Annealed wire, a marvel of metallurgical engineering, finds its place in a vast array of applications, owing to its unique properties of enhanced ductility and reduced brittleness. This process, involving controlled heating and cooling, transforms the wire’s microstructure, making it significantly more malleable and easier to work with. This blog post delves deep into the world of annealed wire, exploring its properties, manufacturing, and diverse applications across various industries.

Understanding the Annealing Process and its Impact on Wire Properties

Annealing is a heat treatment process that alters the physical and mechanical properties of a material, in this case, wire. The process involves heating the wire to a specific temperature, holding it at that temperature for a predetermined time, and then allowing it to cool slowly. This controlled heating and cooling cycle relieves internal stresses within the wire’s crystalline structure. The result is a reduction in hardness and an increase in ductility – the ability of the wire to deform under tensile stress without fracturing. The specific annealing temperature and time vary depending on the type of metal and the desired properties of the final product. For instance, copper wire annealing might involve different parameters than steel wire annealing. The precise control over these parameters is crucial for achieving the desired level of softness and flexibility.

Annealed Wire in the Electronics Industry: Precision and Reliability

The electronics industry relies heavily on annealed wire’s exceptional ductility and conductivity. Its malleability makes it ideal for intricate wiring in electronic devices, where precise bending and shaping are essential. Annealed copper wire, in particular, is a staple in circuit boards, providing reliable electrical connections. The low hardness ensures that the wire doesn’t fracture during the manufacturing process, leading to higher yields and reduced production costs. Furthermore, the consistent electrical conductivity of annealed wire ensures reliable signal transmission and prevents signal loss, a critical factor in the performance of electronic devices. From smartphones to sophisticated computers, annealed wire plays an indispensable role.

Automotive Applications: Strength, Durability, and Safety in Motion

The automotive industry utilizes annealed wire in various components, prioritizing its strength, durability, and resistance to fatigue. Annealed steel wire is commonly used in the manufacturing of springs, which are vital for suspension systems, brakes, and other critical components. The annealing process ensures that these springs can withstand repeated cycles of compression and expansion without failure, contributing significantly to the safety and reliability of vehicles. Furthermore, annealed wire is used in the production of various electrical components within the vehicle, ensuring the reliable operation of lighting systems, power windows, and other electrical systems. The consistent performance of annealed wire is crucial for maintaining the safety and functionality of modern vehicles.

Beyond Electronics and Automotive: Exploring Diverse Applications of Annealed Wire

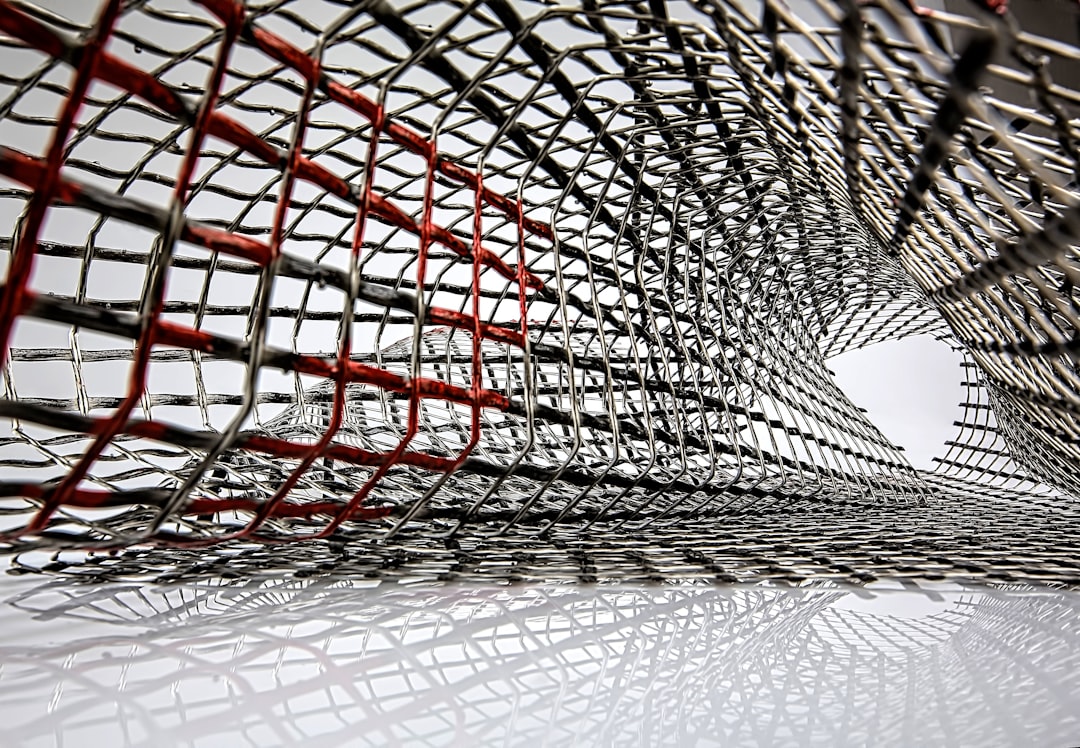

The applications of annealed wire extend far beyond electronics and automotive. In the construction industry, annealed wire is used in reinforcement mesh for concrete, providing structural integrity and preventing cracking. The flexibility of the annealed wire allows for easy installation and adaptation to various shapes and sizes. In the medical field, annealed wire is used in the manufacturing of surgical instruments and implants, where its biocompatibility and malleability are essential. Furthermore, annealed wire is used in the production of various consumer goods, including springs in household appliances, wire mesh in filters, and decorative elements in crafts. Its versatility and adaptability make it a crucial material across a wide spectrum of industries.

Choosing the Right Annealed Wire: Material Selection and Specifications

Selecting the appropriate annealed wire depends heavily on the specific application. Factors such as the required tensile strength, ductility, conductivity, and corrosion resistance must be considered. The choice of base metal (e.g., copper, steel, aluminum) plays a significant role, as each metal possesses unique properties. Furthermore, the diameter and the level of annealing are crucial parameters that influence the wire’s final characteristics. Manufacturers often provide detailed specifications, including tensile strength, elongation, and conductivity, to assist in selecting the most suitable annealed wire for a given application. Careful consideration of these factors ensures the optimal performance and longevity of the final product.

Annealed wire is a fundamental material in numerous industries, its versatility and reliability making it an indispensable component in countless applications. Understanding its properties and applications is crucial for engineers, manufacturers, and anyone involved in the selection and use of this vital material.

SEO Tags:

- Annealed wire

- Annealing process

- Wire applications

- Copper annealed wire

- Steel annealed wire