The steel industry, a cornerstone of global infrastructure and manufacturing, is undergoing a dramatic transformation fueled by relentless research and development (R&D). This isn’t just about incremental improvements; we’re witnessing a revolution in material science, manufacturing processes, and applications, pushing the boundaries of what’s possible with steel.

1. Advanced Alloying and Material Science: The Foundation of Steel Innovation

The quest for stronger, lighter, and more durable steel drives significant R&D efforts in advanced alloying. Researchers are exploring new combinations of elements, including rare earth metals, to fine-tune the properties of steel. This includes focusing on high-strength low-alloy (HSLA) steels, which offer superior strength-to-weight ratios compared to traditional carbon steel. Furthermore, advancements in understanding the microstructure of steel at the atomic level are leading to the development of tailored alloys with specific properties for particular applications. For example, research is ongoing to create steels with enhanced resistance to corrosion, high-temperature oxidation, and fatigue. This granular control over material properties is crucial for developing specialized steels for demanding environments like aerospace, automotive, and energy sectors.

2. Revolutionary Manufacturing Processes: Efficiency and Precision in Steel Production

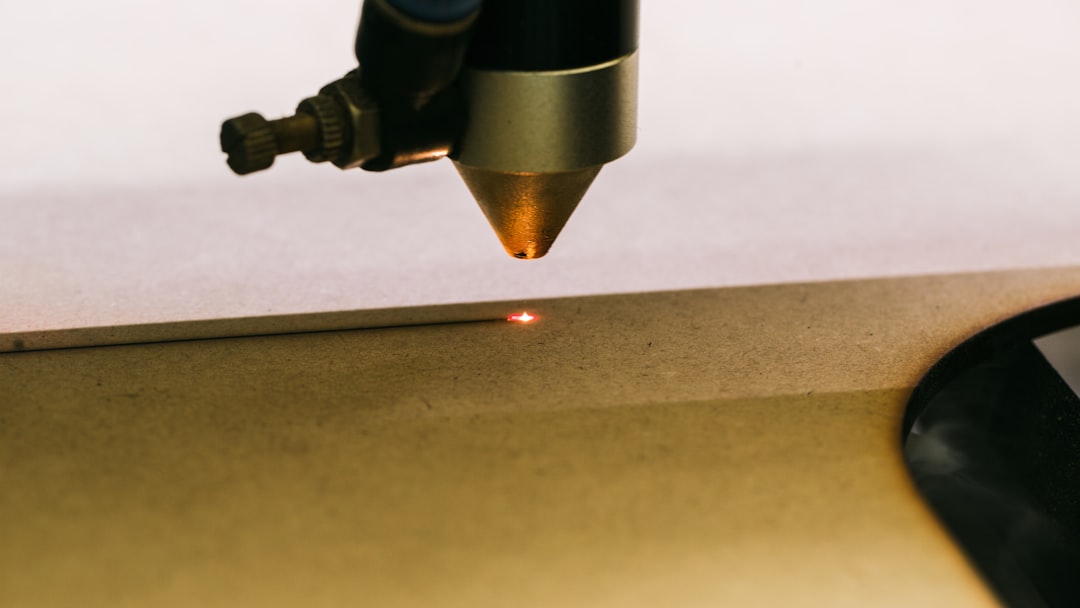

R&D in steel manufacturing is not just about creating better alloys; it’s also about producing them more efficiently and precisely. Techniques like advanced casting methods, including near-net shape casting, minimize waste and improve dimensional accuracy. Additive manufacturing, or 3D printing, using steel powders is gaining traction, enabling the creation of complex geometries and customized parts that were previously impossible to produce using traditional methods. Furthermore, research into optimizing rolling and heat treatment processes is constantly refining the microstructure and properties of steel, leading to improved strength, ductility, and formability. These advancements translate to reduced production costs, faster manufacturing cycles, and improved product quality.

3. Sustainable Steel Production: Minimizing Environmental Impact

The steel industry is under increasing pressure to reduce its environmental footprint. R&D is playing a crucial role in developing more sustainable steel production methods. This includes research into reducing carbon emissions through the use of alternative energy sources in steelmaking processes, such as hydrogen-based reduction. Significant efforts are being made to develop closed-loop recycling systems to minimize waste and maximize the reuse of steel scrap. Furthermore, research is focused on developing steels with enhanced recyclability, making them easier to process and reuse at the end of their lifecycle. This commitment to sustainability is driving innovation and creating a more environmentally responsible steel industry.

4. Expanding Applications of Steel: Beyond Traditional Uses

The advancements in steel R&D are unlocking new and exciting applications for this versatile material. High-strength steel is finding increasing use in lightweight automotive components, contributing to improved fuel efficiency and reduced emissions. Advanced steels are being used in the construction of taller and more resilient buildings and bridges. The energy sector is benefiting from the development of corrosion-resistant steels for use in pipelines and offshore structures. Furthermore, research into biocompatible steels is opening up new possibilities in the medical field, such as for implants and surgical instruments. The versatility of steel, coupled with ongoing R&D, ensures its continued relevance across a wide range of industries.

5. The Future of Steel R&D: Emerging Trends and Challenges

The future of steel R&D is brimming with exciting possibilities. Research into smart steels, incorporating sensors and electronics, is creating materials that can monitor their own condition and provide valuable data for predictive maintenance. The development of bio-inspired steels, mimicking the structures and properties of natural materials, holds the potential for creating even stronger and more resilient materials. However, challenges remain. The need for further reductions in carbon emissions requires continued investment in research into alternative steelmaking processes. The rising cost of some rare earth elements necessitates the exploration of alternative alloying strategies. Overcoming these challenges will be critical to ensuring the continued success and sustainability of the steel industry.

In conclusion, R&D is the driving force behind the ongoing evolution of steel. By pushing the boundaries of material science, manufacturing processes, and applications, researchers are shaping the future of this indispensable material. The innovations discussed here are not just incremental improvements; they represent a fundamental shift in how we understand, produce, and utilize steel, promising a future where this versatile material plays an even more critical role in shaping our world.

SEO Tags:

- Steel Innovation

- R&D in Steel

- Advanced Steel Alloys

- Sustainable Steel Production

- Steel Manufacturing Processes