Stainless steel, a ubiquitous material in modern life, comes in various grades, each with unique properties tailored to specific applications. Two prominent categories are ferritic and austenitic stainless steels. Understanding their differences is crucial for selecting the right material for a given project. This comprehensive guide will explore the key distinctions between these two types of stainless steel, focusing on their microstructure, properties, applications, and limitations.

1. Microstructure: The Foundation of Different Properties

The fundamental difference between ferritic and austenitic stainless steel lies in their microstructure, which dictates their properties. Ferritic stainless steels possess a body-centered cubic (BCC) crystal structure. This structure is characterized by a relatively simple arrangement of iron atoms, resulting in a higher strength and hardness compared to austenitic steels at room temperature. However, this structure also leads to lower ductility and toughness. Austenitic stainless steels, on the other hand, exhibit a face-centered cubic (FCC) crystal structure. This FCC structure allows for easier slip and deformation, resulting in superior ductility, toughness, and formability. The presence of nickel and other alloying elements in austenitic stainless steel stabilizes this FCC structure even at elevated temperatures.

2. Mechanical Properties: Strength, Ductility, and Weldability

The differing microstructures directly impact the mechanical properties of ferritic and austenitic stainless steels. Ferritic stainless steels generally exhibit higher yield strength and tensile strength than their austenitic counterparts, making them suitable for applications requiring high strength. However, they are less ductile and have lower elongation and impact resistance. This lower ductility can make them more challenging to form and weld. Conversely, austenitic stainless steels offer superior ductility, excellent formability, and good toughness. This makes them ideal for applications requiring complex shapes or resistance to impact loads. However, their yield strength is generally lower than that of ferritic steels. Weldability is another crucial factor. Austenitic stainless steels are generally easier to weld than ferritic stainless steels due to their superior ductility and lower susceptibility to cracking during welding. However, proper welding procedures are still essential for both types to avoid issues like sensitization.

3. Corrosion Resistance: The Hallmark of Stainless Steel

Both ferritic and austenitic stainless steels are known for their corrosion resistance, primarily due to the presence of chromium, which forms a passive chromium oxide layer on the surface. However, the level and type of corrosion resistance differ. Ferritic stainless steels typically exhibit good corrosion resistance in many environments, particularly in oxidizing conditions. However, their corrosion resistance can be compromised in reducing environments or in the presence of chlorides. Austenitic stainless steels, particularly those with higher nickel content, generally demonstrate superior corrosion resistance across a wider range of environments, including those with high chloride concentrations. This superior corrosion resistance is attributed to the higher nickel content and the FCC structure, which provides better resistance to pitting and crevice corrosion.

4. Applications: Tailoring the Steel to the Task

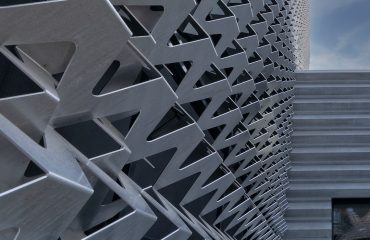

The distinct properties of ferritic and austenitic stainless steels lead to their use in diverse applications. Ferritic stainless steels are commonly used in automotive exhaust systems, appliances, and chemical processing equipment where high strength and moderate corrosion resistance are required. Their lower cost compared to austenitic stainless steels also makes them attractive for many applications. Austenitic stainless steels find applications in demanding environments where high corrosion resistance and ductility are paramount. These include food processing equipment, medical devices, architectural cladding, and cryogenic applications. The superior formability of austenitic stainless steel also makes it ideal for complex shapes and deep drawing processes.

5. Cost and Availability: A Practical Consideration

The cost of ferritic and austenitic stainless steels varies depending on the specific grade and alloying elements. Generally, ferritic stainless steels are less expensive than austenitic stainless steels due to the lower nickel content. This cost difference is a significant factor in material selection, especially for large-scale projects. Both types of stainless steel are widely available from various suppliers, but the availability of specific grades may vary depending on regional factors and demand.

In conclusion, the choice between ferritic and austenitic stainless steel depends on the specific requirements of the application. Understanding their differences in microstructure, mechanical properties, corrosion resistance, and cost is essential for making informed decisions. By carefully considering these factors, engineers and designers can select the optimal stainless steel grade to ensure the performance and longevity of their products.

SEO Tags:

Ferritic stainless steel, Austenitic stainless steel, Stainless steel comparison, Stainless steel properties, Stainless steel applications