body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

h1 {

font-size: 2.5em;

}

h2 {

font-size: 2em;

}

h3 {

font-size: 1.5em;

}

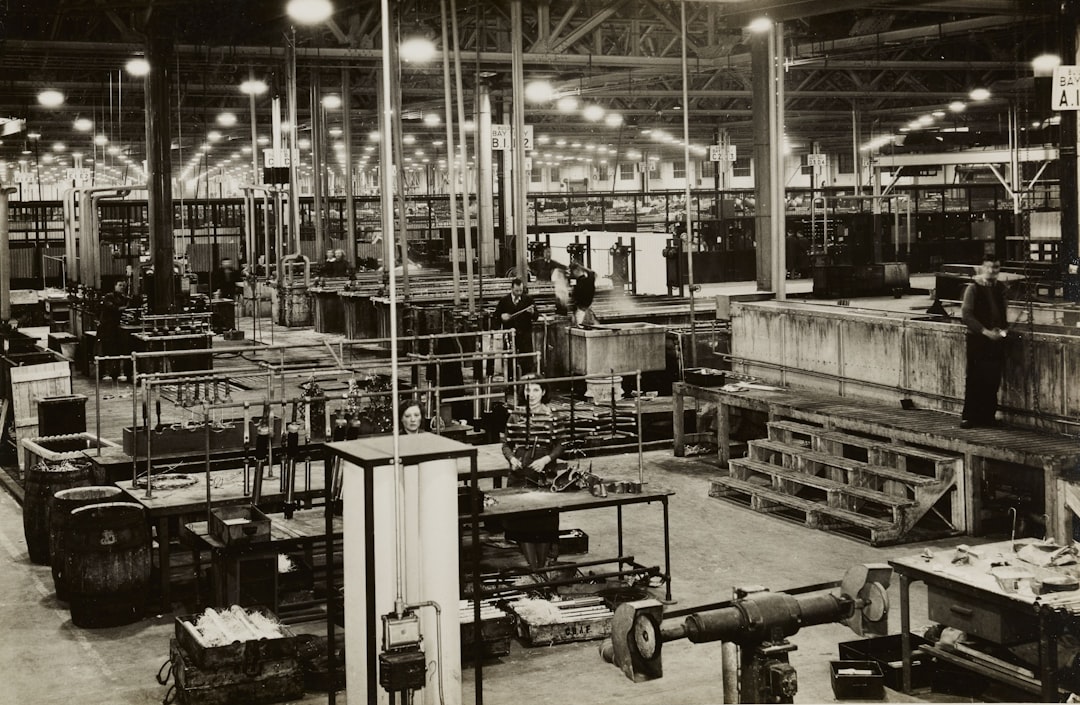

The phrase “000 ton/year production capacity” represents a significant milestone for any manufacturing or industrial operation. This seemingly simple figure encapsulates a complex interplay of factors, ranging from raw material sourcing and processing to logistical considerations and market demand. This post delves into the intricacies of this capacity level, exploring its implications and the challenges it presents.

Understanding the Significance of 000 Ton/Year Production

A production capacity of 000 tons per year signifies a substantial output, the exact implications of which depend heavily on the specific industry and product. For some industries, this might represent a relatively small-scale operation, while for others, it could be a massive undertaking. The significance lies in the scale of operations required to achieve this level of production. It necessitates significant investments in infrastructure, equipment, personnel, and management systems. This level of production often necessitates advanced planning, efficient resource allocation, and rigorous quality control measures to maintain consistent output and meet market demands.

Scaling Challenges Associated with 000 Ton/Year Production

Scaling to a 000 ton/year production capacity presents unique challenges. Simply increasing the number of machines or employees isn’t sufficient. Effective scaling requires a holistic approach addressing several key areas:

- Infrastructure: Adequate facility space, power supply, and transportation infrastructure are crucial. Expansion might require significant capital investment in new buildings, machinery, and storage facilities.

- Supply Chain Management: Securing a consistent supply of raw materials at competitive prices becomes paramount. This often involves establishing strong relationships with suppliers and implementing robust inventory management systems.

- Technology and Automation: Optimizing production processes through automation and advanced technologies is essential to maintain efficiency and productivity at this scale. This could involve implementing robotics, sophisticated control systems, and data analytics tools.

- Human Resources: Managing a larger workforce requires effective recruitment, training, and retention strategies. Clear communication channels and a well-defined organizational structure are crucial for efficient teamwork and coordination.

Market Impact and Demand Forecasting for 000 Ton/Year Output

Achieving a 000 ton/year production capacity necessitates a clear understanding of market demand. Accurately forecasting demand is critical to avoid overproduction or shortages. Market research, competitor analysis, and trend identification are all vital components of this process. Entering a new market with this level of production capacity requires a robust marketing and sales strategy to reach and acquire new customers. Understanding pricing strategies and distribution channels is equally important to effectively penetrate the market and maintain profitability.

Optimizing Efficiency and Reducing Costs at 000 Ton/Year

Maintaining profitability at this production scale demands meticulous attention to efficiency and cost reduction. Several strategies can be employed:

- Lean Manufacturing Principles: Implementing lean manufacturing techniques, such as eliminating waste and streamlining processes, can significantly improve efficiency and reduce costs.

- Inventory Management: Efficient inventory management minimizes storage costs and prevents stockouts. Just-in-time inventory systems can be highly effective.

- Energy Efficiency: Reducing energy consumption through the use of energy-efficient equipment and processes can lead to substantial cost savings.

- Waste Management: Implementing effective waste management strategies reduces disposal costs and minimizes environmental impact.

- Process Optimization: Continuous monitoring and improvement of production processes through data analysis and process optimization techniques are essential to maintain peak efficiency.

Sustainability and Environmental Considerations at Scale

Producing at a 000 ton/year capacity necessitates a strong commitment to sustainability and environmental responsibility. This includes minimizing waste, reducing energy consumption, and responsibly managing resources. Compliance with environmental regulations and adopting eco-friendly practices are not just ethical considerations but also essential for long-term business viability. Investing in renewable energy sources, implementing recycling programs, and reducing carbon emissions are crucial steps toward sustainable production at this scale.

In conclusion, achieving a 000 ton/year production capacity is a significant undertaking that requires careful planning, strategic investment, and a commitment to operational excellence. By addressing the challenges of scaling, market dynamics, efficiency optimization, and sustainability, businesses can unlock the full potential of this impressive production level and achieve long-term success.

Tags: Production Capacity, Manufacturing, Scaling, Efficiency, Sustainability, Market Demand, Industrial Production