The steel industry is a cornerstone of global infrastructure, but its traditional production methods have significant environmental consequences. Creating sustainable steel supply chains is no longer a niche concern; it’s a necessity for a thriving and environmentally responsible future. This post delves into the key aspects of building a more sustainable steel industry, examining the challenges and opportunities along the way.

1. Responsible Raw Material Sourcing: The Foundation of Sustainable Steel

The journey towards sustainable steel begins with responsible sourcing of raw materials. Iron ore mining, a crucial step in steel production, often involves significant environmental impacts, including deforestation, habitat destruction, and water pollution. Sustainable practices require a shift towards:

- Minimizing mining’s environmental footprint: Implementing stricter regulations and best practices to reduce land disturbance, water consumption, and greenhouse gas emissions during mining operations.

- Promoting responsible mining certifications: Utilizing certifications like the Responsible Minerals Initiative (RMI) to ensure ethical and environmentally sound sourcing of raw materials.

- Exploring alternative raw materials: Investigating the use of recycled steel scrap and other secondary materials to reduce reliance on virgin iron ore and minimize mining’s impact.

- Optimizing transportation: Reducing the distance materials travel through efficient logistics and the use of alternative transportation methods to minimize carbon emissions.

2. Energy Efficiency and Carbon Footprint Reduction in Steel Production

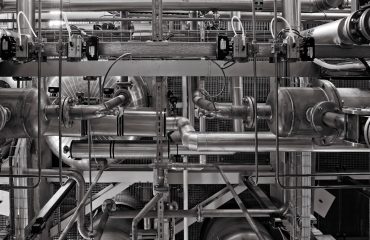

Steel production is an energy-intensive process, contributing significantly to global greenhouse gas emissions. Reducing the carbon footprint requires a multi-pronged approach:

- Transitioning to renewable energy sources: Replacing fossil fuels with renewable energy sources like solar, wind, and hydro power to electrify steel mills and reduce reliance on coal.

- Implementing energy-efficient technologies: Investing in advanced technologies to optimize energy consumption throughout the steelmaking process, including electric arc furnaces (EAFs) which offer significantly lower carbon emissions compared to traditional blast furnaces.

- Carbon Capture, Utilization, and Storage (CCUS): Exploring and implementing CCUS technologies to capture CO2 emissions from steel plants and either store them underground or utilize them in other industrial processes.

- Process optimization: Continuously improving production processes to minimize energy waste and optimize resource utilization.

3. Embracing the Circular Economy: Recycling and Waste Management in Steel

The circular economy model emphasizes reducing waste and maximizing resource utilization. For the steel industry, this translates to:

- Increasing steel recycling rates: Developing robust infrastructure for collecting and processing steel scrap, incentivizing recycling, and improving the quality of recycled steel.

- Designing for recyclability: Creating steel products that are easily disassembled and recycled at the end of their life cycle, minimizing material loss and contamination.

- Waste reduction and management: Implementing strategies to minimize waste generation throughout the steel production process and effectively managing any remaining waste in an environmentally responsible manner.

- Developing innovative recycling technologies: Investing in research and development of new technologies to improve the efficiency and effectiveness of steel recycling.

4. Supply Chain Transparency and Traceability: Ensuring Responsible Practices

Transparency and traceability are crucial for ensuring responsible practices throughout the steel supply chain. This involves:

- Implementing robust tracking systems: Utilizing blockchain technology or other digital tools to track the origin and journey of steel materials, ensuring transparency and accountability.

- Developing industry standards and certifications: Establishing clear industry standards for sustainable steel production and implementing certification schemes to verify compliance.

- Promoting collaboration and information sharing: Encouraging collaboration among stakeholders in the steel supply chain to share best practices and promote transparency.

- Regular audits and assessments: Conducting regular audits and assessments to ensure compliance with sustainability standards and identify areas for improvement.

5. Stakeholder Engagement and Collaboration: A Shared Responsibility

Building truly sustainable steel supply chains requires collaboration and engagement across the entire value chain. This includes:

- Engaging with suppliers and customers: Working with suppliers to promote sustainable practices and collaborating with customers to design and produce more sustainable steel products.

- Collaborating with governments and NGOs: Working with governments to develop supportive policies and regulations and partnering with NGOs to promote awareness and advocate for change.

- Investing in research and development: Continuously investing in research and development to explore and implement new sustainable technologies and practices.

- Promoting education and awareness: Educating stakeholders about the importance of sustainable steel and raising awareness of the environmental and social impacts of the steel industry.

Creating sustainable steel supply chains is a complex but necessary undertaking. By embracing responsible sourcing, energy efficiency, circular economy principles, transparency, and collaboration, the steel industry can forge a greener future for itself and the planet.

Tags: Sustainable Steel, Green Steel, Steel Recycling, Circular Economy Steel, Responsible Sourcing Steel