The combination of steel’s inherent strength and carbon fiber’s exceptional lightness and stiffness creates a material marvel: carbon fiber-coated steel pipes. This innovative technology is revolutionizing various industries, offering unparalleled performance and efficiency. This blog post delves deep into the world of carbon fiber-coated steel pipes, exploring their properties, applications, manufacturing processes, advantages, and future potential.

1. Enhanced Mechanical Properties: A Symphony of Strength and Lightness

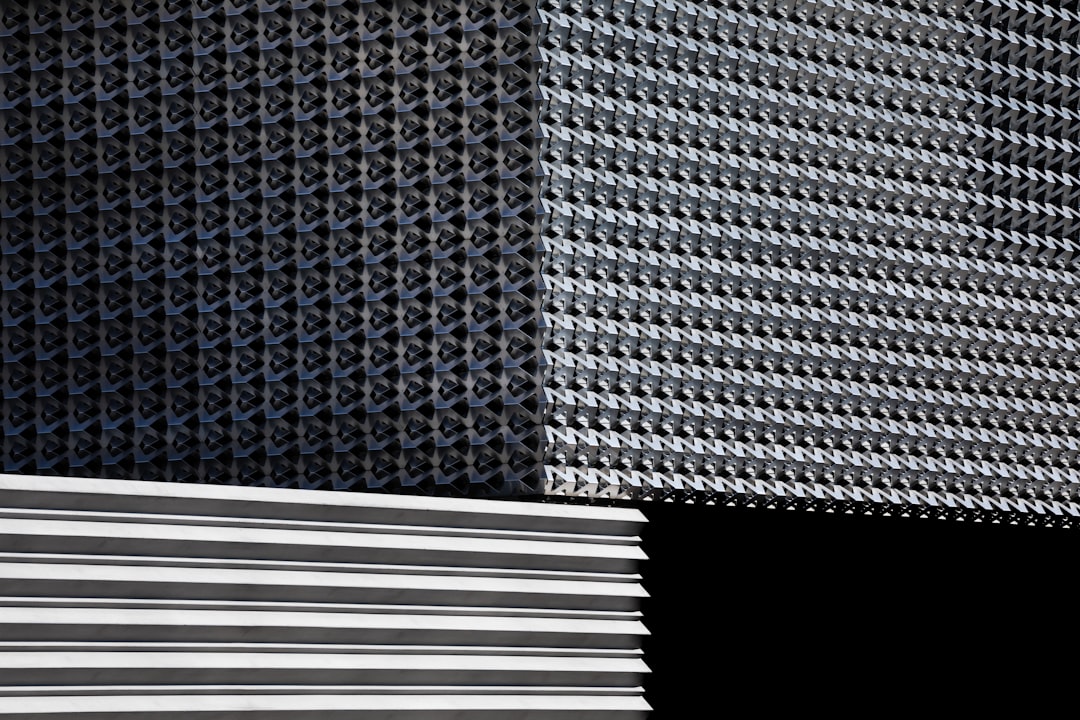

The core advantage of carbon fiber-coated steel pipes lies in the synergistic combination of materials. Steel provides the foundational strength and durability, resisting high pressures and impacts. The carbon fiber coating, on the other hand, significantly enhances stiffness, reduces weight, and improves fatigue resistance. This results in pipes that are stronger, lighter, and more resilient than traditional steel pipes alone. The carbon fiber layer acts as a protective shield, mitigating corrosion and extending the lifespan of the steel core. The precise properties achieved depend heavily on the type and layering of the carbon fiber, the type of steel used, and the bonding techniques employed during manufacturing. For example, using high-modulus carbon fiber results in exceptionally stiff pipes, while using a more flexible variety might prioritize impact resistance.

2. Manufacturing Processes: Precision Engineering for Superior Performance

Creating carbon fiber-coated steel pipes requires a sophisticated manufacturing process that ensures a strong and consistent bond between the steel core and the carbon fiber layer. Several methods exist, each with its own advantages and disadvantages. One common approach involves the application of a prepreg (pre-impregnated) carbon fiber sheet onto the cleaned and prepared steel pipe. This is then cured in an autoclave under controlled temperature and pressure, resulting in a tightly bonded composite structure. Another method involves filament winding, where continuous carbon fiber strands are precisely wound onto the steel pipe, creating a customized layer thickness and orientation. The choice of manufacturing process depends on factors such as the desired pipe diameter, length, and the required mechanical properties. Quality control is paramount throughout the process to ensure consistent performance and prevent defects.

3. Diverse Applications: From Energy to Aerospace

The unique properties of carbon fiber-coated steel pipes have opened up a wide range of applications across diverse industries. In the energy sector, these pipes are used for transporting oil and gas under high pressure, reducing weight and improving efficiency in pipelines. Their corrosion resistance makes them ideal for harsh environments, extending their operational lifespan. In the aerospace industry, they find use in aircraft structures and other applications where a high strength-to-weight ratio is critical. The automotive industry is also exploring their use in high-performance vehicles, particularly in areas requiring lightweight yet strong components. Furthermore, their application extends to infrastructure projects, such as bridges and buildings, where they can contribute to improved structural integrity and reduced weight.

4. Advantages Over Traditional Steel Pipes: A Comprehensive Comparison

Compared to traditional steel pipes, carbon fiber-coated steel pipes offer several key advantages. Firstly, their significantly improved strength-to-weight ratio leads to reduced transportation and installation costs. Secondly, their enhanced corrosion resistance extends their lifespan, reducing maintenance and replacement costs. Thirdly, the increased stiffness improves their resistance to buckling and vibrations, crucial in applications involving high pressures or dynamic loads. Fourthly, the carbon fiber coating can contribute to improved thermal insulation, potentially reducing energy loss in applications like pipelines. Finally, the potential for customization through different carbon fiber types and layering enables engineers to tailor the pipes to specific application requirements, optimizing performance and cost-effectiveness.

5. Future Trends and Innovations: Pushing the Boundaries of Material Science

The field of carbon fiber-coated steel pipes is constantly evolving, with ongoing research and development focused on improving manufacturing processes, exploring new materials, and expanding applications. Researchers are investigating advanced bonding techniques to further enhance the strength and durability of the composite structure. The use of advanced carbon fiber materials with enhanced properties, such as graphene-enhanced carbon fiber, is also being explored to further improve performance. Furthermore, the development of more efficient and cost-effective manufacturing processes is crucial for broader adoption of this technology across various industries. The future likely holds even lighter, stronger, and more versatile carbon fiber-coated steel pipes, contributing to advancements in various technological sectors.

In conclusion, carbon fiber-coated steel pipes represent a significant advancement in material science, offering a compelling combination of strength, lightness, and durability. Their diverse applications and ongoing innovations promise to shape the future of numerous industries, paving the way for lighter, stronger, and more efficient structures and systems.