body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

img {

max-width: 100%;

height: auto;

}

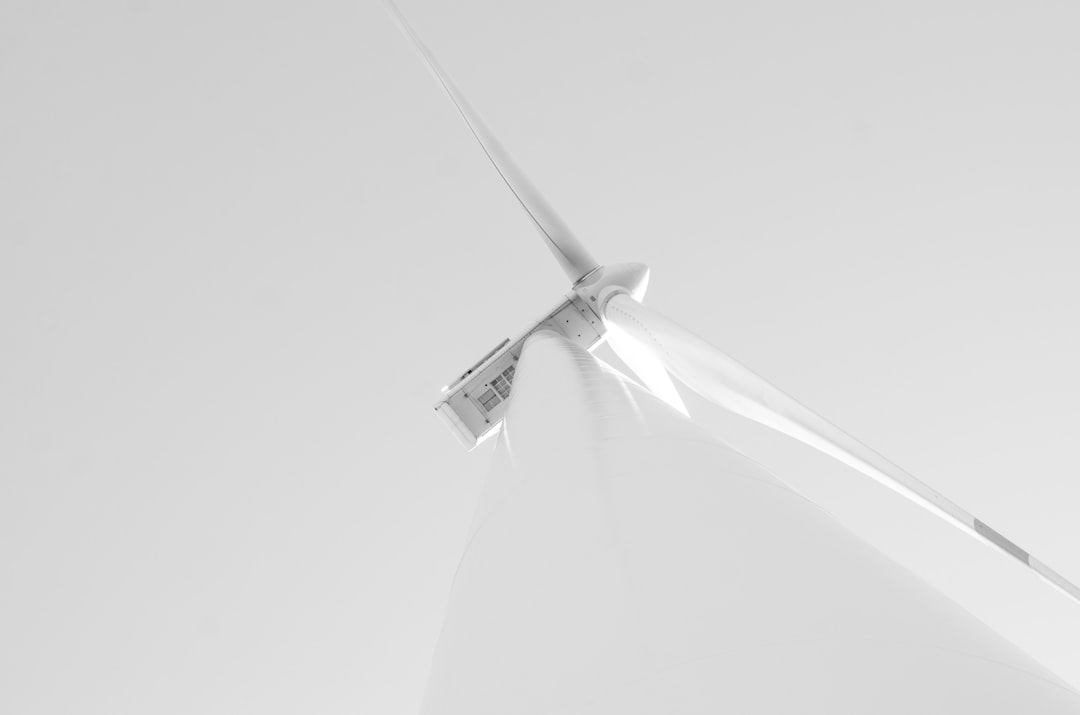

Wind turbines, the silent sentinels of renewable energy, rely on a complex interplay of engineering marvels to harness the power of the wind. While the blades themselves capture the attention, the robust and often overlooked support systems are crucial for efficient and safe operation. These systems, subjected to immense stress and fatigue, play a pivotal role in the longevity and performance of these colossal structures. This post delves into the intricacies of wind turbine blade support systems, exploring their design, materials, maintenance, and future innovations.

1. The Foundation of Power: Pitch Bearing Systems

The pitch bearing system is arguably the most critical component in blade support. It allows for the controlled adjustment of the blade’s angle (pitch) relative to the wind. This adjustment is essential for optimizing energy capture and protecting the turbine during high winds. The system typically consists of a complex arrangement of bearings, actuators, and hydraulic or electric systems. Different designs exist, including:

- Hydraulic Pitch Systems: These utilize hydraulic actuators to adjust the blade pitch. They offer high torque and precise control, but require regular maintenance and can be susceptible to leaks.

- Electric Pitch Systems: These employ electric motors and gearboxes for pitch control. They are increasingly popular due to their higher efficiency, reduced maintenance needs, and improved control accuracy.

The bearings themselves are typically designed to withstand extreme loads, vibrations, and environmental factors. High-quality materials like ceramics and advanced polymers are frequently used to ensure durability and minimize friction.

2. The Backbone of Stability: Blade Root Connections

The connection between the blade and the rotor hub is another crucial aspect of the support system. This connection must be incredibly strong and rigid to withstand the immense forces generated during operation. The design varies depending on the turbine size and type, but generally involves a complex assembly of bolts, flanges, and potentially shear webs. Materials used are typically high-strength steel alloys or composite materials designed for fatigue resistance and high tensile strength.

Careful consideration is given to stress concentration points to minimize the risk of fatigue failure. Advanced techniques like finite element analysis (FEA) are employed during the design phase to simulate real-world operating conditions and ensure structural integrity.

3. Weathering the Storm: Protection Against Environmental Factors

Wind turbines operate in harsh environments, exposed to extreme temperatures, wind speeds, and precipitation. The blade support systems must be designed to withstand these conditions. Corrosion protection is paramount, typically achieved through the use of specialized coatings, galvanization, or stainless steel components. Regular inspections and maintenance are crucial to identify and address any signs of corrosion or degradation.

Furthermore, effective sealing and drainage systems are incorporated to prevent water ingress into critical components, reducing the risk of corrosion and malfunction. The design also considers the impact of icing, especially in colder climates, with measures taken to minimize ice accumulation and prevent structural damage.

4. Monitoring and Maintenance: Ensuring Operational Efficiency

Regular monitoring and maintenance are vital for ensuring the long-term reliability and safety of wind turbine blade support systems. Modern turbines are often equipped with sophisticated monitoring systems that track key parameters such as bearing temperature, vibration levels, and blade pitch angles. This data allows for early detection of potential problems, enabling proactive maintenance and preventing costly downtime.

Maintenance activities range from routine inspections and lubrication to more complex repairs and component replacements. Advanced predictive maintenance techniques, utilizing machine learning and data analytics, are increasingly employed to optimize maintenance schedules and minimize operational disruptions.

5. The Future of Support: Innovation and Advanced Materials

Ongoing research and development efforts are focused on improving the efficiency, reliability, and sustainability of wind turbine blade support systems. This includes the exploration of new materials with enhanced strength-to-weight ratios, improved fatigue resistance, and enhanced corrosion protection. Advanced composite materials, such as carbon fiber reinforced polymers (CFRP), offer significant potential for reducing weight and improving performance.

Furthermore, advancements in sensor technology and data analytics are leading to more intelligent and proactive maintenance strategies. The integration of self-healing materials and autonomous monitoring systems promises to further enhance the reliability and longevity of wind turbine blade support systems, contributing to the continued growth of renewable energy.

In conclusion, the seemingly simple act of supporting a wind turbine blade is a complex engineering challenge requiring sophisticated design, high-quality materials, and rigorous maintenance. Understanding these systems is critical for maximizing the efficiency, lifespan, and safety of wind energy generation.

Tags: Wind Turbine Blades, Blade Support Systems, Pitch Bearing, Wind Turbine Maintenance, Renewable Energy Technology