body {

font-family: sans-serif;

line-height: 1.6;

margin: 20px;

}

h1, h2, h3 {

color: #333;

}

img {

max-width: 100%;

height: auto;

display: block;

margin: 20px auto;

}

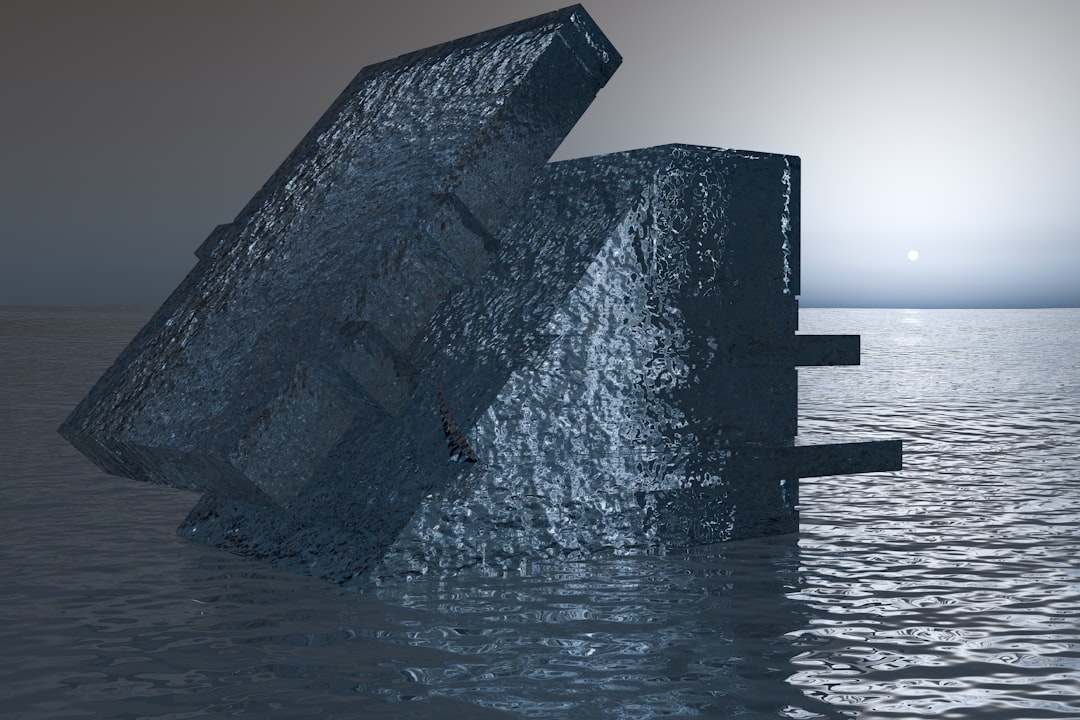

Steel, a ubiquitous material in construction and engineering, faces a formidable challenge in saltwater environments: corrosion. The aggressive nature of saltwater, with its dissolved salts and oxygen, accelerates the deterioration of steel, leading to significant structural weakening and economic losses. Understanding the factors influencing steel’s durability in these harsh conditions is crucial for ensuring the longevity and safety of marine structures, offshore platforms, and coastal infrastructure.

The Mechanisms of Saltwater Corrosion on Steel

Saltwater corrosion is a complex electrochemical process. When steel comes into contact with saltwater, an electrochemical cell is formed. The steel acts as an anode, losing electrons and oxidizing to form iron ions (Fe2+). These ions react with oxygen and water to form iron oxides, commonly known as rust. The cathode, typically a less reactive metal or even another area of the steel itself, gains electrons and undergoes reduction. The presence of chloride ions (Cl–) in saltwater is particularly damaging, as they penetrate the protective rust layer, accelerating the corrosion process. This process is significantly faster than corrosion in freshwater due to the higher conductivity and concentration of aggressive ions in saltwater.

Choosing the Right Steel Alloy for Saltwater Applications

Not all steels are created equal. The choice of steel alloy significantly impacts its resistance to saltwater corrosion. Stainless steels, containing significant amounts of chromium (at least 10.5%), form a passive chromium oxide layer that protects the underlying steel from further corrosion. Different grades of stainless steel offer varying degrees of corrosion resistance, with higher chromium and molybdenum content generally providing better protection in aggressive saltwater environments. Other alloying elements like nickel and nitrogen further enhance corrosion resistance. Specific grades like 316 stainless steel are commonly used in marine applications due to their superior resistance to chloride ion attack.

Protective Coatings: A First Line of Defense Against Corrosion

Applying protective coatings is a vital strategy for enhancing steel’s durability in saltwater. These coatings act as a barrier between the steel and the corrosive environment, preventing the electrochemical reactions that lead to rust. Common coating methods include:

- Galvanization: A zinc coating is applied to the steel, typically through hot-dip galvanizing. Zinc acts as a sacrificial anode, protecting the steel even if the coating is scratched or damaged.

- Painting: Various paint systems, including epoxy, polyurethane, and zinc-rich primers, provide excellent protection when properly applied and maintained. Regular inspection and repainting are crucial for long-term effectiveness.

- Powder Coating: This durable coating offers excellent resistance to abrasion and corrosion, making it suitable for marine applications.

Cathodic Protection: An Active Approach to Corrosion Control

Cathodic protection is an electrochemical technique used to protect steel from corrosion by making it the cathode in an electrochemical cell. This is achieved by either connecting the steel to a more active metal (sacrificial anode) like zinc or aluminum, or by applying an external electrical current (impressed current cathodic protection). The sacrificial anode corrodes instead of the steel, while impressed current systems use an external power source to maintain the steel at a protective potential. Cathodic protection is particularly effective in highly corrosive environments and is commonly used on pipelines, ship hulls, and offshore structures.

Regular Inspection and Maintenance: Key to Long-Term Durability

Even with the best steel alloys and protective coatings, regular inspection and maintenance are essential for ensuring the long-term durability of steel in saltwater environments. Regular visual inspections can help identify early signs of corrosion, such as rust, pitting, or blistering. Prompt repairs and recoating can prevent minor problems from escalating into major structural issues. The frequency of inspections should depend on factors such as the severity of the environment, the type of steel used, and the type of protective coating applied. A well-defined maintenance plan is crucial for maximizing the lifespan of steel structures exposed to saltwater.

By carefully considering the choice of steel alloy, implementing effective protective coatings, utilizing cathodic protection where appropriate, and establishing a robust inspection and maintenance program, we can significantly enhance the durability and lifespan of steel structures in the challenging conditions of saltwater environments. This ensures the safety, reliability, and economic viability of marine and coastal infrastructure.

SEO-Friendly Tags:

- Saltwater Corrosion

- Marine Steel

- Steel Durability

- Corrosion Protection

- Stainless Steel Marine