Boiler tubes are the arteries of power generation and numerous industrial processes, silently facilitating the transfer of immense heat energy. These seemingly simple components play a crucial role in steam generation, impacting efficiency, safety, and overall plant performance. This comprehensive guide delves into the technology and diverse applications of boiler tubes, exploring their materials, manufacturing, maintenance, and future trends.

1. Materials Science: The Backbone of Boiler Tube Strength

The selection of boiler tube material is paramount, directly influencing the tube’s lifespan, resistance to corrosion, and ability to withstand high pressures and temperatures. Common materials include:

- Carbon Steel: A cost-effective option for low-pressure applications, carbon steel offers good strength but is susceptible to corrosion, particularly in high-temperature, high-pressure environments. Its use is often limited to less demanding applications.

- Alloy Steel: Alloying elements like chromium, molybdenum, and vanadium enhance the corrosion resistance and high-temperature strength of steel. These alloys are widely used in high-pressure and high-temperature boilers, offering superior performance compared to carbon steel.

- Stainless Steel: Known for exceptional corrosion resistance, stainless steel (particularly grades like 304 and 316) is ideal for applications involving aggressive chemicals or corrosive environments. However, they might have lower strength at extremely high temperatures compared to some alloy steels.

- Non-Ferrous Metals: Materials like copper and copper alloys (e.g., admiralty brass) find applications in specific situations, particularly where corrosion resistance is critical and high temperatures are not a primary concern. They are often used in feedwater heaters or condenser applications within the overall boiler system.

The choice of material depends heavily on the specific operating conditions of the boiler, including pressure, temperature, and the chemical composition of the water and steam.

2. Manufacturing Processes: Precision Engineering for Optimal Performance

The manufacturing of boiler tubes is a precise process demanding stringent quality control. Common methods include:

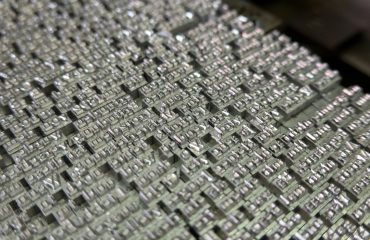

- Seamless Tubes: These tubes are produced by piercing and rolling a solid billet of metal, resulting in a continuous, homogenous structure without welds. Seamless tubes are preferred for high-pressure applications due to their superior strength and resistance to failure.

- Welded Tubes: Manufactured by joining two edges of a metal strip, welded tubes are generally less expensive than seamless tubes. However, the weld itself can be a potential point of weakness, and careful quality control during welding is crucial to ensure integrity.

- Extrusion: This process involves forcing a heated metal billet through a die to create a tube of the desired shape and size. It’s particularly suitable for producing tubes with complex cross-sections.

After manufacturing, tubes undergo rigorous testing to ensure they meet the required specifications for pressure, burst strength, and dimensional accuracy. This ensures the reliability and safety of the boiler system.

3. Diverse Applications: Powering Industries Across the Globe

Boiler tubes are not limited to power plants; their applications are widespread across various industries:

- Power Generation: This is the primary application, with boiler tubes forming the heart of thermal power plants, generating steam to drive turbines for electricity production.

- Industrial Processes: Numerous industries rely on boilers for steam generation, including chemical processing, refining, pulp and paper manufacturing, and food processing. Boiler tubes are essential in these applications for heating, drying, and other processes.

- Heating Systems: In smaller-scale applications, boiler tubes are used in hot water heating systems for buildings and industrial spaces.

- Waste Heat Recovery: Boiler tubes can be integrated into systems to recover waste heat from industrial processes, improving energy efficiency and reducing environmental impact.

The specific type of boiler tube used will vary depending on the application’s demands for pressure, temperature, and corrosive environment.

4. Maintenance and Inspection: Ensuring Longevity and Safety

Regular maintenance and inspection of boiler tubes are critical to prevent failures and ensure the safe operation of the boiler system. This typically includes:

- Visual Inspection: Regular visual checks for signs of corrosion, erosion, or damage.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing and radiographic testing are used to detect internal flaws without damaging the tube.

- Chemical Cleaning: Periodic cleaning to remove deposits and scale that can reduce heat transfer efficiency and accelerate corrosion.

- Tube Replacement: Damaged or worn-out tubes need to be replaced to maintain the integrity of the boiler system.

A comprehensive maintenance program is crucial for extending the lifespan of boiler tubes and preventing costly downtime.

5. Future Trends: Innovation and Sustainability

The future of boiler tube technology is focused on enhancing efficiency, sustainability, and durability. Key trends include:

- Advanced Materials: Research and development into new materials with improved corrosion resistance, higher strength at elevated temperatures, and enhanced thermal conductivity are ongoing.

- Improved Manufacturing Techniques: Advanced manufacturing processes are being developed to produce tubes with even greater precision and improved properties.

- Smart Monitoring Systems: The integration of sensors and data analytics to monitor tube condition in real-time, enabling predictive maintenance and minimizing downtime.

- Sustainable Practices: A focus on reducing the environmental impact of boiler tube manufacturing and disposal, including the use of recycled materials and improved waste management.

These advancements promise to further enhance the performance, reliability, and environmental friendliness of boiler systems.

Boiler tubes are vital components in countless industrial processes and power generation. Understanding their technology and use is crucial for ensuring efficient, safe, and sustainable operations.

Tags: boiler tubes, boiler tube materials, boiler tube manufacturing, boiler tube applications, boiler maintenance