body { font-family: sans-serif; line-height: 1.6; }

h1, h2, h3 { color: #333; }

img { max-width: 100%; height: auto; }

The world of engineering materials is constantly evolving, driven by the need for stronger, lighter, and more durable components. In this quest for innovation, carbon fiber-coated steel pipes have emerged as a powerful solution, combining the best properties of both materials. This comprehensive guide delves into the fascinating world of these composite pipes, exploring their unique characteristics, applications, manufacturing processes, and the future they hold.

The Synergistic Marriage of Steel and Carbon Fiber

Steel pipes have long been a mainstay in various industries due to their strength and relatively low cost. However, steel’s limitations, such as susceptibility to corrosion and relatively high weight, have spurred the search for improvements. Carbon fiber, on the other hand, boasts exceptional strength-to-weight ratio, high tensile strength, and excellent corrosion resistance. By combining these two materials, carbon fiber-coated steel pipes leverage the inherent strengths of each, resulting in a superior product. The steel core provides the necessary compressive strength and bulk, while the carbon fiber coating significantly enhances tensile strength, fatigue resistance, and corrosion protection. This synergistic combination leads to pipes that are both robust and lightweight, opening up a range of new applications.

Manufacturing Processes: Precision and Innovation

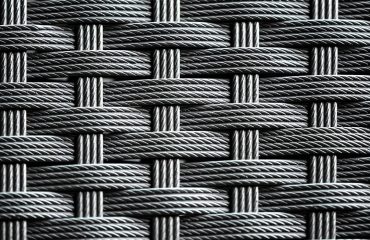

The manufacturing process of carbon fiber-coated steel pipes is a complex yet precise operation. Several methods are employed, each with its own advantages and disadvantages. One common technique involves winding continuous carbon fiber strands around a prepared steel pipe. This process often utilizes a resin system to bind the fibers together, creating a strong and durable composite layer. The precise control of fiber orientation and resin application is crucial for achieving optimal mechanical properties. Other methods include prepreg techniques, where pre-impregnated carbon fiber sheets are wrapped around the steel pipe and cured in an autoclave, and filament winding processes that offer superior control over fiber placement for specific load requirements. The choice of manufacturing method depends on factors such as pipe diameter, desired properties, and production volume.

Applications Across Diverse Industries

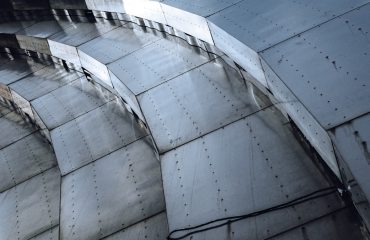

The exceptional properties of carbon fiber-coated steel pipes have led to their adoption across a wide array of industries. In the oil and gas sector, these pipes are increasingly used for transporting high-pressure fluids and gases, offering superior resistance to corrosion and pressure fluctuations compared to traditional steel pipes. The aerospace industry utilizes them in various aircraft components, where weight reduction is critical for fuel efficiency. The automotive industry is exploring their use in high-performance vehicles, improving structural integrity and reducing weight. Furthermore, these pipes find applications in civil engineering projects, such as bridges and buildings, where their strength and durability are invaluable. Even the renewable energy sector benefits, using them in wind turbine structures and geothermal energy systems.

Advantages Over Traditional Steel Pipes: A Comparative Analysis

Compared to traditional steel pipes, carbon fiber-coated steel pipes offer several significant advantages. Firstly, their superior strength-to-weight ratio leads to significant weight savings, reducing transportation costs and improving structural efficiency. Secondly, the carbon fiber coating provides exceptional corrosion resistance, extending the lifespan of the pipes, especially in harsh environments. Thirdly, the increased fatigue resistance minimizes the risk of failure under cyclic loading conditions. Fourthly, their enhanced stiffness improves the overall stability and performance of structures in which they are incorporated. While the initial cost of carbon fiber-coated steel pipes may be higher than that of traditional steel pipes, the long-term cost savings due to increased lifespan and reduced maintenance outweigh the initial investment in many applications.

Future Trends and Innovations: Shaping the Next Generation

The future of carbon fiber-coated steel pipes looks bright. Ongoing research and development efforts are focused on improving the manufacturing processes to enhance efficiency and reduce costs. New resin systems are being developed to further enhance the performance characteristics of the composite material, including improved impact resistance and temperature tolerance. The integration of smart sensors within the pipe walls is also being explored, allowing for real-time monitoring of pressure, temperature, and other critical parameters, enabling predictive maintenance and preventing potential failures. Furthermore, research into sustainable and recyclable carbon fiber materials is crucial for reducing the environmental impact of this technology. As these advancements continue, carbon fiber-coated steel pipes are poised to play an even greater role in various industries, driving innovation and enhancing performance across diverse applications.

In conclusion, carbon fiber-coated steel pipes represent a significant advancement in material science, offering a compelling blend of strength, durability, and lightweight properties. Their versatility and performance advantages are transforming industries and paving the way for a more efficient and sustainable future.

SEO Tags: Carbon Fiber Pipes, Steel Pipes, Composite Pipes, Carbon Fiber-Reinforced Steel, Material Science