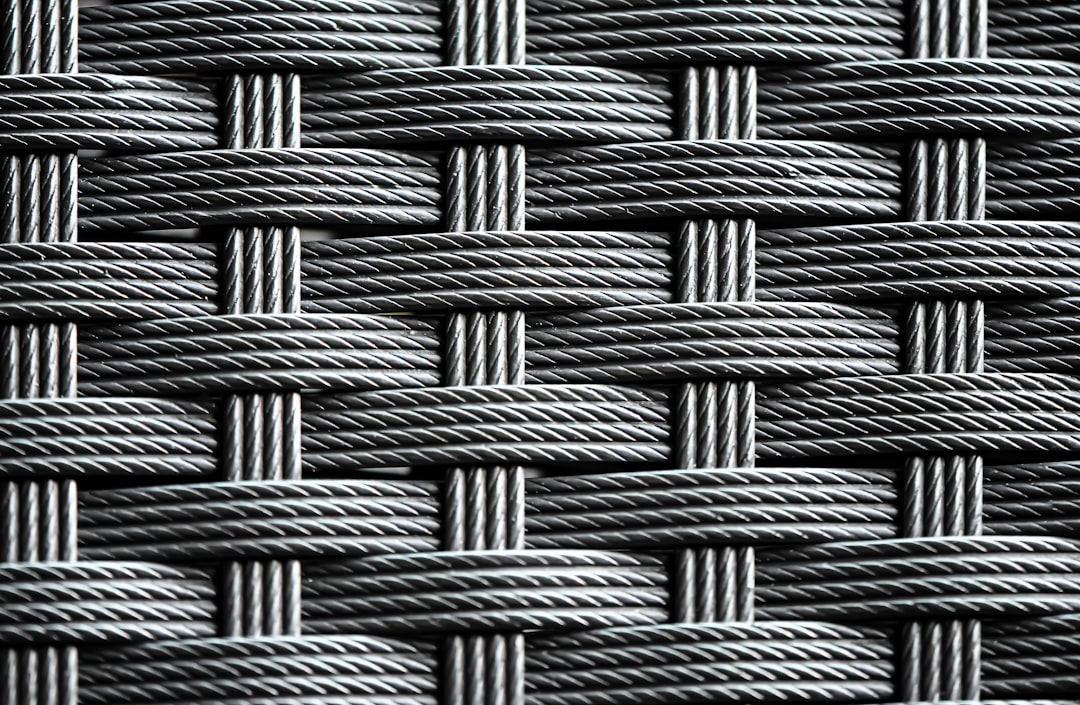

Twisted square wire, with its unique strength and aesthetic appeal, is far more than just a simple piece of metal. Its robust construction and distinctive look make it a versatile material suitable for a wide range of applications, from intricate craft projects to robust structural elements. This post delves into the diverse world of twisted square wire, exploring its uses in detail.

1. Twisted Square Wire in Artistic Crafts and Jewelry Making

The unique texture and visual interest of twisted square wire make it a popular choice for artists and crafters. Its strength allows for intricate designs without the worry of bending or breaking easily. It’s particularly well-suited for:

- Wire Wrapping: The square shape provides a secure grip, making it ideal for wrapping gemstones, beads, and other decorative elements. The twist adds a visually appealing texture that enhances the overall design.

- Jewelry Creation: Twisted square wire can form the foundation of necklaces, bracelets, earrings, and rings. Its strength ensures durability, while its unique texture adds a touch of sophistication.

- Sculpting and Wirework: More experienced crafters can use twisted square wire to create complex three-dimensional sculptures and intricate wirework designs. The square shape lends itself well to creating sharp angles and defined forms.

- Mixed Media Art: Twisted square wire can be incorporated into a variety of mixed media projects, adding texture and visual interest to paintings, collages, and other artistic creations.

2. Utilizing Twisted Square Wire in Construction and Industrial Applications

Beyond its artistic applications, twisted square wire finds its place in various construction and industrial settings. Its strength and durability make it a reliable material for:

- Reinforcement: Twisted square wire can be used as reinforcement in concrete structures, adding tensile strength and preventing cracking. This is particularly useful in smaller-scale projects or areas requiring intricate reinforcement.

- Fence Construction: While not as common as other wire types, twisted square wire can be used in certain fence designs, particularly where a more robust and less flexible fence is desired.

- Industrial Applications: Twisted square wire can be incorporated into various industrial processes, such as binding materials, creating support structures, and even acting as a component in specialized machinery.

- Basket Weaving (Heavy Duty): For particularly strong and durable baskets, twisted square wire provides a sturdy alternative to traditional wicker or rattan.

3. The Advantages of Twisted Square Wire over Other Wire Types

Compared to round wire or other wire types, twisted square wire offers several distinct advantages:

- Increased Strength: The square shape and twisting process contribute to significantly higher tensile strength compared to round wire of the same gauge.

- Unique Aesthetic: The twisted square shape offers a visually appealing texture and pattern, making it a desirable material for artistic endeavors.

- Better Grip: The square shape provides a better grip for wrapping and other applications, facilitating easier handling and more secure connections.

- Versatility: Its combination of strength and aesthetic appeal makes it suitable for a wide range of applications, from delicate jewelry to robust industrial uses.

4. Choosing the Right Gauge and Material of Twisted Square Wire

The choice of gauge (thickness) and material is crucial for ensuring the twisted square wire is appropriate for its intended use. Consider these factors:

- Gauge: Thicker gauges (lower numbers) are stronger and suitable for construction or heavy-duty applications. Thinner gauges (higher numbers) are better suited for delicate crafts and jewelry making.

- Material: Common materials include steel, copper, and aluminum. Steel offers superior strength, while copper and aluminum offer better conductivity (if needed) and may be easier to work with.

- Finish: Twisted square wire is available in various finishes, including bare metal, plated, or coated. The choice of finish depends on the application and desired aesthetic.

5. Safety Precautions When Working with Twisted Square Wire

While generally safe to handle, certain precautions should be taken when working with twisted square wire, particularly with thicker gauges:

- Wear Protective Gear: Always wear safety glasses to protect your eyes from flying debris or sharp edges. Gloves are also recommended to protect your hands.

- Sharp Edges: Be mindful of the sharp edges of the wire, especially when handling thinner gauges. Use caution to avoid cuts or scratches.

- Proper Tools: Utilize appropriate tools for cutting and shaping the wire, such as wire cutters and pliers. Avoid using tools that could damage the wire or cause injuries.

- Disposal: Dispose of scrap wire responsibly, following local regulations for metal recycling.

Twisted square wire is a remarkably versatile material with a wide array of applications. By understanding its properties and choosing the appropriate gauge and material, you can unlock its full potential in your creative projects or industrial endeavors. Remember to always prioritize safety when working with this material.

Tags: twisted square wire, square wire uses, wire crafts, construction wire, metal wire