body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

img {

max-width: 100%;

height: auto;

}

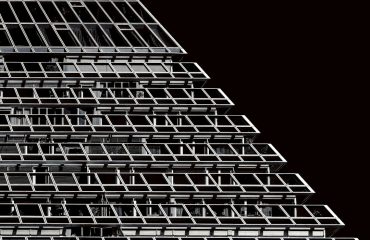

In the world of construction and engineering, energy efficiency is paramount. Minimizing heat loss and maximizing thermal comfort are key objectives, and the choice of materials plays a crucial role. Thermally insulated steel profiles have emerged as a powerful solution, offering a compelling blend of strength, durability, and energy efficiency. This comprehensive guide explores the fascinating world of these innovative profiles, delving into their properties, applications, and future potential.

Understanding the Need for Thermal Insulation in Steel Profiles

Steel, while incredibly strong and versatile, is an excellent conductor of heat. This means that in buildings constructed with standard steel frames, significant heat loss can occur through what are known as “cold bridges.” These are areas where heat readily escapes from the building’s interior, leading to energy waste, discomfort, and even the potential for condensation and mold growth. Thermally insulated steel profiles address this problem by incorporating insulation materials directly into the profile’s design, effectively breaking the cold bridges and significantly improving the building’s thermal performance.

Manufacturing Processes: How Thermally Insulated Steel Profiles are Made

The manufacturing process for thermally insulated steel profiles typically involves several steps. First, a layer of insulating material, such as polyurethane foam, polyisocyanurate foam, or mineral wool, is applied to a steel profile. This insulation core is then encased in a further layer of steel, creating a composite structure. Different manufacturing techniques exist, including continuous casting and roll forming, which ensure the tight bond between the steel and insulation, preventing air gaps that could compromise the thermal performance. Precision is key; the manufacturing process needs to ensure the insulation is evenly distributed to maximize its effectiveness.

Superior Thermal Performance: Breaking Down the U-Values

The effectiveness of thermally insulated steel profiles is often measured by their U-value. The U-value represents the rate of heat transfer through a material; a lower U-value indicates better insulation. Compared to standard steel profiles, thermally insulated versions boast significantly lower U-values, resulting in substantial reductions in energy consumption for heating and cooling. This improvement in thermal performance translates into considerable cost savings for building owners over the lifespan of the structure, making them a financially attractive option. Furthermore, the reduced thermal bridging leads to a more consistent indoor temperature, enhancing comfort and reducing the risk of condensation problems.

Diverse Applications: Where Thermally Insulated Steel Profiles Excel

The versatility of thermally insulated steel profiles makes them suitable for a wide range of applications in the construction industry. They are commonly used in:

- Curtain walls: Providing excellent thermal performance and aesthetic appeal in high-rise buildings.

- Windows and doors: Enhancing energy efficiency and reducing drafts.

- Roofing systems: Minimizing heat loss through the roof and improving overall building insulation.

- Industrial buildings: Providing a robust and energy-efficient solution for large-scale structures.

- Cold storage facilities: Maintaining consistent low temperatures with minimal energy consumption.

Their strength and durability also make them ideal for applications in harsh environments or areas prone to seismic activity.

Future Trends and Innovations in Thermally Insulated Steel Profiles

The field of thermally insulated steel profiles is constantly evolving. Research and development efforts are focused on:

- Improved insulation materials: Exploring new materials with even higher thermal resistance and better environmental properties.

- Enhanced manufacturing processes: Optimizing production techniques to further improve the bond between the steel and insulation, and reduce manufacturing costs.

- Sustainable materials: Incorporating recycled materials and reducing the environmental impact of manufacturing.

- Smart integration: Integrating sensors and other technologies to monitor thermal performance and optimize energy consumption.

- Advanced design features: Developing more sophisticated profile designs to further minimize thermal bridging and enhance aesthetic appeal.

These innovations promise even greater energy efficiency, sustainability, and design flexibility in the future.

Thermally insulated steel profiles represent a significant advancement in building technology, offering a compelling combination of structural integrity and energy efficiency. Their widespread adoption is contributing to the creation of more sustainable and comfortable buildings, while also offering long-term cost savings for building owners.

Tags: Thermally Insulated Steel Profiles, Steel Profiles, Thermal Insulation, Energy Efficiency, Cold Bridges, Construction Materials, Building Envelope