Superalloy steel, a class of advanced metallic materials, isn’t your average steel. Its exceptional properties, including high-temperature strength, corrosion resistance, and creep resistance, make it indispensable in demanding environments. This blog post delves into the fascinating world of superalloy steel, exploring its diverse applications across various industries.

1. Aerospace: Reaching for the Stars with Superalloy Steel

The aerospace industry is perhaps the most significant consumer of superalloy steels. The extreme temperatures and pressures experienced during flight, especially in jet engines, demand materials with exceptional resilience. Nickel-based superalloys, in particular, dominate this sector. These alloys are used in critical components such as turbine blades, combustor liners, and afterburner components. The ability of these superalloys to withstand temperatures exceeding 1000°C (1832°F) is crucial for maintaining engine efficiency and longevity. The lightweight nature of some superalloys, coupled with their high strength-to-weight ratio, is also a critical factor in aircraft design, allowing for fuel efficiency and enhanced performance.

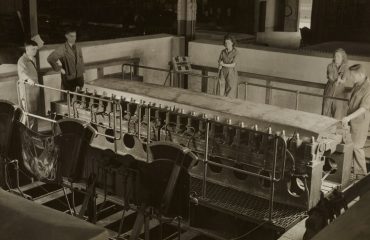

2. Energy Sector: Powering the Future with Superalloy Steel

The energy industry, encompassing power generation and oil & gas extraction, relies heavily on superalloys for their resistance to high temperatures and corrosive environments. In power generation, particularly in gas turbines and steam turbines, superalloys are vital for components exposed to extremely high temperatures and pressures. Their resistance to creep, a phenomenon where materials deform under sustained stress at high temperatures, ensures the long-term reliability of these power plants. In the oil and gas industry, superalloys are used in drilling equipment, valves, and piping systems that encounter harsh conditions, including high pressures, corrosive chemicals, and extreme temperatures.

3. Chemical Processing: Withstanding Harsh Environments

The chemical processing industry faces numerous challenges, including highly corrosive chemicals and high-temperature reactions. Superalloy steels provide the necessary resilience to withstand these harsh environments. Their exceptional corrosion resistance makes them ideal for components in reactors, pumps, and valves used in the processing of various chemicals. The choice of specific superalloy depends on the specific chemical being processed, with some alloys exhibiting superior resistance to certain acids or alkalis.

4. Automotive Industry: Enhancing Performance and Durability

While not as prevalent as in aerospace or energy, superalloys are finding increasing applications in the automotive industry, particularly in high-performance vehicles. Their strength and heat resistance make them suitable for components in turbochargers and exhaust systems. As the demand for fuel efficiency and performance increases, the use of superalloys in automotive applications is expected to grow. The development of more cost-effective superalloy processing techniques could further expand their use in this sector.

5. Medical Implants: A Biocompatible Marvel

Certain superalloys, particularly those with exceptional biocompatibility, are finding niche applications in medical implants. Their strength, corrosion resistance, and biocompatibility make them suitable for components in artificial joints, dental implants, and other medical devices. However, rigorous testing and stringent quality control are necessary to ensure the long-term safety and effectiveness of these implants. Ongoing research is focused on improving the biocompatibility and wear resistance of superalloys for medical applications.

In conclusion, superalloy steels represent a remarkable achievement in materials science, offering exceptional properties that are crucial for a wide range of high-performance applications. Their continued development and refinement will undoubtedly lead to even more innovative uses in the future, shaping advancements across various industries.

SEO-Friendly Tags:

- Superalloy Steel

- Superalloy Applications

- High-Temperature Alloys

- Aerospace Materials

- Nickel-Based Superalloys