Understanding Equal Angle Bars: Definition and Properties

Equal angle bars, also known as equal leg angles, are L-shaped steel sections where both legs (the sides forming the right angle) possess the same length. This symmetrical design contributes to their widespread use in various applications. They are typically manufactured from mild steel, but can also be found in other materials like stainless steel or aluminum, each offering different properties regarding strength, corrosion resistance, and weight. The dimensions of equal angle bars are standardized, usually specified by the length of each leg and the thickness of the material. For instance, a 50x50x6mm equal angle bar indicates legs of 50mm each and a thickness of 6mm. This standardization ensures easy selection and interchangeability in projects.

Manufacturing Processes of Equal Angle Bars

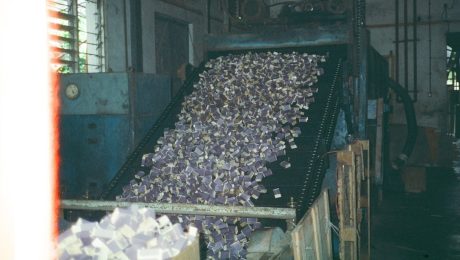

The creation of equal angle bars involves several key steps. It begins with the preparation of the raw material, usually steel billets, which undergo heating in a furnace to achieve the necessary malleability for shaping. The hot steel is then passed through a rolling mill, a series of rollers that progressively shape the billet into the desired L-shape. Precise control over temperature and rolling pressure is crucial to achieve the accurate dimensions and desired mechanical properties. After rolling, the angle bars undergo a cooling process, often followed by straightening and cutting to the required lengths. Quality control measures, including dimensional checks and material testing, are implemented throughout the manufacturing process to ensure adherence to industry standards and customer specifications. Different finishing processes, such as hot-dip galvanizing for corrosion protection or painting for aesthetics, can be applied depending on the intended application.

Diverse Applications of Equal Angle Bars in Construction

Equal angle bars are indispensable in the construction industry, serving a multitude of purposes. They are commonly used as structural supports in frameworks, providing strength and stability to buildings and other structures. Their rigid nature makes them ideal for creating bracing systems, preventing lateral movement and enhancing overall structural integrity. They are also frequently employed in the fabrication of steel stairs, handrails, and other architectural elements, adding both functionality and aesthetic appeal. In addition, equal angle bars are utilized in the creation of scaffolding, providing temporary support during construction and maintenance work. Their versatility extends to the reinforcement of concrete structures, enhancing their load-bearing capacity and resistance to cracking.

Equal Angle Bars in Engineering and Manufacturing

Beyond construction, equal angle bars find extensive use in engineering and manufacturing. They serve as crucial components in machinery, equipment, and various industrial applications. Their ability to withstand significant stress and strain makes them suitable for creating frames, supports, and mounting brackets. In the automotive industry, equal angle bars are often incorporated into vehicle chassis and other structural components. The manufacturing sector utilizes them in the construction of jigs, fixtures, and tooling, facilitating efficient and precise production processes. Their robust nature also makes them suitable for applications requiring high durability and resistance to wear and tear. The precise dimensions and standardized profiles of equal angle bars ensure easy integration into complex systems and assemblies.

Selecting the Right Equal Angle Bar for Your Project: A Guide

Choosing the appropriate equal angle bar depends heavily on the specific requirements of the project. Factors to consider include the desired strength, load capacity, corrosion resistance, and aesthetic considerations. The dimensions of the angle bar, particularly the leg length and thickness, directly influence its strength and load-bearing capacity. The material selection is crucial; mild steel is cost-effective for many applications, while stainless steel offers superior corrosion resistance for outdoor or harsh environments. Understanding the anticipated stresses and loads on the angle bar is vital for ensuring structural integrity. Consulting relevant standards and codes of practice is essential to ensure compliance with safety regulations. It’s advisable to work with experienced engineers or fabricators to determine the optimal angle bar for your specific needs, maximizing efficiency and minimizing risk.

Choosing the right equal angle bar ensures structural integrity, longevity, and safety. Thorough planning and consultation are key to successful project completion.

The safe and efficient transportation of natural gas relies heavily on the integrity of the pipeline network. Corrosion, both internal and external, is a significant threat to this infrastructure, leading to leaks, explosions, and environmental damage. To mitigate these risks, pipeline operators utilize various protective coatings, with epoxy (EP), polypropylene (PP), and polyethylene (PE) coatings standing out as prominent solutions. This article delves into the specifics of these coatings, their applications, and their crucial role in ensuring the long-term reliability of gas pipelines.

Understanding the Three Coating Types: EP, PP, and PE

Each coating type offers unique properties and benefits, making them suitable for different pipeline applications and environments. Let’s break down the characteristics of each:

- Epoxy (EP) Coatings: Epoxy coatings are known for their excellent adhesion, chemical resistance, and mechanical strength. They provide a robust barrier against corrosion and abrasion, making them ideal for pipelines operating in harsh environments or those subjected to significant mechanical stress. The application process often involves a multi-layer system to maximize protection. However, epoxy coatings can be more susceptible to damage from UV radiation, limiting their suitability for above-ground applications without additional UV-resistant topcoats.

- Polypropylene (PP) Coatings: PP coatings offer excellent chemical resistance, particularly to acids and alkalis. They are also known for their high impact resistance and flexibility, making them suitable for pipelines that experience vibrations or bending. PP coatings are often applied as a fusion-bonded epoxy (FBE) system, where the PP layer is fused to the pipe surface, ensuring a strong bond and excellent protection.

- Polyethylene (PE) Coatings: PE coatings, typically high-density polyethylene (HDPE), are renowned for their exceptional flexibility, abrasion resistance, and excellent resistance to a wide range of chemicals. They are often applied as a three-layer system including a fusion bond epoxy primer for optimal adhesion. Their flexibility makes them particularly well-suited for pipelines in areas prone to seismic activity or ground movement. PE coatings are also commonly used in the external coating of pipelines, providing substantial protection against soil corrosion.

Application Methods and Considerations

The application process for each coating type varies slightly, but generally involves meticulous surface preparation of the pipe to ensure optimal adhesion. This often includes cleaning, degreasing, and potentially blasting the pipe surface to create a rough profile for better bonding. The coating is then applied using specialized equipment, often in a controlled environment to maintain consistent thickness and quality. Factors to consider during application include:

- Environmental conditions: Temperature and humidity can significantly impact the curing process of the coating.

- Pipe diameter and length: Larger diameter pipes may require more complex application methods.

- Coating thickness: The required thickness depends on the specific application and environmental conditions.

- Quality control: Regular inspection and testing are essential to ensure the coating meets the required specifications.

Advantages of Using EP/PP/PE Coated Pipes in Gas Pipelines

The use of EP, PP, and PE coated pipes offers numerous advantages, leading to improved pipeline safety, longevity, and efficiency:

- Enhanced Corrosion Protection: The primary benefit is the significant reduction in corrosion rates, extending the lifespan of the pipeline.

- Improved Safety: Reduced corrosion risk minimizes the chances of leaks and explosions, improving overall pipeline safety.

- Reduced Maintenance Costs: Extended pipeline lifespan and reduced corrosion translate to lower maintenance and repair costs.

- Environmental Protection: Preventing leaks helps protect the environment from gas emissions and soil contamination.

- Increased Efficiency: A well-protected pipeline operates more efficiently, reducing downtime and maximizing gas flow.

Choosing the Right Coating for Your Gas Pipeline Project

Selecting the appropriate coating depends on several factors, including the pipeline’s location, operating conditions, soil characteristics, and budget considerations. A thorough risk assessment and careful consideration of the advantages and disadvantages of each coating type are crucial. Consulting with experienced pipeline engineers and coating specialists is recommended to ensure the optimal solution for a specific project.

For instance, pipelines buried in highly corrosive soils might benefit from a thicker EP or FBE coating, while pipelines in areas prone to ground movement might be best served by the flexibility of PE coating. Above-ground applications might necessitate UV-resistant topcoats in conjunction with the primary coating.

Regulations and Standards for Coated Gas Pipelines

The use of coated pipes in gas pipelines is governed by stringent regulations and industry standards to ensure safety and quality. These regulations often specify minimum coating thicknesses, application methods, and testing procedures. Compliance with these standards is crucial for obtaining permits and ensuring the long-term integrity of the pipeline system. Specific standards vary depending on geographical location and regulatory bodies but generally align with international best practices.

In conclusion, the use of EP, PP, and PE coated pipes plays a vital role in safeguarding gas pipelines, ensuring their longevity, and minimizing environmental risks. By carefully considering the specific application requirements and adhering to relevant standards, pipeline operators can leverage the benefits of these protective coatings to maintain a safe and efficient gas transportation network.

SEO Tags: EP coated pipes, PP coated pipes, PE coated pipes, gas pipeline coating, pipeline corrosion protection

Industrial pipes are the unsung heroes of manufacturing. They form the circulatory system of any factory, transporting crucial fluids, gases, and slurries that keep production lines running smoothly. Choosing the right pipes is paramount, impacting efficiency, safety, and the overall lifespan of your equipment. This comprehensive guide delves into the crucial aspects of selecting industrial pipes for your manufacturing facility.

1. Material Selection: The Foundation of Durability and Performance

The material of your industrial pipes is the cornerstone of their performance. The choice depends heavily on the substance being transported, the operating temperature and pressure, and the corrosive environment. Common materials include:

- Carbon Steel: A cost-effective option suitable for many applications, offering good strength and durability. However, it’s susceptible to corrosion, necessitating protective coatings in certain environments.

- Stainless Steel: Highly resistant to corrosion and oxidation, making it ideal for handling aggressive chemicals and high-purity fluids. Different grades (like 304 and 316) offer varying levels of corrosion resistance.

- Ductile Iron: Possesses high tensile strength and excellent resistance to corrosion, making it suitable for underground applications and high-pressure systems.

- PVC (Polyvinyl Chloride): A lightweight and corrosion-resistant option, perfect for handling chemicals and water, but limited in its temperature and pressure tolerance.

- CPVC (Chlorinated Polyvinyl Chloride): Offers superior temperature resistance compared to PVC, expanding its application range.

- Other specialized materials: Depending on specific needs, materials like fiberglass-reinforced plastic (FRP), copper, and various alloys are employed for their unique properties.

Careful consideration of the transported medium and operating conditions is crucial for selecting the appropriate material to avoid costly failures and downtime.

2. Pipe Sizing and Flow Rate Optimization: Ensuring Efficient Transfer

Proper pipe sizing is essential for maintaining efficient fluid flow. Undersized pipes lead to increased pressure drop and reduced flow rates, potentially impacting production. Oversized pipes, while seemingly allowing for greater capacity, can increase material costs and create unnecessary complexity in the system. Accurate sizing requires considering:

- Fluid viscosity: Thicker fluids require larger pipes to maintain adequate flow.

- Flow rate: The desired volume of fluid to be transported per unit time dictates the pipe diameter.

- Pressure drop: Calculations must account for frictional losses along the pipe’s length.

- Pipe roughness: Internal pipe roughness affects friction and pressure drop.

Utilizing specialized software or consulting with experienced engineers ensures optimal pipe sizing for your specific application, maximizing efficiency and minimizing energy consumption.

3. Pressure Ratings and Safety Considerations: Protecting Personnel and Equipment

Industrial pipes operate under varying pressure conditions. Selecting pipes with adequate pressure ratings is critical for safety and preventing catastrophic failures. Pressure ratings are typically expressed in pounds per square inch (PSI) or bars. Factors influencing pressure rating selection include:

- Operating pressure: The maximum pressure expected during normal operation.

- Safety factor: An additional margin added to account for unforeseen pressure surges or fluctuations.

- Temperature: Higher temperatures can reduce the pipe’s pressure capacity.

- Pipe material: Different materials have different pressure tolerances.

Always choose pipes with a pressure rating significantly exceeding the expected operating pressure, ensuring a substantial safety margin. Regular inspections and pressure testing are also essential for maintaining safety and identifying potential issues.

4. Pipe Fittings and Connections: Ensuring Seamless Integration and Leak Prevention

Pipe fittings are essential components that connect pipes, change direction, control flow, and facilitate maintenance. Choosing the right fittings is crucial for ensuring a leak-free and robust piping system. Common fittings include:

- Elbows: Change the direction of the pipe.

- Tees: Create branching points in the piping system.

- Unions: Allow for easy pipe disassembly and maintenance.

- Valves: Control the flow of fluids.

- Flanges: Provide a robust connection between pipes.

The selection of fittings should align with the pipe material and pressure rating to ensure compatibility and prevent leaks. Proper installation techniques are equally crucial for maintaining system integrity.

5. Cost Optimization and Lifecycle Management: Balancing Initial Investment with Long-Term Savings

While initial cost is a consideration, focusing solely on the cheapest option can be shortsighted. A poorly chosen piping system can lead to frequent repairs, replacements, and production downtime, escalating costs significantly over the long run. A lifecycle cost analysis should consider:

- Initial purchase price: The upfront cost of the pipes and fittings.

- Installation costs: Labor and material costs associated with installation.

- Maintenance costs: Costs associated with regular inspections, repairs, and replacements.

- Downtime costs: Production losses due to system failures.

- Energy costs: Energy consumption associated with pumping fluids through the system.

By considering all these factors, businesses can make informed decisions that optimize both initial investment and long-term operational efficiency.

Choosing the right industrial pipes is a crucial decision with significant implications for manufacturing operations. By carefully considering the factors outlined above, manufacturers can ensure a safe, efficient, and cost-effective piping system that supports their production goals for years to come.

SEO Tags:

- Industrial Pipes

- Manufacturing Piping Systems

- Pipe Material Selection

- Industrial Pipe Sizing

- Pressure Rated Pipes

Superalloy steels are a class of high-performance materials renowned for their exceptional strength, resistance to corrosion and oxidation, and ability to withstand extreme temperatures. These remarkable properties make them indispensable in a wide range of demanding applications across various industries. This blog post delves into the fascinating world of superalloy steels, exploring their key characteristics and showcasing their diverse applications.

1. Aerospace: Reaching for the Stars with Superalloys

The aerospace industry is arguably the largest consumer of superalloy steels. These alloys are critical components in jet engines, where temperatures soar to thousands of degrees Fahrenheit. Turbine blades, combustor casings, and other critical parts require materials that can withstand these extreme conditions without compromising performance or structural integrity. Nickel-based superalloys, in particular, are favored due to their excellent high-temperature strength, creep resistance (resistance to deformation under sustained stress), and oxidation resistance. The demand for lighter, more fuel-efficient aircraft continues to drive innovation in superalloy development, with researchers constantly striving to create alloys with even better performance at higher temperatures.

Beyond jet engines, superalloys also find applications in rocket engines, spacecraft components, and other high-stress, high-temperature environments within the aerospace sector. Their ability to maintain strength and stability even under extreme pressure differentials is crucial for the safe and reliable operation of these systems.

2. Power Generation: Fueling Efficiency and Reliability

The energy sector relies heavily on superalloys for efficient and reliable power generation. Gas turbines, used in both power plants and industrial applications, operate at incredibly high temperatures, requiring materials capable of withstanding significant thermal stresses. Superalloys are essential for the construction of turbine blades, disks, and casings, ensuring long operational life and minimizing downtime. Their resistance to corrosion from combustion byproducts also extends the lifespan of these critical components.

Furthermore, superalloys are increasingly employed in advanced nuclear power systems. Their resistance to radiation damage and high-temperature creep makes them suitable for components within nuclear reactors, contributing to the safety and longevity of these power sources. The ongoing development of advanced nuclear technologies further fuels the demand for improved superalloy materials.

3. Chemical Processing: Withstanding Harsh Environments

The chemical processing industry often deals with highly corrosive substances and extreme temperatures. Superalloys, particularly those with enhanced corrosion resistance, are crucial in various applications within this sector. They are used in the construction of reactors, heat exchangers, and other components that come into contact with aggressive chemicals and high-temperature processes. The ability of superalloys to resist degradation in harsh environments ensures the safety and efficiency of chemical plants, minimizing the risk of equipment failure and environmental contamination.

Specific alloy compositions are tailored to withstand specific chemical environments. For instance, alloys with high molybdenum content offer excellent resistance to chloride-induced corrosion, while others with added chromium provide enhanced oxidation resistance at elevated temperatures.

4. Medical Implants: A Vital Role in Healthcare

While less common than in industrial applications, superalloys also play a crucial role in the medical field. Their biocompatibility and high strength make them suitable for certain types of medical implants, particularly those requiring high durability and resistance to wear. For example, some specialized superalloys are used in orthopedic implants, such as hip and knee replacements, where the implant must endure significant stress and remain stable over long periods.

Ongoing research focuses on enhancing the biocompatibility of superalloys to minimize the risk of adverse reactions and improve the longevity of these life-enhancing implants. The unique properties of superalloys make them a promising material for future advancements in medical implant technology.

5. Automotive and Industrial Applications: Beyond the High-Profile Sectors

Although less prominent than aerospace and power generation, superalloys also find niche applications within the automotive and broader industrial sectors. High-performance engines in racing cars and specialized vehicles may utilize superalloys for components requiring extreme durability and high-temperature resistance. In industrial settings, superalloys can be found in specialized machinery, such as high-temperature furnaces and processing equipment, where their strength and resistance to harsh conditions are invaluable.

The increasing demand for efficiency and performance across various industrial applications is driving further research and development in superalloy technology, leading to the discovery of new alloys and expanded applications across a wider range of industries.

In conclusion, superalloy steels are vital materials driving innovation across multiple sectors. Their unique combination of properties makes them essential for applications demanding exceptional performance under extreme conditions. As technology continues to advance, the role of superalloys in shaping the future of various industries is only set to grow.

SEO Tags:

- Superalloy Steel

- Superalloy Applications

- High-Temperature Alloys

- Nickel Superalloys

- Corrosion Resistant Steel

Shot blasting is a powerful surface treatment technique used to clean, deburr, and prepare a wide range of materials for further processing. This comprehensive guide delves into the intricacies of this industrial process, explaining its mechanics, applications, and safety considerations.

Understanding the Shot Blasting Process: A Step-by-Step Breakdown

Shot blasting involves propelling a stream of abrasive media, typically small metallic or non-metallic shot, at high velocity onto a workpiece’s surface. This high-impact process removes contaminants like rust, scale, paint, and other surface imperfections. The process typically involves these steps:

- Workpiece Preparation: The item to be treated is positioned within the shot blasting cabinet or on a conveyor system, ensuring proper access for the abrasive media.

- Media Acceleration: A centrifugal wheel or pressure vessel accelerates the abrasive media to high speed.

- Impact and Cleaning: The high-velocity media stream impacts the workpiece’s surface, removing contaminants and creating a uniform surface profile.

- Media Separation: After impacting the workpiece, the abrasive media is separated from the debris and recycled for reuse.

- Post-Processing: Depending on the application, additional steps like painting or further surface treatment may follow.

Types of Shot Blasting Equipment: Choosing the Right Tool for the Job

Several types of shot blasting equipment cater to different needs and scales of operation. These include:

- Wheel Blast Machines: These utilize a rotating impeller to accelerate the abrasive media, offering high cleaning intensity and are suitable for larger workpieces.

- Air Blast Machines: Compressed air propels the abrasive media, providing greater control and precision, ideal for intricate parts and delicate surfaces.

- Cabinet Blast Machines: Enclosed cabinets protect the operator from the abrasive media and dust, perfect for smaller components.

- Automated Systems: These systems integrate shot blasting into automated production lines, increasing efficiency and throughput.

- Mobile Shot Blasting Units: Portable units provide on-site cleaning and surface preparation in locations where transporting large items isn’t feasible.

Selecting the right equipment depends on factors like workpiece size, material, desired surface finish, and budget.

Applications of Shot Blasting: A Wide Range of Industries

Shot blasting finds extensive applications across diverse industries, including:

- Automotive: Cleaning and preparing car bodies for painting.

- Aerospace: Cleaning and preparing aircraft components.

- Construction: Cleaning and preparing steel structures.

- Manufacturing: Deburring and surface finishing of various components.

- Marine: Cleaning and preparing ship hulls and other marine structures.

- Metal Fabrication: Removing mill scale, rust, and other imperfections from metal parts.

The versatility of shot blasting makes it an indispensable process in many manufacturing and industrial settings.

Benefits of Shot Blasting: Efficiency and Quality Enhancement

Shot blasting offers several key advantages over other surface treatment methods:

- Increased Surface Area: The process creates a roughened surface, improving the adhesion of coatings like paint or powder.

- Enhanced Durability: By removing surface imperfections, shot blasting extends the lifespan of treated parts.

- Improved Corrosion Resistance: A clean, uniform surface is less susceptible to rust and corrosion.

- Cost-Effectiveness: While initial investment might be significant, the process’s efficiency and reduced rework often lead to long-term cost savings.

- High-Quality Finish: Shot blasting produces a consistent and uniform surface finish, crucial for aesthetic and functional requirements.

Safety Precautions in Shot Blasting: Protecting Workers and Equipment

Shot blasting presents potential hazards if proper safety measures aren’t implemented. Crucial safety precautions include:

- Personal Protective Equipment (PPE): Operators must wear appropriate PPE, including safety glasses, respirators, hearing protection, and protective clothing.

- Enclosure and Containment: Shot blasting should be performed in enclosed cabinets or areas with effective dust collection systems.

- Regular Maintenance: Regular maintenance of the equipment is crucial to prevent malfunctions and ensure safe operation.

- Training and Supervision: Operators must receive proper training on safe operating procedures and emergency response protocols.

- Regular Inspections: Regular inspections of the equipment and work area are essential to identify and address potential hazards.

Adhering to stringent safety protocols is paramount to prevent injuries and ensure a safe working environment.

Shot blasting is a powerful and versatile surface treatment technique offering numerous benefits. By understanding the process, equipment, applications, and safety precautions, industries can leverage its capabilities to improve efficiency, enhance product quality, and ensure workplace safety.

Implementing an ISO 9001 quality management system (QMS) can seem daunting, but the benefits – increased efficiency, improved customer satisfaction, and enhanced competitive advantage – are undeniable. This post delves into a real-world scenario, showcasing how a robust ISO 9001 system operates and delivers tangible results.

1. Understanding the Foundation: Defining Scope and Objectives

Before embarking on ISO 9001 implementation, clearly defining the scope is paramount. This involves identifying the specific processes, products, and services the QMS will cover. For example, a manufacturing company might include its design, production, and distribution processes, while a software company might focus on development, testing, and customer support. Defining objectives is equally crucial. These objectives should be SMART (Specific, Measurable, Achievable, Relevant, and Time-bound). Instead of a vague goal like “improve quality,” a SMART objective might be “reduce customer complaints by 15% within six months of QMS implementation.” This clarity ensures everyone understands the goals and how success will be measured. A comprehensive gap analysis comparing current practices against ISO 9001 requirements is also essential at this stage, highlighting areas needing improvement.

2. Process Mapping and Documentation: The Backbone of the System

Once the scope and objectives are defined, the next step involves meticulous process mapping. This involves visually representing each process within the defined scope, outlining inputs, outputs, responsibilities, and key performance indicators (KPIs). Documentation is the heart of an ISO 9001 QMS. This includes documented procedures, work instructions, forms, and records that provide clear guidance on how each process should be executed. For instance, a documented procedure might outline the steps involved in handling customer complaints, ensuring consistency and traceability. Effective documentation also facilitates training, ensuring all employees understand their roles and responsibilities within the QMS. Regular review and updates of these documents are crucial to maintain their relevance and effectiveness.

3. Internal Audits and Management Review: Continuous Improvement in Action

Internal audits are a critical component of the ISO 9001 framework. These audits are conducted by trained internal auditors to assess the effectiveness of the QMS against the established procedures and ISO 9001 requirements. They identify areas of non-compliance, potential improvements, and opportunities for optimization. The findings are documented and corrective actions are implemented to address identified gaps. Management review is another vital process. This involves regular meetings of the management team to review the performance of the QMS, assess the effectiveness of implemented corrective actions, and plan for future improvements. Data from internal audits, customer feedback, and key performance indicators are reviewed to identify trends and areas requiring attention. This iterative process ensures continuous improvement and adaptation of the QMS to changing business needs.

4. Customer Focus and Feedback: The Driving Force for Excellence

ISO 9001 emphasizes a strong customer focus. Understanding customer needs and expectations is fundamental to providing high-quality products and services. This involves actively soliciting customer feedback through surveys, feedback forms, and direct communication. Analyzing customer feedback provides valuable insights into areas requiring improvement and helps tailor products and services to better meet customer expectations. A robust system for managing customer complaints and addressing their concerns is essential. This ensures timely resolution and demonstrates a commitment to customer satisfaction. Customer satisfaction is not just a goal; it’s a continuous process requiring ongoing monitoring and improvement.

5. Sustaining the System: Ongoing Training and Maintenance

Implementing an ISO 9001 QMS is not a one-time event; it requires ongoing maintenance and improvement. Regular training is crucial to ensure all employees understand the QMS, their roles and responsibilities, and the importance of adhering to established procedures. This training should be tailored to the specific needs of each role and updated as the QMS evolves. The system itself needs regular review and updates to ensure it remains effective and relevant. This involves monitoring key performance indicators, analyzing data, and making necessary adjustments to processes and procedures. Regular internal audits and management reviews play a vital role in maintaining the effectiveness and integrity of the QMS, ensuring it continues to deliver value to the organization and its customers.

By implementing and maintaining a robust ISO 9001 QMS, organizations can significantly enhance their operational efficiency, improve customer satisfaction, and gain a competitive edge in the marketplace. The journey may require effort and commitment, but the rewards are substantial and long-lasting.

SEO-Friendly Tags:

- ISO 9001 Implementation

- Quality Management System

- ISO 9001 Certification

- Process Improvement

- Business Excellence

The steel sector, a cornerstone of global infrastructure and manufacturing, presents both immense opportunities and significant challenges for new entrants. Navigating this complex landscape requires a well-defined market entry strategy, tailored to specific market conditions and the company’s capabilities. This comprehensive guide explores various strategies, helping you forge a path to success in the steel industry.

1. Understanding the Global Steel Market Landscape

Before formulating any strategy, thorough market research is paramount. This involves analyzing global steel demand and supply dynamics, identifying key players and their market share, understanding regional variations in steel consumption, and assessing prevailing trade policies and regulations. Factors like infrastructure development, automotive production, construction activity, and government policies significantly influence steel demand. Identifying niche markets with less competition can be a strategic advantage. For example, focusing on specialized steel grades for aerospace or medical applications can offer higher profit margins compared to competing in the mass market for standard steel products. A deep understanding of the competitive landscape, including pricing strategies, production capacities, and technological advancements of existing players, is crucial for successful market entry.

2. Choosing the Right Market Entry Mode: Exporting vs. FDI

The choice between exporting and Foreign Direct Investment (FDI) depends on several factors. Exporting is a lower-risk, lower-investment approach, suitable for companies with limited resources or those testing the waters in a new market. However, it involves higher transportation costs, potential trade barriers (tariffs, quotas), and longer lead times. FDI, on the other hand, involves setting up a manufacturing facility or acquiring an existing steel company in the target market. While higher in risk and capital investment, FDI offers greater control over the production process, potentially lower transportation costs, and closer proximity to customers. The decision also hinges on factors such as the target market’s size, regulatory environment, infrastructure, and the company’s long-term strategic goals. Joint ventures can offer a middle ground, combining the expertise and resources of local and international partners.

3. Navigating Regulatory Hurdles and Trade Policies

The steel industry is heavily regulated, with numerous trade policies impacting imports and exports. Understanding anti-dumping duties, safeguard measures, and other trade barriers is crucial. Compliance with environmental regulations, labor laws, and safety standards is also paramount. Thorough due diligence and legal counsel are essential to ensure compliance and avoid potential penalties. This involves researching specific regulations in the target market, establishing robust compliance systems, and building relationships with relevant government agencies. Proactive engagement with regulatory bodies can help mitigate potential conflicts and facilitate a smoother market entry process. Furthermore, understanding trade agreements and their implications on tariffs and quotas can significantly impact the viability of different market entry strategies.

4. Building Strategic Partnerships and Supply Chains

Establishing strong relationships with local distributors, suppliers, and other stakeholders is vital for success. Strategic partnerships can provide access to local markets, distribution networks, and expertise. For example, collaborating with a local steel distributor can significantly reduce the time and cost associated with market penetration. A well-structured supply chain is also crucial, ensuring a consistent supply of raw materials and efficient logistics. This might involve establishing long-term contracts with suppliers, optimizing transportation routes, and implementing inventory management systems. Understanding local business culture and building trust with partners are equally important for successful collaboration and long-term sustainability in the market.

5. Leveraging Technology and Innovation for Competitive Advantage

The steel industry is undergoing significant technological transformation, with advancements in automation, robotics, and data analytics improving efficiency and productivity. Adopting advanced technologies can offer a significant competitive advantage, enabling companies to produce higher-quality steel at lower costs. This includes investing in advanced manufacturing processes, implementing sophisticated quality control systems, and leveraging data analytics for predictive maintenance and optimized production scheduling. Furthermore, investing in research and development to create innovative steel products with enhanced properties (e.g., high-strength low-alloy steels) can open new market opportunities and command premium prices. Staying abreast of technological advancements and incorporating them into the business model is crucial for long-term competitiveness in the dynamic steel sector.

Entering the steel sector requires a well-defined strategy, meticulous planning, and adaptability. By carefully considering the factors discussed above and tailoring the approach to specific market conditions, companies can significantly increase their chances of success in this challenging yet rewarding industry.

SEO-Friendly Tags:

- Steel Market Entry Strategy

- Steel Industry Investment

- Global Steel Market Analysis

- Steel Export and Import Strategies

- Steel Manufacturing Business Plan

body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

h1 {

font-size: 2.5em;

}

h2 {

font-size: 2em;

}

h3 {

font-size: 1.5em;

}

Industrial machinery relies heavily on a robust and efficient piping system. Often overlooked, these pipes are the circulatory system of the machine, transporting vital fluids, gases, and slurries that power processes and ensure smooth operation. Understanding the nuances of industrial pipe usage is crucial for safety, efficiency, and longevity of any industrial operation. This comprehensive guide explores the key aspects of pipe usage in industrial machinery.

Material Selection: Choosing the Right Pipe for the Job

The selection of pipe material is paramount and depends heavily on the fluid being transported, the operating pressure and temperature, and the surrounding environment. Common materials include:

- Carbon Steel: A versatile and cost-effective option for many applications, particularly for transporting water, steam, and oil at moderate pressures and temperatures. However, it’s susceptible to corrosion, requiring protective coatings or more resistant alloys in corrosive environments.

- Stainless Steel: Offers superior corrosion resistance, making it ideal for handling chemicals, acidic substances, and high-purity fluids. Different grades of stainless steel (e.g., 304, 316) provide varying degrees of corrosion resistance and strength.

- Cast Iron: Used for applications requiring high pressure and temperature resistance, though its brittleness makes it susceptible to damage from impact. Often used in older systems but is gradually being replaced by more modern materials.

- Copper: Excellent thermal conductivity, making it suitable for heat transfer applications. It’s also resistant to corrosion but can be expensive.

- PVC and other Plastics: Lightweight and corrosion-resistant, these are suitable for low-pressure applications and handling chemicals incompatible with metals. However, they have temperature limitations and lower pressure ratings compared to metallic pipes.

Careful consideration of material compatibility with the transported fluid is essential to prevent leaks, corrosion, and contamination.

Design Considerations: Ensuring Optimal Performance and Safety

Proper pipe design is crucial for ensuring efficient fluid transport and preventing failures. Key design considerations include:

- Pipe Diameter and Length: These factors influence flow rate and pressure drop. Incorrect sizing can lead to inefficient operation or excessive pressure build-up.

- Pipe Fittings and Valves: Elbows, tees, flanges, and valves must be correctly selected and installed to minimize pressure loss and ensure proper fluid control. The material compatibility of fittings with the pipe material is crucial.

- Support Structures: Pipes must be adequately supported to prevent sagging, vibration, and potential damage. Support structures need to be designed to handle the weight of the pipe and the fluid it contains, especially at high pressures.

- Expansion Joints: These accommodate thermal expansion and contraction, preventing stress on the pipe system due to temperature fluctuations.

- Pressure Ratings: Pipes and fittings must be selected with pressure ratings exceeding the maximum operating pressure to ensure safety.

Detailed engineering calculations and adherence to industry standards are essential in pipe design to ensure a safe and efficient system.

Safety Protocols: Minimizing Risks in Industrial Piping Systems

Industrial piping systems pose potential hazards, including high pressure, hazardous fluids, and potential leaks. Stringent safety protocols are essential to mitigate these risks:

- Regular Inspections: Routine visual inspections and pressure testing should be carried out to detect leaks, corrosion, or damage.

- Proper Isolation and Lockout/Tagout Procedures: Before any maintenance or repair work, the pipe section must be properly isolated and locked out to prevent accidental release of fluids or activation of equipment.

- Personal Protective Equipment (PPE): Workers handling industrial piping systems must wear appropriate PPE, including safety glasses, gloves, and protective clothing, depending on the fluid being handled.

- Emergency Shutdown Systems: Systems should be equipped with emergency shutdown mechanisms to quickly isolate sections of the piping system in case of leaks or other emergencies.

- Training and Competency: Personnel working with industrial piping systems should receive adequate training on safety procedures and emergency response.

A comprehensive safety program is crucial to prevent accidents and protect workers.

Maintenance and Repair: Ensuring System Longevity

Regular maintenance is vital to ensure the long-term performance and safety of industrial piping systems. This includes:

- Cleaning and Flushing: Periodically cleaning and flushing the pipes to remove sediment, scale, and other contaminants helps maintain efficiency and prevent blockages.

- Corrosion Protection: Applying protective coatings or using corrosion-resistant materials can significantly extend the lifespan of the piping system.

- Leak Detection and Repair: Promptly addressing leaks is crucial to prevent further damage and environmental hazards. Leak detection methods can range from visual inspections to sophisticated leak detection technologies.

- Valve Maintenance: Regular inspection and lubrication of valves ensure proper operation and prevent leaks.

- Scheduled Inspections and Testing: Implementing a preventative maintenance schedule with regular inspections and pressure testing helps identify potential problems before they become major issues.

A proactive maintenance approach significantly reduces the risk of failures and extends the lifespan of the piping system.

Common Applications of Industrial Piping in Machinery

Industrial piping systems are integral to a wide range of machinery and processes:

- Chemical Processing: Transporting various chemicals and solvents.

- Oil and Gas Refineries: Handling crude oil, refined products, and gases.

- Power Generation: Transporting steam, water, and other fluids in power plants.

- Food and Beverage Processing: Transporting fluids and ingredients in food processing plants.

- Pharmaceutical Manufacturing: Handling sterile fluids and chemicals in pharmaceutical production.

- HVAC Systems: Distributing heating and cooling fluids in buildings and industrial facilities.

The specific requirements of the piping system will vary greatly depending on the application, emphasizing the need for careful design and material selection.

In conclusion, the seemingly simple pipe plays a critical role in the performance and safety of industrial machinery. Understanding material selection, design considerations, safety protocols, and maintenance practices is essential for ensuring efficient and safe operation. By prioritizing these aspects, industries can maximize the lifespan and productivity of their equipment while minimizing risks.

Tags: industrial pipes, pipe usage, machinery pipes, pipe design, industrial pipe maintenance

body { font-family: sans-serif; line-height: 1.6; }

h1, h2, h3 { color: #333; }

img { max-width: 100%; height: auto; }

The world of engineering materials is constantly evolving, driven by the need for stronger, lighter, and more durable components. In this quest for innovation, carbon fiber-coated steel pipes have emerged as a powerful solution, combining the best properties of both materials. This comprehensive guide delves into the fascinating world of these composite pipes, exploring their unique characteristics, applications, manufacturing processes, and the future they hold.

The Synergistic Marriage of Steel and Carbon Fiber

Steel pipes have long been a mainstay in various industries due to their strength and relatively low cost. However, steel’s limitations, such as susceptibility to corrosion and relatively high weight, have spurred the search for improvements. Carbon fiber, on the other hand, boasts exceptional strength-to-weight ratio, high tensile strength, and excellent corrosion resistance. By combining these two materials, carbon fiber-coated steel pipes leverage the inherent strengths of each, resulting in a superior product. The steel core provides the necessary compressive strength and bulk, while the carbon fiber coating significantly enhances tensile strength, fatigue resistance, and corrosion protection. This synergistic combination leads to pipes that are both robust and lightweight, opening up a range of new applications.

Manufacturing Processes: Precision and Innovation

The manufacturing process of carbon fiber-coated steel pipes is a complex yet precise operation. Several methods are employed, each with its own advantages and disadvantages. One common technique involves winding continuous carbon fiber strands around a prepared steel pipe. This process often utilizes a resin system to bind the fibers together, creating a strong and durable composite layer. The precise control of fiber orientation and resin application is crucial for achieving optimal mechanical properties. Other methods include prepreg techniques, where pre-impregnated carbon fiber sheets are wrapped around the steel pipe and cured in an autoclave, and filament winding processes that offer superior control over fiber placement for specific load requirements. The choice of manufacturing method depends on factors such as pipe diameter, desired properties, and production volume.

Applications Across Diverse Industries

The exceptional properties of carbon fiber-coated steel pipes have led to their adoption across a wide array of industries. In the oil and gas sector, these pipes are increasingly used for transporting high-pressure fluids and gases, offering superior resistance to corrosion and pressure fluctuations compared to traditional steel pipes. The aerospace industry utilizes them in various aircraft components, where weight reduction is critical for fuel efficiency. The automotive industry is exploring their use in high-performance vehicles, improving structural integrity and reducing weight. Furthermore, these pipes find applications in civil engineering projects, such as bridges and buildings, where their strength and durability are invaluable. Even the renewable energy sector benefits, using them in wind turbine structures and geothermal energy systems.

Advantages Over Traditional Steel Pipes: A Comparative Analysis

Compared to traditional steel pipes, carbon fiber-coated steel pipes offer several significant advantages. Firstly, their superior strength-to-weight ratio leads to significant weight savings, reducing transportation costs and improving structural efficiency. Secondly, the carbon fiber coating provides exceptional corrosion resistance, extending the lifespan of the pipes, especially in harsh environments. Thirdly, the increased fatigue resistance minimizes the risk of failure under cyclic loading conditions. Fourthly, their enhanced stiffness improves the overall stability and performance of structures in which they are incorporated. While the initial cost of carbon fiber-coated steel pipes may be higher than that of traditional steel pipes, the long-term cost savings due to increased lifespan and reduced maintenance outweigh the initial investment in many applications.

Future Trends and Innovations: Shaping the Next Generation

The future of carbon fiber-coated steel pipes looks bright. Ongoing research and development efforts are focused on improving the manufacturing processes to enhance efficiency and reduce costs. New resin systems are being developed to further enhance the performance characteristics of the composite material, including improved impact resistance and temperature tolerance. The integration of smart sensors within the pipe walls is also being explored, allowing for real-time monitoring of pressure, temperature, and other critical parameters, enabling predictive maintenance and preventing potential failures. Furthermore, research into sustainable and recyclable carbon fiber materials is crucial for reducing the environmental impact of this technology. As these advancements continue, carbon fiber-coated steel pipes are poised to play an even greater role in various industries, driving innovation and enhancing performance across diverse applications.

In conclusion, carbon fiber-coated steel pipes represent a significant advancement in material science, offering a compelling blend of strength, durability, and lightweight properties. Their versatility and performance advantages are transforming industries and paving the way for a more efficient and sustainable future.

SEO Tags: Carbon Fiber Pipes, Steel Pipes, Composite Pipes, Carbon Fiber-Reinforced Steel, Material Science

body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

code {

background-color: #f0f0f0;

padding: 2px 4px;

border-radius: 4px;

}

Steel structures are ubiquitous in modern construction, from towering skyscrapers to intricate bridges. Their strength and durability are a testament to meticulous engineering and precise calculations. This post delves into the intricacies of strength calculations in steel structures, providing a comprehensive overview for engineers and students alike.

Understanding Material Properties of Steel

The foundation of any steel structure calculation lies in understanding the material properties of the steel itself. These properties, typically obtained from material test reports or design codes, are crucial for accurate estimations. Key properties include:

- Yield Strength (fy): The stress at which the steel begins to deform plastically. This is a critical parameter in determining the allowable stress.

- Ultimate Tensile Strength (fu): The maximum stress the steel can withstand before failure. Used for ultimate limit state design.

- Young’s Modulus (E): A measure of the steel’s stiffness, representing its resistance to elastic deformation. Essential for elastic analysis.

- Poisson’s Ratio (ν): The ratio of lateral strain to axial strain. Used in more complex stress analyses.

Design codes, such as AISC (American Institute of Steel Construction) or Eurocode 3, provide standardized values for these properties, categorized by steel grade.

Load Determination and Classification

Accurately determining the loads acting on a steel structure is paramount. Loads are broadly classified into:

- Dead Loads: The self-weight of the structure and permanent fixtures.

- Live Loads: Variable loads, such as occupancy loads, snow loads, and wind loads. These require careful consideration of relevant building codes and local climate data.

- Environmental Loads: Include snow, wind, seismic, and temperature effects. Their magnitude depends on geographical location and structural characteristics.

- Impact Loads: Sudden, dynamic loads, such as those from machinery or vehicular traffic. These require dynamic analysis methods.

Load combinations, as specified in design codes, must be considered to ensure the structure can safely withstand various load scenarios. Load factors are applied to account for uncertainties in load estimation.

Stress and Strain Analysis Techniques

Once loads are determined, the next step involves analyzing the resulting stresses and strains within the steel members. Common methods include:

- Simple Bending Theory: Used for beams subjected to bending moments. Calculates bending stress using the bending moment and section modulus.

- Shear Stress Calculation: Determines shear stress in beams due to transverse shear forces. The shear stress distribution depends on the cross-sectional shape.

- Finite Element Analysis (FEA): A powerful numerical method used for complex structures and load cases. FEA software can accurately model stress and strain distributions.

- Direct Stress Calculation: Used for axially loaded members (tension or compression). Stress is calculated by dividing the axial force by the cross-sectional area.

The choice of analysis method depends on the complexity of the structure and the required accuracy.

Design Codes and Allowable Stresses

Design codes provide a framework for ensuring the safety and serviceability of steel structures. These codes specify allowable stresses, which are based on the yield strength of the steel and safety factors. Examples include:

- AISC 360 (American Institute of Steel Construction): Widely used in North America.

- Eurocode 3: The European standard for the design of steel structures.

- AS 4100 (Australia/New Zealand): The standard for Australia and New Zealand.

These codes define allowable stresses for various load combinations and member types. Designers must ensure that the calculated stresses in the structure remain below these allowable limits.

Practical Applications and Case Studies

The principles discussed above are applied to a wide range of steel structures. For instance, designing a simple beam involves calculating bending moments and shear forces, determining the required section modulus, and selecting a suitable steel section from readily available catalogs. More complex structures, like high-rise buildings or bridges, necessitate advanced analysis techniques, such as FEA, to account for complex load paths and structural interactions. Case studies involving specific structures can illustrate the practical application of these calculation methods and highlight the importance of accurate load estimations and material property considerations.

Furthermore, understanding the limitations of simple calculations and when more advanced methods are necessary is crucial. For example, while simple bending theory is suitable for many beam designs, it may not accurately capture the stress distribution in complex geometries or under dynamic loading conditions.

Mastering strength calculations in steel structures requires a solid understanding of material science, structural mechanics, and design codes. By combining theoretical knowledge with practical experience, engineers can ensure the safety and reliability of steel structures for generations to come.

SEO-Friendly Tags:

- Steel Structure Design

- Structural Steel Calculations

- Steel Member Strength

- Load Calculation in Steel Structures

- AISC Steel Design