body { font-family: sans-serif; line-height: 1.6; }

h1, h2, h3 { color: #333; }

img { max-width: 100%; height: auto; }

Electric Resistance Welded (ERW) pipes are a cornerstone of modern construction and industrial applications. Their cost-effectiveness, strength, and versatility make them a popular choice across numerous sectors. This comprehensive guide delves into the world of ERW pipes, exploring their manufacturing, applications, advantages, and limitations.

The ERW Pipe Manufacturing Process: From Coil to Construction

The creation of ERW pipes begins with a continuous coil of steel sheet. This coil is then fed into a forming mill where it’s progressively shaped into a cylindrical form. The edges of the sheet are precisely aligned and then electrically welded together using a high-current process. This process generates heat, melting the edges of the steel and fusing them seamlessly. The weld is then often further strengthened and refined through various post-weld treatments, including sizing, straightening, and potentially heat treatment, depending on the pipe’s intended application and specifications. The resulting pipe is then cut to the desired length, ensuring consistent dimensions and high-quality welds. Precise quality control measures are implemented throughout the entire process to guarantee the integrity and durability of the final product. This rigorous manufacturing process contributes significantly to the reliability and widespread use of ERW pipes.

Diverse Applications of ERW Pipes: Across Industries and Infrastructure

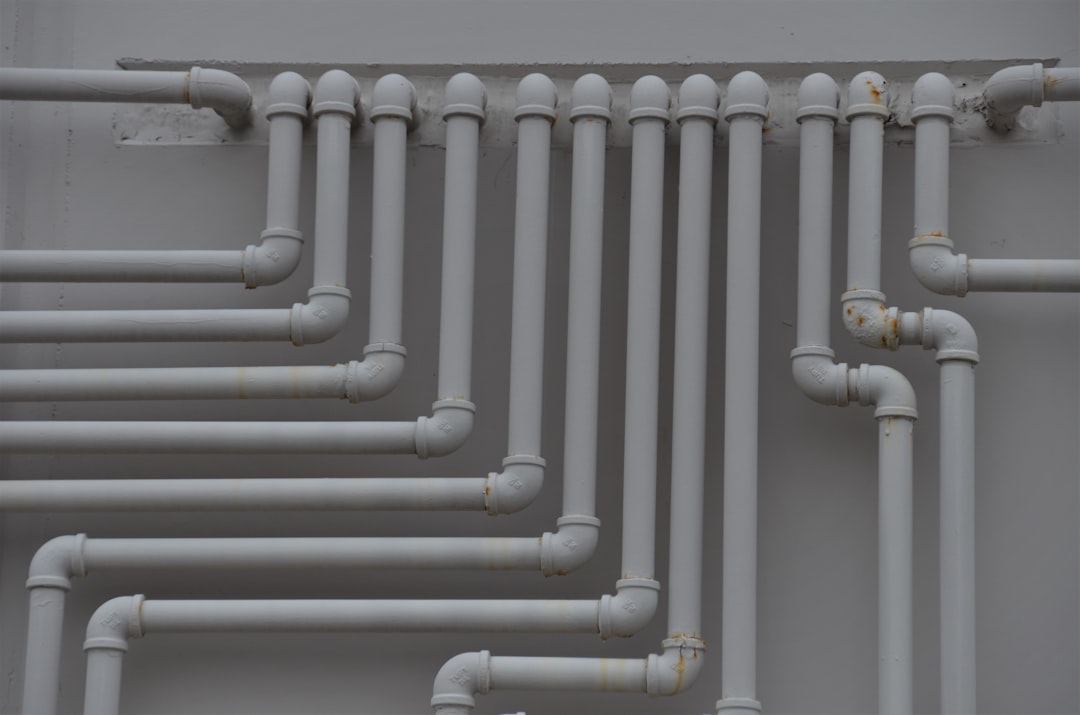

ERW pipes find extensive use in a vast array of applications, showcasing their adaptability and strength. In the construction industry, they are commonly used for structural framing, scaffolding, and piling. Their high strength-to-weight ratio makes them ideal for supporting heavy loads. In the oil and gas industry, ERW pipes are crucial for transporting fluids and gases over long distances. Their ability to withstand high pressures and harsh environments makes them well-suited for pipelines and well casing. The automotive industry also utilizes ERW pipes in various components, leveraging their precision and formability. Furthermore, ERW pipes are integral to water and wastewater management systems, providing efficient and durable pipelines for municipal infrastructure. Finally, they are frequently employed in agricultural irrigation, ensuring efficient water distribution to crops.

Advantages of ERW Pipes: Why They Are a Preferred Choice

Several factors contribute to the popularity and widespread adoption of ERW pipes. Firstly, they are cost-effective compared to other piping solutions, making them a financially attractive option for large-scale projects. Secondly, their high strength and durability ensure long-term performance and reduce the need for frequent replacements. The consistent diameter and wall thickness achieved during manufacturing guarantee reliable performance and easy installation. Moreover, ERW pipes are versatile, adaptable to a range of diameters and wall thicknesses, catering to diverse application needs. Finally, advancements in manufacturing techniques have led to improvements in weld quality and overall pipe integrity, further enhancing their reliability and longevity.

Limitations of ERW Pipes: Understanding Their Constraints

While ERW pipes offer numerous advantages, it’s crucial to understand their limitations. The welding process can potentially introduce residual stresses into the pipe, which may affect its performance under certain conditions. The quality of the weld is paramount, and defects can compromise the integrity of the entire pipe. Careful inspection and quality control are therefore essential throughout the manufacturing and application processes. Moreover, ERW pipes might not be suitable for all applications requiring extreme corrosion resistance or high-temperature operation. In such cases, alternative piping materials might be more appropriate. Understanding these limitations enables informed decision-making regarding the suitability of ERW pipes for specific projects.

Future Trends in ERW Pipe Technology: Innovation and Sustainability

The ERW pipe industry is constantly evolving, with ongoing innovations aimed at enhancing performance, sustainability, and efficiency. There’s a growing focus on developing advanced welding techniques to further improve weld quality and reduce defects. Research is also underway to explore the use of high-strength steel grades and innovative coatings to enhance corrosion resistance and extend the lifespan of ERW pipes. Sustainability is another key driver, with efforts focused on reducing energy consumption during manufacturing and exploring eco-friendly alternatives for coatings and surface treatments. These advancements promise to further expand the applications and enhance the overall value proposition of ERW pipes in the years to come.

In conclusion, ERW pipes represent a crucial component in a wide range of industries and infrastructure projects. Their cost-effectiveness, strength, versatility, and ongoing technological advancements ensure their continued importance in the construction, energy, and manufacturing sectors.

SEO Tags:

ERW Pipes, Electric Resistance Welded Pipes, Pipe Applications, Steel Pipes, Construction Materials