing and maintaining ISO-compliant production processes, businesses can significantly enhance their operational efficiency, product quality, and overall sustainability, positioning themselves for success in a highly competitive global marketplace.

Tags: ISO 9001, ISO 14001, ISO 45001, Production Processes, Quality Management System

The number 500. It’s a seemingly ordinary number, yet it holds a surprising depth of meaning and significance across various cultures, historical periods, and mathematical contexts. This post explores the multifaceted nature of 500, delving into its rich history and uncovering its hidden layers of intrigue.

500 in Ancient Civilizations: A Milestone Achieved

The significance of 500 varies across different ancient civilizations. In Roman numerals, it’s represented by the elegant ‘D’, a symbol that itself carries a certain weight and visual impact. The Romans, known for their meticulous record-keeping, likely viewed 500 as a significant milestone, a halfway point between the smaller units of hundreds and the larger thousands. Evidence suggests that 500 denarii (a Roman coin) represented a substantial sum, highlighting its economic importance. Other ancient cultures, while not necessarily using the same numeral system, likely marked the number with similar importance as a round figure representing accomplishment or progress.

500 in Mathematics: Exploring its Properties

From a purely mathematical perspective, 500 is a composite number, meaning it has more than two factors (1, 2, 4, 5, 10, 20, 25, 50, 100, 125, 250, 500). It’s also a highly divisible number, readily broken down into smaller integers, making it useful in various calculations and applications. Its prime factorization (2² x 5³) provides insights into its divisibility and structure. Furthermore, exploring its properties within specific mathematical branches like number theory could reveal more intricate details and relationships. For instance, its appearance in sequences or patterns could provide valuable information for mathematicians.

500 in Popular Culture: From Films to Folklore

The number 500 has seeped into popular culture, often serving as a symbolic representation of various concepts. The film “500 Days of Summer” uses the number to structure its narrative, illustrating a non-linear depiction of a relationship. In some folklore and superstitions, 500 might hold specific meanings, though these vary considerably across different cultures and traditions. The interpretation often depends on the context and the beliefs of the individuals involved. The number’s frequent appearance in video games, literature, and other forms of media reinforces its pervasive presence in contemporary culture, often without explicit explanation or significance.

500 and the Concept of Milestones: Achieving Significant Goals

The number 500 often represents a significant milestone in various contexts. In business, achieving 500 sales or 500 customers might be a cause for celebration, marking substantial growth and progress. Athletes might aim for 500 points or 500 wins, signifying a high level of achievement in their respective fields. Even personal goals, such as reading 500 books or running 500 miles, use 500 as a marker of accomplishment. The round number provides a clear and easily understandable target, making it a popular choice for setting ambitious yet attainable goals.

500 Years: Historical Events and Anniversaries

Anniversaries marking 500 years hold a special place in history, representing a significant passage of time. The celebration of such anniversaries often involves reflection on the past, commemorating historical events, and looking towards the future. Many historical events and legacies have been marked by 500-year milestones, providing opportunities for scholarly research, public commemorations, and cultural celebrations. These events might range from the founding of cities and institutions to significant political or social movements. The examination of these 500-year periods offers valuable insights into long-term societal change and development.

In conclusion, the seemingly simple number 500 unveils a complex tapestry of meanings and significance. From its mathematical properties to its cultural impact and historical relevance, 500 continues to intrigue and fascinate. Its consistent appearance throughout history and across cultures highlights its enduring importance as a symbol of milestones, achievement, and a significant point of reference.

Tags: 500, number 500, significance of 500, history of 500, mathematics 500, cultural significance, milestones