Superalloy steels, renowned for their exceptional high-temperature strength, creep resistance, and oxidation resistance, are critical components in numerous high-performance applications. These advanced materials are engineered to withstand extreme conditions, pushing the boundaries of what’s possible in various industries. This comprehensive guide delves into the fascinating world of superalloy steels, exploring their unique properties and diverse applications.

1. The Unique Properties of Superalloy Steels: A Foundation of Strength

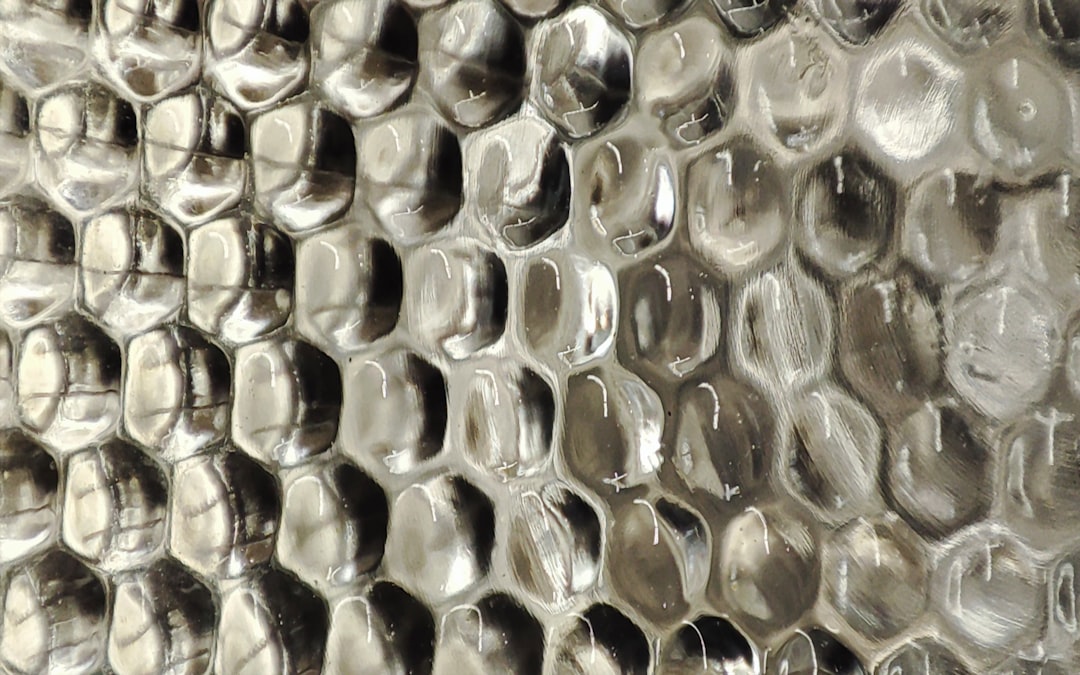

The remarkable performance of superalloys stems from their unique metallurgical composition and microstructure. Typically based on nickel, cobalt, or iron, these alloys are meticulously crafted with additions of elements like chromium, molybdenum, tungsten, aluminum, and titanium. These additions significantly enhance the material’s properties:

- High-Temperature Strength: Superalloys retain their strength at significantly higher temperatures than conventional steels, making them ideal for applications involving intense heat.

- Creep Resistance: Creep, the gradual deformation under sustained stress at high temperatures, is minimized in superalloys due to their unique microstructure, which includes the formation of strengthening precipitates.

- Oxidation Resistance: A protective oxide layer forms on the surface of superalloys, protecting them from corrosion and oxidation even at elevated temperatures.

- Fatigue Resistance: Superalloys exhibit excellent resistance to fatigue failure, ensuring longevity under cyclical loading conditions.

These combined properties make superalloy steels indispensable in demanding environments where conventional materials would fail.

2. Aerospace Applications: Reaching for the Skies with Superalloys

The aerospace industry is a major consumer of superalloy steels. Their ability to withstand extreme temperatures and stresses makes them crucial for components operating in the harsh conditions of jet engines and gas turbines. Key applications include:

- Turbine Blades and Vanes: Superalloys are the material of choice for turbine blades and vanes, the heart of gas turbine engines. They endure incredibly high temperatures and centrifugal forces generated during operation.

- Combustion Chambers: The combustion chambers of jet engines are subjected to intense heat and pressure. Superalloys provide the necessary strength and durability to withstand these demanding conditions.

- Afterburners: In afterburners, where fuel is injected to increase thrust, superalloys are essential for handling the extremely high temperatures generated.

- Rocket Engine Components: In rocket propulsion systems, superalloys are used in components that experience intense heat and pressure during launch and flight.

The lightweight yet robust nature of superalloys is paramount to efficient and safe aerospace operations.

3. Power Generation: Fueling Progress with Superalloy Technology

Beyond aerospace, the power generation sector relies heavily on superalloys for efficient and reliable operation. Their high-temperature capabilities are critical in:

- Gas Turbine Blades in Power Plants: Similar to aerospace applications, superalloys are used in the gas turbine blades of power plants, ensuring efficient energy conversion.

- Fossil Fuel Power Plants: In fossil fuel power plants, superalloys are used in components exposed to high temperatures and corrosive environments.

- Nuclear Power Plants: While less common, some components in nuclear power plants utilize superalloys for their resistance to radiation and high temperatures.

The reliable performance of superalloys in power generation contributes to a stable and efficient energy supply.

4. Manufacturing Processes: Shaping the Strength of Superalloys

The manufacturing of superalloys is a complex process requiring specialized techniques due to their high melting points and tendency to form brittle intermetallic phases. Common methods include:

- Investment Casting: This process allows for the creation of complex shapes with high precision, ideal for turbine blades.

- Powder Metallurgy: This technique involves blending metal powders, pressing them into shape, and then sintering them at high temperatures, leading to improved material properties.

- Directional Solidification: This method creates a microstructure with aligned grains, enhancing creep resistance.

- Forging: Forging helps to refine the grain structure and improve mechanical properties.

These advanced manufacturing techniques are crucial for producing superalloys with the desired microstructure and mechanical properties.

5. Future Trends and Innovations in Superalloy Steel Technology

Research and development continue to push the boundaries of superalloy technology. Future trends include:

- Development of Novel Alloy Compositions: Researchers are constantly exploring new alloy compositions to improve high-temperature strength, creep resistance, and oxidation resistance.

- Advanced Manufacturing Techniques: Additive manufacturing (3D printing) is showing promise for creating complex superalloy components with improved efficiency and reduced material waste.

- Coatings and Surface Treatments: Protective coatings are being developed to further enhance the oxidation and corrosion resistance of superalloys.

- Sustainable Manufacturing Practices: Efforts are underway to make the manufacturing process of superalloys more environmentally friendly.

These advancements will lead to even more efficient and durable superalloy components for a wide range of applications.

Superalloy steels are truly remarkable materials, their exceptional properties and diverse applications shaping modern technology. As research continues to advance, we can expect even more innovative uses for these powerful and versatile materials.

Tags: superalloy steel, superalloy applications, nickel-based superalloys, aerospace applications, high-temperature alloys