body { font-family: sans-serif; line-height: 1.6; }

h1, h2, h3 { color: #333; }

img { max-width: 100%; height: auto; }

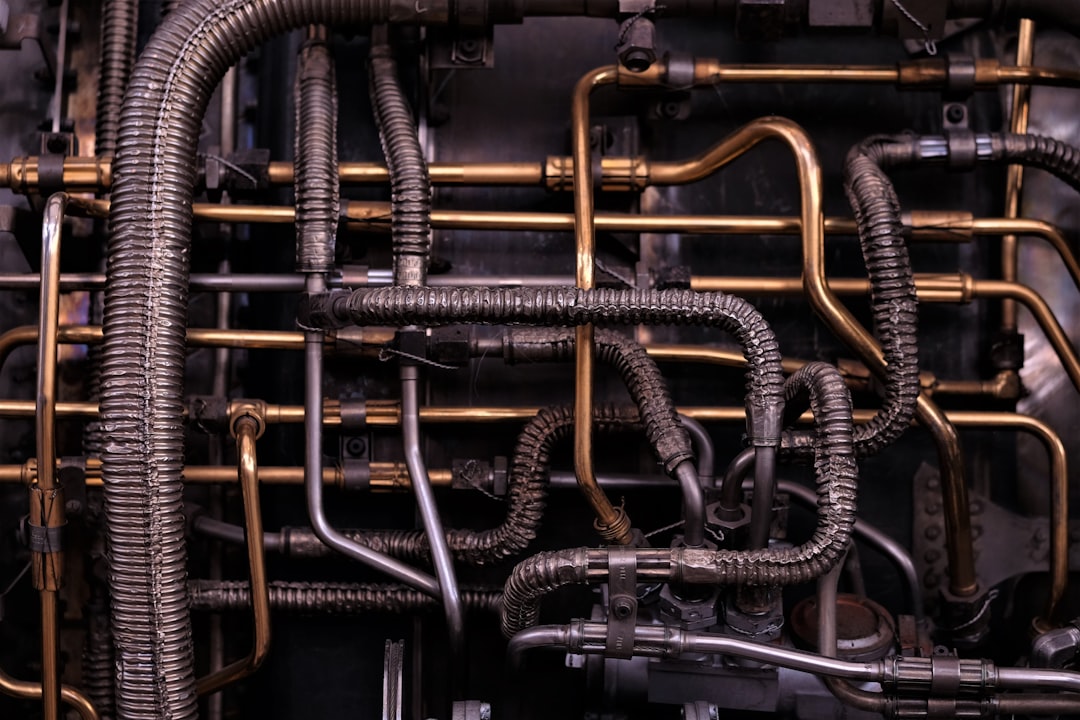

Radiographic inspection (RT) is a crucial non-destructive testing (NDT) method used to detect internal flaws in pipes. This powerful technique utilizes penetrating radiation to create images revealing imperfections that could compromise the integrity and safety of pipelines. From oil and gas transmission to water distribution systems, understanding radiographic inspection is vital for ensuring reliable and safe infrastructure.

Understanding the Principles of Radiographic Pipe Inspection

Radiographic inspection relies on the principle of differential absorption of radiation. A source of ionizing radiation, typically X-rays or gamma rays, is directed at the pipe. The radiation passes through the pipe, and its intensity is reduced depending on the density of the material. Denser areas, like the pipe’s base metal, absorb more radiation, while less dense areas, such as flaws (e.g., cracks, porosity, inclusions), absorb less. A detector, usually a film or digital imaging system, records the variations in radiation intensity, creating a radiograph or image representing the internal structure of the pipe.

The resulting radiograph shows variations in grayscale. Darker areas indicate less radiation absorption (flaws), while lighter areas indicate higher absorption (dense material). Experienced inspectors interpret these variations to identify and characterize the flaws, determining their size, location, and type. This allows for accurate assessment of the pipe’s structural integrity.

Common Techniques Employed in Radiographic Pipe Inspection

Several techniques are employed in radiographic inspection of pipes, each tailored to specific pipe diameters, wall thicknesses, and accessibility. These include:

- Double-Wall Exposure: This technique uses a single exposure to image both walls of the pipe simultaneously. It’s efficient but may limit the detection of small flaws located close to the pipe’s surface.

- Single-Wall Exposure: This method images one pipe wall at a time, providing better resolution and flaw detection, particularly for thinner pipes or when higher precision is required.

- Real-Time Radiography (RTR): RTR uses a digital imaging system to provide immediate results, eliminating the need for film processing. This offers significant time and cost savings, allowing for faster inspection and immediate feedback.

- Computed Radiography (CR): CR uses imaging plates that store the radiation information. These plates are then scanned to create a digital image, offering flexibility and improved image quality compared to traditional film radiography.

Applications of Radiographic Pipe Inspection Across Various Industries

Radiographic pipe inspection finds extensive application across diverse industries, including:

- Oil and Gas: Ensuring the integrity of pipelines transporting highly flammable and hazardous materials is paramount. RT helps detect flaws that could lead to leaks, explosions, or environmental damage.

- Water and Wastewater: Detecting corrosion, pitting, and other defects in water pipelines is crucial for maintaining water quality and preventing leaks and contamination.

- Power Generation: RT is used to inspect pipes carrying high-pressure steam and other fluids in power plants, ensuring safe and efficient operation.

- Chemical Processing: The chemical industry relies on RT to inspect pipes handling corrosive chemicals, preventing leaks and ensuring the safety of personnel and the environment.

- Construction and Manufacturing: RT is used to verify the quality of welded joints and other critical components in pipes used in various construction and manufacturing applications.

Advantages and Limitations of Radiographic Pipe Inspection

Radiographic inspection offers several advantages:

- High Sensitivity: RT can detect even small internal flaws that might be missed by other NDT methods.

- Permanent Record: Radiographs provide a permanent record of the inspection, allowing for future reference and analysis.

- Versatile: RT can be applied to various pipe materials, sizes, and configurations.

- Comprehensive: It provides a comprehensive view of the pipe’s internal structure.

However, it also has limitations:

- Cost: RT can be relatively expensive compared to other NDT methods.

- Safety Concerns: Ionizing radiation poses safety risks, requiring specialized training and safety precautions.

- Accessibility: Access to the pipe may be challenging in some situations.

- Limited Surface Flaws Detection: RT is primarily focused on internal flaws; surface flaws may not be readily detectable.

Safety Procedures and Regulations in Radiographic Pipe Inspection

Safety is paramount in radiographic inspection. Strict adherence to safety procedures and regulations is crucial to protect personnel and the environment from the hazards of ionizing radiation. This includes:

- Radiation Safety Training: Personnel involved in RT must receive thorough training on radiation safety procedures, including proper handling of radiation sources, shielding techniques, and radiation monitoring.

- Radiation Shielding: Adequate shielding is essential to protect personnel from exposure to ionizing radiation. Shielding materials, such as lead, concrete, or specialized enclosures, are used to reduce radiation levels to safe limits.

- Radiation Monitoring: Radiation monitoring devices are used to measure radiation levels in the work area, ensuring that exposure levels remain within acceptable limits.

- Regulatory Compliance: Radiographic inspections must comply with relevant national and international regulations, ensuring that safety standards are met.

- Emergency Procedures: Emergency procedures must be established and regularly practiced to handle any unexpected situations, such as radiation spills or equipment malfunctions.

Radiographic inspection is a powerful tool for ensuring the integrity of pipe systems across various industries. By understanding the principles, techniques, applications, advantages, limitations, and safety procedures, we can effectively utilize this NDT method to maintain safe and reliable infrastructure.

Tags: Radiographic Inspection, Pipe Inspection, NDT, Non-Destructive Testing, X-Ray Inspection, Gamma Ray Inspection