Steel, the backbone of countless industries, demands precise and efficient cutting techniques. From intricate automotive parts to robust structural beams, the method used to cut steel significantly impacts the final product’s quality, cost, and production time. This article explores the diverse world of steel cutting technologies, detailing their processes, applications, and relative merits.

1. Thermal Cutting Processes: Oxy-Fuel and Plasma Cutting

Thermal cutting leverages heat to melt and sever the steel. Two prominent methods are oxy-fuel and plasma cutting. Oxy-fuel cutting, a classic technique, uses a high-velocity jet of oxygen to ignite and burn the steel, effectively cutting through it. This process is relatively inexpensive and suitable for thicker steel sections, but it produces a wider heat-affected zone (HAZ) and a rougher cut edge, requiring further finishing in many applications. The HAZ can lead to alterations in the steel’s metallurgical properties near the cut.

Plasma cutting utilizes a high-temperature plasma arc to melt and vaporize the steel. This method offers greater precision and speed than oxy-fuel cutting, resulting in narrower kerfs (the width of the cut) and a cleaner cut edge. Plasma cutting is versatile, handling a wider range of steel thicknesses compared to oxy-fuel, but it requires more sophisticated equipment and is generally more expensive. The choice often depends on factors like material thickness, desired cut quality, and budget constraints.

2. Laser Cutting: Precision and Versatility

Laser cutting employs a highly focused laser beam to melt and vaporize the steel, creating incredibly precise cuts. The non-contact nature of the process minimizes material deformation and produces clean, burr-free edges. Laser cutting is highly automated, often integrated with CNC (Computer Numerical Control) systems for complex designs and high throughput. This method excels in applications requiring intricate geometries and high-quality surface finishes, making it ideal for industries like automotive manufacturing and aerospace.

However, laser cutting is typically more expensive than other thermal methods and may not be suitable for extremely thick steel sections. The laser’s power and the material’s properties determine the maximum thickness that can be efficiently cut. Furthermore, laser cutting may require additional safety precautions due to the high-energy laser beam.

3. Waterjet Cutting: The Abrasive Power of Water

Waterjet cutting utilizes a high-pressure jet of water mixed with an abrasive material (usually garnet sand) to cut through steel. This method is remarkably versatile, capable of cutting a wide range of materials, including hardened steels that are difficult to process with other techniques. The non-thermal nature of waterjet cutting eliminates the HAZ, preserving the steel’s metallurgical properties. It also produces minimal noise and pollution, making it environmentally friendly.

While waterjet cutting offers excellent precision and versatility, it is generally slower than thermal methods and can be more expensive. The kerf width is relatively wider compared to laser cutting, and the process is less efficient for very thick steel. Despite these limitations, waterjet cutting remains a valuable option for intricate designs and materials requiring minimal heat-affected zones.

4. Mechanical Cutting: Shearing and Sawing

Mechanical cutting methods involve physically shearing or sawing the steel. Shearing is a common technique for cutting relatively thin sheets of steel using powerful blades. It’s a fast and efficient method for straight cuts, but it’s limited in its ability to produce complex shapes. The cut edge may require further deburring.

Sawing, using various types of saws (band saws, circular saws, etc.), is suitable for thicker steel sections and more complex shapes. Band saws offer flexibility and precision, while circular saws are often used for faster, less precise cuts. Mechanical cutting methods generally produce a rougher cut compared to thermal or waterjet methods, requiring more post-processing.

5. CNC Cutting: Automation and Precision

Many modern steel cutting techniques are integrated with CNC systems, enabling automated and highly precise cutting. CNC machines use computer-aided design (CAD) files to control the cutting process, allowing for complex geometries and intricate designs to be produced with high accuracy and repeatability. Regardless of the cutting method (laser, plasma, waterjet, etc.), CNC integration significantly improves efficiency and reduces human error.

The use of CNC technology is becoming increasingly prevalent across various steel cutting applications, as it allows for mass production of high-quality components with minimal waste and improved consistency. The initial investment in CNC machinery can be substantial, but the long-term benefits in terms of productivity and precision often outweigh the cost.

Choosing the right steel cutting technology requires careful consideration of several factors: material thickness, desired cut quality, production volume, budget constraints, and the complexity of the design. Each method offers unique advantages and disadvantages, making it crucial to select the most appropriate technique for the specific application.

SEO-Friendly Tags:

- Steel Cutting Methods

- Laser Cutting Steel

- Plasma Cutting Steel

- Waterjet Cutting Applications

- CNC Steel Cutting

body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

img {

max-width: 100%;

height: auto;

}

Hot rolled flat bars are a ubiquitous material in countless industries, forming the backbone of numerous structures and components. Understanding their properties and applications is crucial for engineers, fabricators, and anyone involved in material selection. This comprehensive guide will unravel the intricacies of hot rolled flat bars, providing a detailed overview of their manufacturing, characteristics, and uses.

The Manufacturing Process: From Ingot to Flat Bar

The journey of a hot rolled flat bar begins with a molten steel ingot. This ingot undergoes a series of rigorous processes to transform it into the desired flat bar shape. The process typically involves:

- Breaking Down: The ingot is initially broken down into smaller, more manageable pieces through processes like continuous casting.

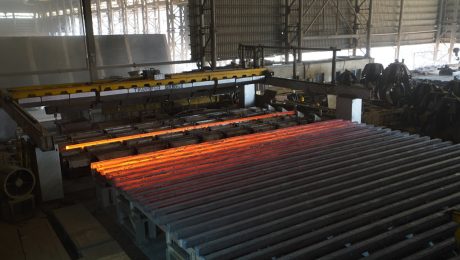

- Hot Rolling: This is the core process where the heated steel is repeatedly passed through a series of rollers, progressively reducing its thickness and shaping it into a flat bar. The high temperature allows for easier deformation and improves the material’s workability.

- Cooling and Straightening: After rolling, the flat bar is allowed to cool and then passed through straightening machines to ensure dimensional accuracy and eliminate any warping or curvature.

- Cutting and Finishing: Finally, the flat bar is cut to the required length and may undergo further finishing processes such as surface treatment (e.g., pickling to remove mill scale) or edge conditioning.

The entire process is highly automated and controlled, ensuring consistent quality and dimensional accuracy in the final product.

Mechanical Properties and Characteristics

Hot rolled flat bars possess distinct mechanical properties that make them suitable for a wide range of applications. Key characteristics include:

- High Strength: The hot rolling process imparts significant strength to the material, making it ideal for load-bearing applications.

- Good Ductility: Hot rolled steel exhibits good ductility, meaning it can be bent and formed without fracturing. This property is crucial for fabrication processes.

- Weldability: Hot rolled flat bars are generally readily weldable, facilitating the joining of components in various applications.

- Surface Finish: The surface finish of hot rolled bars is typically rougher than cold-rolled bars due to the high-temperature rolling process. This is acceptable for many applications but might require further finishing for cosmetic reasons.

- Tolerance: The dimensional tolerances of hot-rolled bars are generally less precise than those of cold-rolled bars.

Applications Across Diverse Industries

The versatility of hot rolled flat bars has led to their widespread adoption across diverse industries. Some key applications include:

- Construction: Used extensively in structural steelwork, reinforcing bars, and various other components in buildings and infrastructure.

- Automotive: Utilized in chassis components, axles, and other structural parts of vehicles.

- Machinery Manufacturing: Forms the basis of many machine parts, including shafts, beams, and supporting structures.

- Railways: Employed in the construction of railway tracks and rolling stock components.

- Agriculture: Used in the manufacturing of agricultural machinery and equipment.

The specific grade and size of the flat bar will be selected based on the demands of the application.

Advantages and Disadvantages of Hot Rolled Flat Bars

Like any material, hot rolled flat bars have both advantages and disadvantages:

Advantages:

- Cost-Effective: Hot rolling is a relatively inexpensive manufacturing process compared to cold rolling.

- High Strength-to-Weight Ratio: Offers a good balance of strength and weight, making it efficient for structural applications.

- Wide Range of Sizes and Grades: Available in a vast array of sizes and grades to suit diverse needs.

- Good Weldability: Facilitates easy joining of components.

Disadvantages:

- Rougher Surface Finish: May require further finishing for cosmetic purposes.

- Less Precise Dimensional Tolerances: Compared to cold-rolled bars.

- Lower Surface Hardness: Compared to cold-rolled bars, resulting in potentially reduced wear resistance in some applications.

Choosing the Right Hot Rolled Flat Bar: Grade and Specifications

Selecting the appropriate hot rolled flat bar requires careful consideration of several factors, including the required mechanical properties, dimensional tolerances, and surface finish. Different grades of steel are available, each with specific properties tailored to certain applications. These grades are often designated by standards such as ASTM (American Society for Testing and Materials) or other international standards. Understanding these specifications is critical for ensuring the chosen material meets the demands of the intended application. Consulting with a materials specialist can be invaluable in making the right selection.

This comprehensive guide provides a foundation for understanding hot rolled flat bars. Remember to always consult relevant standards and specifications for detailed information related to specific applications and material grades.

Tags: Hot rolled flat bar, steel flat bar, hot rolled steel, steel bar applications, metal fabrication

Pipe bending and straightening are crucial processes in numerous industries, from construction and manufacturing to oil and gas. The ability to manipulate pipes accurately and efficiently is essential for creating functional and aesthetically pleasing structures. This comprehensive guide will explore various methods, equipment, and considerations for achieving precise bends and straightening damaged or misaligned pipes.

1. Understanding Pipe Bending Techniques: A Variety of Approaches

Several techniques exist for bending pipes, each suited to different pipe materials, diameters, and desired bend radii. The choice of method depends on factors like material ductility, required accuracy, and production volume.

- Manual Bending: This method uses hand tools like pipe benders and is suitable for smaller diameter, relatively soft pipes. It’s cost-effective for small-scale projects but labor-intensive and less precise for complex bends.

- Hydraulic Bending: Hydraulic pipe benders utilize hydraulic pressure to create precise bends in various pipe materials and diameters. They offer greater control and accuracy compared to manual methods and are suitable for medium to large-scale projects.

- Roll Bending: This technique uses three rollers to gradually bend the pipe into the desired shape. It’s ideal for bending large-diameter pipes and creating complex curves. Roll bending is often used in the manufacturing of large-diameter piping systems.

- Press Bending: Press bending employs a clamping mechanism and a forming die to bend the pipe. This method is highly accurate and suitable for various pipe materials and complex shapes. It’s commonly used in high-precision applications.

- Induction Bending: Induction bending uses localized heating to soften the pipe material before bending. This allows for tighter bends and reduces the risk of material damage. It’s particularly effective with thicker-walled pipes.

2. Pipe Straightening Methods: Rectifying Imperfections

Straightening bent or damaged pipes is crucial for maintaining structural integrity and ensuring proper functionality. Several methods can effectively rectify imperfections, each with its own advantages and limitations.

- Mechanical Straightening: This involves using straightening machines or presses to apply controlled forces to the bent pipe, gradually aligning it. These machines are often equipped with rollers or dies to ensure even pressure distribution.

- Thermal Straightening: This method uses heat to relieve stress and straighten the pipe. It’s particularly effective for pipes with minor bends or those made from materials that are susceptible to cold working.

- Hydraulic Straightening: Similar to hydraulic bending, hydraulic straightening uses hydraulic pressure to gently correct the pipe’s alignment. This method is less likely to cause damage to the pipe compared to more forceful mechanical methods.

- Manual Straightening (for minor imperfections): For very minor bends, manual straightening may be possible using hand tools like hammers and clamps. However, this method requires skill and caution to avoid causing further damage.

3. Choosing the Right Equipment: Considerations for Different Applications

Selecting the appropriate equipment for pipe bending and straightening is crucial for efficiency and accuracy. Several factors need to be considered:

- Pipe Material: Different materials (steel, copper, aluminum, etc.) have varying degrees of ductility and require different bending techniques and equipment.

- Pipe Diameter and Wall Thickness: Larger diameter and thicker-walled pipes require more robust equipment capable of handling higher forces.

- Bend Radius: The desired bend radius influences the choice of bending method and equipment. Tighter bends require more specialized techniques.

- Production Volume: For high-volume production, automated equipment like hydraulic or roll benders is more efficient than manual methods.

- Budget and Space Constraints: The cost and size of the equipment must be considered in relation to available budget and workspace.

4. Safety Precautions: Ensuring a Safe Working Environment

Pipe bending and straightening can be hazardous if proper safety precautions are not followed. Safety measures should always be prioritized:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, gloves, and hearing protection.

- Proper Machine Operation: Ensure that all equipment is properly maintained and operated according to manufacturer instructions.

- Safe Work Practices: Follow established safety procedures and avoid working alone.

- Emergency Procedures: Be familiar with emergency procedures and have appropriate safety equipment readily available.

- Regular Inspections: Regularly inspect equipment for wear and tear and address any potential hazards promptly.

5. Material Considerations: Optimizing for Durability and Performance

The material of the pipe significantly impacts the bending and straightening process. Understanding material properties is crucial for successful manipulation:

- Steel Pipes: Steel pipes are strong and durable but can be challenging to bend, especially at tight radii. Methods like induction bending are often used to minimize stress and cracking.

- Copper Pipes: Copper pipes are relatively ductile and easier to bend than steel. However, they are susceptible to work hardening, so careful bending techniques are necessary.

- Aluminum Pipes: Aluminum pipes are lightweight and easily bendable but can be prone to wrinkling or collapsing if not handled correctly.

- Plastic Pipes: Plastic pipes can be bent using various methods, but excessive heat can damage them. Care must be taken to avoid cracking or deformation.

By understanding the various techniques, equipment, safety precautions, and material properties, you can master the art of pipe bending and straightening, ensuring efficient and safe operations in any industry.

body { font-family: sans-serif; line-height: 1.6; }

h1, h2, h3 { color: #333; }

h1 { font-size: 2.5em; }

h2 { font-size: 2em; }

h3 { font-size: 1.5em; }

The international trade of steel involves intricate logistical arrangements, and understanding the nuances of Incoterms is crucial for both importers and exporters. Two of the most commonly used Incoterms for steel exports are FOB (Free On Board) and CIF (Cost, Insurance, and Freight). This comprehensive guide will dissect the key differences between FOB and CIF, clarifying responsibilities and cost implications to help you make informed decisions.

Understanding Incoterms: The Foundation of International Trade

Incoterms, or International Commercial Terms, are standardized trade terms published by the International Chamber of Commerce (ICC). They define the responsibilities of buyers and sellers regarding delivery, costs, risks, and insurance in international transactions. Choosing the right Incoterm is paramount to avoiding disputes and ensuring a smooth transaction. Incorrectly selecting an Incoterm can lead to significant financial losses and legal complications.

FOB (Free On Board): Seller’s Responsibilities at the Port

With FOB, the seller’s responsibility extends to delivering the goods to the named port of shipment. The seller is responsible for:

- Arranging for the goods to be loaded onto the vessel at the designated port.

- Bearing all costs and risks associated with the goods until they are safely loaded onto the vessel.

- Providing necessary export documentation.

Importantly, the buyer bears all costs and risks associated with the goods from the moment they are loaded onto the vessel. This includes freight, insurance, and any potential damage or loss during transit.

CIF (Cost, Insurance, and Freight): Seller’s Broader Scope

CIF places a significantly broader range of responsibilities on the seller. In addition to delivering the goods to the named port of shipment and loading them onto the vessel, the seller is also responsible for:

- Paying for the freight costs from the port of shipment to the port of destination.

- Securing marine insurance to cover the goods during transit.

- Providing all necessary shipping documents, including the insurance policy.

Under CIF, the risk of loss or damage transfers to the buyer only once the goods have been delivered to the named port of destination. This means the seller bears the risk during the entire voyage.

Cost Implications: FOB vs CIF in Steel Exports

The cost implications of choosing FOB versus CIF are significant. While FOB might seem cheaper initially because the buyer assumes freight and insurance costs, the buyer needs to factor these additional expenses into their budget. Conversely, CIF offers a seemingly higher initial price, but the seller covers the freight and insurance, simplifying the process for the buyer. The overall cost to the buyer can vary depending on market conditions and the distance between the ports. Careful consideration of all costs is essential for both parties.

For steel exports, the volume and weight of the goods significantly impact freight costs. The choice of Incoterm can affect the negotiation of the final price. For instance, if freight rates are volatile, a CIF agreement might provide more price certainty for the buyer, while an FOB agreement might offer more flexibility if the buyer can secure favorable freight rates independently.

Choosing the Right Incoterm: Factors to Consider

Selecting the appropriate Incoterm depends on several factors, including:

- The experience and resources of both the buyer and seller: A buyer with established relationships with freight forwarders and insurers might prefer FOB for greater control. Conversely, a seller with expertise in logistics might prefer CIF for a simpler transaction.

- Market conditions: Fluctuations in freight rates and insurance premiums can influence the choice. A stable market might favor FOB, while a volatile market might favor CIF.

- Risk tolerance: Buyers with a higher risk tolerance might prefer FOB, while buyers seeking greater security might prefer CIF.

- Relationship between buyer and seller: A strong, established relationship might allow for more flexibility in choosing the Incoterm.

Thorough communication and a clear understanding of each party’s responsibilities are crucial in determining the most suitable Incoterm for a steel export transaction.

Conclusion: Understanding the nuances of FOB and CIF is vital for successful steel exports. By carefully considering the responsibilities, costs, and risks associated with each Incoterm, both buyers and sellers can ensure a smooth and profitable transaction. Always consult with legal and logistics professionals to ensure compliance with international trade regulations and best practices.

SEO-Friendly Tags:

- FOB Steel Export

- CIF Steel Export

- Incoterms Steel Trade

- International Steel Shipping

- Steel Export Logistics

The steel industry, a cornerstone of modern construction and manufacturing, is constantly seeking ways to improve the performance and longevity of its products. Enter nanotechnology, a field offering groundbreaking solutions to enhance steel’s properties through innovative surface treatments. This blog post delves into the exciting world of nanotech in steel surface treatments, exploring its various applications, benefits, and the future it holds.

1. Understanding the Fundamentals of Nanotech in Steel Surface Treatment

Nanotechnology, at its core, involves manipulating materials at the atomic and molecular level (1-100 nanometers). In the context of steel, this translates to applying extremely thin coatings or modifying the surface structure using nanoparticles or nano-structured materials. These modifications can dramatically alter the steel’s surface properties, leading to improvements in various aspects like corrosion resistance, wear resistance, hardness, and even aesthetic appeal. Common nanomaterials used include nanoparticles of metals (e.g., silver, zinc, copper), metal oxides (e.g., titanium dioxide, alumina), carbon nanotubes (CNTs), and graphene. These materials are incorporated into coatings, often through techniques like sol-gel processing, chemical vapor deposition (CVD), physical vapor deposition (PVD), and electrophoretic deposition.

2. Enhancing Corrosion Resistance with Nanocoatings

Corrosion is a significant concern for steel structures, leading to costly repairs and replacements. Nanotechnology provides effective solutions by creating barrier coatings that prevent corrosive agents from reaching the steel surface. For example, nano-structured ceramic coatings like titanium dioxide (TiO2) and zinc oxide (ZnO) offer excellent corrosion resistance due to their dense and impermeable nature. Furthermore, the incorporation of nanoparticles of corrosion inhibitors, such as cerium oxide, within the coating matrix can further enhance protection. These nanocoatings can be applied to various steel components, from bridges and pipelines to automotive parts and marine structures, significantly extending their lifespan.

3. Improving Wear Resistance through Nanostructured Surfaces

In applications involving significant friction and wear, such as engine components, cutting tools, and molds, the durability of steel is critical. Nanotechnology allows for the creation of highly wear-resistant surfaces through techniques like nano-indentation and laser surface modification. These methods can alter the surface microstructure, creating a harder, more resistant surface layer. The addition of nanoparticles like tungsten carbide or silicon carbide within the steel matrix during manufacturing can further enhance wear resistance. These nanostructured surfaces exhibit superior performance compared to traditional steel, resulting in longer tool life and reduced maintenance costs.

4. Strengthening Steel with Nanomaterials: Enhanced Mechanical Properties

Beyond corrosion and wear resistance, nanotechnology can also improve the overall mechanical properties of steel. The incorporation of carbon nanotubes (CNTs) or graphene into steel matrices can significantly enhance its strength and stiffness. These nanomaterials act as reinforcing agents, improving the load-bearing capacity and preventing crack propagation. The resulting nanocomposite steels exhibit superior tensile strength, yield strength, and fatigue resistance compared to conventional steel, making them ideal for high-performance applications in aerospace, automotive, and construction industries. Research is ongoing to optimize the dispersion and alignment of these nanomaterials within the steel matrix for maximum effectiveness.

5. The Future of Nanotech in Steel Surface Treatments: Emerging Trends and Challenges

The field of nanotechnology in steel surface treatment is constantly evolving. Emerging trends include the development of self-healing coatings that automatically repair minor scratches and defects, thus prolonging the protective effect. Furthermore, research is focusing on creating multifunctional nanocoatings that provide multiple benefits, such as corrosion resistance, wear resistance, and even antimicrobial properties. However, challenges remain, including the cost-effectiveness of large-scale production of nanocoatings, the potential environmental impact of nanomaterials, and the need for robust quality control measures to ensure consistent performance. Overcoming these challenges will unlock the full potential of nanotechnology in revolutionizing the steel industry.

The application of nanotechnology in steel surface treatments represents a significant advancement in materials science. By enhancing corrosion resistance, wear resistance, and mechanical properties, nanomaterials are transforming the performance and lifespan of steel components across various industries. As research continues and technological barriers are overcome, the future promises even more innovative applications of nanotechnology in the world of steel.

Tags: Nanotechnology, Steel Surface Treatment, Nanocoatings, Corrosion Resistance, Wear Resistance

body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

Oil refineries are complex and hazardous environments, demanding materials that can withstand extreme pressures, temperatures, and corrosive substances. At the heart of this intricate network lies a critical component: steel pipes. These seemingly simple structures are the arteries of the refinery, transporting crucial fluids and gases throughout the process. This post delves into the vital role of steel pipes in oil refineries, exploring their selection, properties, challenges, and future prospects.

1. Material Selection: Choosing the Right Steel for the Job

The selection of steel pipe for oil refinery applications is far from arbitrary. It’s a critical decision influenced by factors such as the transported fluid, operating temperature and pressure, and the potential for corrosion. Common steel grades used include:

- Carbon Steel: A cost-effective option suitable for less demanding applications, often used for low-pressure steam or water lines. However, its corrosion resistance is limited.

- Alloy Steel: Offers enhanced strength and corrosion resistance compared to carbon steel. Specific alloying elements are chosen to combat specific corrosive agents present in the refinery process. Examples include chromium-molybdenum (Cr-Mo) steels, which are frequently used in high-temperature and high-pressure services.

- Stainless Steel: Known for its excellent corrosion resistance, stainless steel is employed where highly corrosive fluids are handled, such as in chemical processing units or in handling sour crude oil (containing hydrogen sulfide).

- Duplex Stainless Steel: Combining the properties of austenitic and ferritic stainless steels, duplex grades offer superior strength and corrosion resistance, particularly in chloride-containing environments.

The precise grade selection involves detailed analysis of the process conditions and a thorough risk assessment to ensure long-term performance and safety.

2. Manufacturing Processes and Quality Control

The manufacturing of steel pipes for refineries adheres to stringent quality control standards. Common manufacturing methods include:

- Seamless Pipes: Produced by piercing a heated steel billet, resulting in a homogenous structure with no welds, offering superior strength and resistance to fatigue.

- Welded Pipes: Created by joining steel plates through welding. While less expensive than seamless pipes, welded pipes require rigorous inspection and testing to ensure weld integrity and prevent leaks.

Quality control involves rigorous testing throughout the manufacturing process, including:

- Chemical Composition Analysis: Verifying that the steel meets the specified chemical composition.

- Mechanical Testing: Assessing the tensile strength, yield strength, and elongation of the steel.

- Non-Destructive Testing (NDT): Techniques like radiography, ultrasonic testing, and magnetic particle inspection are used to detect internal flaws or surface imperfections in the pipes.

- Hydrostatic Testing: Pipes are subjected to internal pressure to verify their ability to withstand operating pressures without leakage.

3. Corrosion Management and Protective Measures

Corrosion is a major concern in oil refineries, threatening the integrity of steel pipes and leading to leaks, spills, and costly downtime. Several measures are employed to mitigate corrosion:

- Material Selection (as discussed above): Choosing corrosion-resistant steel grades is the first line of defense.

- Protective Coatings: Applying coatings such as epoxy resins, paints, or zinc galvanization creates a barrier between the steel and the corrosive environment.

- Corrosion Inhibitors: Chemicals are added to the transported fluids to slow down the corrosion process.

- Cathodic Protection: An electrochemical technique that uses an external current to protect the steel pipes from corrosion.

- Regular Inspection and Maintenance: Periodic inspection and maintenance programs, including internal and external visual inspections, help to identify and address corrosion issues before they become critical.

4. Safety and Regulatory Compliance

The safety implications of steel pipe failure in an oil refinery are severe. Leaks can lead to fires, explosions, and the release of hazardous substances. Therefore, strict safety regulations and standards govern the design, installation, and operation of steel piping systems. These regulations often include:

- Pressure Vessel Codes: Adherence to codes like ASME Section VIII (for pressure vessels) ensures the safe design and fabrication of pipes operating under pressure.

- Welding Standards: Strict welding procedures and qualified welders are essential to ensure the integrity of welded joints.

- Regular Inspections and Maintenance: As mentioned earlier, regular inspections and maintenance are crucial for identifying potential problems and preventing failures.

- Emergency Shutdown Systems: Refineries must have effective emergency shutdown systems to mitigate the consequences of pipe failures.

Compliance with these regulations is crucial for ensuring the safety of personnel and the protection of the environment.

5. Future Trends and Innovations in Steel Pipe Technology

The oil and gas industry is constantly evolving, and so too is the technology surrounding steel pipes. Future trends include:

- Advanced Materials: Research into new steel alloys with enhanced corrosion resistance and higher strength-to-weight ratios is ongoing.

- Smart Pipes: Integration of sensors and monitoring systems into steel pipes allows for real-time monitoring of pressure, temperature, and corrosion levels, enabling predictive maintenance and preventing catastrophic failures.

- Improved Welding Techniques: Advances in welding technologies, such as laser welding and automated welding systems, lead to higher-quality welds and improved efficiency.

- Advanced Coatings and Linings: Development of more durable and effective coatings and linings will further enhance corrosion protection and extend the lifespan of steel pipes.

- Sustainable Practices: Increased focus on environmentally friendly practices, including the use of recycled steel and the reduction of waste during manufacturing, is becoming increasingly important.

In conclusion, steel pipes are indispensable to the safe and efficient operation of oil refineries. Careful material selection, stringent manufacturing processes, robust corrosion management strategies, and adherence to safety regulations are essential for ensuring the reliable performance of these critical components. Ongoing innovations in materials science and technology promise to further enhance the performance, safety, and sustainability of steel pipes in the oil and gas industry.

Tags: Steel pipes, oil refinery, corrosion resistance, ASME, pipeline safety, oil and gas industry

Power plants, the behemoths of energy generation, rely on robust and reliable infrastructure. At the heart of this infrastructure lies a critical component: steel profiles. From the towering structures to the intricate internal machinery, steel profiles provide the strength, durability, and precision necessary for efficient and safe operation. This comprehensive guide delves into the multifaceted role of steel profiles in power plant construction and operation.

1. Structural Steel Profiles: The Backbone of Power Plant Construction

The sheer scale of power plants demands robust structural support. Steel profiles, including I-beams, H-beams, channels, and angles, form the backbone of these structures. These profiles are used in the construction of:

- Boiler Houses: Supporting the immense weight of boilers, fuel storage, and associated equipment.

- Turbine Halls: Providing a stable foundation for turbines, generators, and related machinery.

- Control Rooms and Offices: Constructing safe and reliable spaces for plant operation and administration.

- Cooling Towers: Creating the essential framework for these large structures that dissipate heat.

- Stack Structures: Supporting the tall chimneys that vent exhaust gases.

The selection of steel profiles for structural applications depends on factors such as load-bearing capacity, environmental conditions (corrosion resistance), and the overall design requirements. High-strength steels are often preferred to minimize weight and maximize efficiency.

2. Specialized Steel Profiles for Power Generation Equipment

Beyond the main structural elements, steel profiles play a crucial role in the construction of power generation equipment itself. For example:

- Turbine Components: Precisely engineered steel profiles are used in the fabrication of turbine blades, casings, and internal components, requiring high-strength, heat-resistant alloys.

- Boiler Components: Steel profiles contribute to the construction of boiler supports, internal structures, and components that withstand high temperatures and pressures.

- Generator Frames and Supports: Robust steel profiles provide the necessary support for the massive generators, ensuring stability and preventing vibrations.

- Conveyor Systems: Steel profiles form the framework for conveyor systems used to transport fuel, coal, or other materials within the plant.

- Piping Supports: Steel profiles are essential for supporting and securing the extensive network of pipes carrying steam, water, and other fluids.

The manufacturing processes for these specialized profiles often involve advanced techniques like forging, machining, and heat treatment to ensure the necessary precision and durability.

3. Material Selection and Quality Control in Steel Profile Applications

The choice of steel grade is paramount in power plant applications. Factors influencing the selection include:

- Yield Strength: The ability of the steel to withstand stress before permanent deformation.

- Tensile Strength: The maximum stress the steel can endure before breaking.

- Corrosion Resistance: Essential to prevent degradation due to exposure to moisture, chemicals, and high temperatures.

- Weldability: Crucial for joining different steel components.

- Heat Resistance: Important for components exposed to high temperatures, such as boiler components.

Rigorous quality control measures are implemented throughout the entire process, from material sourcing to final installation. This includes regular inspections, testing, and adherence to industry standards to ensure the safety and reliability of the power plant.

4. Manufacturing Processes and Surface Treatments for Enhanced Durability

The manufacturing of steel profiles for power plants often employs advanced techniques to achieve the required properties. These include:

- Hot Rolling: A common method for producing large quantities of steel profiles.

- Cold Forming: Used to achieve higher precision and tighter tolerances.

- Forging: Employed for creating high-strength components with complex shapes.

- Welding: A crucial process for joining steel profiles to create larger structures.

Surface treatments further enhance the durability and lifespan of the steel profiles. These include:

- Galvanizing: Provides corrosion protection through a zinc coating.

- Painting: Offers aesthetic appeal and additional corrosion resistance.

- Protective Coatings: Specialized coatings provide enhanced protection against specific environmental factors.

5. The Future of Steel Profiles in Power Plant Design and Sustainability

With the increasing focus on sustainable energy solutions, the role of steel profiles is evolving. The industry is exploring the use of:

- High-strength low-alloy (HSLA) steels: These offer improved strength-to-weight ratios, leading to lighter and more efficient structures.

- Recycled steel: Reducing the environmental impact of construction by utilizing recycled materials.

- Advanced manufacturing techniques: Optimizing designs and reducing material waste through digital modeling and fabrication.

- Corrosion-resistant coatings: Extending the lifespan of steel profiles and reducing maintenance costs.

The future of power plant construction hinges on innovation and sustainability, and steel profiles will continue to play a vital role in this transition.

Tags: Steel profiles, power plants, structural steel, energy generation, construction materials

Turkey’s steel industry has emerged as a significant player on the global stage, challenging established giants and carving out a unique niche for itself. This success isn’t accidental; it’s the result of a confluence of factors, from a rich history of metalworking to strategic investments in modern technology and a highly skilled workforce. This post delves into the key elements that contribute to Turkish steel’s competitive edge.

A Legacy Forged in History: The Roots of Turkish Steel

Turkey’s steel industry boasts a history stretching back centuries. The Ottoman Empire, renowned for its craftsmanship, laid the foundation for a tradition of metalworking excellence. This historical context instilled a deep understanding of metallurgy and a commitment to quality that continues to resonate in modern Turkish steel production. While the methods have evolved dramatically, the inherent appreciation for precision and durability remains a core value. This historical legacy provides a strong cultural bedrock for the industry, fostering a sense of pride and expertise that is difficult to replicate.

Technological Prowess: Modernizing the Steelmaking Process

The Turkish steel industry hasn’t rested on its laurels. Significant investments in advanced technologies have propelled it into the modern era. Turkish steel mills employ state-of-the-art equipment, including electric arc furnaces (EAFs), continuous casting machines, and sophisticated rolling mills. These technologies enable the production of high-quality steel with greater efficiency and precision. Furthermore, the industry is increasingly embracing automation and data analytics to optimize production processes, minimize waste, and enhance overall productivity. This commitment to technological advancement ensures Turkish steel remains competitive in a rapidly evolving global market.

Strategic Location: A Gateway to Global Markets

Turkey’s geographic location is a significant factor in its steel industry’s success. Situated at the crossroads of Europe and Asia, it enjoys excellent access to major global markets. This strategic position facilitates efficient transportation and logistics, reducing costs and delivery times for both domestic and international customers. The proximity to key raw material sources, including iron ore and scrap metal, further strengthens the industry’s competitive advantage. This advantageous location minimizes transportation costs and allows for faster response times to market demands.

Skilled Workforce: The Human Element of Success

Behind the advanced technology and strategic location lies a highly skilled and dedicated workforce. Turkey has invested heavily in education and training, producing a generation of engineers, technicians, and skilled laborers capable of operating and maintaining sophisticated steelmaking equipment. This skilled workforce ensures high-quality production, efficient operations, and a commitment to continuous improvement. The dedication and expertise of Turkish steel workers are crucial to maintaining the industry’s competitive edge in the face of global competition.

Government Support and Policies: Fostering Growth and Innovation

The Turkish government has played a crucial role in fostering the growth and development of the steel industry. Supportive policies, including tax incentives, infrastructure investments, and initiatives to promote research and development, have created a favorable environment for investment and innovation. These government efforts have helped to attract both domestic and foreign investment, further strengthening the industry’s capabilities and competitiveness. Furthermore, government regulations ensure adherence to international quality standards, enhancing the reputation and trustworthiness of Turkish steel in global markets.

In conclusion, the success of Turkish steel is a testament to a multifaceted strategy that blends historical legacy with modern technology, strategic location with a skilled workforce, and government support with a commitment to innovation. These factors combine to create a potent competitive edge in the global steel market, positioning Turkey as a significant player for years to come.

SEO Tags:

Turkish Steel, Steel Industry Turkey, Global Steel Market, Turkish Steel Manufacturing, Competitive Steel Production

Navigating the world of European manufacturing standards, specifically those prefixed with “EN,” can feel like traversing a complex maze. These standards, developed by the European Committee for Standardization (CEN), are crucial for ensuring product safety, quality, and interoperability within the European Economic Area (EEA). This comprehensive guide will illuminate the path to EN standard compliance, helping manufacturers understand the process, benefits, and challenges involved.

Understanding EN Standards: More Than Just a Label

EN standards aren’t simply arbitrary regulations; they represent a commitment to consistent quality and safety. They are based on extensive research, testing, and consensus among industry experts, ensuring a level playing field for all manufacturers. Understanding the specific EN standard relevant to your product is the first critical step. These standards cover a vast range of products and processes, from construction materials (EN 1990 series) to electrical appliances (EN 60335 series) and even food safety (EN ISO 22000). Each standard outlines detailed requirements, specifications, and testing procedures that must be met to achieve compliance. Failing to understand these requirements can lead to costly product recalls, legal issues, and reputational damage.

The Importance of Thorough Testing and Verification

Meeting EN standards isn’t a matter of self-declaration; it requires rigorous testing and verification. Independent testing laboratories, accredited by national accreditation bodies, play a vital role in this process. These laboratories use standardized methods to assess whether your products meet the specified requirements. The testing process can be complex and time-consuming, varying significantly depending on the specific EN standard. Some tests might involve physical strength assessments, while others focus on electrical safety, electromagnetic compatibility (EMC), or chemical composition. Thorough testing ensures product reliability and safety, minimizing risks and protecting consumers. Documenting all testing procedures and results is crucial for demonstrating compliance.

Navigating the Certification Process: Obtaining Your Mark of Compliance

Once your product successfully passes all necessary tests, the next step involves obtaining certification. This usually involves a notified body, an organization designated by a member state to assess conformity to specific EN standards. The notified body will audit your manufacturing processes, ensuring they consistently meet the requirements of the relevant standard. They will also review your quality management system (QMS), often based on ISO 9001, to ensure consistent product quality. Successful completion of this audit results in certification, allowing you to affix the CE marking (in most cases) to your products, signifying compliance with relevant EU directives and harmonized standards. This mark is essential for selling your products within the EEA.

Maintaining Compliance: Ongoing Monitoring and Improvement

Obtaining certification is not the end of the journey; it’s the beginning of an ongoing commitment to maintaining compliance. Regular internal audits, monitoring of production processes, and ongoing review of the relevant EN standards are essential. Changes in technology, regulations, or consumer expectations can necessitate updates to your processes and products. Proactive monitoring and continuous improvement are key to staying compliant and maintaining your competitive edge. Regular updates and revisions to the EN standards also necessitate a commitment to staying informed and adapting to these changes.

The Benefits of EN Standard Compliance: Beyond Legal Requirements

Meeting EN standards offers numerous benefits beyond simply avoiding legal penalties. It enhances your brand reputation, demonstrating your commitment to quality and consumer safety. This builds trust with customers and creates a competitive advantage in the marketplace. Compliance also facilitates access to new markets, particularly within the EEA, where EN standards are often mandatory. Furthermore, a robust quality management system, a necessary component of EN standard compliance, improves internal efficiency, reduces waste, and streamlines operations. The long-term benefits of EN compliance far outweigh the initial investment in testing and certification.

Successfully navigating the world of EN standards requires careful planning, meticulous attention to detail, and a proactive approach. By understanding the requirements, investing in thorough testing, and embracing a culture of continuous improvement, manufacturers can not only meet legal obligations but also unlock significant competitive advantages and build a strong reputation for quality and safety.

SEO-Friendly Tags:

- EN Standards

- Manufacturing Compliance

- European Standards Certification

- Product Safety Regulations

- CE Marking

High-performance pipes are the backbone of countless industrial processes and infrastructure projects. Their ability to withstand extreme conditions, optimize fluid flow, and ensure longevity is crucial for efficiency and safety. This post delves into the key features that distinguish these pipes from standard alternatives, exploring how these advancements contribute to enhanced performance and reliability.

1. Superior Material Selection: The Foundation of High Performance

The choice of material is paramount in determining a pipe’s performance characteristics. High-performance pipes often utilize advanced materials engineered to withstand specific challenges. For instance, super duplex stainless steels offer exceptional corrosion resistance in harsh environments, making them ideal for chemical processing and offshore applications. Similarly, high-strength alloys like Inconel are employed where high temperatures and pressures are involved, such as in power generation and aerospace industries. The selection process considers factors like:

- Corrosion Resistance: The ability to withstand chemical attack is crucial, especially in applications involving corrosive fluids or gases.

- Temperature Resistance: High-performance pipes must maintain structural integrity at elevated temperatures without significant creep or degradation.

- Pressure Rating: The pipe must be able to withstand the internal pressure exerted by the fluid without failure.

- Strength and Durability: The material needs to possess sufficient strength to resist internal and external forces, including vibrations and impacts.

Careful material selection ensures the pipe meets the demanding requirements of its intended application, maximizing its lifespan and performance.

2. Enhanced Durability and Longevity: Minimizing Downtime and Maximizing ROI

High-performance pipes are designed for extended service life. This longevity is achieved through various means, including advanced manufacturing techniques and superior material properties. Features contributing to enhanced durability include:

- Improved Weldability: Seamless pipes or those with advanced welding processes minimize weak points and ensure structural integrity across the entire length.

- Enhanced Surface Finish: A smooth internal surface reduces friction, improving flow efficiency and minimizing the risk of corrosion or scaling.

- Resistance to Fatigue: The pipe’s ability to withstand repeated stress cycles without failure is critical in applications with fluctuating pressure or vibrations.

- Impact Resistance: High-performance pipes often exhibit superior resistance to external impacts, reducing the risk of damage from accidental collisions or environmental factors.

By minimizing downtime due to failures and extending the operational lifespan, high-performance pipes contribute significantly to a better return on investment.

3. Advanced Flow Optimization: Reducing Energy Consumption and Increasing Efficiency

Efficient fluid transport is a key consideration in many applications. High-performance pipes achieve this through features that minimize friction and optimize flow characteristics. These include:

- Smooth Internal Surfaces: As mentioned earlier, a smooth inner surface reduces frictional losses, leading to lower energy consumption for pumping.

- Optimized Pipe Diameters: Careful selection of pipe diameter ensures optimal flow velocity, maximizing efficiency and minimizing pressure drop.

- Specialized Coatings: Internal coatings can further reduce friction and improve flow characteristics, particularly in applications with viscous fluids.

- Advanced Design Features: In some cases, specialized pipe designs, such as those incorporating internal flow guides or turbulence promoters, can enhance flow efficiency.

These flow optimization features translate to reduced energy costs and improved overall system efficiency.

4. Superior Corrosion Resistance: Protecting Against Environmental Degradation

Corrosion is a significant concern in many industrial applications, leading to pipe failure and costly repairs. High-performance pipes combat this through various means:

- Corrosion-Resistant Materials: The use of materials like stainless steels, duplex stainless steels, and super duplex stainless steels provides inherent corrosion resistance.

- Protective Coatings: Applying specialized coatings, such as epoxy or polyurethane, creates a barrier against corrosive agents.

- Cathodic Protection: This electrochemical method prevents corrosion by applying a protective current to the pipe’s surface.

- Material Selection Based on Specific Environments: Careful consideration of the specific chemical composition of the transported fluid and the surrounding environment is crucial for selecting the appropriate corrosion-resistant material.

By effectively resisting corrosion, high-performance pipes ensure prolonged service life and minimize the risk of leaks or failures.

5. Advanced Joining and Installation Techniques: Ensuring Seamless Integration

The way pipes are joined significantly impacts the overall system’s performance and reliability. High-performance piping systems often employ advanced joining techniques that ensure a strong, leak-free connection:

- Welding: Advanced welding techniques like orbital welding provide high-quality, consistent welds with minimal defects.

- Flanged Connections: High-pressure flanged connections, often with specialized gaskets, ensure a leak-tight seal under extreme conditions.

- Butt Fusion Welding: For plastic pipes, butt fusion welding creates a strong, seamless joint with excellent structural integrity.

- Specialized Fittings: Using high-quality, precisely engineered fittings minimizes stress points and ensures a smooth flow path.

Careful attention to joining and installation procedures is essential for maximizing the performance and longevity of high-performance piping systems.

In conclusion, high-performance pipes represent a significant advancement in piping technology, offering superior performance, durability, and reliability across a wide range of industries. Understanding the key features discussed above is crucial for selecting the appropriate piping solutions for any given application.

SEO Tags:

- High-performance pipes

- Industrial piping systems

- Corrosion resistant pipes

- Flow optimization in pipes

- Advanced pipe materials