Steel, the backbone of modern infrastructure and countless everyday objects, doesn’t magically appear. Its creation relies on a complex interplay of raw materials, each playing a crucial role in determining the final product’s properties. This comprehensive guide delves into the diverse sources of these essential ingredients, exploring their extraction, processing, and impact on the steelmaking process.

1. Iron Ore: The Foundation of Steel Production

Iron ore, the primary raw material for steelmaking, is a rock or sediment that contains significant amounts of iron oxides. Hematite (Fe₂O₃) and magnetite (Fe₃O₄) are the most commercially important iron oxides. The quality of iron ore is determined by its iron content, the presence of impurities like silica, alumina, and phosphorus, and its ease of processing. High-grade iron ore boasts iron content exceeding 60%, while lower-grade ores require more extensive processing to remove impurities.

Iron ore extraction involves several methods, including open-pit mining for surface deposits and underground mining for deeper reserves. Once mined, the ore undergoes crushing, grinding, and beneficiation processes to increase its iron content and remove unwanted materials. This often involves techniques like magnetic separation, froth flotation, and pelletization, which transforms the fine ore into small, uniform pellets suitable for efficient smelting.

The geographical distribution of iron ore significantly influences steel production costs and global trade. Major iron ore producers include Australia, Brazil, China, India, and Russia, each contributing to the global supply chain.

2. Scrap Metal: A Sustainable Steelmaking Ingredient

Scrap metal, encompassing discarded steel and iron products, plays a crucial role in sustainable steelmaking. Utilizing scrap reduces the need for virgin iron ore, conserving natural resources and minimizing environmental impact. Scrap steel is categorized into various grades based on its chemical composition and cleanliness, influencing its suitability for different steelmaking processes.

The collection and processing of scrap metal involve a complex network of scrap yards, recycling centers, and steel mills. Scrap is sorted, cleaned, and often shredded or processed into smaller pieces before being fed into electric arc furnaces (EAFs) or basic oxygen furnaces (BOFs) for steelmaking. The use of scrap in steelmaking contributes significantly to reducing greenhouse gas emissions compared to using only iron ore.

The increasing demand for sustainable practices in the steel industry has driven a surge in scrap metal recycling, making it an increasingly important component of steel production.

3. Direct Reduced Iron (DRI): An Alternative Iron Source

Direct reduced iron (DRI), also known as sponge iron, is an alternative iron source produced by directly reducing iron ore without smelting it in a blast furnace. This process uses reducing agents like natural gas or coal to remove oxygen from iron ore at high temperatures, resulting in a porous, metallic iron product. DRI offers several advantages over traditional pig iron, including lower energy consumption and reduced carbon emissions.

DRI plants are strategically located near sources of iron ore and reducing agents to minimize transportation costs. The production process involves several steps, including ore preparation, reduction in a rotary kiln or fluidized bed reactor, and cooling and handling of the final DRI product. DRI is commonly used in electric arc furnaces (EAFs), which are increasingly prevalent in the steel industry due to their energy efficiency and flexibility in using scrap metal.

The growing adoption of DRI technology reflects the steel industry’s efforts to reduce its environmental footprint and improve its sustainability profile.

4. Fluxing Materials: Refining the Steelmaking Process

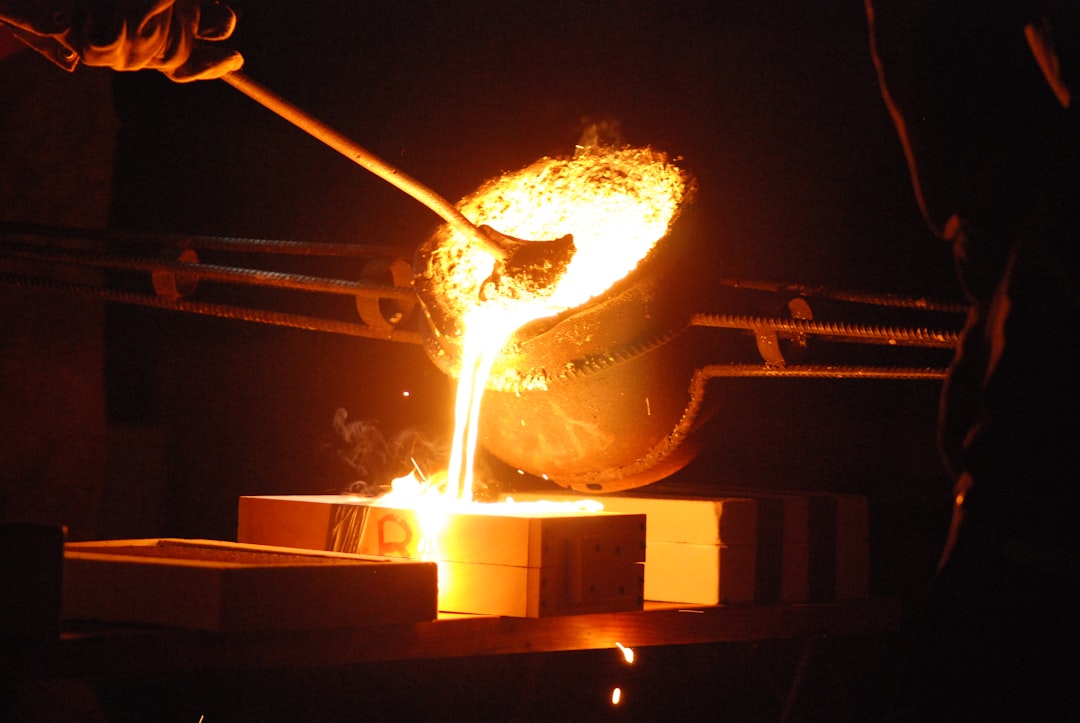

Fluxing materials are essential additives used in steelmaking to remove impurities from molten iron and control the slag composition. Common fluxing materials include limestone (CaCO₃), dolomite (CaMg(CO₃)₂), and silica (SiO₂). These materials react with impurities in the molten iron, forming slag, which floats on top and is easily removed.

The choice of fluxing materials depends on the type of iron ore, the desired steel grade, and the steelmaking process. Proper fluxing is crucial for controlling the chemical composition of the steel, ensuring the desired properties like strength, ductility, and weldability. Careful control of the slag composition is essential to optimize the efficiency and effectiveness of the steelmaking process.

The quality and consistency of fluxing materials significantly impact the overall quality and cost-effectiveness of steel production.

5. Alloying Elements: Tailoring Steel Properties

Alloying elements are added to molten steel to modify its properties and achieve specific characteristics. These elements include manganese, chromium, nickel, molybdenum, vanadium, and many others. Each element contributes unique properties to the steel, influencing its strength, hardness, corrosion resistance, and other characteristics.

The selection of alloying elements depends on the intended application of the steel. For example, stainless steel requires significant amounts of chromium and nickel to provide corrosion resistance, while high-strength low-alloy (HSLA) steels utilize small additions of various elements to enhance their strength and toughness. The precise control of alloying element additions is critical in ensuring the consistent quality and performance of the final steel product.

The sourcing and refining of alloying elements are integral parts of the steelmaking supply chain, contributing to the overall cost and availability of different steel grades.

Understanding the diverse sources of raw materials used in steel production is crucial for appreciating the complexity and sophistication of the steelmaking process. From the extraction of iron ore to the precise addition of alloying elements, each step plays a vital role in determining the final properties and quality of the steel. The continuous evolution of steelmaking technologies and the increasing focus on sustainability are shaping the future of raw material sourcing and utilization in the steel industry.

SEO-Friendly Tags:

- Steel Raw Materials

- Iron Ore Sourcing

- Steel Scrap Recycling

- Direct Reduced Iron (DRI)

- Steelmaking Process