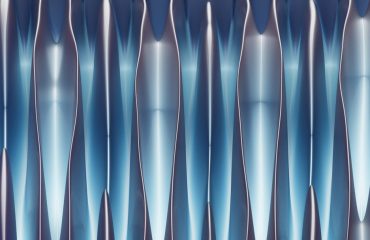

Wind turbines, the silent giants of renewable energy, rely on a complex interplay of components to harness the power of the wind. While the blades themselves are visually striking, their effectiveness hinges critically on a robust and reliable support system. This system, often overlooked, is the backbone of the turbine, ensuring efficient energy conversion and longevity. This post delves into the fascinating world of wind turbine blade support systems, exploring their design, materials, maintenance, and future innovations.

1. The Foundation: Pitch Bearing Systems and Their Crucial Role

The pitch bearing system is arguably the most critical component within the blade support structure. It allows for the controlled adjustment of the blade’s angle (pitch) relative to the wind. This adjustment is crucial for optimizing energy capture and protecting the turbine during high-wind events. The pitch bearing system typically consists of a sophisticated mechanism incorporating hydraulics or electromechanical actuators. These actuators precisely control the pitch angle, enabling the turbine to maximize energy production in moderate winds and feather the blades (turning them edge-on to the wind) during storms to prevent damage. The design and material selection for these bearings are paramount, as they must withstand immense forces and stresses, while maintaining precision and reliability over many years of operation.

2. Material Science: A Deep Dive into Blade Support Materials

The materials used in blade support systems must possess a unique combination of properties. High tensile strength is essential to withstand the immense centrifugal forces generated by the rotating blades, especially at high rotational speeds. Fatigue resistance is equally important, as the system experiences cyclical loading and unloading throughout its operational life. Common materials used include high-strength steel alloys, composites like carbon fiber reinforced polymers (CFRP), and advanced ceramics. The choice of material often depends on factors such as turbine size, operating conditions (e.g., wind speed, temperature), and cost considerations. Recent advancements in material science have led to the development of lighter and stronger materials, improving turbine efficiency and reducing the overall cost of energy.

3. Structural Integrity: Ensuring Safety and Longevity Through Design

The design of the blade support system is a complex engineering challenge, requiring meticulous consideration of factors such as aerodynamics, structural mechanics, and fatigue analysis. Finite element analysis (FEA) plays a crucial role in simulating the stresses and strains experienced by the system under various operating conditions. This allows engineers to optimize the design for maximum strength and minimize the risk of failure. Furthermore, the design must account for factors such as corrosion, icing, and extreme temperature variations, ensuring the system’s long-term reliability and safety. Redundancy is often built into the design, providing backup systems in case of component failure.

4. Maintenance and Inspection: Prolonging the Life of Blade Support Systems

Regular maintenance and inspection are crucial for ensuring the continued safe and efficient operation of wind turbine blade support systems. This includes visual inspections for signs of wear, corrosion, or damage, as well as more in-depth inspections using non-destructive testing (NDT) techniques such as ultrasonic testing or magnetic particle inspection. These techniques allow for the early detection of potential problems, preventing catastrophic failures. Regular lubrication of moving parts is also essential to reduce friction and wear. A comprehensive maintenance schedule, tailored to the specific turbine model and operating conditions, is crucial for maximizing the lifespan of the blade support system and minimizing downtime.

5. Future Innovations: Pushing the Boundaries of Wind Turbine Technology

Ongoing research and development efforts are focused on improving the design, materials, and maintenance strategies for wind turbine blade support systems. This includes exploring new materials with enhanced strength-to-weight ratios, such as advanced composites and lightweight alloys. The integration of smart sensors and predictive maintenance technologies is also gaining traction, enabling real-time monitoring of the system’s health and allowing for proactive maintenance interventions. This reduces the risk of unexpected failures and minimizes downtime, ultimately increasing the efficiency and profitability of wind farms. Furthermore, research is exploring the use of active control systems that can dynamically adjust the blade support system in response to changing wind conditions, further optimizing energy capture and reducing fatigue loads.

In conclusion, the seemingly simple act of supporting a wind turbine blade is a testament to sophisticated engineering. The design, materials, and maintenance of these systems are critical for the safe, efficient, and cost-effective operation of wind turbines. As technology continues to evolve, we can expect even more innovative solutions to emerge, pushing the boundaries of wind energy and paving the way for a cleaner, more sustainable future.

Tags: Wind turbine, blade support system, pitch bearing, wind turbine maintenance, renewable energy, wind energy technology, turbine design.