The steel industry is a cornerstone of modern infrastructure, powering everything from skyscrapers to vehicles. However, its traditional production methods have significant environmental consequences. Fortunately, steel boasts an exceptional characteristic: it’s infinitely recyclable without losing its inherent properties. This blog post explores the vital role of recycling in the steel industry, examining its processes, benefits, challenges, and future prospects.

The Recycling Process: From Scrap to Steel

Steel recycling begins with the collection of scrap metal. This scrap comes from various sources, including demolition debris, end-of-life vehicles, and industrial byproducts. The scrap is then sorted and processed to remove contaminants like plastics, wood, and other non-ferrous metals. This sorting process is crucial to ensure the quality of the recycled steel. Different types of scrap are categorized based on their chemical composition and cleanliness. Heavier scrap, like automotive shredder residue (ASR), requires more intensive processing before it can be used in steelmaking.

Once sorted, the scrap is transported to steel mills, primarily those using Electric Arc Furnaces (EAFs). EAFs are significantly more energy-efficient than traditional blast furnaces, making them ideal for steel recycling. In the EAF, an electric arc melts the scrap metal, and various additives are introduced to refine the steel’s composition and achieve the desired properties. The molten steel is then cast into various forms, such as billets, slabs, or blooms, ready for further processing and manufacturing.

Environmental Benefits of Steel Recycling: A Greener Future

Steel recycling offers substantial environmental advantages compared to producing steel from raw materials like iron ore. The most significant benefit is reduced greenhouse gas emissions. Recycling steel requires significantly less energy than producing virgin steel, leading to a smaller carbon footprint. Studies have shown that recycling steel can reduce CO2 emissions by up to 75% compared to using iron ore. This reduction is crucial in mitigating climate change and achieving sustainability goals.

Furthermore, steel recycling conserves natural resources. Mining iron ore has a considerable environmental impact, including habitat destruction, water pollution, and land degradation. By using recycled steel, we lessen the demand for new iron ore extraction, minimizing these environmental consequences. Recycling also reduces the amount of waste sent to landfills, contributing to a cleaner and healthier environment.

Challenges in Steel Recycling: Overcoming Obstacles

Despite its numerous advantages, steel recycling faces several challenges. One significant hurdle is the inconsistent quality of scrap metal. Contamination can affect the quality of the recycled steel, requiring additional processing steps and potentially increasing costs. Ensuring consistent quality control throughout the recycling process is crucial for maintaining the integrity of the final product.

Another challenge lies in the collection and transportation of scrap metal. Efficient and cost-effective collection systems are essential to ensure a consistent supply of scrap for steel mills. This often involves logistical complexities, particularly in managing diverse sources of scrap and geographically dispersed collection points. Furthermore, the global nature of the steel industry necessitates international collaboration to establish efficient and sustainable recycling practices.

Technological Advancements: Shaping the Future of Steel Recycling

Technological innovations are continuously improving steel recycling processes and expanding its potential. Advancements in sorting technologies, such as automated sorting systems using AI and machine learning, enhance the efficiency and accuracy of separating different types of scrap. These technologies minimize contamination and improve the overall quality of recycled steel.

Research and development are also focused on improving the energy efficiency of EAFs and developing new technologies to process challenging scrap materials like ASR. The development of more sophisticated alloying techniques allows for the production of high-quality steel from recycled materials, meeting the demands of various industries. Furthermore, the integration of circular economy principles into the steel industry’s supply chain is driving innovation in recycling and resource management.

The Circular Economy and the Steel Industry: A Symbiotic Relationship

The concept of a circular economy emphasizes reducing waste and maximizing resource utilization. Steel recycling is a cornerstone of a circular economy for the steel industry. By closing the loop and reusing steel multiple times, we minimize waste, conserve resources, and reduce environmental impact. This approach requires collaboration across the entire steel value chain, from producers and consumers to recyclers and policymakers.

Implementing a robust circular economy model for steel requires several key elements: improved scrap collection infrastructure, enhanced sorting and processing technologies, increased demand for recycled steel, and supportive government policies that incentivize recycling and discourage landfilling. By embracing a circular economy approach, the steel industry can significantly reduce its environmental footprint and contribute to a more sustainable future.

The future of steel production is inextricably linked to recycling. By embracing innovation, investing in efficient recycling infrastructure, and promoting a circular economy model, the steel industry can create a more sustainable and environmentally responsible future, ensuring that steel’s second life is as impactful as its first.

Tags: steel recycling, sustainable steel, scrap metal recycling, electric arc furnace (EAF), circular economy steel

Selecting the appropriate piping system is paramount in any energy project. From oil and gas transmission to renewable energy infrastructure, the choice of pipe significantly impacts safety, efficiency, longevity, and overall project cost. This comprehensive guide will navigate you through the critical considerations for choosing the right pipe, ensuring your project’s success.

1. Material Matters: Selecting the Right Pipe Material

The material of the pipe is the foundational decision. Different materials offer unique properties, impacting their suitability for specific applications. Common materials include:

- Steel: A workhorse in the energy industry, steel pipes offer high strength, durability, and resistance to high pressures. However, they can be susceptible to corrosion, requiring protective coatings or specialized alloys like stainless steel.

- High-Density Polyethylene (HDPE): A popular choice for gas distribution and water pipelines, HDPE pipes are lightweight, flexible, and highly resistant to corrosion. Their flexibility makes them ideal for challenging terrains.

- Polyvinyl Chloride (PVC): Often used in less demanding applications, PVC pipes are cost-effective and corrosion-resistant. Their lower pressure rating limits their use in high-pressure energy projects.

- Fiber Reinforced Polymers (FRP): These composite pipes offer high strength-to-weight ratios and excellent corrosion resistance. They are a viable alternative to steel in certain corrosive environments.

- Ductile Iron: Known for its strength and durability, ductile iron pipes are frequently used in water distribution systems and some industrial applications. Their resistance to corrosion is good, but not as high as HDPE or FRP.

The choice of material depends heavily on factors like the transported fluid (oil, gas, water, steam), pressure requirements, environmental conditions (soil type, temperature), and project budget.

2. Pressure’s On: Understanding Pressure Ratings and Design Codes

Pipes are designed to withstand specific pressures. The pressure rating, often expressed in pounds per square inch (psi) or bar, is a critical factor. Exceeding the pressure rating can lead to catastrophic failures. Design codes, such as ASME B31.4 (Pipeline Transportation Systems) and ASME B31.8 (Gas Transmission and Distribution Piping Systems), provide guidelines for pipe selection and installation based on pressure, material, and operating conditions. It’s crucial to adhere to these codes to ensure safety and compliance.

Factors influencing pressure rating selection include the maximum operating pressure of the system, safety factors, and potential pressure surges. Proper pressure calculations, performed by qualified engineers, are essential to avoid under- or over-designing the pipeline.

3. Sizing Up: Determining the Optimal Pipe Diameter

The diameter of the pipe directly impacts the flow rate and pressure drop within the system. An undersized pipe can lead to excessive pressure drops and reduced efficiency, while an oversized pipe increases material costs and may create other engineering challenges. Accurate hydraulic calculations, utilizing software like PIPE-FLO or similar, are necessary to determine the optimal pipe diameter based on the required flow rate, fluid properties, and acceptable pressure drop.

Furthermore, future expansion should be considered. Choosing a slightly larger diameter might accommodate future increases in demand, preventing costly replacements or upgrades later in the project’s lifecycle.

4. Beyond the Basics: Considering Environmental Factors and Regulations

Environmental considerations are crucial in energy projects. Pipe selection must account for the potential impact on soil, water, and air quality. Regulations related to pipeline construction, operation, and maintenance vary by region and jurisdiction. Compliance with these regulations is mandatory, and failure to comply can lead to significant penalties.

Factors to consider include the potential for soil erosion, groundwater contamination, and greenhouse gas emissions. Choosing environmentally friendly materials and employing environmentally responsible construction practices are essential for sustainable energy projects.

5. Installation and Maintenance: Long-Term Considerations

The ease of installation and long-term maintenance requirements are often overlooked but equally important factors in pipe selection. Some materials are easier to install than others, impacting labor costs and project timelines. Regular maintenance, including inspections and repairs, is essential to ensure the continued safe and efficient operation of the pipeline.

The chosen pipe material’s resistance to corrosion, its susceptibility to damage from external factors, and the availability of skilled labor for installation and maintenance are all factors that should be considered before making a final decision.

By carefully considering these factors, energy project managers can make informed decisions about pipe selection, ensuring the safety, efficiency, and long-term success of their projects.

Tags: energy pipes, pipeline selection, pipe material, pressure rating pipes, pipeline diameter

body { font-family: sans-serif; line-height: 1.6; }

h1, h2, h3 { color: #333; }

img { max-width: 100%; height: auto; }

Electric Resistance Welded (ERW) pipes are a cornerstone of modern construction and industrial applications. Their cost-effectiveness, strength, and versatility make them a popular choice across numerous sectors. This comprehensive guide delves into the world of ERW pipes, exploring their manufacturing, applications, advantages, and limitations.

The ERW Pipe Manufacturing Process: From Coil to Construction

The creation of ERW pipes begins with a continuous coil of steel sheet. This coil is then fed into a forming mill where it’s progressively shaped into a cylindrical form. The edges of the sheet are precisely aligned and then electrically welded together using a high-current process. This process generates heat, melting the edges of the steel and fusing them seamlessly. The weld is then often further strengthened and refined through various post-weld treatments, including sizing, straightening, and potentially heat treatment, depending on the pipe’s intended application and specifications. The resulting pipe is then cut to the desired length, ensuring consistent dimensions and high-quality welds. Precise quality control measures are implemented throughout the entire process to guarantee the integrity and durability of the final product. This rigorous manufacturing process contributes significantly to the reliability and widespread use of ERW pipes.

Diverse Applications of ERW Pipes: Across Industries and Infrastructure

ERW pipes find extensive use in a vast array of applications, showcasing their adaptability and strength. In the construction industry, they are commonly used for structural framing, scaffolding, and piling. Their high strength-to-weight ratio makes them ideal for supporting heavy loads. In the oil and gas industry, ERW pipes are crucial for transporting fluids and gases over long distances. Their ability to withstand high pressures and harsh environments makes them well-suited for pipelines and well casing. The automotive industry also utilizes ERW pipes in various components, leveraging their precision and formability. Furthermore, ERW pipes are integral to water and wastewater management systems, providing efficient and durable pipelines for municipal infrastructure. Finally, they are frequently employed in agricultural irrigation, ensuring efficient water distribution to crops.

Advantages of ERW Pipes: Why They Are a Preferred Choice

Several factors contribute to the popularity and widespread adoption of ERW pipes. Firstly, they are cost-effective compared to other piping solutions, making them a financially attractive option for large-scale projects. Secondly, their high strength and durability ensure long-term performance and reduce the need for frequent replacements. The consistent diameter and wall thickness achieved during manufacturing guarantee reliable performance and easy installation. Moreover, ERW pipes are versatile, adaptable to a range of diameters and wall thicknesses, catering to diverse application needs. Finally, advancements in manufacturing techniques have led to improvements in weld quality and overall pipe integrity, further enhancing their reliability and longevity.

Limitations of ERW Pipes: Understanding Their Constraints

While ERW pipes offer numerous advantages, it’s crucial to understand their limitations. The welding process can potentially introduce residual stresses into the pipe, which may affect its performance under certain conditions. The quality of the weld is paramount, and defects can compromise the integrity of the entire pipe. Careful inspection and quality control are therefore essential throughout the manufacturing and application processes. Moreover, ERW pipes might not be suitable for all applications requiring extreme corrosion resistance or high-temperature operation. In such cases, alternative piping materials might be more appropriate. Understanding these limitations enables informed decision-making regarding the suitability of ERW pipes for specific projects.

Future Trends in ERW Pipe Technology: Innovation and Sustainability

The ERW pipe industry is constantly evolving, with ongoing innovations aimed at enhancing performance, sustainability, and efficiency. There’s a growing focus on developing advanced welding techniques to further improve weld quality and reduce defects. Research is also underway to explore the use of high-strength steel grades and innovative coatings to enhance corrosion resistance and extend the lifespan of ERW pipes. Sustainability is another key driver, with efforts focused on reducing energy consumption during manufacturing and exploring eco-friendly alternatives for coatings and surface treatments. These advancements promise to further expand the applications and enhance the overall value proposition of ERW pipes in the years to come.

In conclusion, ERW pipes represent a crucial component in a wide range of industries and infrastructure projects. Their cost-effectiveness, strength, versatility, and ongoing technological advancements ensure their continued importance in the construction, energy, and manufacturing sectors.

SEO Tags:

ERW Pipes, Electric Resistance Welded Pipes, Pipe Applications, Steel Pipes, Construction Materials

Annealed wire, a metal wire that has undergone a heat treatment process called annealing, boasts exceptional ductility and malleability. This makes it incredibly versatile and suitable for a wide array of applications across various industries. Understanding the unique properties of annealed wire is key to appreciating its widespread use.

1. Annealed Wire in Electrical Applications

One of the most prominent uses of annealed wire lies in the electrical industry. Its high conductivity, particularly when it’s made from copper or aluminum, makes it ideal for conducting electricity with minimal energy loss. Annealing reduces the internal stresses within the metal, improving its ability to carry current without overheating or breaking. This is crucial in applications such as:

- Wiring in homes and buildings: Annealed copper wire is the backbone of electrical systems in residential and commercial structures, safely distributing power to various outlets and appliances.

- Automotive wiring: The reliability and flexibility of annealed wire are essential for the complex wiring harnesses found in modern vehicles.

- Power transmission lines: While often larger gauge wires are used, the annealing process is still crucial for ensuring the durability and conductivity of these lines, even under immense stress.

- Electronic components: In smaller electronic devices, the fine annealed wire is used for intricate circuitry and connections.

2. Annealed Wire in Spring Manufacturing

The enhanced ductility of annealed wire makes it a preferred material for spring manufacturing. Its ability to withstand repeated bending and stretching without fracturing is critical for the performance of springs in various applications. The annealing process carefully controls the wire’s tensile strength and elasticity, ensuring consistent spring characteristics. This is vital in:

- Automotive suspensions: Helical springs in vehicles rely on annealed wire’s resilience to absorb shocks and vibrations.

- Mechanical components: From small clock springs to larger industrial springs, annealed wire provides the necessary flexibility and strength.

- Medical devices: The biocompatibility of certain annealed metal wires makes them suitable for use in medical implants and devices requiring flexibility and durability.

- Aerospace applications: High-quality annealed wire is crucial in aerospace components where reliability and resistance to fatigue are paramount.

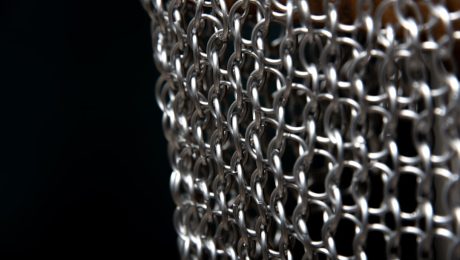

3. Annealed Wire in the Manufacturing of Wire Mesh and Fencing

Annealed wire’s malleability lends itself perfectly to the creation of wire mesh and fencing. The process of weaving or welding annealed wire into mesh structures requires a material that can be easily shaped and manipulated without breaking. This is crucial for creating:

- Security fencing: Annealed steel wire is commonly used for constructing robust and durable security fences.

- Wire mesh for industrial applications: From filtering systems to reinforcement structures, annealed wire mesh offers strength and versatility.

- Agricultural fencing: Annealed wire is used extensively in agricultural settings to create fences for livestock and crop protection.

- Decorative wire mesh: The malleability of annealed wire allows for the creation of decorative and artistic wire mesh structures.

4. The Role of Annealed Wire in Welding and Brazing

In welding and brazing applications, annealed wire serves as a crucial filler material. Its clean surface and consistent properties ensure a strong and reliable weld. The annealing process minimizes impurities and ensures uniform flow during the welding process. This is particularly important in:

- Joining dissimilar metals: Annealed wire can facilitate the joining of metals with different melting points.

- Repairing damaged components: Annealed wire can be used to repair cracks or other damage in metal components.

- Creating intricate metal structures: Annealed wire’s ability to flow smoothly during welding makes it ideal for creating complex shapes.

- High-precision welding: The consistent properties of annealed wire are crucial for achieving high-precision welds.

5. Choosing the Right Type of Annealed Wire: Material and Gauge Considerations

The selection of annealed wire depends heavily on the specific application. Different materials, such as copper, steel, aluminum, and various alloys, each offer unique properties. The gauge of the wire, which refers to its diameter, also plays a crucial role. Thicker gauge wires offer greater strength, while thinner gauges provide greater flexibility. Careful consideration of both material and gauge is essential to ensure the wire meets the demands of the application.

Understanding the interplay between these factors is crucial for selecting the optimal annealed wire for any given project. Factors such as required tensile strength, conductivity, corrosion resistance, and cost all contribute to the decision-making process.

In conclusion, annealed wire’s versatility stems from the controlled heat treatment process that enhances its inherent properties. Its widespread use across numerous industries highlights its importance as a fundamental material in modern manufacturing and technology.

The world of engineering materials is constantly evolving, driven by the need for stronger, lighter, and more durable components. In the realm of piping systems, a significant advancement is the development of carbon fiber-coated steel pipes. This innovative technology combines the inherent strength and affordability of steel with the exceptional tensile strength and lightweight nature of carbon fiber, resulting in a superior product with a wide range of applications.

The Manufacturing Process: Weaving Strength and Durability

The creation of carbon fiber-coated steel pipes is a multi-stage process requiring precision and expertise. It typically begins with the selection of high-quality steel pipes, ensuring consistent dimensions and material properties. The surface of the steel pipe is then meticulously prepared, often involving cleaning, degreasing, and potentially surface treatments to enhance adhesion. Next, the carbon fiber layers are applied. This can be done using various techniques, including filament winding, pultrusion, or prepreg layup, depending on the desired pipe diameter, thickness, and performance characteristics. The carbon fiber is carefully oriented to maximize its contribution to the pipe’s overall strength and stiffness. Finally, the composite structure is cured, often using heat and pressure, to achieve the desired level of bonding between the carbon fiber and the steel substrate. Quality control measures are implemented throughout the process to ensure the integrity and performance of the finished product.

Enhanced Mechanical Properties: Strength Beyond Steel

The primary advantage of carbon fiber-coated steel pipes lies in their significantly enhanced mechanical properties. The addition of carbon fiber dramatically increases the tensile strength, flexural strength, and stiffness of the pipe compared to uncoated steel pipes. This makes them ideal for applications requiring high load-bearing capacity, resistance to deformation, and reduced weight. The carbon fiber also contributes to improved fatigue resistance, meaning the pipes can withstand repeated cyclical loading without failure. This increased strength-to-weight ratio is particularly advantageous in applications where weight is a critical factor, such as in aerospace, automotive, and offshore industries.

Corrosion Resistance and Longevity: Protecting Against the Elements

Steel pipes are susceptible to corrosion, especially in harsh environments. The carbon fiber coating provides an additional layer of protection against corrosion, significantly extending the lifespan of the pipe. The carbon fiber itself is highly resistant to degradation from environmental factors, and the coating acts as a barrier, preventing moisture and corrosive agents from reaching the underlying steel. This improved corrosion resistance reduces maintenance costs and minimizes the risk of pipe failure due to corrosion-related damage. This is particularly beneficial in applications such as pipelines transporting corrosive fluids or in marine environments.

Applications Across Industries: A Versatile Solution

The unique combination of strength, durability, and corrosion resistance makes carbon fiber-coated steel pipes suitable for a wide range of applications across various industries. In the oil and gas sector, they are used in high-pressure pipelines and subsea applications. The aerospace industry utilizes them for fuel lines and other critical components. The automotive industry employs them in high-performance vehicles for weight reduction and enhanced structural integrity. Other applications include infrastructure projects, such as bridges and buildings, where high strength and stiffness are essential. Even in the renewable energy sector, these pipes find use in wind turbine structures and geothermal energy systems.

Limitations and Future Developments: Addressing Challenges and Expanding Horizons

Despite their numerous advantages, carbon fiber-coated steel pipes also have some limitations. The manufacturing process can be relatively complex and expensive compared to traditional steel pipes. The cost of carbon fiber itself contributes to the overall expense. Additionally, the design and implementation of proper joining techniques for these composite pipes require careful consideration to ensure structural integrity. Future developments in the field are focusing on improving the manufacturing process to reduce costs and enhance efficiency. Research is also underway to explore new materials and techniques to further enhance the performance and durability of carbon fiber-coated steel pipes, potentially leading to even wider adoption across diverse industries.

In conclusion, carbon fiber-coated steel pipes represent a significant advancement in piping technology, offering a compelling blend of strength, durability, and corrosion resistance. While challenges remain, ongoing research and development efforts promise to further unlock the potential of this innovative material, solidifying its role in critical infrastructure and high-performance applications across a multitude of sectors.

SEO Tags:

- Carbon Fiber Coated Steel Pipes

- Composite Pipes

- Steel Pipe Reinforcement

- Carbon Fiber Pipe

- High-Strength Piping

In today’s rapidly evolving business landscape, the ability to adapt and improve continuously is no longer a competitive advantage – it’s a necessity. A culture of continuous improvement, often referred to as Kaizen, is the key to unlocking sustained growth, increased efficiency, and enhanced employee engagement. But fostering such a culture requires a deliberate and strategic approach. This post will delve into the essential elements needed to create a truly thriving continuous improvement environment.

1. Laying the Foundation: Establishing a Mindset of Continuous Improvement

The first step towards a successful continuous improvement culture is establishing a mindset shift within the entire organization. This means moving away from a culture of complacency and accepting the status quo, towards one that actively seeks out opportunities for improvement. This requires leadership buy-in at all levels. Leaders must model the desired behavior, actively participate in improvement initiatives, and openly celebrate successes, no matter how small. Furthermore, open communication channels are crucial. Employees need to feel safe and empowered to identify problems, suggest solutions, and voice concerns without fear of retribution. Regular training and workshops on continuous improvement methodologies, like Lean and Six Sigma, can further reinforce this mindset.

2. Empowering Employees: Fostering Ownership and Accountability

A truly effective continuous improvement culture empowers employees at all levels to take ownership of their work and contribute to the improvement process. This requires delegating authority, providing employees with the resources and training they need, and encouraging them to take initiative. Implementing suggestion schemes, where employees can submit ideas for improvement, is a powerful tool. These suggestions should be reviewed, discussed, and implemented where feasible, with feedback provided to the employee. Creating cross-functional teams that collaborate on improvement projects can also foster a sense of shared responsibility and ownership. Regular feedback and recognition for contributions, both big and small, are essential for maintaining motivation and engagement.

3. Measuring Progress: Implementing Data-Driven Improvement Strategies

Continuous improvement is not about making changes blindly; it’s about making data-driven decisions. Implementing key performance indicators (KPIs) and regularly monitoring progress is crucial for tracking the effectiveness of improvement initiatives. This data should be transparent and accessible to all employees, allowing them to see the impact of their contributions and identify areas needing further attention. Using data visualization tools can make this information more readily digestible and engaging. Regular reviews of KPIs should be incorporated into team meetings and company-wide updates, ensuring that everyone is aware of the progress being made and any challenges encountered.

4. Embracing Failure as a Learning Opportunity: Fostering a Culture of Experimentation

A key component of a thriving continuous improvement culture is the ability to learn from failures. Instead of viewing mistakes as setbacks, they should be seen as valuable learning opportunities. Creating a psychologically safe environment where employees feel comfortable taking calculated risks and experimenting with new approaches is essential. Post-mortems, where teams analyze what went wrong and what could be done differently, are a valuable tool for learning from failures. It’s important to focus on the process and the lessons learned, rather than assigning blame. This culture of experimentation encourages innovation and helps the organization adapt more quickly to change.

5. Sustaining Momentum: Building Continuous Improvement into Daily Operations

Building a continuous improvement culture is not a one-time project; it’s an ongoing process that requires consistent effort and commitment. To sustain momentum, continuous improvement should be integrated into daily operations. This can be achieved through regular meetings dedicated to reviewing progress, identifying new areas for improvement, and sharing best practices. Regular training and development opportunities should be provided to employees to keep them updated on new methodologies and tools. Celebrating successes, both big and small, is crucial for maintaining motivation and engagement. Finally, regular audits and assessments can help identify areas where improvements are still needed and ensure that the culture of continuous improvement remains strong.

By implementing these strategies, organizations can cultivate a thriving continuous improvement culture that drives innovation, enhances efficiency, and fosters a more engaged and empowered workforce. The journey may not always be easy, but the rewards – sustained growth, increased profitability, and a more fulfilling work environment – are well worth the effort.

SEO Tags:

- Continuous Improvement

- Kaizen

- Lean Methodology

- Six Sigma

- Organizational Culture

body { font-family: sans-serif; line-height: 1.6; }

img { max-width: 100%; height: auto; display: block; margin: 20px auto; }

h1, h2 { color: #333; }

h1 { font-size: 2.5em; }

h2 { font-size: 1.8em; }

Steel. The very word conjures images of strength, resilience, and unwavering durability. But beyond its inherent properties lies a world of incredible versatility, shaping our world in countless ways. This visual gallery explores the diverse and fascinating applications of steel, showcasing its impact on our infrastructure, manufacturing processes, and everyday lives.

1. Steel in Construction: Skyscrapers to Sustainable Structures

Steel’s high strength-to-weight ratio makes it the backbone of modern construction. From towering skyscrapers that pierce the clouds to intricate bridges spanning vast distances, steel’s ability to withstand immense loads and stresses is unparalleled. Its malleability allows for complex designs, pushing the boundaries of architectural innovation. Furthermore, advancements in sustainable steel production are making it an increasingly environmentally responsible choice for eco-conscious construction projects. We see steel used in everything from the structural frames of buildings to reinforcing bars (rebar) within concrete, ensuring stability and longevity.

2. Steel in Infrastructure: Building the Backbone of Our World

Our global infrastructure relies heavily on steel’s robust nature. Roads, railways, tunnels, and pipelines – all benefit from steel’s resistance to corrosion and its ability to withstand significant wear and tear. The longevity of steel infrastructure projects ensures a long-term return on investment, minimizing the need for frequent repairs and replacements. The construction of large-scale infrastructure projects, such as high-speed rail lines and massive dams, would be virtually impossible without the use of steel.

3. Steel in Manufacturing: From Automobiles to Appliances

Steel’s versatility extends to the manufacturing sector, where it serves as a crucial component in countless products. The automotive industry is heavily reliant on steel, utilizing it for car bodies, chassis, and various internal components. Appliances, tools, and machinery all incorporate steel due to its durability and resistance to damage. The precision with which steel can be shaped and formed allows for the creation of intricate and complex parts, driving innovation in various manufacturing processes.

4. Steel in Energy: Powering a Sustainable Future

Steel plays a vital role in the energy sector, particularly in renewable energy sources. Wind turbines, for example, rely on steel for their robust towers and blades, capable of withstanding extreme weather conditions. Steel’s strength and longevity make it ideal for the construction of power plants and energy transmission infrastructure. Even in traditional energy sources, steel remains a critical component in various aspects of the power generation process.

5. Beyond the Basics: Specialized Steel Applications

The applications of steel extend far beyond the commonly known examples. Specialized steel alloys are used in the medical field for implants and surgical instruments, requiring exceptional biocompatibility and strength. The aerospace industry relies on high-strength, lightweight steel alloys for aircraft components. Even in art and design, steel’s malleability and aesthetic appeal make it a popular medium for sculptures and architectural features. The ongoing development of new steel alloys continues to expand its potential across a wide range of specialized applications.

This visual journey through the world of steel applications demonstrates its profound impact on our lives. From the buildings we inhabit to the vehicles we drive, steel’s unwavering strength and versatility continue to shape our world, paving the way for innovation and progress.

SEO Tags:

- Steel Applications

- Steel Uses

- Steel Construction

- Steel Infrastructure

- Industrial Steel

“`

Remember to replace the placeholder image URLs (“placeholder-skyscraper.jpg”, etc.) with actual image URLs. This HTML provides a basic structure; you might want to add CSS for improved styling and responsiveness.

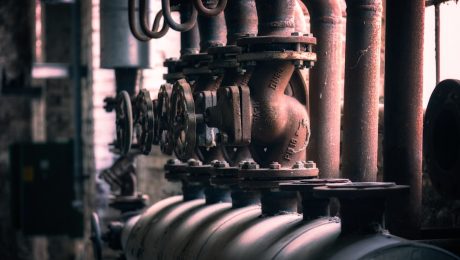

High-pressure piping systems are integral to numerous industries, from oil and gas to chemical processing and power generation. While essential for efficient operations, these systems present significant safety challenges if not properly designed, installed, and maintained. This comprehensive guide explores key aspects of high-pressure pipe safety, providing insights into best practices and crucial considerations to mitigate risks and ensure operational excellence.

1. Design and Material Selection: The Foundation of Safety

The foundation of any safe high-pressure piping system lies in its design and the materials used. Careful consideration must be given to factors such as operating pressure, temperature, fluid properties (corrosiveness, viscosity), and potential external forces (earthquakes, thermal expansion). Design engineers utilize rigorous calculations and simulations to determine the appropriate pipe diameter, wall thickness, and material specifications to withstand the anticipated stresses. Materials must possess high tensile strength, yield strength, and fatigue resistance to prevent failure under pressure. Common materials include carbon steel, stainless steel, alloy steel, and specialized polymers depending on the specific application. Proper stress analysis, including Finite Element Analysis (FEA), is crucial to identify potential weak points and optimize the design for safety.

2. Rigorous Inspection and Testing: Identifying Potential Hazards

Regular and thorough inspection is paramount to maintaining the integrity of high-pressure piping systems. This involves both visual inspections, checking for corrosion, erosion, dents, and leaks, and non-destructive testing (NDT) methods such as ultrasonic testing (UT), radiographic testing (RT), and magnetic particle inspection (MPI). These NDT techniques allow for the detection of internal flaws and weaknesses that might not be visible to the naked eye. Hydrostatic testing, a critical part of the commissioning process and periodic maintenance, involves pressurizing the system with water to a pressure exceeding the operating pressure to verify its structural integrity. Regular inspections and testing help identify potential hazards early, allowing for timely repairs and preventing catastrophic failures.

3. Effective Maintenance and Repair Strategies: Proactive Safety Measures

Proactive maintenance is crucial for preventing failures and ensuring the long-term safety of high-pressure piping systems. This includes regular cleaning to remove debris and corrosion, lubrication of valves and fittings, and timely replacement of worn or damaged components. A comprehensive maintenance plan should be developed and implemented, outlining the frequency of inspections, testing, and repairs. Proper documentation of all maintenance activities is essential for tracking the system’s history and identifying trends that might indicate potential problems. When repairs are necessary, qualified personnel should perform them using appropriate procedures and materials, ensuring that the repaired section meets the original design specifications and safety standards.

4. Emergency Procedures and Response: Preparedness for Unexpected Events

Despite the best design, inspection, and maintenance practices, accidents can still occur. Therefore, having well-defined emergency procedures and a robust response plan is crucial. This includes establishing clear communication protocols, identifying potential emergency scenarios (leaks, ruptures, fires), and training personnel on proper emergency response techniques. Emergency shut-off valves should be readily accessible and clearly marked, and personnel should be trained on their proper operation. Developing a detailed emergency response plan, including evacuation procedures and contact information for emergency services, is essential to minimize the impact of any unforeseen event. Regular drills and simulations help ensure that personnel are prepared to respond effectively in a crisis.

5. Compliance with Safety Regulations and Standards: Adherence to Best Practices

Operating high-pressure piping systems requires strict adherence to relevant safety regulations and industry standards. These standards, often developed by organizations like ASME (American Society of Mechanical Engineers), provide detailed guidelines on design, materials, inspection, testing, and operation. Compliance with these standards is crucial not only for ensuring safety but also for meeting legal requirements and avoiding potential penalties. Regular audits and inspections by regulatory bodies help ensure that operations adhere to the established safety standards. Staying updated on the latest safety regulations and best practices is crucial for maintaining a safe and compliant operating environment.

High-pressure pipe safety is not a one-time effort but rather an ongoing commitment to rigorous practices. By prioritizing design, inspection, maintenance, emergency preparedness, and regulatory compliance, industries can effectively mitigate risks and ensure the safe and efficient operation of their high-pressure piping systems.

SEO Tags:

high-pressure pipe safety, pipeline safety, pressure vessel safety, pipe inspection, pipe maintenance

body { font-family: sans-serif; line-height: 1.6; }

h1, h2, h3 { color: #333; }

img { max-width: 100%; height: auto; }

Steel’s strength, durability, and versatility make it an essential material in the construction and operation of modern power plants. From the foundational structures to intricate components within the power generation process, steel plays a critical role in ensuring efficient, reliable, and safe energy production. This post delves into the multifaceted relationship between steel and power plant integration, exploring its various applications and the ongoing innovations shaping the industry.

1. Steel’s Structural Foundation in Power Plant Construction

Power plants, regardless of their generation technology (fossil fuel, nuclear, renewable), require robust and durable structures to withstand environmental stresses and operational loads. Steel’s high tensile strength and formability make it ideal for constructing the plant’s primary framework. This includes the main buildings housing turbines, generators, and control systems, as well as supporting structures for cooling towers, stacks, and transmission lines. Steel’s ability to be fabricated into various shapes and sizes allows for efficient construction, minimizing on-site work and reducing construction time. Furthermore, advancements in steel design and fabrication techniques, such as high-strength low-alloy (HSLA) steels and advanced welding processes, have led to lighter yet stronger structures, optimizing material usage and reducing overall costs.

2. Steel’s Role in Boiler and Turbine Systems (Fossil Fuel and Biomass Plants)

In conventional thermal power plants fueled by coal, oil, or biomass, steel plays a pivotal role in the high-pressure, high-temperature environment of the boiler and turbine systems. Boiler components, including pressure vessels, tubes, headers, and superheaters, require materials capable of withstanding extreme temperatures and pressures without compromising structural integrity. High-temperature alloys, often containing chromium, molybdenum, and other alloying elements, are specifically designed to resist oxidation, creep, and corrosion at elevated temperatures. Similarly, turbine blades and casings are manufactured from specialized steel alloys to withstand the immense centrifugal forces and thermal stresses encountered during operation. The precise machining and manufacturing processes involved in producing these components demand high-quality steel with exceptional metallurgical properties.

3. Steel in Nuclear Power Plant Components

Nuclear power plants present unique challenges due to the high levels of radiation and the need for extreme safety measures. Steel, specifically low-activation steel, plays a crucial role in the construction of the reactor vessel, containment structures, and other critical components. Low-activation steel minimizes the production of long-lived radioactive isotopes, reducing the long-term waste disposal challenges. The selection of steel for nuclear applications undergoes rigorous testing and quality control to ensure its ability to withstand radiation damage and maintain structural integrity over its operational lifespan. Welding and inspection techniques employed in nuclear power plant construction are exceptionally stringent to guarantee the absence of flaws that could compromise safety.

4. Steel’s Contribution to Renewable Energy Infrastructure

While often associated with fossil fuel and nuclear plants, steel is also integral to renewable energy infrastructure. Wind turbines, for example, rely heavily on steel for their towers, nacelles, and blades. The towers require high-strength steel to withstand significant wind loads and bending moments. Similarly, solar power plants utilize steel in the support structures for photovoltaic panels, ensuring stability and durability in various environmental conditions. The use of steel in these renewable energy applications contributes to the efficiency and longevity of these crucial clean energy systems.

5. Challenges and Innovations in Steel Application for Power Plants

Despite its widespread use, the application of steel in power plants faces some challenges. Corrosion, particularly in coastal or high-humidity environments, remains a concern. The development of corrosion-resistant steels and advanced coating technologies is crucial for extending the lifespan of power plant components. Furthermore, the increasing demand for energy efficiency necessitates the development of lighter and stronger steel alloys to reduce the overall weight and material consumption in power plant construction. Research and development efforts are focused on enhancing the mechanical properties of steel through alloying additions and advanced manufacturing techniques like additive manufacturing (3D printing) to create complex components with improved performance and reduced manufacturing costs.

In conclusion, steel remains an indispensable material in the construction and operation of power plants, regardless of their energy source. Its strength, durability, and versatility are crucial for ensuring the safe, efficient, and reliable generation of electricity. Ongoing innovations in steel technology promise to further enhance its role in meeting the world’s growing energy demands while addressing the challenges of sustainability and environmental responsibility.

SEO Tags: Steel in power plants, Power plant construction, Steel alloys, Renewable energy infrastructure, Nuclear power plant materials

The integrity of pipe systems is paramount across numerous industries, from oil and gas to water management and construction. A single point of failure can lead to catastrophic consequences, highlighting the critical need for robust quality control systems throughout the pipe production process. This comprehensive guide explores the key aspects of ensuring high-quality pipe products, from raw material selection to final inspection.

1. Raw Material Inspection: The Foundation of Quality

The journey to a high-quality pipe begins long before the manufacturing process. Rigorous inspection of raw materials is crucial. This involves testing for chemical composition, ensuring it meets the specified grade and standards (e.g., ASTM, ASME). For steel pipes, this might include analyzing carbon content, manganese, silicon, and other alloying elements. Non-destructive testing (NDT) methods like ultrasonic testing (UT) can detect internal flaws in the raw material before it even enters the manufacturing process. Detailed documentation of these tests and their results is essential for traceability and accountability.

Furthermore, the dimensions and surface quality of the raw material are also carefully checked. Variations in size or surface imperfections can significantly impact the final product’s quality and integrity. This stage often involves visual inspection, dimensional measurements using calibrated tools, and potentially surface roughness testing.

2. In-Process Quality Control: Monitoring Manufacturing

Maintaining quality isn’t just about the beginning; it’s a continuous process throughout manufacturing. In-process quality control involves regular monitoring and testing at various stages of pipe production. For example, during the forming process (whether seamless or welded), parameters like wall thickness, diameter, and ovality are continuously monitored. Automated systems with real-time feedback mechanisms are often employed to ensure consistency and identify deviations from specifications immediately. This allows for prompt corrective actions, minimizing waste and ensuring consistent product quality.

Welding processes, if applicable, require particularly stringent quality control. Procedures must adhere to strict codes and standards (e.g., AWS D1.1). Non-destructive testing methods like radiographic testing (RT), ultrasonic testing (UT), and magnetic particle inspection (MPI) are crucial for detecting welding defects like porosity, cracks, and incomplete penetration. Qualified welders and rigorous welding procedure specifications are essential for consistent, high-quality welds.

3. Dimensional and Physical Testing: Ensuring Conformity

Once the pipes are manufactured, rigorous dimensional and physical testing is carried out to verify conformity with the specified standards. This involves precise measurements of the pipe’s outer diameter, inner diameter, wall thickness, length, and straightness. Deviations from the specified tolerances are carefully documented and analyzed. Physical tests assess the pipe’s mechanical properties, including tensile strength, yield strength, elongation, and hardness. These tests determine the pipe’s ability to withstand pressure, stress, and other operating conditions.

Hydrostatic testing is a common method used to evaluate the pipe’s ability to withstand internal pressure. Pipes are filled with water and pressurized to a level exceeding the expected operating pressure. This test helps identify any weaknesses or leaks. Other tests, such as burst testing (to determine ultimate pressure capacity) and impact testing (to assess resistance to shock), may also be performed depending on the application and pipe material.

4. Non-Destructive Testing (NDT): Unveiling Hidden Flaws

NDT methods play a vital role in ensuring pipe quality without damaging the product. As mentioned earlier, these techniques are used throughout the manufacturing process, from raw material inspection to finished product verification. Different NDT methods are employed depending on the type of defect being sought and the pipe material. Ultrasonic testing (UT) uses high-frequency sound waves to detect internal flaws, while radiographic testing (RT) uses X-rays or gamma rays to create images revealing internal structures and defects.

Magnetic particle inspection (MPI) is used to detect surface and near-surface cracks in ferromagnetic materials. Dye penetrant testing (PT) is another surface inspection method used to detect cracks and other surface discontinuities. The selection of appropriate NDT methods is crucial for effective defect detection and ensures that the pipes meet the required quality standards.

5. Documentation and Traceability: Maintaining a Clear Record

Meticulous documentation and traceability are essential components of any effective quality control system. Every stage of the process, from raw material sourcing to final inspection, should be thoroughly documented. This includes test results, inspection reports, and any corrective actions taken. A robust traceability system allows for the identification of the origin of any defective pipe, facilitating prompt investigations and corrective actions. This is crucial for ensuring product liability and maintaining customer confidence.

Digitalization of quality control processes is becoming increasingly common. Software solutions can help manage test data, generate reports, and ensure traceability across the entire supply chain. These systems can improve efficiency, reduce errors, and enhance overall quality control effectiveness.

Implementing a comprehensive pipe product quality control system requires a commitment to excellence throughout the entire production process. By combining rigorous testing, advanced technologies, and meticulous documentation, manufacturers can ensure the delivery of high-quality pipes that meet the stringent demands of various industries and contribute to the safety and reliability of critical infrastructure.

SEO Tags:

Pipe Quality Control, Pipe Manufacturing, Non-Destructive Testing, Pipe Inspection, Quality Assurance Pipes