Pipe bending and straightening are crucial processes in various industries, from construction and manufacturing to plumbing and oil and gas. Achieving the desired shape and ensuring the integrity of the pipe requires understanding the available methods and selecting the appropriate tools and techniques. This comprehensive guide will delve into the intricacies of pipe bending and straightening, providing you with the knowledge to tackle your projects with confidence.

1. Understanding Pipe Bending Techniques

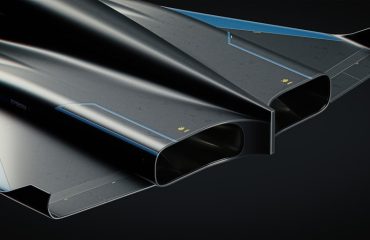

Several methods exist for bending pipes, each suited to different pipe materials, diameters, and desired bend radii. The choice depends on factors like material strength, required precision, and the available resources. Common techniques include:

- Manual Bending: This involves using hand tools like pipe benders, which are suitable for smaller diameter pipes and simpler bends. This method is often chosen for its simplicity and low cost, but it can be labor-intensive and less precise for complex bends.

- Hydraulic Bending: Hydraulic pipe benders utilize hydraulic pressure to bend pipes, offering greater control and precision, especially for larger diameter pipes and tighter bends. This method is faster and more efficient than manual bending but requires specialized equipment.

- Rotary Draw Bending: This technique uses a rotating die to pull the pipe through a bending die, producing consistent and accurate bends. It’s ideal for high-volume production and complex bends but requires significant investment in equipment.

- Roll Bending: Roll benders use three rollers to progressively bend the pipe. This method is suitable for large diameter pipes and long radius bends, often used in structural applications.

Choosing the right bending technique is critical for avoiding pipe damage and ensuring the structural integrity of the finished product. Factors such as material type (steel, copper, aluminum), wall thickness, and the desired bend radius must be carefully considered.

2. Essential Tools and Equipment for Pipe Bending

The tools required for pipe bending vary considerably depending on the chosen method. For manual bending, you’ll need pipe benders appropriate for the pipe diameter and material. These can range from simple hand-held tools to more sophisticated lever-action benders. Hydraulic bending necessitates a hydraulic pipe bender, which comes in various sizes and capacities. Rotary draw bending and roll bending require specialized and often expensive machinery.

Beyond the primary bending equipment, you’ll likely need supporting tools such as:

- Pipe measuring tools: Accurate measurements are crucial for precise bending.

- Marking tools: To precisely mark the bending points on the pipe.

- Pipe supports: To hold the pipe securely during the bending process.

- Safety equipment: Gloves, eye protection, and potentially hearing protection are essential for safety.

Investing in high-quality tools is essential for achieving accurate and efficient results. Poor quality tools can lead to inaccurate bends, pipe damage, and even injury.

3. Addressing Pipe Straightening Needs

Pipes can become bent or misaligned during transportation, installation, or due to external forces. Straightening bent pipes is often necessary to maintain structural integrity and ensure proper functionality. Methods for straightening pipes include:

- Manual Straightening: For minor bends, manual straightening using hammers and wooden blocks can be effective. This method requires skill and care to avoid damaging the pipe.

- Hydraulic Straightening: Hydraulic presses are used for straightening severely bent pipes. This method is more precise and efficient than manual straightening but requires specialized equipment.

- Three-Roll Straightening: Similar to roll bending, three-roll straightening machines use rollers to progressively straighten the pipe. This method is suitable for larger diameter pipes and is commonly used in industrial settings.

The choice of straightening method depends on the severity of the bend, the pipe material, and the available resources. It’s crucial to carefully assess the condition of the pipe before attempting to straighten it, as severely damaged pipes may be beyond repair.

4. Safety Precautions During Pipe Bending and Straightening

Pipe bending and straightening can be hazardous if proper safety precautions aren’t followed. Always prioritize safety by:

- Wearing appropriate personal protective equipment (PPE): This includes safety glasses, gloves, and hearing protection.

- Ensuring proper machine operation: Follow the manufacturer’s instructions carefully and never operate equipment beyond its capacity.

- Using proper lifting techniques: Heavy pipes require proper lifting techniques to avoid injuries.

- Maintaining a clean and organized workspace: A cluttered workspace increases the risk of accidents.

- Regularly inspecting equipment: Check for any damage or wear and tear before operating any equipment.

Safety should be the top priority in any pipe bending or straightening operation. A thorough understanding of safety procedures is crucial to prevent accidents and injuries.

5. Choosing the Right Pipe Bending and Straightening Solutions for Your Project

Selecting the appropriate pipe bending and straightening solutions depends on several factors: the pipe material, diameter, wall thickness, desired bend radius, volume of work, and budget. For small-scale projects with simple bends, manual methods may suffice. However, for large-scale projects, complex bends, or high-precision requirements, specialized equipment and techniques are necessary.

Consider consulting with experienced professionals to determine the best approach for your specific project. They can help you assess your needs and recommend the most efficient and cost-effective solutions. Proper planning and selection of tools and techniques are essential for achieving successful and safe results.

By understanding the various methods, tools, and safety considerations, you can confidently tackle your pipe bending and straightening projects. Remember to always prioritize safety and choose the most appropriate techniques for your specific needs.

Tags: pipe bending, pipe straightening, hydraulic bending, manual bending, pipe bending tools, pipe straightening techniques, industrial pipe bending