The construction industry is a significant contributor to global greenhouse gas emissions. However, a surprising champion in the fight for sustainable building practices is steel. Often perceived as an environmentally unfriendly material, steel, when produced and utilized responsibly, offers a compelling case for its role in creating a greener future for construction.

1. The Carbon Footprint of Steel: A Closer Look

It’s crucial to acknowledge that steel production does involve carbon emissions. The process of smelting iron ore in blast furnaces is energy-intensive and releases CO2. However, significant advancements are being made to reduce this footprint. The use of electric arc furnaces (EAFs), which utilize scrap steel as their primary feedstock, drastically reduces carbon emissions compared to traditional blast furnaces. EAFs can reduce CO2 emissions by up to 70% compared to the traditional method. Furthermore, innovations like carbon capture and storage (CCS) technologies are being implemented to further minimize the environmental impact of steel production.

Furthermore, the embodied carbon – the carbon emitted throughout a material’s lifecycle, from extraction to manufacturing – of steel can be offset by its long lifespan and recyclability. A well-designed steel structure can last for decades, minimizing the need for frequent replacements and associated carbon emissions.

2. Recycled Steel: A Circular Economy Champion

Steel’s remarkable recyclability is a key factor in its sustainability profile. Steel can be recycled endlessly without losing its properties, making it a truly circular material. This significantly reduces the demand for virgin materials and minimizes the environmental impact associated with extraction and processing. In fact, the steel industry boasts one of the highest recycling rates of any material globally. Using recycled steel in construction projects demonstrably lowers the overall carbon footprint of the building.

The increased use of recycled steel not only reduces reliance on new resources but also decreases landfill waste, contributing to a cleaner environment. This closed-loop system makes steel a truly sustainable choice for environmentally conscious construction projects.

3. Lightweight Steel Construction: Optimizing Resource Use

Lightweight steel construction techniques offer significant sustainability advantages. These methods utilize high-strength, low-alloy steels to create lighter, more efficient structures. This reduces the amount of material required for a project, leading to lower transportation costs and emissions. The reduced weight also translates to lower foundation requirements, potentially saving on materials and energy during the construction phase.

Furthermore, the precision and speed of steel construction processes minimize construction time and waste. Prefabrication techniques, often employed in lightweight steel construction, allow for efficient off-site manufacturing and assembly, reducing on-site disruption and waste generation.

4. Durability and Longevity: Reducing the Need for Replacement

Steel structures are known for their exceptional durability and longevity. They are resistant to fire, pests, and weathering, resulting in longer lifespans compared to some other building materials. This extended lifespan reduces the need for frequent repairs, renovations, or replacements, minimizing the associated environmental impact over the building’s lifetime. The reduced need for future construction projects contributes significantly to the overall sustainability of the steel choice.

Proper maintenance and design considerations further enhance the longevity of steel structures, ensuring their resilience against environmental factors and extending their useful life for decades, if not centuries.

5. Steel’s Role in Sustainable Building Design

Steel’s versatility allows architects and engineers to design innovative and sustainable building forms. Its strength and flexibility enable the creation of lightweight, energy-efficient structures that optimize natural light and ventilation. Steel’s ability to support large spans also allows for the creation of open floor plans, maximizing space utilization and reducing the environmental impact of building materials.

Furthermore, steel’s compatibility with other sustainable materials, such as timber and recycled concrete, allows for the creation of hybrid structures that combine the strengths of various materials for optimal environmental performance. The integration of steel into sustainable building design strategies contributes to the creation of environmentally responsible and aesthetically pleasing structures.

In conclusion, while the steel production process does have an environmental footprint, its inherent recyclability, durability, and the advancements in production methods are making it an increasingly sustainable choice for the construction sector. By embracing responsible sourcing, innovative construction techniques, and a focus on the circular economy, the construction industry can harness the sustainable strength of steel to build a greener future.

SEO Tags:

Sustainable Construction, Steel Construction, Green Building Materials, Recycled Steel, Sustainable Steel

For centuries, materials like stone and concrete have defined architectural landscapes. However, a new era is upon us, one where steel’s inherent strength, flexibility, and aesthetic appeal are propelling it to the forefront of modern architectural design. This resurgence isn’t merely a trend; it’s a testament to steel’s evolving capabilities and its crucial role in shaping the buildings of tomorrow.

The Unmatched Strength and Versatility of Steel

Steel’s exceptional tensile strength allows architects to create structures of unprecedented scale and complexity. Unlike traditional materials, steel can withstand immense loads while maintaining a relatively lightweight profile. This characteristic is pivotal in designing skyscrapers that reach for the sky, long-span bridges that seamlessly connect distant points, and intricate, dynamic facades that push the boundaries of architectural expression. The malleability of steel further enhances its versatility. It can be easily shaped, bent, and welded, allowing for intricate designs and customized components that would be impossible with other materials. This adaptability is evident in the intricate latticework of modern museums, the flowing curves of contemporary stadiums, and the sleek, minimalist lines of high-rise residential buildings.

Sustainable Steel: Addressing Environmental Concerns

For years, the environmental impact of steel production has been a concern. However, significant advancements in steel manufacturing processes have led to a dramatic reduction in carbon emissions. The use of recycled steel, for instance, significantly reduces the energy required compared to producing steel from raw materials. Furthermore, advancements in electric arc furnaces and the development of low-carbon steel alloys are further minimizing the environmental footprint. The durability and longevity of steel structures also contribute to sustainability. Steel buildings can withstand the test of time, reducing the need for frequent replacements and minimizing the associated waste and environmental impact. Modern architects are increasingly embracing sustainable steel practices, aligning their designs with environmentally conscious building strategies.

Iconic Steel Structures: Shaping the Modern Skyline

The impact of steel on the modern architectural landscape is undeniable. Iconic structures across the globe showcase steel’s transformative power. The Burj Khalifa, the world’s tallest building, relies heavily on steel for its structural integrity. Similarly, the Eiffel Tower, a timeless symbol of Parisian elegance, stands as a testament to steel’s early architectural prowess. Modern marvels like the Shard in London and the One World Trade Center in New York City further demonstrate steel’s ability to create breathtaking, awe-inspiring designs. These structures aren’t just functional; they are powerful statements, embodying the ambition, innovation, and aesthetic sensibilities of modern architecture. The use of steel allows for a unique interplay of form and function, producing buildings that are both visually stunning and structurally sound.

Innovative Steel Design Techniques: Pushing the Boundaries

The architectural application of steel is continuously evolving. Innovative design techniques are unlocking new possibilities, enabling architects to create increasingly complex and aesthetically compelling structures. Advanced computer modeling and analysis allow for precise structural calculations, optimizing steel usage and minimizing material waste. This precision allows for the creation of lightweight yet incredibly strong structures, pushing the limits of architectural design. Furthermore, the integration of other materials with steel, such as glass and concrete, creates hybrid structures that combine the strengths of different materials. This synergistic approach allows for even greater design flexibility and opens up new avenues for creative expression.

The Future of Steel in Architecture: A Promising Outlook

The future of steel in architecture looks exceptionally bright. Continued advancements in steel technology, coupled with a growing awareness of its sustainability credentials, suggest an even greater role for steel in shaping the built environment. Research into new steel alloys with enhanced properties, such as increased strength and corrosion resistance, will further expand the possibilities of steel construction. Furthermore, the integration of smart technologies into steel structures, such as sensors for structural health monitoring, will enhance building efficiency and safety. As architects continue to explore the full potential of steel, we can expect to see even more innovative and sustainable designs that redefine the modern skyline.

Steel’s versatility, strength, and sustainability are driving its resurgence in modern architecture. It’s a material that seamlessly blends functionality with aesthetic appeal, enabling architects to push the boundaries of design and create structures that are both impressive and environmentally responsible. The future undoubtedly holds even greater innovations in steel architecture, shaping the urban landscapes of tomorrow.

The skyline of any major city today is a testament to the power and versatility of steel. From soaring skyscrapers to elegant bridges, steel’s impact on modern architecture is undeniable. This post explores the fascinating journey of steel, from its early tentative uses to its current status as the backbone of many of the world’s most iconic structures.

The Dawn of Steel in Construction: From Bridges to Buildings

While iron had been used in construction for centuries, the mass production of steel in the late 19th century marked a revolutionary turning point. The Bessemer process and later advancements significantly reduced the cost and increased the strength of steel, making it a viable and increasingly attractive alternative to traditional materials like stone and brick. Initially, steel’s strength was primarily harnessed in bridge construction, with iconic structures like the Brooklyn Bridge showcasing its potential. However, it wasn’t long before architects began to envision the possibilities of steel in building construction, leading to the emergence of taller, lighter, and more complex structures. This early adoption paved the way for the skyscraper revolution.

The Rise of the Skyscraper: Steel’s Defining Moment

The late 19th and early 20th centuries saw the rapid development of the skyscraper, a building type that would be unthinkable without steel. The ability of steel to support immense weight and span vast distances allowed architects to push the boundaries of height and design. The Home Insurance Building in Chicago, often cited as the first true skyscraper, utilized a steel frame construction, demonstrating the potential of this new material. This innovation led to a rapid escalation in building heights, with steel frameworks enabling the creation of ever-taller and more complex structures. The development of elevators further fueled this trend, making high-rise buildings practical and desirable.

Beyond the Skyscraper: Steel’s Diverse Applications

While skyscrapers are the most obvious representation of steel’s impact, its applications in modern architecture are far more diverse. Steel is used extensively in the construction of bridges, stadiums, museums, and even residential buildings. Its versatility allows for a wide range of architectural styles and designs, from the sleek and minimalist to the ornate and expressive. The use of steel also allows for prefabrication, enabling faster construction times and reduced on-site labor. This efficiency is particularly crucial in large-scale projects.

Steel and Sustainability: Balancing Strength and Responsibility

The environmental impact of steel production is a significant concern in the modern era. However, advancements in steel manufacturing processes are leading to more sustainable practices. Recycled steel is increasingly used, reducing the need for virgin materials and minimizing the carbon footprint. Furthermore, the durability and longevity of steel structures contribute to their sustainability, as they require less frequent replacement than structures built with other materials. Architects are also exploring innovative designs that optimize steel usage and minimize waste, further enhancing the sustainability of steel-framed buildings.

The Future of Steel in Architecture: Innovation and Integration

Steel continues to evolve as a building material. New alloys and manufacturing techniques are constantly being developed, leading to stronger, lighter, and more versatile steel products. Architects are exploring innovative ways to integrate steel with other materials, such as concrete and glass, creating hybrid structures that combine the best properties of each. The use of parametric design and computational modeling allows for complex steel structures that would have been impossible to create just a few decades ago. As technology advances, we can expect to see even more daring and innovative uses of steel in architecture, pushing the boundaries of design and engineering.

In conclusion, the rise of steel in modern architecture is a story of innovation, ingenuity, and the relentless pursuit of taller, stronger, and more beautiful structures. From its humble beginnings in bridge construction to its current dominance in the world’s most iconic buildings, steel has fundamentally reshaped the urban landscape and continues to inspire architects and engineers alike.

Tags: steel architecture, modern architecture, skyscraper construction, structural steel, steel design

In the world of industrial building construction, the choice of materials significantly impacts the project’s success. From massive warehouses to intricate manufacturing plants, the material that consistently proves its worth is steel. Its inherent properties make it the cornerstone of robust, efficient, and sustainable industrial structures. This post delves into the multifaceted importance of steel in industrial building construction.

Unmatched Strength and Durability: The Foundation of Industrial Resilience

Steel’s exceptional strength-to-weight ratio is unparalleled. This means that steel structures can withstand immense loads and pressures, crucial for industrial buildings housing heavy machinery, large inventories, and potentially hazardous materials. Unlike other materials, steel doesn’t degrade significantly over time, ensuring the longevity of the building and minimizing the need for costly repairs and replacements. Its resistance to extreme weather conditions, including high winds, heavy snowfall, and seismic activity, further solidifies its position as the preferred material for industrial applications. The ability to withstand fire for extended periods, offering valuable time for evacuation and minimizing property damage, is another significant advantage.

Versatility in Design and Functionality: Adapting to Diverse Industrial Needs

Steel’s versatility is a major factor in its widespread use. It can be easily shaped and molded into various forms, allowing for the creation of complex and customized structures. This flexibility caters to the diverse needs of different industries. Whether it’s a high-bay warehouse requiring vast open spaces or a multi-story manufacturing facility with intricate internal layouts, steel can be adapted to meet the specific requirements. The prefabrication of steel components off-site also speeds up construction time significantly, reducing project completion time and overall costs. This modular approach allows for easy expansion and modification of the building in the future, accommodating evolving business needs.

Sustainability and Environmental Considerations: A Green Choice for Industrial Construction

While often viewed as a non-renewable resource, steel’s sustainability credentials are stronger than many assume. Steel is 100% recyclable, meaning that the material used in demolished structures can be reused repeatedly without losing its strength or quality. This significantly reduces the demand for virgin materials and minimizes the environmental impact associated with mining and manufacturing. Furthermore, the longevity of steel structures reduces the frequency of building replacements, further contributing to its overall environmental sustainability. Modern steel production methods are also incorporating more sustainable practices, minimizing carbon emissions and promoting responsible resource management.

Cost-Effectiveness and Return on Investment: A Smart Financial Decision

Despite its initial cost, steel offers long-term cost-effectiveness. The durability and longevity of steel structures translate into reduced maintenance and repair costs over the building’s lifespan. Faster construction times, thanks to prefabrication and efficient assembly, also contribute to lower labor costs. The potential for future expansion and modification without significant structural changes further adds to the financial benefits. The overall return on investment for steel-constructed industrial buildings is often higher compared to buildings constructed using alternative materials, making it a fiscally responsible choice.

Advanced Steel Technologies: Enhancing Performance and Efficiency

Continuous advancements in steel technology are further enhancing its performance and efficiency in industrial buildings. High-strength low-alloy (HSLA) steels offer increased strength and ductility, allowing for lighter and more efficient structures. Innovative coating technologies improve corrosion resistance, extending the lifespan of the building even further. The development of advanced steel connections simplifies construction, improves structural integrity, and reduces overall costs. These technological advancements demonstrate steel’s ongoing evolution and its continued suitability for the demanding requirements of modern industrial applications. The integration of smart technologies with steel structures, like sensors for monitoring structural health and energy efficiency, is also gaining traction, enhancing the overall performance and sustainability of industrial buildings.

In conclusion, steel’s reign as the king of industrial building construction is well-deserved. Its unparalleled strength, versatility, sustainability, cost-effectiveness, and the continuous advancements in its technology make it the ideal material for creating robust, efficient, and sustainable industrial structures. Choosing steel ensures a long-term investment that yields significant returns for both businesses and the environment.

Tags: Industrial building materials, steel construction, steel buildings, industrial building design, sustainable construction

The world runs on steel. From skyscrapers piercing the clouds to the intricate components of our vehicles, steel’s strength and versatility are undeniable. But behind every robust structure and efficient machine lies a commitment to rigorous quality standards. This commitment ensures safety, reliability, and performance, making steel a truly indispensable material. This post delves into the critical aspects of maintaining these standards throughout the steel production process.

1. Raw Material Selection: The Foundation of Quality

The journey to high-quality steel begins long before the smelting process. The selection of raw materials – primarily iron ore, scrap steel, and various alloying elements – is paramount. The chemical composition of the iron ore, its purity, and the presence of impurities like sulfur and phosphorus directly impact the final product’s properties. Careful analysis and rigorous testing are crucial at this stage. Suppliers must adhere to strict specifications, and incoming materials are subjected to comprehensive checks, including chemical analysis, particle size distribution analysis, and moisture content determination. Any deviation from the established norms can lead to defects and inconsistencies in the final steel product, potentially compromising its strength, ductility, and other critical properties.

2. The Smelting Process: Refining the Raw Material

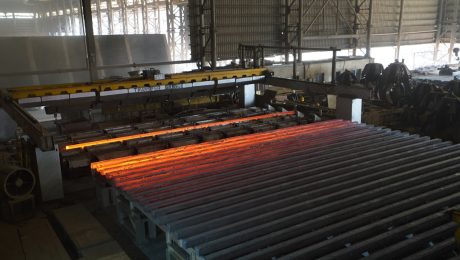

The smelting process, often involving blast furnaces or electric arc furnaces, transforms the raw materials into molten pig iron. Maintaining consistent temperature, oxygen levels, and chemical composition during this stage is vital. Advanced process control systems monitor and regulate these parameters, ensuring the pig iron meets the required specifications. Continuous monitoring and adjustments are crucial to prevent defects like slag inclusions and gas porosity, which can severely weaken the final steel. The quality of the pig iron directly influences the subsequent steelmaking steps, underscoring the importance of meticulous control throughout the smelting process.

3. Steelmaking: Achieving the Desired Alloy Composition

Once the pig iron is produced, it undergoes further refining in steelmaking processes like the basic oxygen furnace (BOF) or electric arc furnace (EAF). These processes remove impurities and introduce alloying elements to achieve the desired chemical composition and mechanical properties. Precise control over the addition of alloying elements like manganese, chromium, nickel, and molybdenum is crucial. These elements significantly influence the steel’s strength, hardness, corrosion resistance, and other characteristics. Sophisticated analytical techniques, such as spectroscopy, are employed to monitor the chemical composition in real-time, allowing for immediate adjustments to maintain the desired properties. Variations from the target composition can lead to significant performance issues in the final product.

4. Casting and Rolling: Shaping the Steel

After steelmaking, the molten steel is cast into various forms, such as slabs, blooms, or billets, depending on the intended application. The casting process must ensure the absence of defects like cracks, inclusions, and segregation. Careful control of the cooling rate and solidification process is essential to prevent these defects. Subsequently, the cast material undergoes rolling, shaping it into the desired dimensions and form. Rolling parameters, such as temperature, roll speed, and reduction, are carefully controlled to achieve the required mechanical properties and surface finish. Any inconsistencies in these processes can lead to dimensional inaccuracies, surface imperfections, and internal defects, potentially compromising the steel’s structural integrity.

5. Quality Control and Testing: Ensuring Conformance to Standards

Throughout the entire steel production process, rigorous quality control measures are implemented. At each stage, samples are taken and subjected to various tests to ensure the material meets the specified standards. These tests include chemical analysis, mechanical testing (tensile strength, yield strength, elongation, hardness), non-destructive testing (ultrasonic testing, radiographic testing), and metallurgical examination. The results of these tests are meticulously documented and analyzed to identify any deviations from the established norms. This data-driven approach ensures continuous improvement and helps identify potential sources of defects, allowing for corrective actions to be taken promptly. Adherence to international standards, such as ISO 9001, is essential to guarantee the quality and reliability of the final steel product.

The production of high-quality steel requires a meticulous approach, combining advanced technologies with rigorous quality control measures. Every step, from raw material selection to final testing, contributes to the overall excellence of the final product. By adhering to these stringent standards, the steel industry ensures the safety, reliability, and performance of countless applications, shaping the world we live in.

SEO-Friendly Tags:

- Steel Production

- Steel Quality Standards

- Steel Manufacturing Processes

- Quality Control in Steel

- ISO 9001 Steel

Earthquakes are unpredictable and devastating natural disasters. The ability to design and construct buildings that can withstand these powerful forces is paramount to saving lives and minimizing economic losses. Steel, with its unique properties, plays a crucial role in creating earthquake-resistant structures. This post explores the multifaceted contribution of steel to seismic design and construction.

1. The Superior Strength and Ductility of Steel

Steel’s inherent strength is a primary reason for its widespread use in earthquake-resistant design. Its high tensile strength allows it to withstand significant forces without fracturing. However, equally important is its ductility – the ability to deform significantly under stress before failure. This characteristic allows steel structures to absorb seismic energy through yielding and deformation, rather than experiencing brittle failure. This energy dissipation is critical in preventing catastrophic collapse during an earthquake. Unlike brittle materials like concrete, which can shatter under seismic loads, steel bends and deforms, thus reducing the impact of the ground shaking. This ductility enables the structure to “give” during an earthquake, minimizing damage and protecting occupants.

2. Steel’s Role in Moment-Resisting Frames

Moment-resisting frames are a fundamental component of earthquake-resistant building design. These frames consist of interconnected steel beams and columns that form a rigid structural system. The steel’s high strength and ductility allow these frames to resist lateral forces generated by earthquakes. The connections between the beams and columns are meticulously designed to ensure adequate energy dissipation and prevent premature failure. Advanced welding techniques and high-strength bolts are used to create strong and reliable connections that can withstand the intense stresses imposed during an earthquake. The design of these frames often incorporates specific detailing to encourage ductile behavior, focusing energy dissipation at pre-determined points to prevent global collapse.

3. Steel’s Contribution to Seismic Dampers and Isolation Systems

Beyond the structural frame, steel is integral to advanced seismic protection systems. Steel is a key component in various types of seismic dampers, devices designed to absorb and dissipate seismic energy. These dampers, often incorporating viscous fluids or other energy-absorbing mechanisms within steel housings, reduce the impact of ground shaking on the building. Steel is also used extensively in base isolation systems, which decouple the building from the ground movement. These systems typically involve steel bearings or sliders that allow the building to move independently of the foundation during an earthquake, significantly reducing the forces transmitted to the structure. The use of steel in these systems ensures durability and reliability under extreme conditions.

4. Steel’s Adaptability in Different Seismic Design Approaches

Steel’s versatility allows it to be incorporated into a variety of seismic design approaches. It can be used in both conventional moment-resisting frames and more advanced systems like braced frames, which utilize steel bracing members to enhance lateral stability. The choice of design approach depends on factors such as the building’s height, occupancy, and the seismic hazard level of the location. Steel’s adaptability makes it a suitable material for a wide range of building types and seismic conditions, from low-rise residential structures to high-rise commercial buildings. The ability to tailor the design and detailing of the steel components to meet specific seismic demands further underscores its importance in earthquake engineering.

5. Sustainability and the Future of Steel in Earthquake-Resistant Construction

The sustainability of steel is an increasingly important consideration in construction. Steel is a recyclable material, reducing the environmental impact of building construction and demolition. Furthermore, advancements in steel production are leading to the development of higher-strength, lighter-weight steels, which can reduce the overall material usage in earthquake-resistant structures. Ongoing research into new steel alloys and innovative connection techniques continues to enhance the performance and sustainability of steel in seismic design. The pursuit of more efficient and environmentally friendly steel production methods further strengthens its position as a vital material for creating resilient and sustainable buildings in earthquake-prone regions.

In conclusion, steel’s exceptional strength, ductility, and adaptability make it an indispensable material in earthquake-resistant construction. Its use in moment-resisting frames, seismic dampers, and base isolation systems contributes significantly to the safety and resilience of buildings in earthquake-prone areas. Continuous advancements in steel technology and design techniques further cement its crucial role in protecting lives and property from the devastating effects of earthquakes.

SEO Tags:

- Earthquake-resistant structures

- Steel structures

- Seismic design

- Earthquake engineering

- Steel construction

Choosing the right roofing system is a crucial investment for any homeowner or business owner. While various options exist, steel roofing stands out as a superior choice, offering a compelling combination of durability, longevity, and cost-effectiveness. This comprehensive guide delves into the significant advantages of steel roof systems, highlighting why they are an increasingly popular choice for protecting properties from the elements.

Unmatched Durability and Longevity: A Lifetime of Protection

Steel roofs are renowned for their exceptional durability. Unlike asphalt shingles that are susceptible to cracking, curling, and granule loss, steel roofs are resistant to impact damage, high winds, and heavy snowfall. Their robust construction ensures they can withstand extreme weather conditions, providing unwavering protection for decades. The lifespan of a properly installed steel roof can easily exceed 50 years, significantly longer than most other roofing materials. This longevity translates into substantial long-term cost savings, eliminating the need for frequent replacements and repairs.

Superior Fire Resistance: Protecting Your Investment from Flames

Fire safety is paramount, and steel roofing offers unmatched protection in this regard. Steel is inherently non-combustible, meaning it won’t ignite or contribute to the spread of fire. This inherent fire resistance significantly reduces the risk of property damage and loss in the event of a fire, providing peace of mind and potentially lower insurance premiums. This feature makes steel roofing an excellent choice for areas prone to wildfires or where fire safety is a primary concern.

Energy Efficiency: Saving Money and Reducing Your Carbon Footprint

Steel roofs contribute significantly to energy efficiency. Many steel roofing systems incorporate reflective coatings that minimize heat absorption. This reduces the amount of heat transferred into the building, lowering cooling costs during the summer months. Furthermore, some steel roofs are designed with enhanced insulation capabilities, further improving energy efficiency and contributing to a smaller carbon footprint. The long-term savings on energy bills can significantly offset the initial investment in a steel roof.

Low Maintenance and Easy Cleaning: Saving Time and Effort

Unlike other roofing materials that require regular maintenance and cleaning, steel roofs are remarkably low-maintenance. Their smooth surface sheds water and debris effectively, minimizing the risk of moss, algae, or lichen growth. Cleaning is typically straightforward, often requiring only occasional rinsing with a garden hose. This low-maintenance nature saves time, effort, and money in the long run, making steel roofing a practical and convenient choice.

Cost-Effectiveness: A Long-Term Investment with Significant Returns

While the initial cost of a steel roof might be higher than some other roofing materials, the long-term cost-effectiveness is undeniable. The exceptional lifespan, low maintenance requirements, and energy savings significantly outweigh the initial investment. The reduced need for repairs and replacements over the years translates into substantial savings, making steel roofing a financially sound decision for both residential and commercial properties. Furthermore, increased property value due to the enhanced durability and longevity of the roof can further add to its cost-effectiveness.

In conclusion, steel roofing systems offer a compelling combination of durability, fire resistance, energy efficiency, low maintenance, and cost-effectiveness. These advantages make them a superior choice for protecting your property from the elements and ensuring long-term value. Consider the significant benefits of steel roofing when making your next roofing decision.

Tags: Steel Roofing, Metal Roofing, Roofing Materials, Roofing Advantages, Durable Roofing

“`

Heavy industry, the backbone of modern economies, demands robust, durable, and reliable infrastructure and machinery. Steel, with its exceptional strength-to-weight ratio, versatility, and cost-effectiveness, plays a pivotal role in meeting these demands. This blog post delves into the multifaceted applications of steel construction within the heavy industrial landscape, showcasing its enduring significance.

1. Steel’s Reign in Industrial Infrastructure: Foundations and Frameworks

The very foundation of many heavy industrial facilities relies heavily on steel. From massive steel-reinforced concrete structures supporting colossal machinery to the intricate frameworks of processing plants, steel provides the essential structural integrity. Steel’s high tensile strength allows for the construction of large spans without the need for numerous intermediate supports, maximizing operational space. Furthermore, steel’s weldability facilitates the creation of complex and customized structures tailored to specific industrial needs. Think of the massive storage tanks, towering silos, and extensive pipework networks – all predominantly constructed using steel to ensure longevity and safety under demanding conditions. The design flexibility of steel also allows for easy expansion and modification of existing structures, accommodating future growth and technological advancements within the plant.

2. Heavy Machinery and Equipment: Forging Strength with Steel

Heavy machinery, the workhorses of heavy industry, is largely built using steel. Components like gears, shafts, housings, and frames all benefit from steel’s high strength and resistance to wear and tear. The ability to forge, cast, and machine steel into intricate shapes allows for the creation of complex machinery components with precise tolerances. Consider the construction of excavators, cranes, and rolling mills – these machines rely on steel’s strength and durability to withstand immense forces and operate reliably in harsh environments. The use of high-strength, low-alloy steels further enhances the performance and lifespan of these critical pieces of equipment, minimizing downtime and maintenance costs.

3. Steel in Material Handling and Transportation Systems

Efficient material handling is crucial in heavy industry. Steel plays a significant role in this process, forming the backbone of conveyor systems, cranes, and other material handling equipment. Steel’s ability to withstand heavy loads and repeated stresses makes it ideal for constructing durable and reliable conveyors that transport raw materials and finished products across large distances within a plant. Similarly, steel is the primary material used in the construction of overhead cranes, bridge cranes, and gantry cranes, crucial for lifting and moving heavy loads within factories and warehouses. Rail transport systems, integral to many heavy industries, also rely extensively on steel for the construction of tracks, rolling stock, and supporting infrastructure.

4. Specialized Steel Applications: Tailoring Strength to Specific Needs

The versatility of steel extends to specialized applications within heavy industry. High-strength, low-alloy steels are employed where weight reduction and enhanced strength are paramount, while stainless steels offer superior corrosion resistance in corrosive environments. Heat-resistant steels are essential for applications involving high temperatures, such as furnaces and power generation equipment. The use of these specialized steels ensures that the structures and machinery withstand the unique challenges of their specific operating conditions, optimizing performance and extending their lifespan. This targeted application of different steel grades demonstrates the material’s adaptability and its ability to meet the diverse demands of heavy industry.

5. Sustainability and the Future of Steel in Heavy Industry

While steel production has an environmental footprint, the industry is actively pursuing sustainable practices. Recycling steel is highly efficient, significantly reducing the need for virgin materials and minimizing environmental impact. Furthermore, advancements in steel manufacturing are leading to the development of more sustainable steel production methods, reducing energy consumption and emissions. The durability and long lifespan of steel structures and machinery contribute to reduced waste and lower replacement costs over time. The ongoing commitment to sustainable practices ensures that steel will continue to play a vital role in heavy industry, balancing its economic benefits with environmental responsibility.

In conclusion, the applications of steel construction in heavy industry are vast and multifaceted. From foundational structures to intricate machinery, steel’s strength, versatility, and cost-effectiveness make it an indispensable material. As the industry continues to evolve, the role of steel will remain crucial, shaped by ongoing innovations in material science and a growing focus on sustainability.

SEO Tags:

- Steel Construction

- Heavy Industry Applications

- Industrial Steel Structures

- Steel Fabrication for Industry

- Structural Steel Design

“`

“`html

Steel, the backbone of modern infrastructure and countless industries, demands rigorous quality control throughout its production. From the initial smelting process to the final product, adherence to stringent quality standards is paramount. This comprehensive guide delves into the key aspects that ensure the consistent production of high-quality steel, fulfilling diverse industrial needs and maintaining safety and reliability.

1. Chemical Composition: The Foundation of Steel Quality

The chemical composition of steel dictates its inherent properties. Variations in the percentages of carbon, manganese, silicon, phosphorus, sulfur, and other alloying elements significantly impact the steel’s strength, hardness, ductility, weldability, and machinability. Standards like ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) define acceptable ranges for these elements depending on the intended application of the steel. For instance, high-carbon steel, used in tools and cutting instruments, requires a much higher carbon content than mild steel used in construction. Precise control over the chemical composition is achieved through careful selection of raw materials, precise alloying additions during the steelmaking process, and rigorous laboratory analysis using techniques such as spectroscopy and chemical analysis.

2. Mechanical Properties: Measuring Steel’s Performance

Beyond its chemical makeup, the mechanical properties of steel are critical to its performance. These properties, including tensile strength, yield strength, elongation, hardness, and impact resistance, are determined through standardized testing methods. Tensile testing, for example, measures the steel’s ability to withstand tensile forces before fracture, providing crucial data on its strength and ductility. Hardness testing, using methods like Rockwell or Brinell, assesses the steel’s resistance to indentation, indicating its wear resistance. Impact testing, such as Charpy or Izod, evaluates the steel’s ability to absorb energy upon impact, vital for applications in cold climates or where sudden shocks are expected. These tests are conducted at various stages of steel production and are documented to ensure compliance with specified standards and customer requirements.

3. Non-Destructive Testing (NDT): Ensuring Internal Integrity

While destructive testing provides crucial data, non-destructive testing (NDT) methods are employed to evaluate the integrity of the steel without damaging the material. NDT techniques, such as ultrasonic testing (UT), radiographic testing (RT), magnetic particle inspection (MPI), and liquid penetrant inspection (LPI), detect internal flaws like cracks, porosity, and inclusions that could compromise the steel’s strength and reliability. These methods are crucial for ensuring the quality of finished products and for identifying potential defects early in the manufacturing process, preventing costly rework or product recalls. The choice of NDT method depends on the type of steel, its thickness, and the specific defects being sought.

4. Traceability and Certification: Maintaining Accountability

Maintaining a comprehensive and accurate record of the steel’s production process is crucial for traceability and certification. This involves meticulous documentation of the raw materials used, the manufacturing processes employed, the test results obtained, and the final product specifications. This detailed record allows for the identification of any potential issues and facilitates corrective actions if necessary. Furthermore, independent certification bodies, such as those accredited by ISO, verify the steel’s compliance with relevant standards and issue certificates of conformity, providing assurance to customers regarding the quality and reliability of the product. This traceability and certification process is integral to building trust and maintaining a strong reputation within the steel industry.

5. Continuous Improvement and Technological Advancements

The pursuit of higher quality standards in steel production is an ongoing process. Continuous improvement initiatives, driven by technological advancements, play a pivotal role in enhancing efficiency and minimizing defects. Advanced process control systems, utilizing real-time data analysis and automation, optimize the steelmaking process, ensuring consistent chemical composition and mechanical properties. The development and implementation of new steel grades with enhanced performance characteristics, tailored to specific applications, are also crucial to meeting the ever-evolving demands of various industries. Furthermore, research into new and improved testing techniques contributes to more accurate and efficient quality control methods.

In conclusion, the pursuit of excellence in steel production relies on a multifaceted approach encompassing precise chemical control, rigorous mechanical testing, non-destructive evaluation, comprehensive traceability, and a commitment to continuous improvement. By adhering to these quality standards, the steel industry ensures the production of reliable, high-performance materials vital for countless applications, underpinning safety and progress across diverse sectors.

Tags: Steel quality standards, steel production, ISO standards, steel testing, mechanical properties of steel

“`

“`html

Prefabricated buildings are revolutionizing the construction industry, offering faster build times, reduced costs, and increased efficiency. While various materials can be used in prefab construction, steel stands out as the ideal choice for a multitude of reasons. Its inherent strength, versatility, and sustainability make it the backbone of many innovative and efficient building projects. Let’s delve deeper into why steel reigns supreme in the world of prefabricated structures.

Unmatched Strength and Durability: The Steel Advantage

Steel’s exceptional strength-to-weight ratio is a game-changer in prefabricated construction. It allows for the creation of lightweight yet incredibly robust structures that can withstand extreme weather conditions, seismic activity, and the test of time. Unlike wood or concrete, steel is not susceptible to rot, insect infestation, or significant degradation, ensuring the longevity of the building and minimizing maintenance costs over its lifespan. This inherent durability translates directly into a lower total cost of ownership for the building owner.

Furthermore, steel’s high tensile strength allows for larger spans and open floor plans, maximizing usable space and minimizing the need for internal support columns. This is particularly advantageous in commercial and industrial settings where spaciousness is crucial for productivity and efficiency. The inherent strength also allows for the creation of buildings designed to withstand specific environmental pressures, making them suitable for even the most challenging locations.

Speed and Efficiency: Revolutionizing Construction Timelines

Prefabricated steel buildings are assembled significantly faster than traditionally constructed buildings. The components are manufactured off-site in a controlled factory environment, minimizing weather delays and logistical challenges. This controlled environment also leads to higher precision and quality control, resulting in fewer on-site errors and rework. Once the components are ready, assembly on-site is typically swift and efficient, significantly reducing the overall project timeline.

This speed translates to faster occupancy, quicker return on investment for developers, and reduced labor costs. The streamlined process also minimizes disruption to surrounding areas, making steel-framed prefab buildings a more environmentally considerate option during the construction phase itself.

Sustainability and Environmental Responsibility: A Greener Choice

Steel is a highly recyclable material, making it a sustainable choice for environmentally conscious builders. At the end of a building’s life, the steel components can be easily dismantled and recycled, significantly reducing waste and minimizing the environmental impact. Moreover, the use of steel in prefabricated buildings often reduces the overall amount of material used compared to traditional construction methods, further contributing to environmental sustainability.

Beyond recyclability, steel manufacturing processes are continuously improving in terms of energy efficiency and emissions reduction. The industry is actively working towards further minimizing its carbon footprint, making steel a responsible choice for those committed to building a greener future.

Design Flexibility and Architectural Freedom: Beyond the Ordinary

Steel’s versatility allows for a wide range of design possibilities. It can be easily shaped, molded, and fabricated into various forms, accommodating diverse architectural styles and functional requirements. From sleek, modern designs to more traditional aesthetics, steel can adapt to any vision. This flexibility is particularly valuable in prefabricated construction where customization is often a key selling point.

The ability to create complex shapes and intricate details with steel opens up opportunities for unique and visually striking buildings. This adaptability allows architects to push creative boundaries and deliver buildings that are both functional and aesthetically pleasing, making steel a preferred choice for projects requiring unique design solutions.

Cost-Effectiveness and Long-Term Value: A Smart Investment

While the initial cost of steel may seem higher than some other materials, the long-term cost-effectiveness of steel-framed prefabricated buildings is undeniable. The faster construction times, reduced labor costs, minimized waste, and lower maintenance requirements all contribute to significant savings over the building’s lifespan. The durability and longevity of steel also reduce the need for frequent repairs and replacements, further enhancing its cost-effectiveness.

The precision of factory fabrication minimizes on-site errors, reducing costly rework and delays. This predictable and efficient process leads to a more accurate budgeting process and a lower risk of cost overruns, making steel a financially sound investment for both residential and commercial projects.

In conclusion, steel’s superior strength, speed of construction, sustainability, design flexibility, and cost-effectiveness make it the ideal material for prefabricated buildings. Its combination of performance and environmental responsibility positions it as a leading choice for the future of construction.

Tags: steel buildings, prefabricated buildings, prefab construction, steel construction, sustainable building materials

“`