body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

img {

max-width: 100%;

height: auto;

}

Wind turbines, the silent giants of renewable energy, rely on intricate support systems to harness the power of the wind. While the blades themselves are visually striking, the unseen infrastructure supporting them is equally crucial for efficient and reliable operation. This post delves into the complexities of wind turbine blade support systems, exploring their design, materials, maintenance, and future innovations.

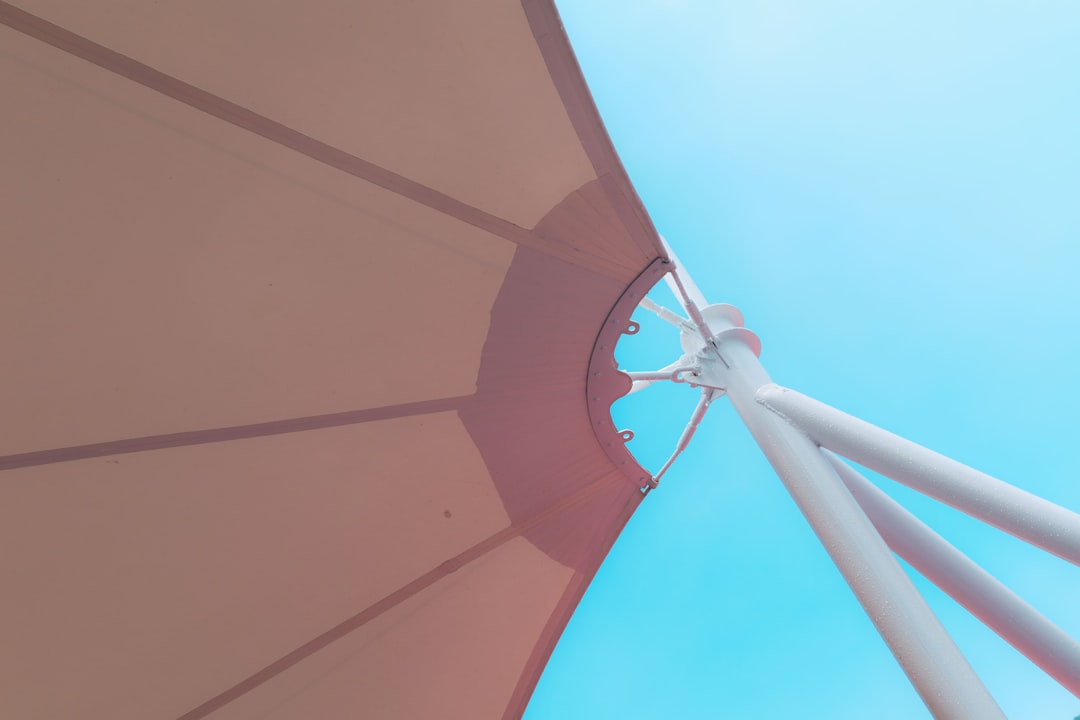

1. The Foundation: Understanding the Nacelle and Hub Assembly

The journey of wind energy begins at the nacelle, a large housing unit situated atop the tower. Inside this crucial component resides the gearbox, generator, and the hub – the central point where the blades connect. The hub assembly is the primary support structure for the blades, transferring the immense forces generated by the rotating blades to the rest of the turbine. It’s a complex system of bearings, shafts, and housings, designed to withstand significant loads, both static (due to blade weight) and dynamic (from wind forces and centrifugal effects). The materials used are typically high-strength steel alloys, chosen for their durability and resistance to fatigue under cyclic loading. Precise manufacturing and rigorous quality control are paramount in ensuring the longevity and safety of this critical component.

2. Blade Pitch Systems: Controlling the Angle of Attack

Wind turbine blades don’t simply rotate at a fixed angle. To optimize energy capture and protect the turbine during high-wind events, sophisticated blade pitch systems are employed. These systems allow for the adjustment of the angle of attack of each blade. Hydraulic or electric actuators are commonly used to precisely control the pitch angle, which is crucial for maximizing energy output across varying wind speeds. In high winds, the blades are pitched to a feathering position, reducing the surface area exposed to the wind and preventing damage. The support system for the pitch mechanism must be robust enough to handle the forces involved, often incorporating highly engineered bearings and precision gears. Regular maintenance and lubrication are essential for ensuring the smooth and reliable operation of the pitch system.

3. Material Selection: Balancing Strength, Weight, and Durability

The choice of materials for wind turbine blade support systems is a critical design consideration. The components must be lightweight to minimize stress on the tower and gearbox, yet strong enough to withstand extreme loads. High-strength steel alloys, composites (like carbon fiber reinforced polymers), and advanced aluminum alloys are frequently used, each offering a unique balance of strength-to-weight ratio and fatigue resistance. The selection of materials is also influenced by environmental factors, such as corrosion resistance and the ability to withstand extreme temperature fluctuations. Ongoing research focuses on developing lighter, stronger, and more durable materials to improve turbine efficiency and longevity.

4. Maintenance and Inspection: Ensuring Operational Integrity

Regular maintenance and inspection are vital for the safe and efficient operation of wind turbine blade support systems. This involves visual inspections for signs of wear, tear, or damage, as well as more thorough assessments using non-destructive testing techniques. Regular lubrication of bearings and other moving parts is crucial for preventing premature wear and tear. Advanced monitoring systems are increasingly being deployed to remotely track the condition of the support systems, providing early warnings of potential problems. Predictive maintenance strategies, based on data analysis and machine learning, are gaining traction, allowing for more efficient and cost-effective maintenance scheduling.

5. Future Innovations: Towards Lighter, Smarter, and More Resilient Systems

The ongoing drive for increased efficiency and cost-effectiveness in wind energy is pushing the boundaries of wind turbine blade support system design. Research and development efforts are focused on several key areas: the use of advanced materials with even higher strength-to-weight ratios, the integration of smart sensors and data analytics for predictive maintenance, and the development of more robust and resilient designs capable of withstanding harsher environmental conditions. The incorporation of active control systems, capable of dynamically adjusting the support structure in response to changing wind conditions, is another promising area of innovation. These advancements will contribute to the development of even more efficient, reliable, and sustainable wind energy technologies.

In conclusion, the seemingly simple act of supporting wind turbine blades involves a sophisticated interplay of engineering, materials science, and operational expertise. Understanding the intricacies of these support systems is crucial for ensuring the safe, efficient, and long-term viability of wind energy as a key component of a sustainable energy future.

SEO Tags:

Wind Turbine Blades, Wind Turbine Support Systems, Nacelle Assembly, Blade Pitch Systems, Wind Turbine Maintenance