body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

Scaffolding is an indispensable element in construction, providing temporary access to heights for workers and materials. At the heart of most scaffolding systems lie scaffolding pipes – strong, versatile, and crucial for ensuring worker safety and project success. This comprehensive guide delves into the world of scaffolding pipes, exploring their types, applications, safety considerations, erection procedures, and relevant regulations.

Types of Scaffolding Pipes Used in Construction

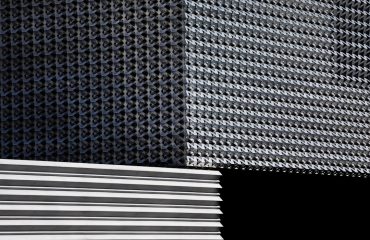

Scaffolding pipes are typically made from high-strength steel, designed to withstand significant loads and environmental conditions. Several types are commonly used, each with its own strengths and weaknesses:

- Standard Scaffolding Pipes: These are the most common type, usually black, galvanized, or powder-coated for corrosion resistance. They come in various diameters and lengths, conforming to specific industry standards. The diameter is crucial for load-bearing capacity. Larger diameter pipes are stronger and suitable for heavier loads.

- Couplers: These are essential components that connect scaffolding pipes together, allowing for the creation of complex scaffold structures. Couplers come in various types, including swivel couplers, right-angle couplers, and adjustable couplers, each designed for specific connections and adjustments.

- Alloy Steel Pipes: For projects requiring increased strength and durability, especially in harsh environments or with heavy loads, alloy steel scaffolding pipes are employed. These pipes offer superior resistance to corrosion and wear, extending their lifespan.

- Aluminum Scaffolding Pipes: Lighter than steel, aluminum scaffolding pipes are used where weight is a significant factor, such as in renovations or work on delicate structures. However, they possess lower load-bearing capacity compared to steel pipes.

Safe Erection and Dismantling of Scaffolding Pipes

The safe erection and dismantling of scaffolding is paramount. Improper procedures can lead to serious accidents. Key considerations include:

- Proper Planning: Thorough planning, including detailed drawings and risk assessments, is essential before any scaffolding erection commences. This ensures that the scaffold is adequately designed for the specific task and load requirements.

- Qualified Personnel: Only trained and experienced personnel should erect and dismantle scaffolding. They should be familiar with all safety regulations and procedures.

- Base Stability: The base of the scaffold must be stable and level, ensuring that the entire structure is secure and won’t collapse. Using base plates and ensuring proper ground conditions are crucial.

- Tie-in Points: Scaffolding structures, especially taller ones, need to be secured to the building or structure using appropriate tie-in points to prevent sway and collapse. The frequency and strength of tie-ins depend on the height and load.

- Regular Inspections: Regular inspections throughout the construction process are vital to identify any potential hazards or damage to the scaffolding. This helps prevent accidents and ensures worker safety.

Common Applications of Scaffolding Pipes in Construction

Scaffolding pipes find extensive use across various construction applications:

- Building Construction: Providing access for workers to all levels of a building during construction, from foundations to roofing.

- Bridge Construction: Supporting workers and materials during the construction and maintenance of bridges.

- Industrial Projects: Used in industrial settings for maintenance, repairs, and construction work on large-scale structures such as tanks, chimneys, and power plants.

- Renovations and Repairs: Providing access for workers during renovations and repairs of existing buildings.

- Event Staging: Creating temporary staging for events, concerts, and other outdoor activities.

Safety Regulations and Standards for Scaffolding Pipes

Strict adherence to safety regulations and standards is crucial when working with scaffolding pipes. These regulations vary depending on location, but common elements include:

- Regular Inspections: Frequent inspections by competent personnel are mandatory to identify and rectify any potential hazards.

- Proper Training: Workers must receive adequate training on the safe erection, use, and dismantling of scaffolding.

- Protective Equipment: Appropriate personal protective equipment (PPE), such as hard hats, safety harnesses, and safety boots, must be worn at all times.

- Load Capacity: The scaffolding must be designed and erected to support the intended load without exceeding its capacity.

- Compliance with Codes: All scaffolding must comply with relevant national and local building codes and standards.

Maintaining and Extending the Lifespan of Scaffolding Pipes

Proper maintenance can significantly extend the lifespan of scaffolding pipes and ensure their continued safe use:

- Regular Cleaning: Regularly cleaning the pipes removes dirt, debris, and corrosive substances, preventing premature deterioration.

- Corrosion Protection: Applying protective coatings, such as paint or galvanizing, helps prevent corrosion and extends the life of the pipes, especially in harsh environments.

- Damage Inspection: Regularly inspect the pipes for any signs of damage, such as dents, cracks, or bends. Damaged pipes should be replaced immediately.

- Proper Storage: When not in use, scaffolding pipes should be stored properly to prevent damage and corrosion. This includes keeping them dry and protected from the elements.

- Record Keeping: Maintaining detailed records of inspections, repairs, and replacements helps track the condition of the scaffolding and ensures compliance with safety regulations.

In conclusion, scaffolding pipes are fundamental to safe and efficient construction. Understanding their types, applications, safety regulations, and proper maintenance practices is vital for ensuring worker safety and project success. By adhering to best practices and prioritizing safety, construction professionals can leverage the strength and versatility of scaffolding pipes to reach new heights.

Tags: scaffolding pipes, construction safety, scaffolding erection, scaffolding regulations, scaffolding materials