body {

font-family: sans-serif;

line-height: 1.6;

margin: 20px;

}

h1, h2, h3 {

color: #333;

}

img {

max-width: 100%;

height: auto;

display: block;

margin: 20px auto;

}

In the world of industrial design, the choice of structural elements is paramount. Strength, efficiency, and cost-effectiveness are key considerations. While I-beams often steal the spotlight, IPN beams (Parallel Flange I-beams) offer a compelling alternative, boasting unique properties that make them ideal for a wide range of applications. This comprehensive guide delves into the world of IPN beams, exploring their advantages, applications, and design considerations.

Understanding IPN Beam Properties and Advantages

IPN beams, also known as parallel flange I-beams, are characterized by their parallel flanges—unlike the sloped flanges of traditional I-beams. This distinct feature offers several key advantages. The parallel flanges provide greater stability and simplify connections, especially when it comes to welding or bolting. The consistent flange width allows for easier design calculations and more predictable load distribution. Furthermore, IPN beams often demonstrate superior resistance to torsional stress compared to their I-beam counterparts, making them ideal for applications involving twisting forces. Their inherent strength-to-weight ratio also contributes to their popularity in applications where minimizing weight is crucial, such as in construction and transportation.

Common Applications of IPN Beams in Industrial Design

The versatility of IPN beams makes them suitable for a vast array of industrial applications. They are frequently employed in:

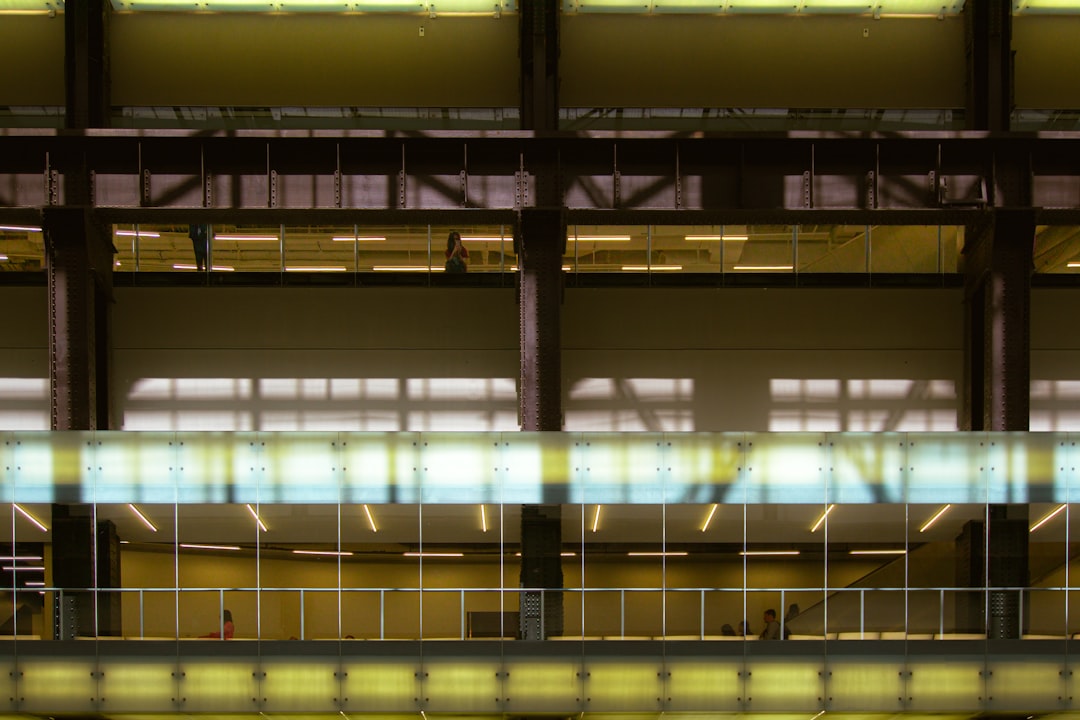

- Structural Frameworks: IPN beams form the backbone of many industrial structures, including warehouses, factories, and bridges. Their high load-bearing capacity and stability make them an excellent choice for supporting heavy machinery and equipment.

- Machine Frames and Bases: The rigidity and resistance to torsion offered by IPN beams are invaluable in the construction of robust machine frames and bases. These beams provide essential support and minimize vibrations, leading to improved machine performance and longevity.

- Transportation Infrastructure: In the transportation sector, IPN beams are used in the construction of railway platforms, bridges, and other critical infrastructure components where strength, durability, and resistance to dynamic loads are essential.

- Offshore Platforms: The corrosion resistance (when using appropriate materials) and high strength-to-weight ratio of IPN beams make them suitable for use in demanding offshore environments.

- Steel Structures: Generally speaking, IPN beams are a preferred choice in many steel structures due to their ease of fabrication and welding, leading to reduced construction time and costs.

Design Considerations for Incorporating IPN Beams

While IPN beams offer numerous benefits, careful consideration during the design phase is crucial to ensure optimal performance and safety. Factors to consider include:

- Load Calculations: Accurate load calculations are paramount to determine the appropriate size and grade of IPN beam for a specific application. This involves considering dead loads, live loads, and any dynamic forces.

- Support Conditions: The type of support (e.g., simply supported, fixed, cantilever) significantly impacts the beam’s behavior under load. Careful consideration of support conditions is essential for accurate design calculations.

- Connection Design: The design of connections between IPN beams and other structural elements is crucial for ensuring the overall stability and integrity of the structure. Welding, bolting, and other connection methods should be carefully selected and executed.

- Material Selection: The choice of material affects the beam’s strength, durability, and resistance to corrosion. Factors such as environmental conditions and the specific application should guide material selection.

- Deflection and Vibration: Excessive deflection or vibration can compromise the performance and longevity of a structure. Design calculations should account for these factors to ensure acceptable levels of deflection and vibration.

Comparing IPN Beams with Other Structural Sections

IPN beams are often compared with other structural sections, such as I-beams, H-beams, and channels. While all these sections offer structural support, IPN beams stand out due to their parallel flanges, which lead to several advantages. Compared to I-beams, IPN beams generally offer better resistance to torsion and simplify connections. Compared to H-beams, IPN beams may be lighter for the same load capacity in certain scenarios. The choice of the optimal section depends on the specific requirements of the application.

Cost-Effectiveness and Sustainability Aspects of IPN Beams

The cost-effectiveness of IPN beams stems from their efficient design and ease of fabrication. Their parallel flanges simplify manufacturing processes and reduce material waste, contributing to lower production costs. Furthermore, the optimized strength-to-weight ratio can lead to reduced transportation costs and lower overall project expenses. From a sustainability perspective, using IPN beams can contribute to more efficient resource utilization, leading to reduced environmental impact. The use of recycled steel in the production of IPN beams further enhances their sustainability credentials.

In conclusion, IPN beams represent a powerful and versatile tool in the industrial designer’s arsenal. Their unique properties, combined with careful consideration during the design phase, make them ideal for a wide range of applications demanding strength, efficiency, and cost-effectiveness. Understanding their advantages and limitations is crucial for maximizing their potential in diverse industrial projects.

Tags: IPN beams, parallel flange I-beams, industrial design, structural engineering, steel construction, structural elements, beam design