Pipe bending and straightening are crucial processes in various industries, from construction and manufacturing to plumbing and oil and gas. Achieving precise bends and straightness is essential for functionality, safety, and aesthetics. This comprehensive guide explores the various methods, tools, and considerations involved in mastering these techniques.

1. Understanding Pipe Material and its Impact on Bending and Straightening

The material of the pipe significantly influences the bending and straightening process. Different materials possess varying degrees of flexibility, ductility, and strength. Steel pipes, for example, require more force and specialized equipment for bending compared to copper or aluminum pipes. Understanding the material’s properties is crucial for selecting the appropriate bending and straightening techniques and tools to avoid damage or failure.

Steel Pipes: These require powerful bending machines or hydraulic presses due to their high tensile strength. Improper bending can lead to cracking or weakening. Heat may be necessary for larger diameter pipes to aid in the bending process.

Copper Pipes: Relatively malleable, copper pipes can be bent manually using hand tools like pipe benders. However, excessive bending can lead to work hardening and cracking. Proper lubrication is essential to prevent damage.

Aluminum Pipes: Similar to copper, aluminum is relatively easy to bend. However, it’s softer and more susceptible to kinking if not handled carefully. Using appropriate bending tools and techniques is vital.

PVC Pipes: These are relatively brittle and require careful handling. Excessive force can cause cracking. Heating can make them more pliable, but overheating can damage the material.

2. Exploring Different Pipe Bending Methods and Technologies

Several methods exist for bending pipes, each suited to different materials, diameters, and desired bend radii. These methods range from manual techniques to sophisticated automated systems.

Manual Bending: Using hand tools such as pipe benders, this method is suitable for smaller diameter, softer pipes. It’s cost-effective but labor-intensive and may not yield consistent results for complex bends.

Hydraulic Bending: Hydraulic presses and benders utilize hydraulic pressure to bend pipes, offering greater control, precision, and the ability to handle larger diameter and thicker-walled pipes.

Rotary Draw Bending: This sophisticated method uses a rotating die to pull the pipe through a bending mandrel, resulting in consistent and accurate bends, particularly useful for tight radii.

Roll Bending: This method uses three rolls to progressively bend the pipe, ideal for larger diameter pipes and long bends.

3. Effective Techniques for Pipe Straightening

Straightening bent pipes requires careful consideration of the material and the degree of bending. Improper straightening can weaken the pipe, rendering it unusable.

Manual Straightening: For minor bends in softer materials, gentle manual straightening using hammers and mallets might suffice. However, this method is prone to errors and can easily damage the pipe.

Hydraulic Straightening: Hydraulic presses can effectively straighten severely bent pipes by applying controlled force. This method offers greater precision and control compared to manual straightening.

Three-Roll Straightening: Similar to roll bending, three rolls are used to progressively straighten the pipe. This method is effective for long sections of bent pipe.

Mechanical Straightening: Specialized straightening machines utilize mechanical force to correct bends, often used for mass production and high-precision straightening.

4. Essential Tools and Equipment for Pipe Bending and Straightening

The selection of tools and equipment depends largely on the pipe material, diameter, and the desired bend or straightness. Investing in high-quality tools ensures accuracy and prevents damage to the pipe.

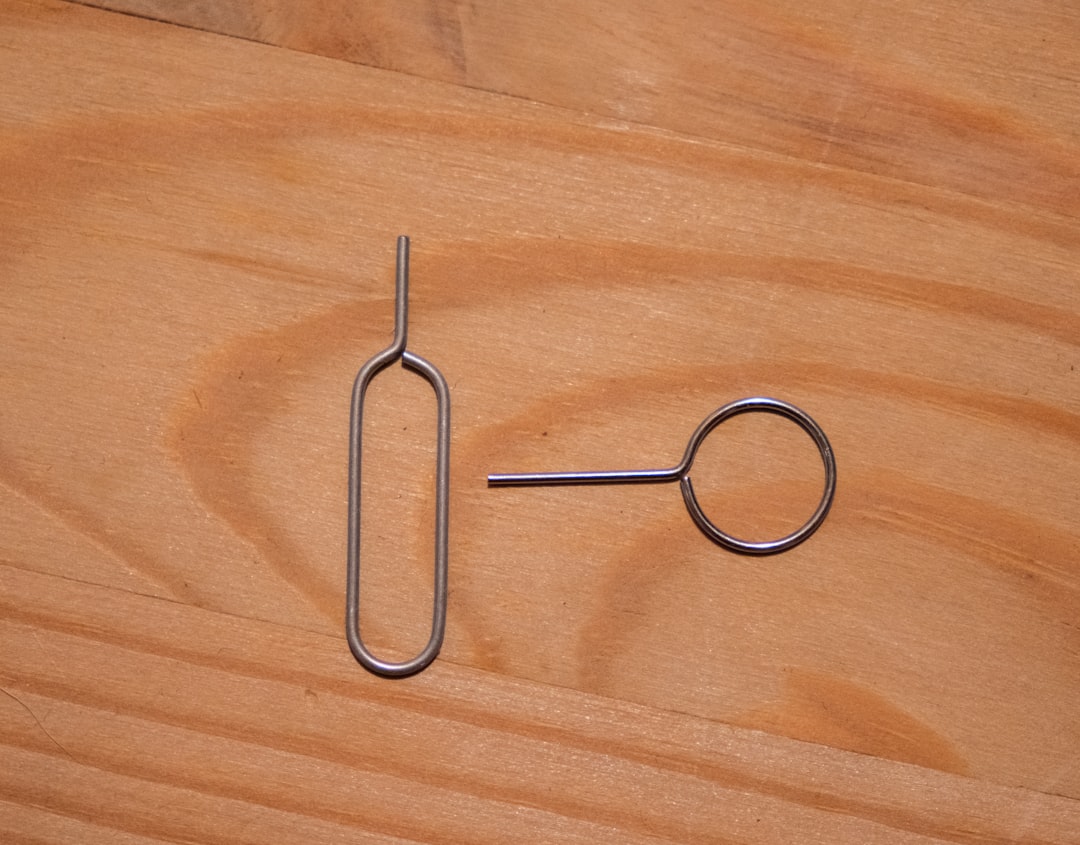

Pipe Benders (Hand-operated): Various types are available, including spring benders, hickey benders, and roller benders, each suitable for different pipe sizes and materials.

Hydraulic Presses and Benders: These are essential for larger diameter pipes and require significant investment. They offer precise control and high bending capacity.

Pipe Straighteners (Mechanical and Hydraulic): These machines are designed for straightening bent pipes efficiently and accurately. The choice depends on the pipe material, size, and the severity of the bend.

Measuring Tools: Accurate measurement is crucial. Use calibrated measuring tapes, protractors, and levels to ensure precision.

Safety Gear: Always wear appropriate safety gear, including gloves, eye protection, and hearing protection, when working with pipe bending and straightening equipment.

5. Safety Precautions and Best Practices

Pipe bending and straightening can be hazardous if proper safety precautions are not followed. Always prioritize safety to prevent injuries and damage to equipment.

Proper Training: Ensure that all personnel involved are properly trained in the safe operation of the equipment.

Use of Safety Gear: Always wear appropriate safety gear, including gloves, eye protection, and hearing protection.

Regular Equipment Maintenance: Regularly inspect and maintain all equipment to ensure safe operation.

Work Area Safety: Maintain a clean and organized work area to prevent accidents.

Emergency Procedures: Establish and communicate clear emergency procedures in case of accidents.

By understanding the principles of pipe bending and straightening, selecting the appropriate tools and techniques, and prioritizing safety, you can achieve precise and reliable results in your projects. Remember to always consult relevant industry standards and safety regulations.

SEO Tags: pipe bending, pipe straightening, pipe bending machines, hydraulic pipe bending, pipe bending techniques