In today’s world, noise pollution is a significant concern, impacting productivity, health, and overall well-being. Whether it’s in industrial settings, busy offices, or residential spaces, effective noise control is paramount. Acoustic steel profile systems offer a robust and reliable solution for managing sound transmission, creating quieter and more comfortable environments. This comprehensive guide delves into the intricacies of these systems, exploring their design, applications, and benefits.

Understanding the Mechanics of Acoustic Steel Profile Systems

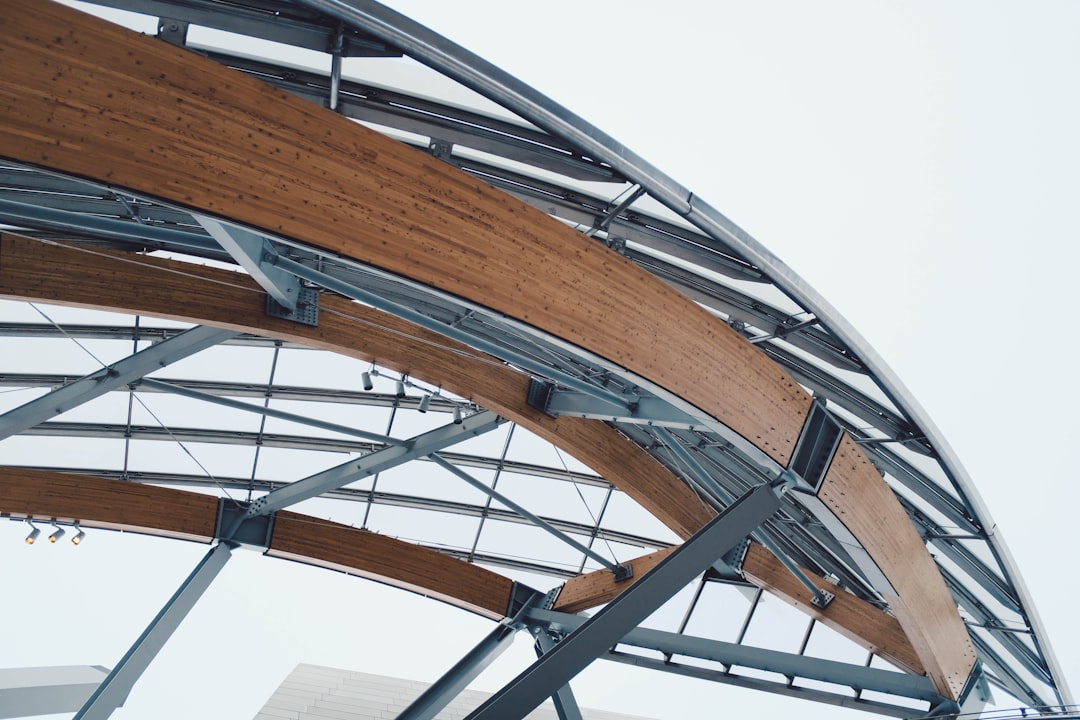

Acoustic steel profile systems are engineered structures designed to minimize the transmission of airborne and structure-borne sound. Unlike traditional methods relying on dense materials alone, these systems utilize a combination of strategically designed steel profiles, vibration damping materials, and sound-absorbing components. The steel profiles provide a robust framework, while the damping materials reduce vibrational energy, preventing sound from traveling through the structure. Sound-absorbing materials, often placed within the cavity created by the profiles, further mitigate sound reflection and absorption.

The effectiveness of these systems hinges on several key factors: the profile’s design (including its weight, geometry, and material properties), the type and thickness of damping materials used, and the overall system’s airtightness. Proper installation is crucial, as gaps or leaks can significantly compromise performance.

Diverse Applications: Where Acoustic Steel Profile Systems Excel

The versatility of acoustic steel profile systems makes them suitable for a wide range of applications. Their robust nature and excellent sound-dampening capabilities make them ideal for:

- Industrial settings: Mitigating noise from machinery and equipment in factories, workshops, and power plants.

- Commercial buildings: Creating quieter office spaces, reducing noise transfer between rooms, and improving speech privacy in open-plan layouts.

- Residential constructions: Increasing sound insulation between apartments, reducing noise intrusion from external sources, and enhancing the overall acoustic comfort of homes.

- Recording studios and theaters: Providing superior sound isolation and minimizing unwanted reverberation.

- Transportation infrastructure: Reducing noise pollution from railways and highways through the construction of noise barriers.

Design Considerations: Optimizing Acoustic Performance

The design of an acoustic steel profile system is a crucial step in ensuring optimal performance. Several factors need careful consideration:

- Frequency range: The system’s design must account for the specific frequency range of the noise being controlled. Different frequencies require different solutions.

- Sound transmission class (STC) ratings: STC ratings provide a quantitative measure of a system’s ability to block sound. The desired STC rating will depend on the specific application and the required level of noise reduction.

- Material selection: Choosing appropriate steel profiles, damping materials, and sound-absorbing materials is critical for achieving the desired acoustic performance. The density, thickness, and stiffness of each component play a vital role.

- System integration: The system must be seamlessly integrated with the existing building structure to ensure proper functionality and prevent sound leakage.

Installation Techniques: Ensuring Effective Sound Control

Proper installation is just as crucial as the design of the acoustic steel profile system. Any gaps or imperfections can significantly compromise its effectiveness. Key aspects of installation include:

- Precise measurements and planning: Accurate measurements are essential to ensure a perfect fit and avoid any gaps.

- Careful assembly: The steel profiles must be assembled precisely according to the manufacturer’s instructions.

- Proper sealing: All joints and seams must be carefully sealed to prevent sound leakage.

- Quality control: Regular inspections throughout the installation process are crucial to ensure that the system is installed correctly and meets the required specifications.

Benefits Beyond Noise Reduction: The Advantages of Acoustic Steel Profile Systems

Beyond their primary function of noise control, acoustic steel profile systems offer several additional benefits:

- Durability and longevity: Steel is a robust material, ensuring the system’s long-term performance and resistance to damage.

- Fire resistance: Steel profiles offer inherent fire resistance, contributing to overall building safety.

- Design flexibility: These systems can be adapted to fit various architectural designs and building layouts.

- Sustainability: Steel is a recyclable material, making these systems environmentally friendly.

- Cost-effectiveness: While the initial investment may be higher than some alternative solutions, the long-term cost savings from reduced noise pollution and improved energy efficiency can be significant.

In conclusion, acoustic steel profile systems represent a sophisticated and effective approach to noise control. By understanding their mechanics, applications, design considerations, and installation techniques, architects, engineers, and contractors can harness their potential to create quieter, more comfortable, and productive environments. The long-term benefits of investing in these systems far outweigh the initial costs, making them a worthwhile investment for a wide range of applications.

Tags: acoustic steel profiles, noise control, soundproofing, steel profile systems, acoustic design, building acoustics