Navigating the steel market can feel like navigating a minefield. Prices fluctuate wildly, supply chains are complex, and choosing the right procurement strategy is crucial for profitability. Two dominant approaches stand out: spot contracts and long-term contracts. This in-depth guide will dissect the nuances of each, helping you determine which strategy best aligns with your business needs.

Understanding Spot Steel Contracts: Riding the Price Wave

Spot steel contracts are agreements for the immediate purchase and delivery of steel. They’re characterized by their short-term nature, often ranging from a few days to a few weeks. The price is determined at the time of purchase, reflecting the current market conditions. This means you benefit from potentially lower prices during market downturns but face the risk of price spikes during periods of high demand or supply chain disruptions.

Advantages of Spot Contracts:

- Price Flexibility: Capitalize on low prices when the market dips.

- Flexibility in Volume: Purchase only what you need, reducing storage costs and inventory risks.

- Faster Procurement: Quick turnaround times are ideal for urgent projects.

Disadvantages of Spot Contracts:

- Price Volatility: Exposure to significant price fluctuations can impact profitability.

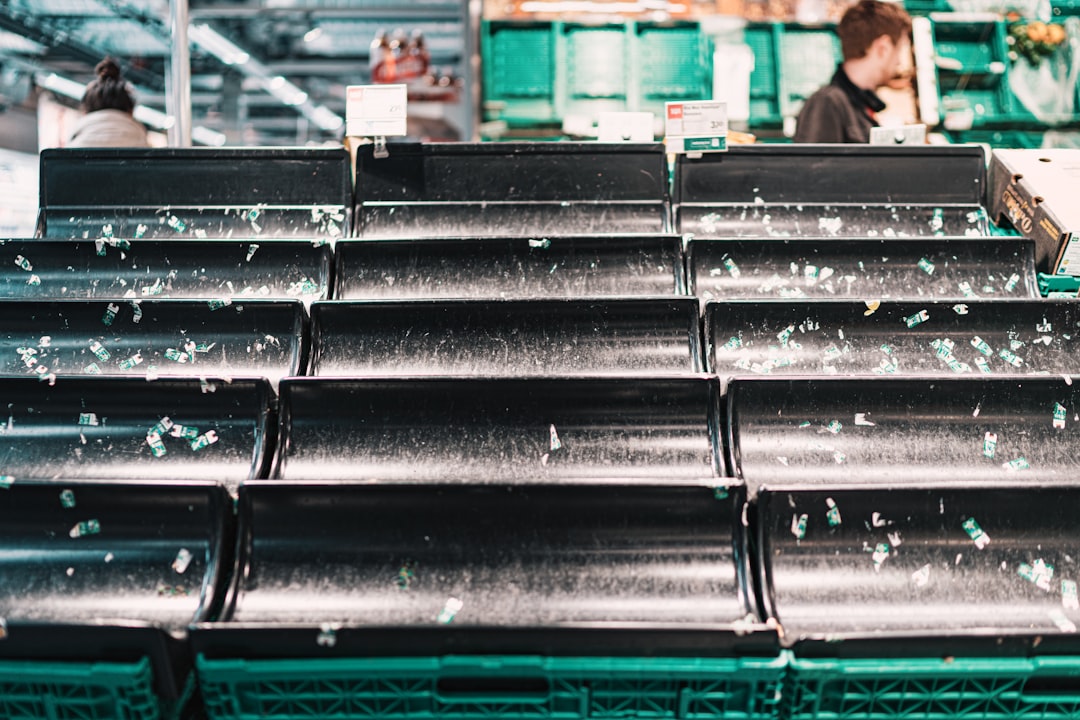

- Supply Uncertainty: Finding reliable suppliers and securing timely delivery can be challenging.

- Increased Transaction Costs: Frequent procurement necessitates more administrative overhead.

Long-Term Steel Contracts: Stability and Predictability

Long-term steel contracts, in contrast, involve agreements for the supply of steel over an extended period, typically ranging from several months to several years. These contracts often stipulate a fixed price or a price-adjustment mechanism based on established indices, offering greater price certainty than spot contracts. They provide a degree of supply chain stability, ensuring a consistent flow of materials.

Advantages of Long-Term Contracts:

- Price Stability: Reduces exposure to market price volatility, improving budgeting accuracy.

- Guaranteed Supply: Secures a reliable source of steel, minimizing supply chain disruptions.

- Improved Supplier Relationships: Cultivates strong partnerships with preferred suppliers.

- Potential for Volume Discounts: Large-volume commitments often lead to negotiated price reductions.

Disadvantages of Long-Term Contracts:

- Price Risk in a Downward Market: Locked-in prices might be higher than prevailing market rates during price drops.

- Less Flexibility: Adjusting procurement volumes can be challenging due to contractual obligations.

- Potential for Contractual Disputes: Misunderstandings or unforeseen circumstances can lead to legal complications.

Risk Management: A Key Consideration in Steel Procurement

Both spot and long-term contracts involve inherent risks. Spot contracts expose you to price volatility and supply chain uncertainty, while long-term contracts carry the risk of price lock-in during market downturns. Effective risk management strategies are crucial regardless of your chosen approach.

For spot contracts, consider using hedging strategies, diversifying your supplier base, and maintaining robust inventory management systems. For long-term contracts, carefully analyze market trends, negotiate flexible pricing mechanisms, and ensure clear contractual terms to mitigate potential disputes.

Supply Chain Stability: Ensuring Consistent Steel Supply

Maintaining a stable and reliable steel supply is paramount for any manufacturing business. Long-term contracts excel in this area by guaranteeing a consistent flow of materials, reducing the risk of production delays due to supply shortages. However, even with long-term contracts, unforeseen events such as natural disasters or geopolitical instability can still affect supply. Therefore, diversification of suppliers, even within a long-term contract strategy, can be a valuable risk mitigation technique.

Choosing the Right Contract: Aligning Strategy with Business Needs

The optimal choice between spot and long-term steel contracts depends heavily on your specific business context. Factors to consider include your risk tolerance, production volume, forecasting accuracy, and the stability of your demand. Companies with stable, predictable demand and a higher risk aversion generally favor long-term contracts. Businesses with fluctuating demand, a higher risk tolerance, and the ability to adjust quickly to market changes may find spot contracts more suitable. In some cases, a hybrid approach, combining elements of both spot and long-term contracts, can be the most effective solution.

Ultimately, a thorough understanding of market dynamics, careful analysis of your business needs, and a well-defined risk management strategy are essential for making informed decisions about steel procurement.

Tags: steel contracts, spot steel, long-term steel contracts, steel pricing, steel supply chain