Galvanized steel, a ubiquitous material in construction, infrastructure, and manufacturing, owes its widespread use to its exceptional corrosion resistance. This property significantly extends the lifespan of products and structures, saving both money and resources. But what exactly makes galvanized steel so resistant to rust, and are there any limitations to its protective capabilities? This comprehensive guide delves into the science behind galvanized steel’s corrosion resistance, exploring its applications, limitations, and comparisons with other materials.

The Science Behind Galvanized Steel’s Corrosion Resistance

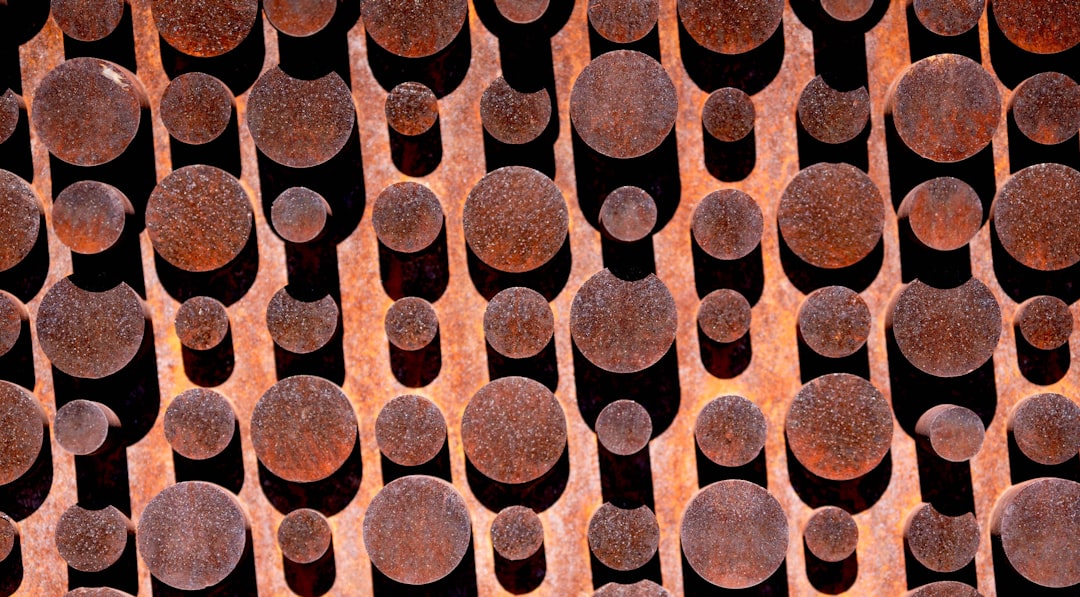

The remarkable corrosion resistance of galvanized steel stems from the zinc coating applied to the steel substrate. This process, known as galvanization, involves immersing the steel in a molten zinc bath, resulting in a tightly bonded zinc layer. The zinc acts as a sacrificial anode, meaning it preferentially corrodes instead of the underlying steel. This process is based on the electrochemical principle where zinc, being more electropositive than iron (the primary component of steel), readily loses electrons and forms zinc oxide, a protective layer that prevents further corrosion.

This protective layer isn’t just a simple barrier; it’s a dynamic system. The zinc oxide layer reacts with atmospheric components like carbon dioxide and moisture to form a more complex, stable carbonate layer. This multi-layered structure provides robust and long-lasting protection against corrosion, even in harsh environments.

Types of Galvanization and Their Impact on Corrosion Resistance

There are two primary methods of galvanization: hot-dip galvanization and electro-galvanization. Hot-dip galvanization, as described above, involves immersing the steel in a molten zinc bath, resulting in a thicker, more durable zinc coating. This method offers superior corrosion resistance, particularly in demanding environments with high humidity or exposure to chemicals.

Electro-galvanization, on the other hand, uses an electrolytic process to deposit a thinner zinc layer onto the steel. While less expensive, electro-galvanized steel offers lower corrosion resistance compared to hot-dip galvanized steel. The choice between these methods depends on the specific application and the required level of corrosion protection.

Applications of Galvanized Steel: Where Corrosion Resistance Matters Most

The exceptional corrosion resistance of galvanized steel makes it ideal for a wide range of applications, particularly in environments where exposure to the elements is unavoidable. Common applications include:

- Construction: Roofing, siding, structural components, fencing, and guardrails.

- Automotive: Body panels, chassis components, and exhaust systems.

- Infrastructure: Bridges, pipelines, and transmission towers.

- Manufacturing: Storage tanks, containers, and various industrial equipment.

- Agriculture: Greenhouse structures, fencing, and storage silos.

In each of these applications, the longevity and reliability provided by galvanized steel’s corrosion resistance are crucial for long-term performance and cost-effectiveness.

Limitations of Galvanized Steel’s Corrosion Resistance

While galvanized steel offers excellent corrosion protection, it’s not invincible. Its effectiveness can be compromised under certain conditions:

- Highly acidic environments: Strong acids can attack the zinc coating, leading to corrosion of the underlying steel.

- Abrasion and scratches: Damage to the zinc coating exposes the steel substrate, making it vulnerable to rust.

- High temperatures: Prolonged exposure to extremely high temperatures can degrade the zinc coating’s protective properties.

- Exposure to specific chemicals: Certain chemicals, such as chlorides (found in seawater), can accelerate corrosion.

Understanding these limitations is crucial for selecting the appropriate material for a given application and ensuring long-term performance.

Galvanized Steel vs. Other Corrosion-Resistant Materials

Galvanized steel is often compared to other corrosion-resistant materials, such as stainless steel and aluminum. Stainless steel achieves corrosion resistance through alloying, creating a passive oxide layer that inhibits corrosion. While offering excellent corrosion resistance, stainless steel is generally more expensive than galvanized steel.

Aluminum also exhibits good corrosion resistance due to the formation of a protective aluminum oxide layer. However, aluminum is less strong than steel, limiting its applications in certain structural applications. The choice between galvanized steel and other materials depends on factors such as cost, required strength, and the specific corrosive environment.

In conclusion, the exceptional corrosion resistance of galvanized steel is a result of the sacrificial protection provided by the zinc coating. Understanding the science behind this protection, the different types of galvanization, and the limitations of the material is essential for engineers, designers, and anyone involved in selecting materials for long-lasting and reliable structures and products.