The automotive industry, construction sector, and countless other manufacturing giants rely heavily on Original Equipment Manufacturers (OEMs) for the production of crucial steel components. This intricate process, from initial design to final delivery, involves a complex interplay of engineering, manufacturing expertise, and stringent quality control. This comprehensive guide delves into the world of OEM steel component production, uncovering the intricacies and challenges involved.

1. The Design and Engineering Phase: Blueprint to Reality

The journey of an OEM steel component begins long before any steel is even touched. This initial phase focuses on meticulous design and engineering. OEMs work closely with their clients to understand the specific requirements of the component, considering factors such as:

- Functional Requirements: What is the component’s purpose? What stresses and loads will it endure? What tolerances are acceptable?

- Material Selection: The type of steel used is crucial, determined by factors like strength, durability, corrosion resistance, and cost. Different grades of steel offer varying properties, impacting the final product’s performance and lifespan.

- Manufacturing Processes: The design must be compatible with the chosen manufacturing process – this might involve forging, casting, rolling, stamping, or a combination of techniques. The design needs to account for the limitations and capabilities of each method.

- Cost Optimization: OEMs strive for optimal designs that balance performance, quality, and cost-effectiveness. This often involves exploring different manufacturing techniques and material options.

Computer-aided design (CAD) and computer-aided engineering (CAE) software play a pivotal role in this stage, allowing for simulations and analysis to ensure the component meets all requirements before physical production begins.

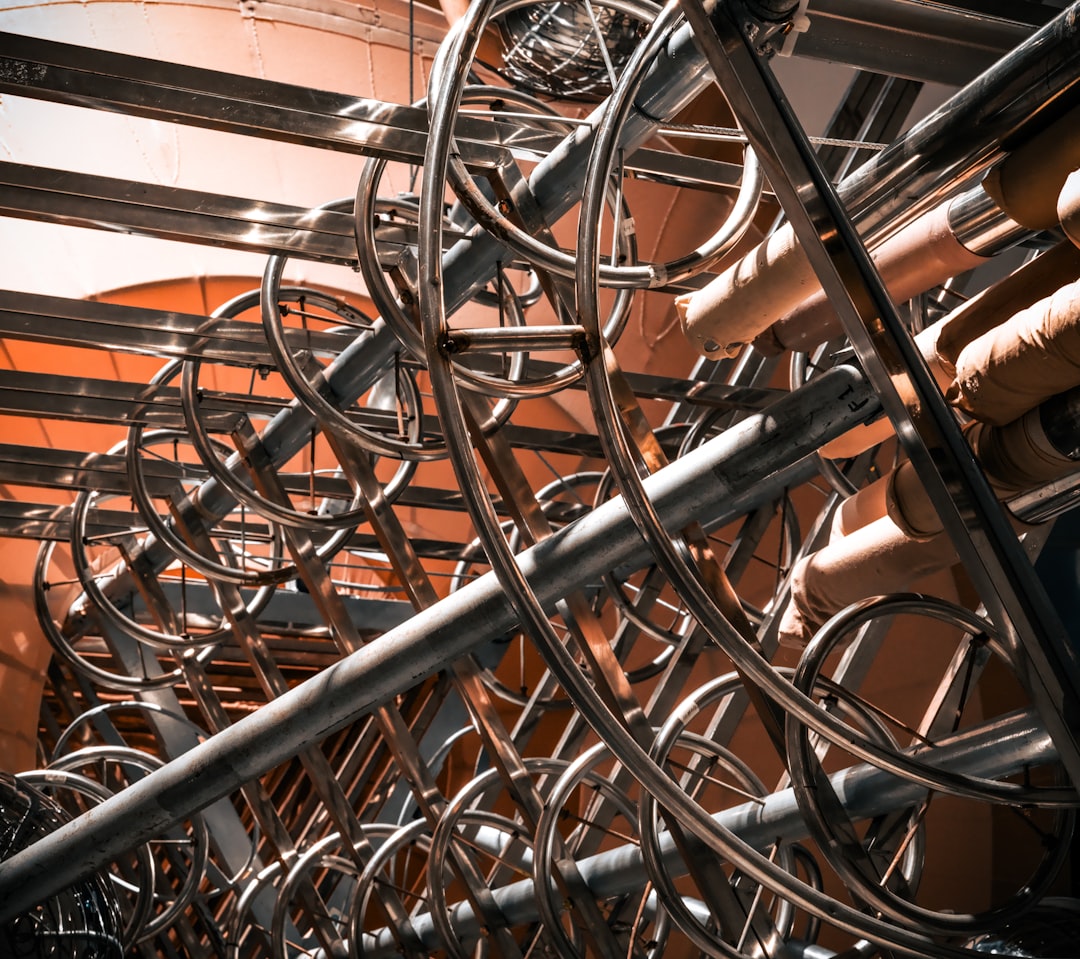

2. Manufacturing Processes: Shaping the Steel

Once the design is finalized, the actual manufacturing process begins. Several methods are commonly employed in OEM steel component production, each with its own strengths and weaknesses:

- Forging: This process involves shaping metal using compressive forces, resulting in high strength and durability. Forging is ideal for components requiring high tensile strength and resistance to fatigue.

- Casting: Molten steel is poured into a mold to create the desired shape. Casting is suitable for complex shapes but may result in lower strength compared to forging.

- Rolling: Steel is passed through rollers to reduce its thickness and create sheets or bars. This is a cost-effective method for mass production of simpler components.

- Stamping: Sheet metal is shaped using dies and presses. Stamping is highly efficient for producing large quantities of identical components.

- Machining: This involves removing material from a workpiece to achieve precise dimensions and surface finishes. Machining is often used as a secondary process to refine components produced by other methods.

The choice of manufacturing process depends heavily on the component’s design, required tolerances, and production volume.

3. Quality Control and Assurance: Ensuring Excellence

Maintaining stringent quality control throughout the entire process is paramount in OEM steel component production. This involves rigorous testing and inspection at every stage, from raw material inspection to final product verification. Key quality control measures include:

- Material Testing: Ensuring the steel meets the specified chemical composition and mechanical properties.

- Dimensional Inspection: Verifying that the component meets the required tolerances and dimensions.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing and radiography are used to detect internal flaws without damaging the component.

- Surface Finish Inspection: Checking for surface imperfections like scratches, pitting, or corrosion.

- Performance Testing: Subjecting the component to simulated real-world conditions to verify its strength, durability, and functionality.

Implementing robust quality control procedures ensures that the final product meets the highest standards and performs reliably in its intended application.

4. Supply Chain Management: A Seamless Flow

Efficient supply chain management is crucial for successful OEM steel component production. This involves coordinating the procurement of raw materials, managing inventory, and ensuring timely delivery of finished products. Key aspects include:

- Raw Material Sourcing: Establishing relationships with reliable suppliers of high-quality steel.

- Inventory Management: Optimizing inventory levels to minimize storage costs while ensuring sufficient materials are available for production.

- Logistics and Transportation: Efficiently transporting raw materials and finished products to minimize delays and costs.

- Supplier Relationship Management: Building strong relationships with suppliers to ensure consistent quality and timely delivery.

A well-managed supply chain ensures a smooth and uninterrupted production flow, minimizing disruptions and delays.

5. Future Trends in OEM Steel Component Production

The field of OEM steel component production is constantly evolving. Several trends are shaping the future of this industry:

- Advanced Materials: The development and adoption of advanced steel alloys with enhanced properties, such as higher strength-to-weight ratios and improved corrosion resistance.

- Additive Manufacturing: 3D printing technologies are gaining traction, offering the potential for customized component designs and reduced material waste.

- Automation and Robotics: Increased automation and robotics are improving efficiency, precision, and consistency in manufacturing processes.

- Sustainable Manufacturing: A growing focus on environmentally friendly practices, including reducing energy consumption and minimizing waste.

- Digitalization and Data Analytics: Utilizing data analytics to optimize production processes, improve quality control, and predict potential issues.

Embracing these trends will be crucial for OEMs to remain competitive and meet the evolving demands of the market.

In conclusion, OEM steel component production is a complex and multifaceted process requiring a high level of expertise and precision. By focusing on design optimization, efficient manufacturing, robust quality control, and strategic supply chain management, OEMs can deliver high-quality components that meet the stringent requirements of various industries.

Tags: OEM steel components, steel component manufacturing, automotive steel parts, industrial steel components, steel fabrication