In industries where equipment faces constant vibration, impact, and extreme conditions, reliable connections are paramount. A failure in a connection system can lead to catastrophic consequences, from equipment malfunction to complete system failure. This is where shock-resistant connection systems become indispensable. This comprehensive guide delves into the critical aspects of these systems, exploring their design, materials, applications, and testing methodologies.

Understanding the Challenges of Shock and Vibration

Shock and vibration represent significant threats to the longevity and performance of any connection system. Shock, a sudden, high-magnitude force, can cause immediate damage, including fractures, disconnections, and component failure. Vibration, on the other hand, is a repetitive, lower-magnitude force that leads to fatigue and eventual failure over time. The cumulative effect of these forces can significantly reduce the lifespan of connections, leading to downtime, repair costs, and potential safety hazards. Understanding the specific shock and vibration profiles of the operating environment is crucial for designing an effective shock-resistant connection system.

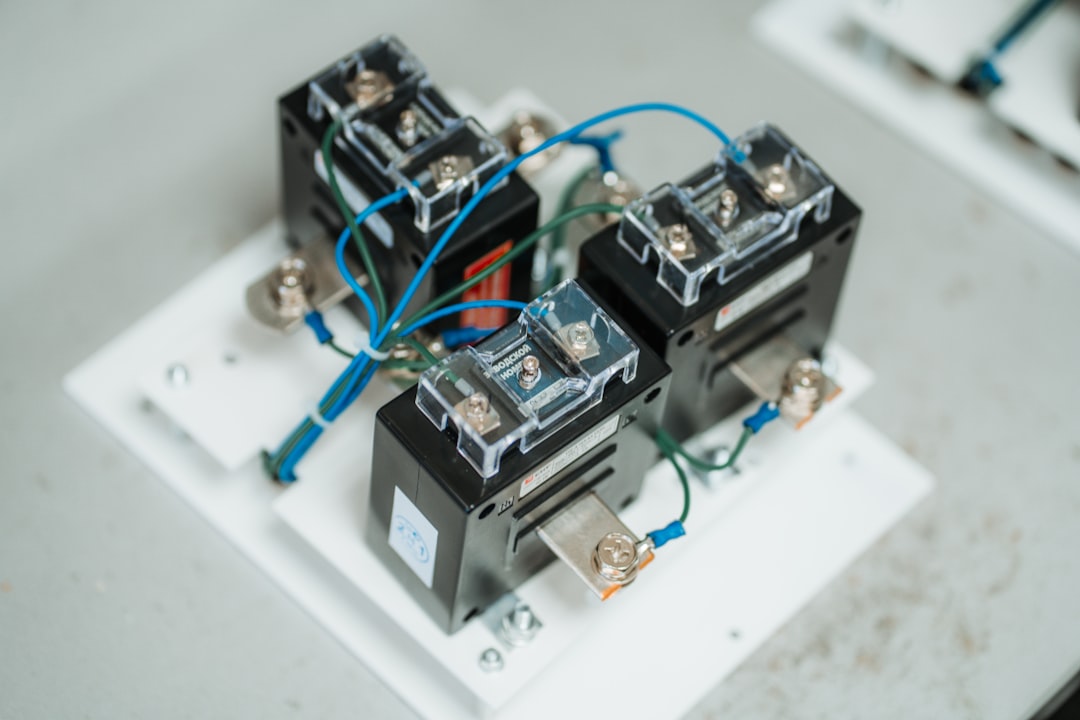

Key Design Principles for Shock-Resistant Connections

Designing a robust connection system requires careful consideration of several key factors. Firstly, **material selection** plays a crucial role. High-strength materials like hardened steel, titanium alloys, and specialized polymers are often employed to withstand high impact forces. Secondly, **geometry and design** are critical. Features like interlocking mechanisms, redundant connections, and vibration damping elements contribute to enhanced shock resistance. Thirdly, **proper assembly and installation** are essential. Incorrect installation can negate the benefits of even the most robust design. Finally, **consideration of the overall system design** is important. The connection system needs to be integrated seamlessly into the larger system to effectively distribute and absorb shock loads.

Materials Used in Shock-Resistant Connection Systems

The choice of material significantly impacts the shock resistance of a connection system. High-strength alloys like stainless steel and titanium provide excellent strength and durability, but can be expensive. Aluminum alloys offer a good balance of strength and weight, making them suitable for applications where weight is a concern. Advanced polymers, such as high-performance thermoplastics and elastomers, are increasingly used due to their ability to absorb shock and vibration. These materials often incorporate fillers and additives to enhance their mechanical properties, such as impact resistance and temperature tolerance. The selection of the optimal material depends on the specific application requirements, considering factors like strength, weight, cost, and environmental conditions.

Testing and Validation of Shock-Resistant Connections

Rigorous testing is essential to ensure the effectiveness of shock-resistant connection systems. Several standard tests are used to evaluate their performance under various shock and vibration scenarios. These include:

- Shock tests: These tests simulate sudden, high-magnitude impacts using equipment like drop towers or shock machines. The tests measure the ability of the connection to withstand these forces without failure.

- Vibration tests: These tests expose the connection to controlled vibrations over a specified frequency range and amplitude. The tests assess the connection’s ability to withstand repetitive stress and prevent fatigue failures.

- Environmental tests: These tests evaluate the connection’s performance under various environmental conditions, such as temperature extremes, humidity, and salt spray. These tests ensure the connection’s reliability in real-world operating conditions.

The specific test methods and parameters are determined based on the application requirements and relevant industry standards.

Applications of Shock-Resistant Connection Systems

Shock-resistant connection systems find wide applications across diverse industries. In the **aerospace industry**, they are crucial for ensuring the reliable operation of aircraft and spacecraft components, which experience significant shock and vibration during launch and flight. In the **military industry**, these systems are essential for the ruggedness and reliability of weapons systems and other critical equipment. The **automotive industry** utilizes them in applications such as engine mounts and suspension systems. Other applications include industrial machinery, robotics, and medical devices, where reliable connections are crucial for safety and operational efficiency. The specific design and materials used vary depending on the application’s unique requirements.

In conclusion, the development and implementation of effective shock-resistant connection systems are critical for ensuring the reliability and longevity of equipment in demanding environments. By carefully considering the design principles, material selection, and rigorous testing, engineers can create robust connections that withstand the rigors of shock and vibration, contributing to improved safety, efficiency, and reduced downtime across various industries.

Tags: shock resistant connectors, impact resistant connections, vibration damping, connection system design, robust connectors