High-pressure piping systems are integral to numerous industries, from oil and gas to chemical processing and power generation. While essential for efficient operations, these systems present significant safety challenges if not properly designed, installed, and maintained. This comprehensive guide explores key aspects of high-pressure pipe safety, providing insights into best practices and crucial considerations to mitigate risks and ensure operational excellence.

1. Design and Material Selection: The Foundation of Safety

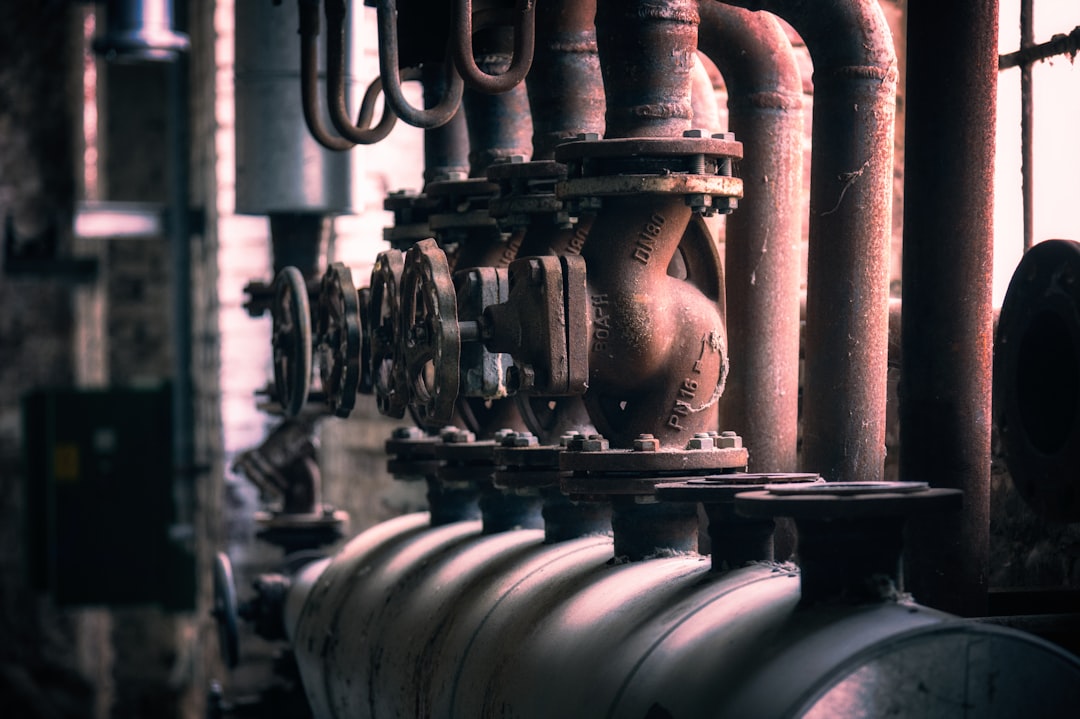

The foundation of any safe high-pressure piping system lies in its design and the materials used. Careful consideration must be given to factors such as operating pressure, temperature, fluid properties (corrosiveness, viscosity), and potential external forces (earthquakes, thermal expansion). Design engineers utilize rigorous calculations and simulations to determine the appropriate pipe diameter, wall thickness, and material specifications to withstand the anticipated stresses. Materials must possess high tensile strength, yield strength, and fatigue resistance to prevent failure under pressure. Common materials include carbon steel, stainless steel, alloy steel, and specialized polymers depending on the specific application. Proper stress analysis, including Finite Element Analysis (FEA), is crucial to identify potential weak points and optimize the design for safety.

2. Rigorous Inspection and Testing: Identifying Potential Hazards

Regular and thorough inspection is paramount to maintaining the integrity of high-pressure piping systems. This involves both visual inspections, checking for corrosion, erosion, dents, and leaks, and non-destructive testing (NDT) methods such as ultrasonic testing (UT), radiographic testing (RT), and magnetic particle inspection (MPI). These NDT techniques allow for the detection of internal flaws and weaknesses that might not be visible to the naked eye. Hydrostatic testing, a critical part of the commissioning process and periodic maintenance, involves pressurizing the system with water to a pressure exceeding the operating pressure to verify its structural integrity. Regular inspections and testing help identify potential hazards early, allowing for timely repairs and preventing catastrophic failures.

3. Effective Maintenance and Repair Strategies: Proactive Safety Measures

Proactive maintenance is crucial for preventing failures and ensuring the long-term safety of high-pressure piping systems. This includes regular cleaning to remove debris and corrosion, lubrication of valves and fittings, and timely replacement of worn or damaged components. A comprehensive maintenance plan should be developed and implemented, outlining the frequency of inspections, testing, and repairs. Proper documentation of all maintenance activities is essential for tracking the system’s history and identifying trends that might indicate potential problems. When repairs are necessary, qualified personnel should perform them using appropriate procedures and materials, ensuring that the repaired section meets the original design specifications and safety standards.

4. Emergency Procedures and Response: Preparedness for Unexpected Events

Despite the best design, inspection, and maintenance practices, accidents can still occur. Therefore, having well-defined emergency procedures and a robust response plan is crucial. This includes establishing clear communication protocols, identifying potential emergency scenarios (leaks, ruptures, fires), and training personnel on proper emergency response techniques. Emergency shut-off valves should be readily accessible and clearly marked, and personnel should be trained on their proper operation. Developing a detailed emergency response plan, including evacuation procedures and contact information for emergency services, is essential to minimize the impact of any unforeseen event. Regular drills and simulations help ensure that personnel are prepared to respond effectively in a crisis.

5. Compliance with Safety Regulations and Standards: Adherence to Best Practices

Operating high-pressure piping systems requires strict adherence to relevant safety regulations and industry standards. These standards, often developed by organizations like ASME (American Society of Mechanical Engineers), provide detailed guidelines on design, materials, inspection, testing, and operation. Compliance with these standards is crucial not only for ensuring safety but also for meeting legal requirements and avoiding potential penalties. Regular audits and inspections by regulatory bodies help ensure that operations adhere to the established safety standards. Staying updated on the latest safety regulations and best practices is crucial for maintaining a safe and compliant operating environment.

High-pressure pipe safety is not a one-time effort but rather an ongoing commitment to rigorous practices. By prioritizing design, inspection, maintenance, emergency preparedness, and regulatory compliance, industries can effectively mitigate risks and ensure the safe and efficient operation of their high-pressure piping systems.

SEO Tags:

high-pressure pipe safety, pipeline safety, pressure vessel safety, pipe inspection, pipe maintenance