body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

h1 {

font-size: 2.5em;

}

h2 {

font-size: 2em;

}

h3 {

font-size: 1.5em;

}

In the ever-evolving landscape of construction and building design, energy efficiency is paramount. Thermally insulated steel profiles are emerging as a key player in achieving sustainable and high-performance buildings. This comprehensive guide delves into the intricacies of these innovative profiles, exploring their benefits, applications, manufacturing processes, performance characteristics, and future trends.

Understanding the Core: What are Thermally Insulated Steel Profiles?

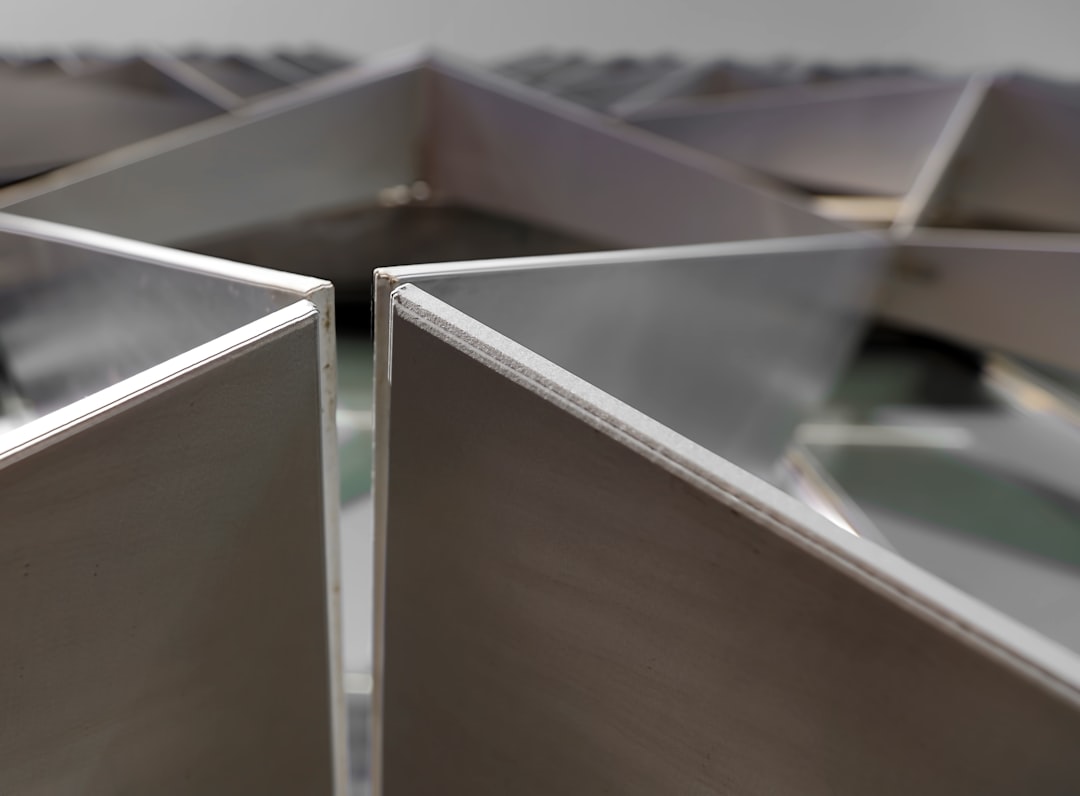

Thermally insulated steel profiles are essentially steel sections that incorporate a layer of insulating material, typically polyurethane or polyisocyanurate foam, within their structure. This strategic integration creates a significant thermal break, dramatically reducing heat transfer through the profile. Unlike traditional steel sections, which readily conduct heat, insulated steel profiles offer superior thermal performance, leading to reduced energy consumption for heating and cooling.

The insulating core is strategically positioned to interrupt the flow of heat, minimizing thermal bridging – a phenomenon where heat travels unimpeded through conductive materials like steel. This results in improved energy efficiency and a more comfortable indoor environment.

Superior Thermal Performance: Benefits of Insulated Steel Profiles

The primary advantage of thermally insulated steel profiles lies in their enhanced thermal performance. This translates to several key benefits:

- Reduced Energy Consumption: Lower heat transfer means less energy is required for heating and cooling, leading to significant cost savings over the building’s lifespan.

- Improved Indoor Comfort: Minimized temperature fluctuations result in a more comfortable and consistent indoor environment, reducing drafts and cold spots.

- Enhanced Sound Insulation: The insulating core also contributes to improved sound insulation, making the building quieter and more peaceful.

- Reduced Condensation: By preventing temperature drops on the surface of the profile, the risk of condensation and potential mold growth is significantly reduced.

- Sustainability: Reduced energy consumption contributes to a smaller carbon footprint, aligning with sustainable building practices.

Diverse Applications: Where are Insulated Steel Profiles Used?

The versatility of thermally insulated steel profiles makes them suitable for a wide range of applications in the construction industry:

- Curtain Walls: These profiles are ideal for creating energy-efficient curtain wall systems in high-rise buildings and commercial structures.

- Doors and Windows: Insulated steel frames enhance the thermal performance of doors and windows, contributing to overall building energy efficiency.

- Industrial Buildings: Their strength and thermal properties make them suitable for various industrial applications, including cold storage facilities and manufacturing plants.

- Residential Construction: Increasingly, insulated steel profiles are being used in residential buildings to improve energy efficiency and comfort.

- Cold Storage Facilities: Their ability to minimize heat transfer makes them ideal for maintaining low temperatures in cold storage facilities, reducing energy costs and improving food preservation.

Manufacturing Processes: Creating Insulated Steel Profiles

The manufacturing process of thermally insulated steel profiles involves several key steps:

- Steel Profile Formation: The steel profile is formed using various methods, such as rolling or extrusion, to achieve the desired shape and dimensions.

- Insulation Core Injection: A layer of polyurethane or polyisocyanurate foam is injected into the steel profile, filling the cavity and creating the thermal break.

- Curing and Finishing: The foam is allowed to cure, and the surface of the profile is often treated to enhance durability and aesthetics.

- Quality Control: Rigorous quality control measures are implemented to ensure that the profile meets the required specifications in terms of thermal performance, strength, and durability.

Different manufacturing techniques and materials may be used depending on the specific requirements of the application and the desired thermal performance.

Future Trends and Innovations in Insulated Steel Profiles

The field of thermally insulated steel profiles is constantly evolving. Future trends include:

- Improved Insulation Materials: Research and development are focused on developing even more efficient insulation materials with higher R-values and better durability.

- Advanced Manufacturing Techniques: Innovations in manufacturing processes are aimed at improving efficiency, reducing costs, and enhancing the quality of the profiles.

- Integration with Smart Building Technologies: Future insulated steel profiles may be integrated with smart building technologies to optimize energy consumption and enhance building performance.

- Sustainable Materials: The industry is exploring the use of more sustainable materials in the manufacturing process, reducing the environmental impact of the profiles.

- Increased Design Flexibility: Future developments will likely lead to greater design flexibility, allowing architects and engineers to create more innovative and aesthetically pleasing structures.

Thermally insulated steel profiles represent a significant advancement in building technology, offering a powerful combination of structural strength and energy efficiency. As research and development continue, we can expect even more innovative and sustainable solutions in the future.

Tags: Thermally Insulated Steel Profiles, Insulated Steel Sections, Energy Efficient Steel, Sustainable Building Materials, Thermal Break Profiles