body {

font-family: sans-serif;

line-height: 1.6;

}

img {

max-width: 100%;

height: auto;

display: block;

margin: 20px auto;

}

h1, h2 {

text-align: center;

}

1. Skyscrapers and Architectural Marvels: Steel’s Role in Construction

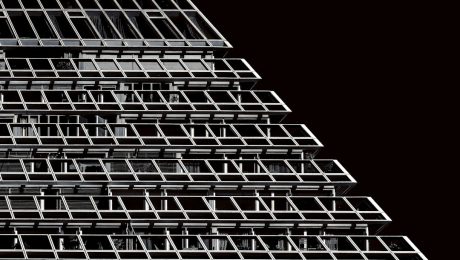

Steel’s high strength-to-weight ratio makes it the backbone of modern architecture. From the iconic Empire State Building to the futuristic Burj Khalifa, steel’s ability to support immense weight and withstand extreme forces is unparalleled. Its use in high-rise construction allows for taller, more slender designs, maximizing space and minimizing land usage. The images below showcase the intricate steel frameworks that form the foundation of these architectural wonders. The use of advanced steel alloys further enhances durability and resistance to corrosion, ensuring the longevity of these structures. Furthermore, steel’s versatility allows for intricate designs, enabling architects to create visually stunning and functional buildings. Prefabricated steel components also expedite construction, reducing project timelines and costs. [Insert image of a skyscraper’s steel framework]. [Insert image of a modern architectural building with visible steel elements].

2. Bridges that Span Generations: Steel’s Contribution to Infrastructure

Steel’s strength and durability are crucial in bridge construction. Whether it’s a graceful suspension bridge spanning a vast waterway or a sturdy cantilever bridge traversing a rugged landscape, steel provides the necessary structural integrity. Its ability to be easily shaped and welded allows for complex designs, optimizing load distribution and ensuring structural stability under various stress conditions. [Insert image of a suspension bridge]. [Insert image of a modern steel bridge with intricate design]. The longevity of steel bridges is evident in many structures that have stood the test of time, demonstrating the material’s resilience and lasting impact on infrastructure development. Modern advancements in steel alloys and protective coatings enhance corrosion resistance, extending the lifespan of these vital transportation arteries. Moreover, prefabricated steel components streamline the construction process, minimizing disruption and ensuring timely completion of these critical projects.

3. Manufacturing and Industry: Steel’s Indispensable Role

Steel’s versatility extends beyond construction into numerous manufacturing processes. From automotive parts and machinery to appliances and tools, steel’s strength, malleability, and durability make it an indispensable material. Its ability to be easily formed, cut, and welded makes it ideal for mass production techniques. [Insert image of a car chassis]. [Insert image of industrial machinery with steel components]. The use of different steel grades allows manufacturers to tailor the material’s properties to specific applications, optimizing performance and cost-effectiveness. The image below showcases the precision and intricacy possible with steel in high-tech manufacturing. [Insert image of a precision-engineered steel component]. Steel’s strength ensures the reliability and safety of countless products we use daily.

4. Transportation and Logistics: Steel’s Impact on Mobility

The transportation industry relies heavily on steel. From the bodies of vehicles and trains to the tracks they run on and the ships that carry goods across oceans, steel plays a vital role. Its strength, durability, and weldability are essential for creating safe and reliable transportation systems. [Insert image of a train]. [Insert image of a cargo ship]. Steel’s ability to withstand impact and wear makes it perfect for applications where safety is paramount. Advanced steel alloys with enhanced strength-to-weight ratios are increasingly being used to improve fuel efficiency in vehicles and reduce the overall weight of transportation infrastructure. This contributes to environmental sustainability and economic efficiency within the logistics sector. [Insert image of a modern steel railway track].

5. Beyond the Obvious: Unexpected Applications of Steel

Steel’s applications are far-reaching and often surprising. Its use extends to medical devices, where its biocompatibility and strength are utilized in implants and surgical tools. It is also found in renewable energy infrastructure, such as wind turbine towers and solar panel supports. [Insert image of a wind turbine]. [Insert image of steel used in medical equipment]. Steel’s ability to be recycled endlessly further highlights its sustainability. The continuous development of new steel alloys with enhanced properties continues to expand its applications, pushing the boundaries of innovation across various industries. [Insert image of recycled steel]. These innovative uses showcase steel’s adaptability and enduring importance in a constantly evolving technological landscape.

This visual gallery only scratches the surface of steel’s widespread applications. Its versatility, strength, and sustainability make it a cornerstone of modern society, and its continued innovation ensures its vital role for generations to come.

SEO Tags:

steel applications, steel uses, steel construction, industrial steel, sustainable steel

In today’s complex global supply chains, ensuring product traceability is no longer a luxury but a necessity. From enhancing quality control to managing recalls efficiently and bolstering brand reputation, a robust traceability system is paramount for modern manufacturers. This comprehensive guide delves into the intricacies of product traceability, exploring its benefits, implementation strategies, challenges, and future trends.

What is Product Traceability in Manufacturing?

Product traceability, in the manufacturing context, refers to the ability to track a product’s journey throughout its entire lifecycle. This encompasses all stages, from raw material sourcing and processing to manufacturing, packaging, distribution, and finally, to the end consumer. Effective traceability involves recording and maintaining detailed information about each product’s origin, handling, and transformations. This information is crucial for various aspects of the business, including quality control, regulatory compliance, and supply chain management.

Imagine a scenario where a batch of faulty products is discovered. With a robust traceability system, manufacturers can quickly identify the source of the defect, isolate the affected products, and prevent further distribution. This minimizes financial losses, protects brand reputation, and prevents potential harm to consumers. Conversely, without proper traceability, pinpointing the problem can be a lengthy and costly process, potentially impacting the entire business.

Benefits of Implementing a Traceability System

The advantages of implementing a comprehensive product traceability system are multifaceted and far-reaching. Here are some key benefits:

- Enhanced Quality Control: Traceability allows for rapid identification and isolation of defective products, minimizing waste and improving overall product quality.

- Efficient Recall Management: In the event of a product recall, traceability significantly streamlines the process, reducing the time and cost associated with identifying and retrieving affected products.

- Improved Supply Chain Transparency: Traceability provides a clear picture of the entire supply chain, enhancing visibility and allowing for better management of risks and inefficiencies.

- Strengthened Brand Reputation: Demonstrating a commitment to product safety and transparency builds consumer trust and strengthens brand loyalty.

- Regulatory Compliance: Many industries are subject to strict regulations regarding product traceability. A robust system ensures compliance, avoiding potential penalties and legal issues.

- Reduced Waste and Costs: By identifying and addressing quality issues early in the process, traceability minimizes waste and reduces overall production costs.

- Improved Inventory Management: Real-time tracking of products throughout the supply chain enhances inventory management, optimizing stock levels and minimizing storage costs.

Methods and Technologies for Product Traceability

Implementing a product traceability system requires careful consideration of various methods and technologies. The optimal approach depends on factors like the industry, product type, and budget. Some common methods include:

- Barcodes and QR Codes: These are widely used for identifying and tracking individual products throughout the supply chain. They provide a simple and cost-effective way to capture and access product information.

- RFID (Radio-Frequency Identification): RFID tags offer a more advanced solution, allowing for automatic data capture without line-of-sight. They are particularly useful for tracking large volumes of products or products moving through complex environments.

- Blockchain Technology: Blockchain provides a secure and transparent way to record and share product information across the supply chain. Its decentralized nature enhances data integrity and security.

- Serialisation: Assigning a unique serial number to each product allows for precise tracking and identification. This is especially important for high-value or sensitive products.

- GPS Tracking: For products transported over long distances, GPS tracking provides real-time location information, enhancing visibility and security.

- Data Management Systems: Sophisticated software systems are crucial for managing and analyzing the vast amounts of data generated by traceability systems. These systems often integrate with other enterprise resource planning (ERP) systems.

Challenges in Implementing Product Traceability

While the benefits of product traceability are undeniable, implementing a robust system can present several challenges:

- Cost of Implementation: Implementing a comprehensive traceability system can require significant upfront investment in hardware, software, and training.

- Data Integration: Integrating data from various sources across the supply chain can be complex and require significant effort.

- Data Security and Privacy: Protecting sensitive product and consumer data is paramount. Robust security measures are essential to prevent data breaches and ensure compliance with privacy regulations.

- Supply Chain Complexity: Managing traceability across complex and geographically dispersed supply chains can be challenging.

- Lack of Standardization: The absence of industry-wide standards for data formats and communication protocols can hinder interoperability between different systems.

- Resistance to Change: Implementing a new traceability system may require significant changes in business processes and employee workflows, potentially encountering resistance from some stakeholders.

The Future of Product Traceability in Manufacturing

The future of product traceability is likely to be shaped by advancements in technology and evolving consumer expectations. We can expect to see:

- Increased Adoption of AI and Machine Learning: AI and ML can be used to analyze traceability data, identify patterns, and predict potential problems before they occur.

- Greater Emphasis on Data Security and Privacy: As data volumes increase, so will the need for robust security measures and compliance with evolving privacy regulations.

- Wider Adoption of Blockchain Technology: Blockchain’s ability to provide secure and transparent data sharing is expected to drive its adoption in the traceability space.

- Integration with IoT (Internet of Things): Connecting various devices and sensors throughout the supply chain will provide even more granular data for traceability purposes.

- Increased Consumer Demand for Transparency: Consumers are increasingly demanding greater transparency about the origin and journey of the products they buy. This will further drive the adoption of traceability systems.

In conclusion, product traceability is an essential aspect of modern manufacturing. While challenges exist, the benefits far outweigh the costs. By adopting appropriate technologies and strategies, manufacturers can build robust traceability systems that enhance quality control, streamline recall management, and strengthen their brand reputation in the long run.

Tags: Product Traceability, Manufacturing Traceability, Supply Chain Traceability, Food Traceability, Blockchain in Manufacturing

In today’s complex technological landscape, clear and concise technical documentation is paramount. Whether you’re a software developer, hardware engineer, or simply someone trying to assemble flat-pack furniture, understanding and utilizing technical guides and manuals is crucial. This comprehensive guide will delve into the creation, utilization, and optimization of these essential resources.

The Importance of Effective Technical Writing

Effective technical writing isn’t just about listing steps; it’s about conveying complex information in a simple, accessible way. A well-written manual can significantly reduce user frustration, improve product adoption, and even minimize support calls. Poorly written documentation, on the other hand, can lead to errors, delays, and ultimately, customer dissatisfaction. Key elements of effective technical writing include:

- Clarity and Conciseness: Avoid jargon and technical terms whenever possible. Use simple language and short sentences.

- Logical Structure: Organize information in a clear and logical manner, using headings, subheadings, and bullet points to guide the reader.

- Visual Aids: Incorporate diagrams, illustrations, screenshots, and videos to enhance understanding and engagement.

- Accessibility: Ensure your documentation is accessible to a wide range of users, including those with disabilities. Consider using alt text for images and providing different formats (e.g., PDF, HTML).

- Accuracy and Up-to-Date Information: Ensure all information is accurate and reflects the latest version of the product or software.

Different Types of Technical Guides and Manuals

The type of technical documentation you need will depend on the product or service you’re documenting. Some common types include:

- User Manuals: Provide step-by-step instructions on how to use a product or software.

- Installation Guides: Detail the process of installing hardware or software.

- Troubleshooting Guides: Offer solutions to common problems and errors.

- API Documentation: Explains how to use application programming interfaces (APIs).

- System Administrator Guides: Provide instructions for managing and maintaining complex systems.

- Training Manuals: Offer comprehensive training on specific software or hardware.

Creating High-Quality Technical Documentation

Creating effective technical documentation requires careful planning and execution. Here are some key steps to follow:

- Audience Analysis: Identify your target audience and tailor your language and style accordingly.

- Information Gathering: Gather all the necessary information from subject matter experts and other relevant sources.

- Content Outline: Create a detailed outline of your document to ensure a logical flow of information.

- Writing and Editing: Write clear, concise, and accurate content, and then thoroughly edit and proofread your work.

- Review and Feedback: Get feedback from your target audience to identify areas for improvement.

- Version Control: Implement a version control system to track changes and ensure that everyone is working with the latest version.

Utilizing and Maintaining Technical Manuals

A well-crafted manual is only as good as its accessibility and ongoing maintenance. Consider these points:

- Online Accessibility: Make your manuals easily accessible online, ideally through a searchable knowledge base or help center.

- Regular Updates: Keep your manuals up-to-date with the latest product information and bug fixes.

- Feedback Mechanisms: Provide a way for users to provide feedback on your manuals, allowing for continuous improvement.

- Multi-Language Support: Consider translating your manuals into multiple languages to reach a wider audience.

- Search Functionality: If your manuals are online, ensure they have robust search functionality to allow users to quickly find the information they need.

Improving Technical Documentation with Technology

Technology plays a significant role in both creating and delivering effective technical documentation. Tools like:

- Documentation Generators: Automatically generate documentation from code comments.

- Version Control Systems (e.g., Git): Track changes and collaborate on documentation.

- Content Management Systems (e.g., WordPress): Manage and publish documentation online.

- Screen Recording Software: Create video tutorials and walkthroughs.

- Interactive Tutorials: Offer engaging and interactive learning experiences.

can significantly streamline the process and improve the quality of your technical manuals.

By following these guidelines, you can create and utilize technical guides and manuals that are clear, concise, and effective, leading to improved user experience and overall product success.

Tags: technical guides, manuals, technical writing, user manuals, documentation

body {

font-family: sans-serif;

line-height: 1.6;

margin: 20px;

}

h1, h2, h3 {

color: #333;

}

img {

max-width: 100%;

height: auto;

display: block;

margin: 20px auto;

}

Hexagonal steel bars, often overlooked in favor of their round counterparts, offer a unique set of properties and advantages that make them ideal for a variety of applications. This comprehensive guide explores the world of hexagonal steel bars, delving into their characteristics, manufacturing processes, and diverse uses.

Understanding the Properties of Hexagonal Steel Bars

Hexagonal steel bars inherit the inherent strength and durability of steel, but their unique shape contributes to specific properties. The six-sided profile provides increased surface area compared to a round bar of the same cross-sectional area. This larger surface area can enhance:

- Grip Strength: The increased surface area provides superior grip when used in concrete reinforcement, leading to improved bond strength and structural integrity.

- Resistance to Bending: The hexagonal shape offers greater resistance to bending moments compared to a round bar of equivalent weight, enhancing structural stability.

- Torsional Strength: The multifaceted shape contributes to improved resistance to twisting forces, particularly beneficial in applications requiring high torsional rigidity.

The specific properties, such as tensile strength and yield strength, depend heavily on the grade of steel used in manufacturing. Common steel grades include mild steel, medium carbon steel, and high carbon steel, each offering a different balance of strength, ductility, and weldability.

Manufacturing Processes: From Ingot to Hexagonal Bar

The creation of hexagonal steel bars involves a multi-stage process. It typically begins with the melting and refining of iron ore to produce steel ingots. These ingots are then subjected to a series of processes to achieve the desired hexagonal shape:

- Hot Rolling: This is the primary shaping method. The heated ingot is passed through a series of rollers, progressively reducing its cross-section and shaping it into a hexagonal profile. Precise control of temperature and rolling pressure is crucial to achieve the desired dimensions and tolerances.

- Cold Drawing: This process involves pulling the hot-rolled bar through a die of smaller hexagonal dimensions at room temperature. Cold drawing enhances the surface finish, improves dimensional accuracy, and increases the tensile strength of the bar.

- Heat Treatment: Depending on the required properties, heat treatment processes like annealing or quenching and tempering may be employed to modify the microstructure of the steel and optimize its mechanical properties.

Quality control measures are implemented throughout the manufacturing process to ensure that the final product meets the required specifications in terms of dimensions, mechanical properties, and surface finish.

Diverse Applications of Hexagonal Steel Bars

The unique properties of hexagonal steel bars make them suitable for a wide range of applications across various industries:

- Construction and Civil Engineering: Hexagonal steel bars are frequently used as reinforcement in concrete structures, offering superior bond strength compared to round bars. They are particularly useful in situations where high grip strength and resistance to bending are crucial.

- Mechanical Engineering: These bars find use in machinery components where high strength, rigidity, and resistance to twisting are required. Examples include shafts, spindles, and structural elements in heavy-duty machinery.

- Automotive Industry: Hexagonal steel bars can be incorporated into vehicle components where strength and durability are paramount. They may be used in chassis reinforcement, suspension systems, or other structural elements.

- Handrails and Fencing: The aesthetic appeal of hexagonal bars, combined with their strength and durability, makes them a popular choice for handrails, fences, and other decorative applications.

- Agricultural Equipment: Their robustness makes them suitable for components in agricultural machinery that experience significant stress and wear.

Advantages of Choosing Hexagonal Steel Bars

Several advantages contribute to the growing popularity of hexagonal steel bars:

- Enhanced Grip Strength: The increased surface area provides superior bond strength in concrete, leading to more robust and durable structures.

- Improved Bending and Torsional Resistance: The hexagonal shape offers superior resistance to bending and twisting forces compared to round bars of equivalent weight.

- Greater Structural Integrity: The combination of enhanced grip, bending, and torsional resistance leads to improved overall structural integrity.

- Aesthetic Appeal: The unique shape can be visually appealing, making them suitable for applications where aesthetics are important.

- Versatile Applications: Hexagonal steel bars can be employed across a wide range of industries and applications.

Considerations When Specifying Hexagonal Steel Bars

When selecting hexagonal steel bars for a specific application, several factors need consideration:

- Steel Grade: The choice of steel grade depends on the required strength, ductility, and weldability. Higher carbon steel grades offer greater strength but may be less ductile.

- Dimensions: Precise dimensions are crucial for ensuring proper fit and function in the intended application. Tolerances should be carefully specified.

- Surface Finish: The desired surface finish affects both the aesthetic appeal and the performance of the bar. Cold-drawn bars typically have a smoother and more accurate finish.

- Cost: The cost of hexagonal steel bars can vary depending on the grade of steel, dimensions, and quantity ordered.

- Supplier Selection: Choosing a reputable supplier is crucial to ensure the quality and consistency of the materials.

Careful consideration of these factors will ensure that the selected hexagonal steel bars meet the specific requirements of the application and contribute to a successful project.

Tags: hexagonal steel bar, hexagonal steel, steel bars, steel reinforcement, concrete reinforcement, hexagonal rebar

In a world where fire safety is paramount, fire-resistant steel stands as a crucial bulwark against the destructive power of flames. From skyscrapers to industrial plants, these specialized materials play a vital role in protecting lives and property. This comprehensive guide delves into the fascinating world of fire-resistant steel, exploring its properties, applications, and the ongoing innovations shaping its future.

Understanding the Properties of Fire-Resistant Steel

Fire-resistant steel isn’t simply steel that’s been treated to withstand high temperatures; it’s a carefully engineered material with specific properties designed to maintain its structural integrity under intense heat. These properties include:

- High-Temperature Strength: Fire-resistant steel retains significant strength even at elevated temperatures, preventing collapse or deformation during a fire.

- Creep Resistance: This refers to the material’s resistance to deformation under sustained high temperatures and loads. This is critical for ensuring long-term structural stability.

- Oxidation Resistance: Exposure to high temperatures can cause rapid oxidation (rusting), weakening the steel. Fire-resistant steels are formulated to minimize this oxidation process.

- Thermal Stability: These steels maintain their dimensional stability even when subjected to significant temperature fluctuations, preventing warping or buckling.

- Ductility: While strength is key, maintaining some ductility (ability to deform without breaking) is important to absorb some energy during a fire event, further enhancing safety.

Types of Fire-Resistant Steel: A Comparative Analysis

Several types of fire-resistant steel exist, each with its own unique composition and properties tailored to specific applications. These include:

- Stainless Steels: Certain grades of stainless steel exhibit inherent fire resistance due to their chromium content, which forms a protective oxide layer. These are often used in less demanding applications.

- High-Strength Low-Alloy Steels (HSLA): These steels offer a balance of high strength and good fire resistance, making them suitable for structural applications in buildings and bridges.

- Alloy Steels: These steels contain specific alloying elements like molybdenum, vanadium, and niobium to enhance their high-temperature strength and creep resistance. They are commonly used in high-risk environments.

- Heat-Resistant Steels: These are specifically designed for prolonged exposure to extreme temperatures, often found in industrial furnaces and power plants. While extremely heat-resistant, they may not always offer the same level of structural integrity under fire conditions as specifically fire-resistant steels.

The choice of steel type depends on factors such as the anticipated fire temperature, duration of exposure, and the required structural performance.

Applications of Fire-Resistant Steel: Protecting Lives and Property

The versatility of fire-resistant steel makes it indispensable in a wide range of applications where fire safety is critical:

- Structural Components in Buildings: Columns, beams, and other structural elements in high-rise buildings, hospitals, and other critical structures are often constructed from fire-resistant steel.

- Fire Doors and Walls: Fire-resistant steel forms the backbone of fire-rated doors and walls, creating crucial fire barriers within buildings.

- Industrial Applications: Fire-resistant steel is essential in industrial settings like refineries, power plants, and chemical processing facilities, where the risk of fire is inherently higher.

- Transportation: Certain components in vehicles, especially those designed for hazardous materials transport, utilize fire-resistant steel for enhanced safety.

- Offshore Platforms: The harsh marine environment and potential for fire make fire-resistant steel a critical material in offshore oil and gas platforms.

Testing and Certification of Fire-Resistant Steel

Rigorous testing is crucial to ensure that fire-resistant steel meets the required performance standards. These tests evaluate the material’s ability to withstand high temperatures and maintain its structural integrity. Common testing methods include:

- Fire Resistance Tests: These tests subject samples of the steel to controlled fire conditions to assess their performance at different temperatures and durations.

- Mechanical Testing: Tests like tensile testing and impact testing are performed at elevated temperatures to determine the steel’s strength and ductility under fire conditions.

- Corrosion Testing: Tests evaluate the steel’s resistance to oxidation and corrosion at high temperatures.

Certification from recognized organizations ensures that the fire-resistant steel conforms to established standards and provides assurance of its quality and performance.

Future Innovations in Fire-Resistant Steel Technology

Research and development continue to push the boundaries of fire-resistant steel technology. Future innovations include:

- Advanced Alloying: Developing new alloy compositions to enhance high-temperature strength, creep resistance, and oxidation resistance.

- Improved Coating Technologies: Developing advanced coatings that further protect the steel from oxidation and enhance its fire resistance.

- Lightweight Fire-Resistant Steels: Research focuses on creating fire-resistant steels with reduced weight while maintaining their performance characteristics.

- Smart Materials: Incorporating sensors and other smart technologies to monitor the steel’s condition during a fire and provide real-time data on its performance.

These advancements promise to make fire-resistant steel even more effective in protecting lives and property from the devastating effects of fire.

Tags: fire resistant steel, fireproof steel, high temperature steel, structural steel, fire safety

body { font-family: sans-serif; line-height: 1.6; }

h1, h2, h3 { color: #333; }

img { max-width: 100%; height: auto; }

High-performance pipes are no longer just conduits; they’re critical components in numerous industries, demanding superior strength, durability, and efficiency. This comprehensive guide delves into the key features that differentiate these pipes from standard alternatives, exploring the materials, manufacturing processes, and design considerations that contribute to their exceptional performance.

1. Superior Material Selection: The Foundation of High Performance

The choice of material is paramount in determining a pipe’s performance characteristics. High-performance applications often necessitate materials exceeding the capabilities of standard steel or PVC. Let’s explore some prominent options:

- High-Yield Strength Steels: These steels, often alloyed with elements like chromium, molybdenum, and nickel, offer significantly increased tensile strength and yield strength compared to standard carbon steel. This translates to greater resistance to deformation under pressure and stress, making them ideal for high-pressure applications like oil and gas pipelines.

- Stainless Steels: Known for their exceptional corrosion resistance, stainless steels are crucial in environments with aggressive chemicals or high humidity. Different grades of stainless steel offer varying levels of strength and corrosion resistance, allowing for tailored selection based on specific application needs. Austenitic stainless steels are particularly common due to their excellent ductility and weldability.

- Superalloys: For extremely demanding applications, such as those involving high temperatures and corrosive environments, superalloys are employed. These nickel-based alloys exhibit exceptional high-temperature strength, oxidation resistance, and creep resistance, making them essential in power generation and aerospace industries.

- Fiber-Reinforced Polymers (FRP): Offering a lightweight yet strong alternative, FRP pipes are gaining popularity due to their corrosion resistance and high strength-to-weight ratio. They are particularly suitable for applications where weight is a significant factor or corrosive environments are prevalent.

2. Advanced Manufacturing Techniques: Precision and Efficiency

The manufacturing process plays a crucial role in achieving the desired performance characteristics. High-performance pipes often utilize advanced techniques to ensure precision, consistency, and enhanced properties:

- Seamless Pipe Manufacturing: Seamless pipes, created by piercing and rolling a solid billet, eliminate welded joints, increasing strength and resistance to fatigue. This is particularly important in high-pressure applications where weld integrity is crucial.

- Advanced Welding Techniques: For welded pipes, techniques like submerged arc welding (SAW) and gas tungsten arc welding (GTAW) ensure high-quality, strong welds with minimal defects. These methods often involve sophisticated quality control measures to guarantee weld integrity.

- Cold Forming and Extrusion: These processes enhance the mechanical properties of the pipe material through controlled deformation, leading to increased strength and dimensional accuracy. Cold forming is particularly effective in improving the yield strength of the pipe.

- Heat Treatment: Heat treatments, such as annealing and tempering, are used to control the microstructure of the pipe material, optimizing its strength, toughness, and ductility. This ensures the pipe meets the specific performance requirements of the application.

3. Enhanced Design Considerations: Optimizing Performance

The design of high-performance pipes is far from simplistic. Several factors must be carefully considered to maximize efficiency and longevity:

- Wall Thickness Optimization: Precise calculation of wall thickness is crucial to balance strength, weight, and cost. Finite element analysis (FEA) is often used to simulate stress and strain under various operating conditions, ensuring optimal wall thickness for the specific application.

- Internal Coatings and Linings: Internal coatings, such as epoxy or polyurethane, protect the pipe from corrosion and abrasion, extending its lifespan and preventing contamination of the transported fluid. The choice of coating depends on the nature of the transported material and the operating environment.

- External Coatings and Insulation: External coatings provide protection against environmental factors like corrosion and UV degradation. Insulation is crucial in applications where temperature control is vital, minimizing heat loss or gain.

- Flanges and Fittings: High-performance pipes often utilize high-quality flanges and fittings that are designed to withstand the operating pressures and temperatures. These components must be carefully selected to ensure compatibility with the pipe material and overall system integrity.

4. Rigorous Quality Control and Testing: Ensuring Reliability

The reliability of high-performance pipes is paramount. Rigorous quality control measures and testing protocols are implemented throughout the manufacturing process to ensure that the final product meets the specified performance criteria:

- Non-Destructive Testing (NDT): Techniques such as radiographic testing (RT), ultrasonic testing (UT), and magnetic particle testing (MT) are used to detect internal flaws and imperfections in the pipe material and welds.

- Hydrostatic Testing: This involves pressurizing the pipe with water to verify its ability to withstand the intended operating pressure without failure. This is a crucial step in ensuring the pipe’s integrity and safety.

- Material Testing: Tensile testing, hardness testing, and chemical analysis are performed to verify that the pipe material meets the required specifications and possesses the desired mechanical properties.

- Dimensional Inspection: Precise measurements are taken to ensure that the pipe dimensions conform to the design specifications, guaranteeing a proper fit and function within the system.

5. Applications Across Diverse Industries: High-Performance in Action

High-performance pipes are integral components in a wide array of industries, enabling efficient and reliable operation in demanding environments:

- Oil and Gas: High-pressure pipelines transporting oil and gas require pipes with exceptional strength and corrosion resistance to ensure safe and efficient operation.

- Chemical Processing: Pipes handling corrosive chemicals need superior material selection and protective coatings to prevent degradation and leaks.

- Power Generation: High-temperature applications in power plants necessitate pipes made from superalloys or high-temperature resistant steels.

- Water Treatment: Pipes used in water treatment plants require corrosion resistance and the ability to withstand the chemicals used in the purification process.

- Aerospace: Lightweight yet strong pipes made from advanced materials are crucial in aerospace applications to minimize weight and maximize performance.

In conclusion, the features of high-performance pipes are a result of careful consideration of material selection, advanced manufacturing techniques, optimized design, and rigorous quality control. These factors combine to create pipes that deliver exceptional performance, reliability, and longevity across a diverse range of demanding applications.

Tags: High-performance pipes, pipe materials, pipe manufacturing, pipe design, industrial pipes

The steel manufacturing industry is a vital cog in global infrastructure, but its inherent processes pose significant occupational safety risks. From extreme heat and molten metal to heavy machinery and hazardous materials, the potential for accidents is substantial. This comprehensive guide explores the critical aspects of occupational safety within steel manufacturing, highlighting best practices and emphasizing the importance of proactive risk management.

1. Identifying and Assessing Hazards in Steel Manufacturing

Hazard identification is the cornerstone of any effective safety program. In steel manufacturing, hazards are diverse and pervasive. These include:

- Thermal Hazards: Extremely high temperatures from furnaces, molten metal, and hot work processes pose severe burn risks. Workers need adequate protection and training to mitigate these dangers.

- Mechanical Hazards: Heavy machinery, moving parts, and falling objects present significant risks of crushing injuries, lacerations, and amputations. Proper machine guarding, lockout/tagout procedures, and safe work practices are essential.

- Chemical Hazards: Exposure to various chemicals, including dusts, fumes, and gases, can lead to respiratory problems, skin irritation, and other health issues. Proper ventilation, respiratory protection, and safe handling practices are crucial.

- Electrical Hazards: High-voltage equipment and electrical arcs pose electrocution risks. Regular inspections, proper insulation, and adherence to electrical safety regulations are paramount.

- Noise Hazards: The constant noise from machinery can lead to hearing loss. Hearing protection, regular hearing tests, and noise reduction measures are necessary.

- Heat-resistant clothing: Specialized clothing, including jackets, trousers, gloves, and footwear, protects against burns from heat and molten metal.

- Safety footwear: Steel-toe boots protect feet from falling objects and crushing hazards.

- Safety helmets: Protect the head from falling objects and impacts.

- Eye and face protection: Safety glasses, goggles, and face shields protect against flying debris, sparks, and molten metal splashes.

- Respiratory protection: Respirators protect against inhalation of harmful dusts, fumes, and gases.

- Hearing protection: Earplugs or earmuffs protect against noise-induced hearing loss.

- Elimination: Removing the hazard entirely is the most effective control measure. This might involve replacing a dangerous process with a safer one.

- Substitution: Replacing a hazardous substance or process with a less hazardous alternative.

- Engineering Controls: Implementing physical changes to the workplace, such as machine guarding, ventilation systems, and improved lighting.

- Administrative Controls: Implementing procedures and policies, such as safe work practices, training programs, and regular inspections.

- Emergency response plan: A comprehensive plan outlining procedures for handling various emergencies, such as fires, explosions, chemical spills, and injuries.

- Emergency training: Regular training for all employees on emergency procedures, including evacuation routes, fire drills, and first aid.

- Emergency equipment: Adequate fire extinguishers, emergency showers, eye wash stations, and other emergency equipment must be readily available and properly maintained.

- Communication systems: Effective communication systems are crucial for alerting employees to emergencies and coordinating response efforts.

- Emergency medical services: Establishing clear procedures for contacting and coordinating with emergency medical services.

- Regular safety meetings: Providing a platform for employees to discuss safety concerns and contribute to safety improvement initiatives.

- Safety audits and inspections: Regular audits and inspections to identify potential hazards and ensure compliance with safety regulations.

- Incident investigation and reporting: Thorough investigation of all incidents to identify root causes and implement corrective actions.

- Safety training and education: Providing comprehensive safety training to all employees, including new hires and existing staff.

- Safety culture: Fostering a strong safety culture where employees are empowered to report hazards and participate in safety improvement initiatives.

A thorough hazard assessment, often involving job safety analysis (JSA) and risk assessments, is crucial to identify the likelihood and severity of each hazard and prioritize control measures.

2. Personal Protective Equipment (PPE) in Steel Mills

Personal Protective Equipment (PPE) plays a vital role in protecting workers from identified hazards. Appropriate PPE varies depending on the specific task and the hazards involved. Examples include:

Regular inspection and maintenance of PPE are crucial to ensure its effectiveness. Training on proper PPE use and selection is also essential.

3. Risk Management and Control Measures in Steel Production

Effective risk management involves implementing control measures to eliminate or mitigate identified hazards. This hierarchical approach prioritizes elimination, substitution, engineering controls, administrative controls, and finally, PPE.

Regular risk assessments and audits are crucial to ensure the effectiveness of control measures and identify any emerging hazards.

4. Emergency Procedures and Response in Steel Manufacturing Plants

Having well-defined emergency procedures and a robust response system is crucial in steel manufacturing. This includes:

Regular drills and simulations help ensure that employees are prepared to respond effectively in emergencies.

5. Regulatory Compliance and Ongoing Safety Improvement

Steel manufacturing is heavily regulated, and compliance with relevant safety regulations is crucial. This involves understanding and adhering to national and international standards and regulations related to occupational safety and health. Regular inspections by regulatory bodies are common. Beyond compliance, continuous improvement is key. This involves:

By prioritizing safety and continuously striving for improvement, steel manufacturers can create a safer and more productive work environment.

Tags: steel manufacturing safety, occupational safety, industrial safety, steel mill safety, workplace safety

The steel industry, a cornerstone of global infrastructure, faces increasing pressure to minimize its environmental footprint. A significant aspect of this challenge lies in effectively managing the substantial waste generated throughout the steelmaking process. This blog post delves into the complexities of waste management in steel production, exploring the various waste streams, innovative recycling techniques, and the crucial role of sustainable practices in building a greener future for the industry.

1. Understanding the Diverse Waste Streams in Steel Production

Steel production generates a diverse range of waste materials, each requiring specific handling and treatment methods. These waste streams can be broadly categorized as:

- Slag: A significant byproduct, slag is a molten byproduct formed during the smelting process. Its composition varies depending on the raw materials used and the steelmaking process. While traditionally considered waste, slag finds applications in construction materials (cement, aggregates), agriculture (soil amendment), and even in the production of certain types of glass.

- Dust and Fumes: These particulate emissions contain valuable metals and other compounds. Effective dust collection systems are essential to prevent air pollution and recover valuable materials. Advanced technologies like electrostatic precipitators and bag filters are employed to capture these emissions. The collected dust often undergoes further processing for metal recovery.

- Spent Refractories: These materials line furnaces and vessels, protecting them from high temperatures and corrosion. Over time, they degrade and need replacement, generating large quantities of waste. Recycling spent refractories is challenging but increasingly important, as it reduces reliance on virgin materials and minimizes landfill disposal.

- Pickling Liquors: Used to remove scale and impurities from steel sheets, these acidic solutions contain dissolved metals and chemicals. Treatment is crucial to neutralize acidity and prevent water pollution. Recycling or recovery of valuable metals from these liquors is also gaining traction.

- Scrap Metal: While not strictly “waste,” scrap metal is a crucial feedstock for steel production, facilitating a circular economy approach. Effective scrap metal collection and sorting systems are essential to ensure high-quality recycled steel input.

2. Innovative Recycling and Resource Recovery Techniques

The steel industry is actively exploring and implementing innovative technologies to maximize resource recovery and minimize waste disposal. These include:

- Slag Granulation and Utilization: Granulating slag improves its handling and facilitates its use in various applications. Research is ongoing to optimize slag properties for specific applications, enhancing its value as a secondary raw material.

- Metal Recovery from Dust and Fumes: Advanced separation techniques, such as hydrometallurgy and pyrometallurgy, are used to recover valuable metals from dust and fumes, reducing waste and providing a source of secondary raw materials.

- Spent Refractory Recycling: Technologies are being developed to process and recycle spent refractories, recovering valuable components and reducing the need for virgin materials. This often involves crushing, sorting, and potentially chemical treatment to separate valuable components.

- Closed-Loop Water Management: Minimizing water consumption and recycling process water helps reduce the environmental impact of pickling and other water-intensive processes. This often involves advanced treatment systems to remove contaminants and reuse the treated water.

3. Environmental Regulations and Sustainability Initiatives

Stringent environmental regulations are driving the steel industry towards more sustainable practices. These regulations often focus on:

- Air Emissions: Limits on particulate matter, sulfur dioxide, and other pollutants are crucial for protecting air quality.

- Water Pollution: Strict regulations on wastewater discharge are essential to prevent contamination of water bodies.

- Waste Disposal: Minimizing landfill disposal and promoting recycling and resource recovery are key objectives.

Many steel producers are also proactively implementing sustainability initiatives, including setting ambitious reduction targets for greenhouse gas emissions, water consumption, and waste generation. These initiatives often involve investing in cleaner technologies, improving process efficiency, and implementing circular economy principles.

4. The Role of Technological Advancements in Waste Management

Technological advancements are playing a crucial role in improving waste management practices in the steel industry. These include:

- Advanced Sensors and Monitoring Systems: Real-time monitoring of process parameters helps optimize operations and minimize waste generation.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML can be used to optimize resource utilization, predict equipment failures, and improve the efficiency of waste treatment processes.

- Automation and Robotics: Automation can improve the safety and efficiency of waste handling and processing operations.

5. The Future of Waste Management in Steel Production: Towards a Circular Economy

The future of waste management in steel production is inextricably linked to the development of a circular economy. This involves:

- Maximizing resource recovery: Developing innovative technologies to recover valuable materials from all waste streams.

- Minimizing waste generation: Improving process efficiency and adopting cleaner production methods.

- Promoting the use of recycled materials: Increasing the use of recycled steel and other secondary raw materials.

- Collaboration and knowledge sharing: Sharing best practices and fostering collaboration among stakeholders to accelerate the adoption of sustainable solutions.

By embracing these principles, the steel industry can significantly reduce its environmental impact and contribute to a more sustainable future.

Tags: steel production, waste management, steel recycling, slag utilization, sustainable steel

Superalloy steel, a class of advanced metallic materials, isn’t your average steel. Its exceptional properties, including high-temperature strength, corrosion resistance, and creep resistance, make it indispensable in demanding environments. This blog post delves into the fascinating world of superalloy steel, exploring its diverse applications across various industries.

1. Aerospace: Reaching for the Stars with Superalloy Steel

The aerospace industry is perhaps the most significant consumer of superalloy steels. The extreme temperatures and pressures experienced during flight, especially in jet engines, demand materials with exceptional resilience. Nickel-based superalloys, in particular, dominate this sector. These alloys are used in critical components such as turbine blades, combustor liners, and afterburner components. The ability of these superalloys to withstand temperatures exceeding 1000°C (1832°F) is crucial for maintaining engine efficiency and longevity. The lightweight nature of some superalloys, coupled with their high strength-to-weight ratio, is also a critical factor in aircraft design, allowing for fuel efficiency and enhanced performance.

2. Energy Sector: Powering the Future with Superalloy Steel

The energy industry, encompassing power generation and oil & gas extraction, relies heavily on superalloys for their resistance to high temperatures and corrosive environments. In power generation, particularly in gas turbines and steam turbines, superalloys are vital for components exposed to extremely high temperatures and pressures. Their resistance to creep, a phenomenon where materials deform under sustained stress at high temperatures, ensures the long-term reliability of these power plants. In the oil and gas industry, superalloys are used in drilling equipment, valves, and piping systems that encounter harsh conditions, including high pressures, corrosive chemicals, and extreme temperatures.

3. Chemical Processing: Withstanding Harsh Environments

The chemical processing industry faces numerous challenges, including highly corrosive chemicals and high-temperature reactions. Superalloy steels provide the necessary resilience to withstand these harsh environments. Their exceptional corrosion resistance makes them ideal for components in reactors, pumps, and valves used in the processing of various chemicals. The choice of specific superalloy depends on the specific chemical being processed, with some alloys exhibiting superior resistance to certain acids or alkalis.

4. Automotive Industry: Enhancing Performance and Durability

While not as prevalent as in aerospace or energy, superalloys are finding increasing applications in the automotive industry, particularly in high-performance vehicles. Their strength and heat resistance make them suitable for components in turbochargers and exhaust systems. As the demand for fuel efficiency and performance increases, the use of superalloys in automotive applications is expected to grow. The development of more cost-effective superalloy processing techniques could further expand their use in this sector.

5. Medical Implants: A Biocompatible Marvel

Certain superalloys, particularly those with exceptional biocompatibility, are finding niche applications in medical implants. Their strength, corrosion resistance, and biocompatibility make them suitable for components in artificial joints, dental implants, and other medical devices. However, rigorous testing and stringent quality control are necessary to ensure the long-term safety and effectiveness of these implants. Ongoing research is focused on improving the biocompatibility and wear resistance of superalloys for medical applications.

In conclusion, superalloy steels represent a remarkable achievement in materials science, offering exceptional properties that are crucial for a wide range of high-performance applications. Their continued development and refinement will undoubtedly lead to even more innovative uses in the future, shaping advancements across various industries.

SEO-Friendly Tags:

- Superalloy Steel

- Superalloy Applications

- High-Temperature Alloys

- Aerospace Materials

- Nickel-Based Superalloys

The safe and efficient transportation of natural gas relies heavily on the integrity of the pipelines. Corrosion is a significant threat to pipeline longevity and safety, leading to leaks, explosions, and environmental damage. To combat this, various protective coatings are applied to pipes, with epoxy (EP), polypropylene (PP), and polyethylene (PE) coatings being prominent choices. This article delves into the specifics of each coating, exploring their properties, applications, and the advantages they offer for gas pipeline applications.

Understanding the Need for Coated Pipes in Gas Pipelines

Gas pipelines are often buried underground or submerged underwater, exposing them to harsh environmental conditions. These conditions include:

- Soil corrosion: Acidic soils, electrochemical reactions, and the presence of microorganisms can accelerate pipe corrosion.

- Water ingress: Groundwater can penetrate the pipe, leading to internal corrosion and reduced lifespan.

- Mechanical damage: During installation or due to external forces, the pipe can suffer scratches and damage, compromising its integrity.

- Microbiological Influenced Corrosion (MIC): Certain bacteria thrive in the presence of moisture and can accelerate the corrosion process.

Coated pipes provide a barrier against these threats, extending the pipeline’s operational life and ensuring its safety. The selection of the appropriate coating depends on factors such as the soil type, pipeline location, and operational pressure.

Epoxy (EP) Coated Pipes: A Robust Solution

Epoxy coatings are known for their excellent adhesion, chemical resistance, and mechanical strength. They form a hard, protective layer that effectively prevents corrosion. EP coatings are typically applied using a fusion-bonded epoxy (FBE) process, where the epoxy powder is electrostatically sprayed onto the pipe and then cured in a furnace. This creates a uniform, seamless coating.

Advantages of EP coatings:

- High mechanical strength and impact resistance

- Excellent adhesion to the pipe surface

- Good resistance to chemicals and solvents

- Relatively low permeability to water and gases

- Suitable for high-pressure applications

Disadvantages of EP coatings:

- Can be brittle and susceptible to cracking under stress

- Requires careful surface preparation before application

- Application process can be complex and requires specialized equipment

Polyethylene (PE) Coated Pipes: Flexibility and Durability

Polyethylene (PE) coatings offer excellent flexibility and resistance to stress cracking. They are applied using extrusion or fusion bonding methods, resulting in a smooth, continuous coating. PE coatings are commonly used for pipelines operating under lower pressures and in less aggressive environments.

Advantages of PE coatings:

- High flexibility and resistance to stress cracking

- Good resistance to abrasion and impact

- Excellent chemical resistance

- Relatively easy and cost-effective to apply

- Suitable for a wide range of applications

Disadvantages of PE coatings:

- Lower mechanical strength compared to EP coatings

- Can be susceptible to UV degradation if exposed to sunlight

- May not be suitable for high-pressure or high-temperature applications

Polypropylene (PP) Coated Pipes: A Versatile Option

Polypropylene (PP) coatings provide a good balance between flexibility, strength, and chemical resistance. They are often applied using extrusion or powder coating methods. PP coatings are a suitable choice for applications where moderate chemical resistance and flexibility are required.

Advantages of PP coatings:

- Good flexibility and impact resistance

- Excellent chemical resistance to many acids and alkalis

- Relatively lightweight and easy to handle

- Suitable for a range of operating temperatures

Disadvantages of PP coatings:

- Lower resistance to UV degradation compared to PE

- May not be as robust as EP coatings for high-pressure applications

- Adhesion to the pipe surface can be a concern if not properly prepared

Choosing the Right Coating for Your Gas Pipeline Project

The selection of the appropriate coating depends on several factors, including:

- Pipeline diameter and wall thickness: Larger diameter pipes may require coatings with higher mechanical strength.

- Operating pressure and temperature: High-pressure applications necessitate coatings with excellent pressure resistance.

- Soil conditions: Aggressive soils require coatings with superior corrosion resistance.

- Environmental regulations: Compliance with environmental regulations is crucial in selecting a suitable coating.

- Cost considerations: The cost of the coating material and application process should be factored into the decision.

A thorough risk assessment and consultation with experienced engineers are essential to ensure the selection of the most appropriate coating for a given gas pipeline project.

In conclusion, the choice between EP, PP, and PE coated pipes for gas pipelines is a crucial decision impacting safety, longevity, and cost-effectiveness. Careful consideration of the specific project requirements is vital to ensure the selection of the most suitable and reliable solution.

Tags: EP coated pipes, PP coated pipes, PE coated pipes, gas pipeline coating, pipeline corrosion protection