body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

img {

max-width: 100%;

height: auto;

}

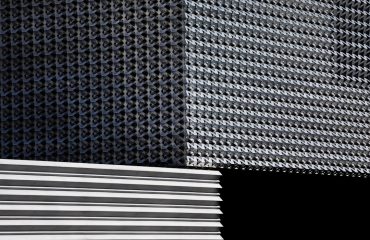

The engineering world is constantly seeking materials that offer superior strength, lightweight properties, and corrosion resistance. Carbon fiber-coated steel pipes represent a significant advancement in this pursuit, combining the inherent strength and durability of steel with the exceptional lightweight and high tensile strength of carbon fiber. This innovative combination opens up a wide array of applications across diverse industries.

The Science Behind the Strength: Material Properties and Composition

Carbon fiber-coated steel pipes leverage the synergistic properties of both constituent materials. The steel core provides the foundational strength and stiffness, while the carbon fiber coating enhances several key characteristics. The steel core, typically made from high-strength grades like API 5L X42 or X52, offers excellent compressive strength and resistance to buckling. The carbon fiber layer, usually composed of unidirectional or woven fibers embedded in a resin matrix (epoxy is common), drastically increases the tensile strength, flexural rigidity, and fatigue resistance of the pipe. This composite structure results in a material that is significantly stronger and lighter than steel pipes of comparable diameter and wall thickness.

The precise composition of the carbon fiber and resin matrix can be tailored to meet specific application requirements. For example, using high-modulus carbon fiber yields a stiffer pipe, while using a high-tensile strength fiber results in a pipe with superior resistance to breakage under tension. The resin system plays a crucial role in bonding the carbon fiber to the steel substrate and protecting the fibers from environmental degradation.

Manufacturing Processes: A Blend of Precision and Innovation

The manufacturing of carbon fiber-coated steel pipes involves a sophisticated process that requires precision and expertise. Several techniques are employed, including filament winding, pultrusion, and prepreg wrapping. Filament winding involves precisely wrapping continuous carbon fiber strands around a steel mandrel, creating a layer-by-layer build-up of the composite coating. Pultrusion involves pulling continuous fibers through a resin bath and then through a shaping die to create a profile, which is then bonded to the steel pipe. Prepreg wrapping uses pre-impregnated carbon fiber sheets that are wrapped around the steel pipe and cured in an autoclave under controlled temperature and pressure.

The choice of manufacturing method depends on factors such as pipe diameter, desired thickness of the carbon fiber coating, and production volume. Quality control throughout the process is crucial to ensure the proper adhesion between the carbon fiber and steel, as well as the integrity of the composite structure.

Applications Across Industries: Where Innovation Meets Demand

The unique properties of carbon fiber-coated steel pipes make them highly suitable for a variety of applications where high strength-to-weight ratio, corrosion resistance, and durability are critical. These include:

- Oil and Gas Industry: Transporting high-pressure fluids and gases in harsh environments.

- Chemical Processing: Handling corrosive chemicals and preventing leaks.

- Aerospace: Constructing lightweight yet strong components for aircraft and spacecraft.

- Automotive: Creating high-performance drive shafts and other structural components.

- Infrastructure: Building durable and lightweight bridges, pipelines, and other structures.

The ability to customize the properties of the carbon fiber coating allows for the tailoring of the pipe to specific application requirements, further expanding its versatility.

Advantages Over Traditional Steel Pipes: A Comparative Analysis

Compared to traditional steel pipes, carbon fiber-coated steel pipes offer several significant advantages:

- Increased Strength and Stiffness: The carbon fiber coating significantly enhances the tensile strength and flexural rigidity of the pipe, allowing for the use of thinner walls while maintaining structural integrity.

- Reduced Weight: The lighter weight of the carbon fiber coating reduces transportation and installation costs, while also decreasing the overall load on supporting structures.

- Enhanced Corrosion Resistance: The carbon fiber coating provides an effective barrier against corrosion, extending the lifespan of the pipe, especially in harsh environments.

- Improved Fatigue Resistance: The composite structure exhibits superior fatigue resistance compared to steel alone, reducing the risk of failure due to cyclic loading.

- Increased Durability: The combination of materials results in a pipe that is more resistant to damage from impacts and other external forces.

These advantages translate into significant cost savings over the long term, due to reduced maintenance, extended lifespan, and improved efficiency.

Future Trends and Innovations: Shaping the Next Generation

The field of carbon fiber-coated steel pipes is constantly evolving. Research and development efforts are focused on improving the manufacturing process, exploring new types of carbon fibers and resin systems, and expanding the range of applications. Future innovations may include:

- Advanced Manufacturing Techniques: Utilizing additive manufacturing (3D printing) to create complex pipe geometries and customized coatings.

- Smart Sensors Integration: Embedding sensors within the pipe to monitor its condition and detect potential problems.

- Self-Healing Materials: Developing self-healing capabilities to repair minor damage and extend the lifespan of the pipe.

- Sustainable Materials: Utilizing recycled carbon fiber and bio-based resins to reduce the environmental impact of manufacturing.

These advancements promise to further enhance the performance and sustainability of carbon fiber-coated steel pipes, solidifying their role as a key material in various industries.

Tags: Carbon Fiber Pipes, Steel Pipes, Composite Pipes, Carbon Fiber Coating, Pipe Manufacturing