In today’s competitive landscape, customer satisfaction is no longer a luxury—it’s a necessity. Happy customers are loyal customers, driving repeat business, positive word-of-mouth referrals, and ultimately, sustainable growth. This post delves into effective strategies to cultivate exceptional customer satisfaction and transform it into a powerful engine for your business success.

1. Proactive Customer Service: Preventing Problems Before They Arise

Proactive customer service goes beyond simply reacting to complaints. It’s about anticipating customer needs and addressing potential issues before they escalate. This involves a deep understanding of your customer base, their pain points, and their expectations. Here are some key strategies:

- Personalized Communication: Utilize data to segment your customer base and tailor your communication. Personalized emails, targeted offers, and proactive support based on individual customer history create a sense of value and appreciation.

- Knowledge Base and FAQs: A comprehensive knowledge base and frequently asked questions section on your website can empower customers to self-serve, resolving many issues independently and reducing the burden on your support team. This also improves response times.

- Regular Check-ins: Reach out to customers periodically, not just when there’s a problem. A simple email or phone call expressing appreciation for their business can go a long way in building rapport and loyalty.

- Product/Service Monitoring: Implement systems to monitor product performance and identify potential issues before they impact customers. Proactive recall or improvement strategies demonstrate your commitment to customer well-being.

2. Harnessing the Power of Feedback: Listening and Responding Effectively

Customer feedback is invaluable, offering insights into what’s working well and what needs improvement. However, simply collecting feedback isn’t enough; you must actively listen and respond. Effective feedback mechanisms include:

- Surveys: Utilize online surveys (e.g., through platforms like SurveyMonkey or Typeform) to gather quantitative and qualitative data on customer satisfaction. Keep surveys concise and focused to maximize response rates.

- Social Media Monitoring: Track mentions of your brand on social media platforms to identify both positive and negative feedback. Respond promptly and professionally to all comments and messages.

- Customer Reviews: Encourage customers to leave reviews on platforms like Google My Business, Yelp, and Trustpilot. Respond to both positive and negative reviews, demonstrating your willingness to address concerns.

- Feedback Forms: Integrate feedback forms on your website and within your product or service to make it easy for customers to share their thoughts.

- Focus Groups and Interviews: Conduct in-depth interviews or focus groups to gather rich qualitative data and understand customer perspectives on a deeper level.

3. Building a Customer-Centric Culture: Empowering Your Team

Customer satisfaction isn’t solely the responsibility of the customer service department; it requires a company-wide commitment. Cultivating a customer-centric culture involves:

- Training and Empowerment: Equip your employees with the skills and knowledge they need to provide exceptional customer service. Empower them to make decisions and resolve issues efficiently.

- Open Communication: Foster a culture of open communication where employees feel comfortable sharing feedback and ideas. Regular team meetings and feedback sessions can facilitate this.

- Employee Recognition and Rewards: Acknowledge and reward employees who consistently deliver exceptional customer service. This reinforces positive behaviors and motivates the team.

- Customer-Focused Metrics: Track key metrics related to customer satisfaction, such as Net Promoter Score (NPS), Customer Satisfaction (CSAT), and Customer Effort Score (CES). Use these metrics to measure progress and identify areas for improvement.

4. Leveraging Technology for Enhanced Customer Experience

Technology plays a crucial role in improving customer satisfaction. Tools and platforms can streamline processes, improve communication, and personalize the customer journey. Consider:

- CRM Systems: Customer Relationship Management (CRM) systems centralize customer data, providing a 360-degree view of each customer’s interactions with your business.

- Live Chat: Integrate live chat functionality on your website to provide instant support and answer customer questions in real-time.

- Chatbots: Utilize chatbots to handle routine inquiries and provide 24/7 support, freeing up human agents to focus on more complex issues.

- Self-Service Portals: Create a self-service portal where customers can access information, troubleshoot problems, and manage their accounts independently.

- Automated Email Responses: Implement automated email responses to acknowledge receipt of inquiries and provide updates on progress.

5. Continuous Improvement: The Ongoing Pursuit of Excellence

Customer satisfaction is an ongoing journey, not a destination. Continuous improvement requires a commitment to regularly reviewing and refining your strategies. This involves:

- Regular Feedback Analysis: Analyze customer feedback data regularly to identify trends and areas for improvement. Use this data to inform your decision-making.

- A/B Testing: Experiment with different approaches to customer service and support to determine what works best. A/B testing allows you to measure the effectiveness of various strategies.

- Competitive Benchmarking: Analyze the customer satisfaction initiatives of your competitors to identify best practices and areas where you can improve.

- Employee Feedback: Solicit feedback from your employees on ways to improve customer satisfaction. They often have valuable insights from the front lines.

- Adaptability: Be prepared to adapt your strategies as customer needs and expectations evolve. The customer satisfaction landscape is constantly changing.

By implementing these customer satisfaction initiatives, you can foster loyalty, drive growth, and build a thriving business. Remember, happy customers are the cornerstone of a successful enterprise.

Tags: customer satisfaction, customer loyalty, customer experience, feedback management, customer service

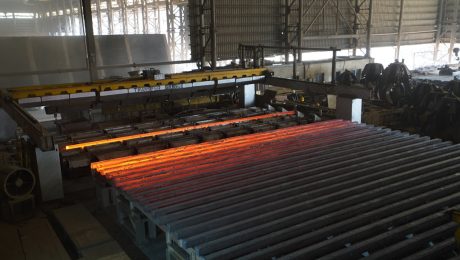

The steel industry is a backbone of modern construction and manufacturing. Efficient delivery of this heavy, high-value commodity is paramount to profitability and customer satisfaction. Logistics optimization is no longer a luxury but a necessity for steel companies aiming to thrive in a competitive market. This post delves into key strategies for optimizing steel delivery logistics, leading to reduced costs, improved on-time delivery rates, and enhanced customer relationships.

1. Route Optimization: Minimizing Mileage and Maximizing Efficiency

Route optimization is a cornerstone of efficient steel delivery. Traditional methods often rely on experience and guesswork, leading to unnecessary mileage, increased fuel costs, and longer delivery times. Advanced route planning software utilizes sophisticated algorithms to consider factors like traffic patterns, road conditions, weight restrictions, and delivery windows. These systems analyze vast datasets to generate optimal routes, minimizing distance and travel time. Furthermore, real-time tracking capabilities allow for dynamic route adjustments based on unforeseen events like traffic jams or road closures, ensuring timely delivery despite unexpected challenges. Implementing a robust route optimization system can significantly reduce fuel consumption, lower transportation costs, and improve the overall efficiency of the delivery process.

2. Inventory Management: Striking the Balance Between Supply and Demand

Effective inventory management is crucial in the steel industry, where storage costs are high and material spoilage is minimal. Overstocking ties up capital and increases storage expenses, while understocking leads to production delays and lost sales opportunities. Implementing a robust inventory management system, often integrated with the route optimization software, allows for precise forecasting of steel demand based on historical data, sales projections, and market trends. This system helps maintain optimal stock levels, minimizing storage costs while ensuring sufficient materials are available to meet customer demands promptly. Real-time tracking of inventory levels across various warehouses and distribution centers provides better visibility into the supply chain, allowing for proactive adjustments to prevent stockouts or overstocking.

3. Transportation Management: Selecting the Right Mode and Carrier

Steel delivery often involves a variety of transportation modes, including trucks, rail, and even ships for long-distance transport. Selecting the optimal mode depends on factors such as distance, volume, delivery time constraints, and cost considerations. For short-distance deliveries, trucks might be the most efficient option. However, for large-scale shipments over long distances, rail or sea freight might be more cost-effective. A sophisticated transportation management system (TMS) helps companies compare different modes and carriers, considering factors like cost, transit time, reliability, and capacity. The TMS facilitates carrier selection, shipment tracking, and documentation management, streamlining the entire transportation process and optimizing costs.

4. Leveraging Technology: Real-Time Tracking and Data Analytics

Technology plays a vital role in modern steel delivery logistics. Real-time tracking systems provide visibility into the location and status of shipments, allowing for proactive management of potential delays or issues. GPS tracking devices installed on vehicles provide accurate location data, enabling dispatchers to monitor progress, reroute vehicles if necessary, and provide customers with accurate estimated time of arrival (ETA). Data analytics tools analyze vast amounts of data from various sources, including transportation management systems, inventory management systems, and customer relationship management (CRM) systems. This data-driven approach enables companies to identify trends, patterns, and inefficiencies in their logistics operations, providing insights for continuous improvement and optimization.

5. Collaboration and Communication: Strengthening the Supply Chain Ecosystem

Effective collaboration and communication are crucial for optimizing steel delivery logistics. Strong relationships with suppliers, carriers, and customers are essential for seamless information flow and efficient coordination. Utilizing technologies like cloud-based platforms and collaborative software facilitates communication and data sharing across the supply chain. Real-time updates on shipment status, inventory levels, and potential delays can be shared with all stakeholders, ensuring transparency and proactive problem-solving. Open communication channels help build trust and foster collaboration, leading to a more efficient and responsive supply chain.

By implementing these strategies, steel companies can significantly improve their logistics operations, leading to reduced costs, enhanced customer satisfaction, and a stronger competitive advantage in the market. The journey towards optimized steel delivery requires a holistic approach, encompassing technological advancements, strategic planning, and a commitment to continuous improvement.

SEO-Friendly Tags:

- Steel Delivery Optimization

- Steel Logistics Management

- Route Optimization for Steel

- Supply Chain Management Steel

- Efficient Steel Transportation

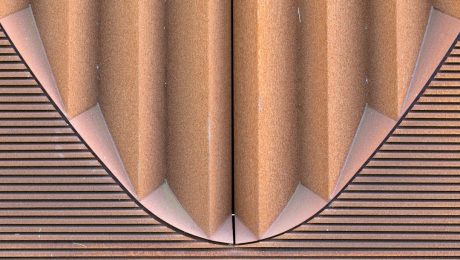

Corrosion in pipes is a significant concern across various industries, leading to costly repairs, system failures, and environmental hazards. Protecting your pipeline investment requires a robust and reliable solution. Primer-coated pipes offer precisely that – a superior level of corrosion resistance that extends the lifespan of your infrastructure and minimizes downtime. This comprehensive guide delves into the world of primer-coated pipes, exploring their benefits, application, and selection.

Understanding the Role of Primer Coatings in Corrosion Protection

Primer coatings act as the first line of defense against corrosion. They create a barrier between the pipe’s substrate (usually steel) and the environment, preventing moisture and oxygen from reaching the metal surface. This is crucial because corrosion is an electrochemical process that requires both oxygen and moisture to initiate and progress. The primer’s adhesion to the pipe is paramount; a poorly adhered primer will allow ingress of corrosive agents, negating its protective effect. Different primer types offer varying levels of protection depending on the specific environmental conditions and the type of pipe material.

Types of Primer Coatings for Pipes: A Detailed Overview

Several types of primer coatings are available, each with its own strengths and weaknesses. The choice depends on factors like the pipe material, the corrosive environment, and the budget. Common types include:

- Epoxy Primers: Known for their excellent adhesion, chemical resistance, and durability. They provide a robust barrier against a wide range of corrosive agents and are suitable for both internal and external pipe coating.

- Zinc-Rich Primers: These primers contain a high percentage of zinc, which acts as a sacrificial anode. This means the zinc corrodes preferentially, protecting the underlying steel even if the primer is scratched or damaged. They are particularly effective in aggressive environments.

- Polyurethane Primers: Offering excellent flexibility and impact resistance, polyurethane primers are suitable for applications where the pipe may experience mechanical stress or vibration. They also provide good chemical resistance.

- Acrylic Primers: These primers are typically less expensive than epoxy or polyurethane options but may offer slightly lower chemical resistance. They are often used as a cost-effective solution in less demanding environments.

Application Methods for Achieving Optimal Primer Coverage

Proper application is crucial for the effectiveness of primer coatings. Improper application can lead to pinholes, inconsistencies, and reduced protection. Common application methods include:

- Spray Application: This method offers excellent coverage and efficiency, particularly for large-diameter pipes. Airless spray systems are commonly used to ensure a uniform coating thickness.

- Brush Application: Suitable for smaller pipes or areas that are difficult to reach with spray equipment. Careful application is essential to avoid brush marks and ensure complete coverage.

- Roller Application: Offers a good balance between coverage and ease of application. It is often used for medium-sized pipes and can provide a smooth finish.

Regardless of the chosen method, surface preparation is paramount. The pipe surface must be clean, dry, and free from rust, scale, or other contaminants to ensure optimal adhesion of the primer.

Benefits of Using Primer-Coated Pipes: A Cost-Effective Solution

Investing in primer-coated pipes offers numerous advantages, including:

- Extended Pipe Lifespan: The protective barrier provided by the primer significantly extends the service life of the pipes, reducing the frequency of replacements and associated costs.

- Reduced Maintenance Costs: By preventing corrosion, primer coatings minimize the need for costly repairs and maintenance, saving both time and money.

- Enhanced Safety: Corrosion can weaken pipes, leading to leaks and potential safety hazards. Primer coatings mitigate this risk, ensuring the safe and reliable operation of the pipeline.

- Environmental Protection: Preventing corrosion minimizes the release of harmful substances into the environment, contributing to a more sustainable infrastructure.

- Improved Efficiency: Reduced corrosion means improved flow efficiency in pipelines, leading to lower energy consumption and operational costs.

Choosing the Right Primer-Coated Pipes for Your Specific Needs

Selecting the appropriate primer-coated pipes requires careful consideration of several factors:

- Environmental Conditions: The corrosive nature of the surrounding environment (soil, water, atmosphere) will dictate the type of primer required.

- Pipe Material: The primer must be compatible with the pipe material (usually steel, but can also be other metals or plastics).

- Application Requirements: The size and location of the pipeline will influence the application method and the type of primer that can be effectively applied.

- Budgetary Constraints: Different primer types have varying costs, and selecting the most cost-effective solution without compromising protection is essential.

- Regulatory Compliance: Ensure that the chosen primer-coated pipes meet all relevant industry standards and regulations.

Consulting with experienced pipeline professionals is crucial to ensure the selection of the most suitable primer-coated pipes for your specific application.

By understanding the importance of primer coatings and the various factors involved in their selection and application, you can make informed decisions to protect your infrastructure and ensure its long-term performance. Investing in primer-coated pipes is a strategic move towards a more robust, reliable, and sustainable pipeline system.

The construction of modern ports demands innovative and robust solutions to meet the increasing demands of global trade. Steel pipes, with their inherent strength, durability, and versatility, are emerging as a game-changer in this field. This post delves into the various aspects of utilizing steel pipes in port construction, exploring their advantages, challenges, and future prospects.

1. Design and Engineering Considerations for Steel Pipe Ports

Designing a port structure using steel pipes necessitates careful consideration of several factors. The diameter, wall thickness, and grade of the steel pipes are crucial for ensuring structural integrity and load-bearing capacity. The design must account for various environmental loads, including wave action, currents, and wind forces. Finite element analysis (FEA) is commonly employed to simulate these loads and optimize the pipe configuration. Furthermore, the design must incorporate appropriate corrosion protection measures, such as coatings and cathodic protection systems, to extend the lifespan of the structure in the harsh marine environment. Detailed plans for assembly, welding, and inspection are also critical to ensure a successful project.

2. Advantages of Utilizing Steel Pipes in Port Construction

Steel pipes offer several compelling advantages in port construction. Their high strength-to-weight ratio allows for the creation of lightweight yet robust structures, reducing material costs and transportation challenges. The prefabricated nature of steel pipe components enables faster construction times compared to traditional methods, minimizing project delays and accelerating the return on investment. Steel pipes are highly resistant to compression and bending, making them ideal for supporting heavy loads and withstanding the dynamic forces encountered in port operations. Moreover, their modular design allows for easy expansion and modification of the port infrastructure as needed, adapting to future growth and changing demands. Finally, the recyclability of steel contributes to the environmental sustainability of the project.

3. Addressing the Challenges in Steel Pipe Port Construction

While steel pipes offer many benefits, certain challenges must be addressed. Corrosion remains a significant concern, requiring careful selection of steel grades, appropriate coatings, and regular maintenance. Welding of large-diameter steel pipes requires specialized equipment and skilled welders to ensure high-quality joints. The transportation and handling of these large and heavy components can be logistically complex, requiring careful planning and specialized equipment. Furthermore, the design must account for potential scour around the pipe foundations, requiring robust anchoring and protection measures. Finally, ensuring compliance with relevant safety regulations and industry standards is crucial throughout the entire construction process.

4. Case Studies: Successful Implementations of Steel Pipe Ports

Several successful examples demonstrate the efficacy of steel pipe technology in port construction. For instance, the use of steel pipe piles in breakwater construction has proven highly effective in resisting wave action and protecting coastal areas. In offshore port development, steel pipe structures are used to create stable platforms for various port facilities. Several ports around the world have incorporated steel pipe elements into their jetties, piers, and other infrastructure, showcasing the versatility and effectiveness of this material. These case studies highlight the successful implementation of innovative design solutions and construction techniques, demonstrating the long-term durability and cost-effectiveness of steel pipe port structures. Detailed analysis of these projects provides valuable insights for future endeavors.

5. Future Trends and Innovations in Steel Pipe Port Construction

The future of steel pipe port construction looks promising, with ongoing research and development focusing on enhancing the performance and sustainability of these structures. Advanced materials, such as high-strength steel alloys and corrosion-resistant coatings, are being explored to further improve the durability and lifespan of steel pipe structures. Innovative design techniques, such as the use of computational fluid dynamics (CFD) for optimizing structural design and minimizing environmental impacts, are also being investigated. Furthermore, the integration of smart sensors and monitoring systems allows for real-time assessment of structural health and proactive maintenance, enhancing the safety and reliability of port infrastructure. The growing demand for sustainable and resilient port infrastructure will further drive innovation and adoption of steel pipe technology in the years to come.

In conclusion, steel pipes represent a significant advancement in port construction, offering a compelling combination of strength, durability, cost-effectiveness, and sustainability. While challenges exist, ongoing innovations and careful planning ensure the successful implementation of this technology, shaping the future of modern port infrastructure.

SEO Tags:

- Steel pipe port construction

- Port construction methods

- Steel pipe structures

- Offshore port construction

- Sustainable port infrastructure

body { font-family: sans-serif; line-height: 1.6; }

h1, h2, h3 { color: #333; }

img { max-width: 100%; height: auto; }

Liquefied Natural Gas (LNG) pipelines represent a critical link in the global energy infrastructure, transporting this vital fuel across vast distances. However, the unique challenges posed by transporting cryogenic fluids necessitate stringent specifications to ensure safety, efficiency, and longevity. This comprehensive guide delves into the key aspects of LNG pipeline specifications, exploring the critical considerations involved in their design, construction, and operation.

1. Material Selection: Withstanding Cryogenic Temperatures

The most crucial aspect of LNG pipeline specifications is the material selection. LNG operates at extremely low temperatures, typically around -162°C (-260°F). Standard steel pipelines are unsuitable due to the risk of brittle fracture at these temperatures. Therefore, specialized materials with excellent cryogenic properties are essential. Common choices include:

- Austenitic Stainless Steels: These steels, like 304L and 316L, possess excellent ductility and toughness at cryogenic temperatures, making them suitable for many LNG pipeline applications.

- 9% Nickel Steel: This alloy exhibits exceptional strength and toughness at low temperatures, often preferred for high-pressure applications.

- Aluminum Alloys: Certain aluminum alloys, particularly those with high strength and low temperature brittleness, are also employed, particularly in smaller diameter pipelines or specific sections.

The choice of material depends on factors such as pipeline diameter, operating pressure, and environmental conditions. Detailed metallurgical testing and analysis are essential to verify the material’s suitability for the specific application.

2. Design Considerations: Pressure, Temperature, and Terrain

LNG pipeline design requires meticulous consideration of several factors. The pipeline must withstand significant internal pressure due to the liquefied gas, while simultaneously managing the extreme low temperatures. The design process includes:

- Pressure Rating: Determining the maximum allowable operating pressure (MAOP) is crucial for safety. This is influenced by the pipeline material, diameter, and wall thickness.

- Thermal Stress Analysis: The extreme temperature difference between the LNG and the surrounding environment necessitates careful analysis to mitigate thermal stresses and prevent cracking or deformation.

- Terrain Considerations: The pipeline route must be carefully planned to minimize environmental impact and account for geographical features such as mountains, rivers, and seismic zones. This includes considerations for pipeline depth and support structures.

- Expansion Joints: To accommodate thermal expansion and contraction, expansion joints are incorporated at strategic points along the pipeline to prevent excessive stress buildup.

3. Safety and Regulatory Compliance: Mitigation of Risks

LNG pipelines pose unique safety challenges due to the flammable nature of LNG and the potential for leaks. Stringent safety measures are implemented throughout the pipeline’s lifecycle, including:

- Leak Detection Systems: Advanced monitoring systems are crucial for detecting leaks promptly and preventing potential incidents. These systems often incorporate sensors, pressure monitoring, and automated shut-off valves.

- Emergency Shut-Down Systems: Rapidly shutting down the pipeline in case of an emergency is crucial. These systems need to be highly reliable and readily accessible.

- Regulatory Compliance: LNG pipelines must adhere to stringent national and international regulations regarding design, construction, operation, and maintenance. Compliance with these regulations is essential for ensuring safety and preventing environmental damage.

- Right-of-Way Management: Careful management of the pipeline’s right-of-way is crucial to prevent damage from external sources such as excavation or third-party interference.

4. Construction and Installation: Precision and Expertise

The construction and installation of LNG pipelines demand high levels of precision and expertise. The process involves:

- Welding: Specialized welding techniques are employed to ensure high-quality welds that can withstand the extreme operating conditions. Non-destructive testing (NDT) is used to verify the integrity of the welds.

- Pipeline Coating: External coatings are applied to protect the pipeline from corrosion and environmental factors. These coatings are often designed to withstand the low temperatures and protect against external damage.

- Installation Techniques: Depending on the terrain, various installation methods are employed, including trenching, directional drilling, and above-ground installation. Each method requires careful planning and execution to ensure pipeline integrity.

- Quality Control: Rigorous quality control procedures are implemented throughout the construction process to ensure compliance with specifications and prevent defects.

5. Maintenance and Inspection: Ensuring Long-Term Reliability

Regular maintenance and inspection are vital for ensuring the long-term reliability and safety of LNG pipelines. This includes:

- Periodic Inspections: Regular inspections using methods such as in-line inspection (ILI) tools are conducted to detect any internal corrosion, defects, or damage.

- Leak Surveys: Periodic leak surveys are conducted to identify any external leaks or signs of damage.

- Preventive Maintenance: Regular maintenance activities, such as cleaning and repair of valves and fittings, are essential to prevent equipment failure and ensure operational efficiency.

- Corrosion Monitoring: Monitoring corrosion rates is crucial for assessing the pipeline’s remaining life and planning for future maintenance or replacement.

By adhering to these stringent specifications and implementing a comprehensive maintenance program, the longevity and safety of LNG pipelines can be ensured, supporting the reliable delivery of this crucial energy resource.

Tags: LNG pipeline, cryogenic pipeline, pipeline specifications, LNG transportation, pipeline safety

API 5L is a globally recognized standard for line pipe, crucial for the safe and efficient transportation of oil and gas. Understanding its intricacies is vital for engineers, contractors, and anyone involved in the pipeline industry. This comprehensive guide will delve into the key aspects of API 5L, providing a clear and concise explanation of its specifications, applications, and importance.

Understanding API 5L Specifications and Grades

API 5L, published by the American Petroleum Institute, specifies the requirements for seamless and welded line pipe intended for use in oil and gas pipelines. The standard covers various aspects, including material properties, manufacturing processes, testing procedures, and dimensional tolerances. A crucial element is the grading system, which categorizes pipes based on their strength, ductility, and weldability. These grades are denoted by letters (e.g., X42, X52, X65, X70, X80, and L80) with the number representing the minimum specified yield strength in thousands of pounds per square inch (ksi). Higher numbers indicate greater strength. The ‘X’ denotes seamless or welded pipe suitable for high-pressure applications, while ‘L’ designates pipes typically used for lower pressure applications. The choice of grade depends on the specific pipeline’s operating pressure, diameter, and environmental conditions.

API 5L Pipe Manufacturing Processes: Seamless vs. Welded

API 5L pipes are manufactured using two primary processes: seamless and welded. Seamless pipes are produced by piercing and rolling a solid steel billet, resulting in a continuous, homogeneous structure without welds. This process generally leads to superior strength and resistance to cracking. Welded pipes, on the other hand, are fabricated by joining two or more steel plates using various welding techniques like submerged arc welding (SAW) or electric resistance welding (ERW). While welded pipes can be cost-effective, they require rigorous quality control to ensure the weld’s integrity. API 5L specifies strict requirements for both manufacturing processes, ensuring the final product meets the required strength and quality standards. The choice between seamless and welded often depends on factors like diameter, wall thickness, and cost considerations.

Critical Testing and Inspection Procedures in API 5L Compliance

Rigorous testing and inspection are integral to API 5L compliance. Manufacturers must perform various tests on the pipes throughout the production process to verify that they meet the specified requirements. These tests include:

- Tensile testing: Determines the pipe’s tensile strength, yield strength, and elongation.

- Bend testing: Assesses the pipe’s ductility and ability to withstand bending without fracturing.

- Hydrostatic testing: Checks the pipe’s ability to withstand internal pressure without leaking or bursting.

- Flattening test: Evaluates the pipe’s resistance to deformation under compressive forces.

- Nondestructive testing (NDT): Techniques like ultrasonic testing (UT) and radiographic testing (RT) are used to detect internal flaws and weld defects without damaging the pipe.

These tests ensure that the pipes meet the specified quality and safety requirements before they are used in pipelines. Third-party inspections are often employed to ensure independent verification of compliance.

Applications of API 5L Line Pipes: Across Diverse Industries

API 5L line pipes find widespread application in the transportation of various fluids, primarily in the oil and gas industry. They are crucial components in onshore and offshore pipelines, transporting crude oil, natural gas, refined petroleum products, and other fluids. Beyond the energy sector, API 5L pipes are also used in other industries where high-strength, reliable piping is required, including water transmission systems, chemical processing plants, and industrial applications requiring high-pressure fluid transfer. The versatility and stringent quality standards of API 5L pipes make them a reliable choice across numerous applications.

Ensuring API 5L Compliance: Importance and Best Practices

Compliance with API 5L is paramount for ensuring the safety and reliability of pipelines. Non-compliance can lead to serious consequences, including leaks, ruptures, environmental damage, and potential loss of life. To ensure compliance, companies must follow strict procedures throughout the entire process, from material selection and manufacturing to testing and inspection. Proper documentation, traceability, and adherence to quality control measures are essential. Regular audits and inspections by qualified personnel are crucial for identifying and rectifying any potential non-compliance issues. Investing in quality control and adhering to API 5L standards is not merely a regulatory requirement; it is a crucial aspect of responsible and sustainable operations in the pipeline industry.

Understanding API 5L is essential for anyone involved in the design, construction, and operation of pipelines. This comprehensive overview provides a solid foundation for navigating the complexities of this critical standard. By adhering to these standards, the industry ensures the safe and efficient transportation of vital resources globally.

body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

code {

background-color: #f0f0f0;

padding: 2px 4px;

border-radius: 4px;

}

Industrial machinery relies heavily on efficient and robust piping systems. From transporting vital fluids and gases to managing pressure and temperature, pipes are the circulatory system of many industrial processes. Understanding the various types of pipes, their applications, and crucial safety and maintenance practices is paramount for ensuring operational efficiency and preventing costly downtime.

Types of Pipes Used in Industrial Machinery

The choice of pipe material depends heavily on the transported medium, operating pressure, temperature, and the corrosive nature of the environment. Common types include:

- Steel Pipes: The workhorse of industrial piping, offering high strength and durability. Carbon steel is widely used for its cost-effectiveness, while stainless steel provides superior corrosion resistance for applications involving chemicals or high temperatures. Different grades of steel are chosen based on the specific application’s demands.

- Plastic Pipes (PVC, HDPE, CPVC): Lightweight, corrosion-resistant, and often cost-effective, plastic pipes are ideal for applications involving less demanding pressure and temperature requirements. HDPE (High-Density Polyethylene) is particularly durable and suitable for handling chemicals.

- Copper Pipes: Known for their excellent corrosion resistance and thermal conductivity, copper pipes are often used in applications requiring high purity or where heat transfer is crucial. However, they are more expensive than steel.

- Cast Iron Pipes: These offer high strength and durability, making them suitable for high-pressure applications. However, their weight and susceptibility to corrosion can limit their use.

- Fiberglass Reinforced Pipes (FRP): Lightweight and highly corrosion-resistant, FRP pipes are ideal for handling aggressive chemicals and are often used in harsh environments.

Applications of Industrial Piping in Different Industries

The applications of industrial piping are vast and varied, depending on the specific industry. Some examples include:

- Chemical Processing: Pipes transport various chemicals, solvents, and reactants throughout the process, requiring careful material selection to prevent corrosion and leaks.

- Oil and Gas Industry: High-pressure pipelines are essential for transporting crude oil, natural gas, and refined products over long distances. Materials must withstand extreme pressures and temperatures.

- Power Generation: Pipes handle steam, water, and other fluids in power plants, requiring materials that can tolerate high temperatures and pressures.

- Food and Beverage Processing: Sanitary piping systems are crucial for maintaining hygiene and preventing contamination. Materials like stainless steel are preferred for their ease of cleaning and corrosion resistance.

- Pharmaceutical Manufacturing: Cleanroom piping systems are essential to avoid contamination. Materials must be biocompatible and easily sterilizable.

Safety Considerations in Industrial Pipework

Safety is paramount when working with industrial piping systems. Potential hazards include:

- High Pressure: Failures in high-pressure systems can lead to catastrophic consequences. Regular inspections, pressure testing, and safety valves are crucial.

- Hazardous Materials: Pipelines transporting toxic or flammable substances require stringent safety protocols, including leak detection systems and emergency shutdown mechanisms.

- Corrosion: Corrosion can weaken pipes, leading to leaks or ruptures. Regular inspections and appropriate corrosion protection measures are essential.

- Thermal Burns: Hot pipes can cause severe burns. Insulation and safety barriers are necessary to protect personnel.

- Proper Installation and Maintenance: Incorrect installation or inadequate maintenance can lead to leaks, failures, and safety hazards. Qualified personnel should always handle installation and maintenance tasks.

Maintenance and Inspection of Industrial Piping Systems

Regular maintenance and inspection are vital for preventing failures and ensuring the longevity of industrial piping systems. This includes:

- Visual Inspections: Regular visual checks for signs of corrosion, leaks, damage, or wear and tear.

- Pressure Testing: Periodic pressure testing to verify the integrity of the system and identify potential weaknesses.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing, radiographic testing, and magnetic particle testing can detect internal flaws without damaging the pipe.

- Corrosion Monitoring: Monitoring corrosion rates to determine the effectiveness of corrosion protection measures.

- Leak Detection: Implementing leak detection systems to quickly identify and address leaks before they escalate.

- Regular Cleaning: Depending on the application, regular cleaning of the pipes may be necessary to remove buildup or contaminants.

Advanced Technologies in Industrial Pipework

Technological advancements are continuously improving the efficiency, safety, and reliability of industrial piping systems. These include:

- Smart Pipes: Sensors embedded in pipes can monitor pressure, temperature, flow rate, and other parameters, providing real-time data for predictive maintenance and improved operational efficiency.

- Advanced Materials: The development of new materials with enhanced properties, such as higher strength, corrosion resistance, and temperature tolerance, is constantly expanding the possibilities of industrial pipework.

- 3D Printing of Pipes: Additive manufacturing techniques are being explored for creating customized pipes with complex geometries and improved performance characteristics.

- Improved Joining Techniques: Advanced welding and joining methods ensure stronger and more reliable connections, reducing the risk of leaks and failures.

- Digital Twins: Virtual models of piping systems allow for simulations and analysis, helping to optimize design, predict potential problems, and improve maintenance strategies.

In conclusion, the efficient and safe operation of industrial machinery is heavily reliant on well-designed, properly maintained, and regularly inspected piping systems. By understanding the different types of pipes, their applications, safety considerations, and maintenance practices, industries can minimize downtime, reduce costs, and ensure the safe operation of their facilities.

Tags: Industrial Piping, Pipework, Industrial Machinery, Pipe Maintenance, Piping Systems

The construction and manufacturing industries are undergoing a significant transformation, driven by the urgent need for sustainability. Steel, a cornerstone of modern infrastructure, is no exception. This post delves into the exciting world of energy-efficient steel products, exploring their benefits, production methods, and the positive impact they have on reducing our carbon footprint.

1. The Environmental Impact of Traditional Steel Production

Traditional steelmaking is a notoriously energy-intensive process. The blast furnace method, which has been the dominant production technique for centuries, relies heavily on coking coal, a significant source of greenhouse gas emissions. The process involves high temperatures, leading to substantial energy consumption and the release of carbon dioxide (CO2), methane (CH4), and other pollutants into the atmosphere. This high carbon footprint has prompted a global push for more sustainable steel production methods.

Beyond CO2 emissions, traditional steel production also consumes vast quantities of water and generates significant amounts of waste. The environmental consequences extend beyond the immediate vicinity of the steel plant, impacting air and water quality in surrounding areas. The need for a greener alternative is undeniable.

2. Emerging Technologies for Energy-Efficient Steelmaking

Fortunately, significant advancements are being made in steel production technology, paving the way for a more sustainable future. Several innovative approaches aim to reduce energy consumption and minimize greenhouse gas emissions:

- Electric Arc Furnaces (EAFs): EAFs utilize electricity to melt scrap steel, significantly reducing reliance on coking coal. This method offers a substantial reduction in CO2 emissions compared to blast furnaces, particularly when powered by renewable energy sources.

- Hydrogen-based Steelmaking: Research and development are rapidly progressing in using hydrogen as a reducing agent in steelmaking, replacing coking coal entirely. This approach has the potential to eliminate direct CO2 emissions from the process, offering a truly green steel production pathway. However, challenges remain in terms of hydrogen production and cost-effectiveness.

- Carbon Capture, Utilization, and Storage (CCUS): CCUS technologies capture CO2 emissions from steel plants and either utilize them in other industrial processes or store them underground. While not a complete solution, CCUS can significantly reduce the overall carbon footprint of steel production.

- Improved Process Optimization: Even within traditional steelmaking methods, significant improvements can be made through process optimization, leading to reduced energy consumption and waste generation. This includes advancements in automation, heat recovery systems, and improved material handling.

3. Energy-Efficient Steel Products: A Range of Applications

The benefits of energy-efficient steel extend beyond the production process itself. The resulting steel products offer superior properties and are ideally suited for a range of applications where sustainability is paramount:

- Green Building Construction: Energy-efficient steel is a crucial component in green building designs, contributing to improved thermal performance and reduced energy consumption in buildings. Lightweight steel structures can also reduce the overall embodied carbon of a building.

- Renewable Energy Infrastructure: The manufacturing of wind turbines, solar panels, and other renewable energy infrastructure relies heavily on steel. Using energy-efficient steel in these applications enhances the overall sustainability of the renewable energy sector.

- Sustainable Transportation: Lightweight steel components in vehicles contribute to improved fuel efficiency and reduced emissions. The use of recycled steel further minimizes the environmental impact.

- Infrastructure Development: Bridges, railways, and other infrastructure projects can benefit from the strength and durability of energy-efficient steel, while also reducing their overall environmental footprint.

4. Lifecycle Assessment and Embodied Carbon

Understanding the entire lifecycle of a steel product, from raw material extraction to end-of-life disposal, is crucial for assessing its overall environmental impact. Lifecycle assessment (LCA) methodologies are used to quantify the embodied carbon – the total greenhouse gas emissions associated with a product’s entire lifecycle. Energy-efficient steel products generally exhibit a lower embodied carbon footprint compared to those produced using traditional methods.

By considering the embodied carbon throughout the product’s lifecycle, designers and engineers can make informed decisions to minimize the environmental impact of their projects. This includes selecting materials wisely, optimizing designs for material efficiency, and considering end-of-life management strategies such as recycling.

5. The Future of Sustainable Steel: Innovation and Collaboration

The transition to a more sustainable steel industry requires a concerted effort from all stakeholders. Continued innovation in steelmaking technology, coupled with supportive government policies and industry collaboration, is essential to accelerate the adoption of energy-efficient steel products. This includes investing in research and development, promoting the use of recycled steel, and developing robust carbon pricing mechanisms to incentivize greener production practices.

The future of steel lies in its ability to adapt and evolve to meet the challenges of climate change. By embracing energy-efficient production methods and promoting the use of sustainable steel products, we can build a more environmentally responsible and sustainable future.

SEO Tags: Energy-efficient steel, sustainable steel, green steel, steel production, embodied carbon

body { font-family: sans-serif; line-height: 1.6; }

h1, h2, h3 { color: #333; }

img { max-width: 100%; height: auto; }

Equal angle bars, also known as equal leg angles, are ubiquitous in construction, engineering, and manufacturing. These versatile steel components, characterized by their two equal legs meeting at a right angle, offer exceptional strength and structural integrity. This comprehensive guide delves into the world of equal angle bars, exploring their properties, manufacturing, applications, and selection considerations.

Understanding the Properties of Equal Angle Bars

Equal angle bars are typically made from mild steel, although other materials like stainless steel and aluminum alloys can be used depending on the application’s requirements. Key properties that contribute to their widespread use include:

- High Tensile Strength: Their shape allows for efficient load distribution, resulting in high tensile strength relative to their weight.

- Excellent Bending Resistance: The right-angled design provides robust resistance to bending forces, making them ideal for structural support.

- Weldability: Equal angle bars are readily weldable, allowing for easy connection to other structural elements.

- Durability: When properly protected against corrosion (e.g., through galvanizing or painting), they offer excellent longevity.

- Cost-Effectiveness: Compared to other structural shapes, equal angle bars often provide a cost-effective solution for many applications.

Manufacturing Process of Equal Angle Bars

The production of equal angle bars typically involves a hot-rolling process. Steel billets are heated to high temperatures and then passed through a series of rollers, gradually shaping them into the desired angle profile. After rolling, the bars undergo cooling, cutting to length, and potentially further processing, such as surface treatment (e.g., galvanizing) or precision machining.

The precise dimensions and tolerances of the equal angle bars are carefully controlled throughout the manufacturing process to ensure consistency and quality. This is crucial for their structural integrity and reliable performance in various applications.

Diverse Applications of Equal Angle Bars in Construction and Industry

The versatility of equal angle bars makes them invaluable in a wide range of applications. Some prominent examples include:

- Structural Support: Used extensively in building frameworks, supporting beams, columns, and bracing systems.

- Metal Fabrication: Forming the basis of many fabricated metal structures, including gates, fences, and railings.

- Machine Frames: Providing strong and rigid support for machinery and equipment.

- Automotive Industry: Used in chassis construction and other structural components.

- Agricultural Equipment: Found in the construction of trailers, implements, and other agricultural machinery.

- Bridge Construction: Contributing to the structural integrity of bridges and overpasses.

- Scaffolding: Used as bracing and support members in scaffolding systems.

Selecting the Right Equal Angle Bar: A Comprehensive Guide

Choosing the appropriate equal angle bar depends on several factors, including:

- Size and Dimensions: The length, leg length, and thickness of the bar must be chosen to meet the required load-bearing capacity and structural requirements.

- Material Grade: The choice of material (mild steel, stainless steel, etc.) depends on the application’s environmental conditions and required strength.

- Surface Finish: Consider whether a protective coating (e.g., galvanizing, painting) is needed to enhance corrosion resistance.

- Load Requirements: A thorough structural analysis is essential to determine the appropriate size and material grade to withstand anticipated loads.

- Budgetary Constraints: Balancing cost-effectiveness with performance requirements is crucial in selecting the appropriate equal angle bar.

Advantages and Disadvantages of Using Equal Angle Bars

While equal angle bars offer many advantages, it’s important to acknowledge their limitations:

Advantages:

- High strength-to-weight ratio

- Versatility in applications

- Easy to fabricate and weld

- Relatively low cost

- Widely available

Disadvantages:

- Susceptible to torsion (twisting) under certain loading conditions.

- May require additional reinforcement for certain applications.

- Prone to corrosion if not properly protected.

- Limited load-bearing capacity compared to some other structural shapes for specific applications.

Equal angle bars are a fundamental component in countless structures and applications. Understanding their properties, manufacturing, and selection criteria is crucial for engineers, fabricators, and anyone involved in projects utilizing these versatile structural elements.

Keywords: Equal angle bar, equal leg angle, steel angle, structural steel, metal fabrication, construction materials, engineering materials, hot rolled steel, angle iron

Entering international markets is a significant step for any business. However, before you can sell your products globally, you need to understand the complex landscape of international product certifications. These certifications are not just bureaucratic hurdles; they are crucial for ensuring product safety, quality, and compliance with local regulations, ultimately building consumer trust and facilitating smooth market entry.

Understanding the Importance of International Product Certifications

International product certifications demonstrate your commitment to quality, safety, and environmental responsibility. They are essentially passports that allow your products access to specific countries or regions. Without the appropriate certifications, your products may be seized at customs, face hefty fines, or even be banned from sale. Furthermore, certifications provide a competitive advantage, reassuring customers of the product’s reliability and adherence to stringent standards. This builds brand credibility and trust, leading to increased sales and market share.

Key International Certification Standards and Their Scope

The world is not a monolithic market; different regions and countries have their own specific certification requirements. Some of the most prominent international standards include:

- CE Marking (European Union): Indicates conformity with health, safety, and environmental protection legislation within the European Economic Area. It covers a wide range of products, from toys and electrical appliances to machinery and medical devices. It’s not a single certification but rather a self-declaration of conformity based on relevant directives.

- FCC Certification (United States): The Federal Communications Commission certifies electronic products for compliance with radio frequency emissions and interference standards. This is crucial for devices that emit radio waves, such as smartphones, Wi-Fi routers, and Bluetooth devices.

- UL Certification (United States and Globally): Underwriters Laboratories provides safety testing and certification services for a vast array of products, focusing on electrical safety, fire safety, and other hazard assessments. Their certifications are widely recognized globally.

- ISO 9001 (International): This is a quality management system standard that demonstrates a company’s commitment to consistent quality in its processes and products. While not a product-specific certification, it is often a prerequisite for other certifications or a key factor in winning international contracts.

- IEC 60950-1 (International): This standard covers the safety of information technology equipment, setting out requirements for electrical safety and preventing hazards. Many IT products require certification based on this standard or its successor, IEC 62368-1.

It’s essential to research the specific requirements for your target markets, as these vary considerably.

The Certification Process: Steps to Success

The certification process can be intricate and time-consuming. Generally, it involves these steps:

- Product Identification and Selection of Standards: Identify the applicable standards and regulations for your target market(s).

- Testing and Evaluation: Your product undergoes rigorous testing by a certified laboratory to ensure it meets the requirements of the selected standards.

- Documentation Preparation: Thorough documentation is crucial, including technical specifications, test reports, and quality management system documentation.

- Application and Review: Submit a formal application to the relevant certification body, who will review your documentation and potentially conduct audits.

- Certification Issuance: Upon successful completion of the review, the certification body will issue the certificate, allowing you to legally market your product in the designated region.

- Ongoing Compliance and Surveillance: Regular audits and inspections may be required to ensure ongoing compliance with the standards.

The exact process varies depending on the specific certification and the certification body.

Cost and Time Considerations for International Certifications

The cost of obtaining international product certifications can vary significantly depending on the complexity of the product, the number of standards involved, and the chosen certification body. The process can also be lengthy, sometimes taking several months or even years to complete. Therefore, planning and budgeting are crucial. Consider factors like testing fees, application fees, documentation costs, and potential travel expenses for audits.

Choosing the Right Certification Body

Selecting a reputable and accredited certification body is paramount. Look for bodies with a strong track record, recognized accreditation, and expertise in your specific industry and product category. Check their credentials and client testimonials before making a decision. Working with a reputable body ensures the integrity and validity of your certification, increasing your credibility in the international market.

Navigating the world of international product certifications can seem daunting, but with careful planning, thorough research, and the right guidance, you can successfully unlock global markets and achieve significant growth for your business.