The construction industry is undergoing a significant transformation, driven by the need for sustainable, efficient, and cost-effective building solutions. Hybrid construction, a revolutionary approach combining traditional building methods with modern techniques, is at the forefront of this change. This comprehensive guide explores the diverse facets of hybrid construction, examining its benefits, challenges, and future potential.

1. Understanding the Core Principles of Hybrid Construction

Hybrid construction isn’t simply mixing materials; it’s a strategic approach to leverage the strengths of different building systems. It involves integrating traditional materials like timber, brick, or concrete with modern elements such as steel, prefabricated components, or advanced materials like cross-laminated timber (CLT). The goal is to create a structure that’s optimized for specific project requirements, considering factors like speed of construction, cost-effectiveness, sustainability, and structural performance. This approach allows for flexibility in design and material selection, enabling architects and engineers to tailor solutions to unique project needs and site conditions. For example, a project might use a concrete core for structural stability combined with a lightweight timber frame for the external walls, minimizing weight and maximizing energy efficiency.

2. Popular Hybrid Construction Methods and Material Combinations

Several hybrid construction methods are gaining popularity. One common approach involves combining steel frames with precast concrete panels. The steel frame provides structural support and allows for greater flexibility in design, while precast concrete panels offer speed of construction, improved insulation, and reduced on-site labor. Another popular combination is timber framing with CLT panels. CLT, a highly engineered wood product, offers exceptional strength and stiffness, making it ideal for larger structures. This combination delivers a sustainable, aesthetically pleasing, and structurally sound building. Furthermore, concrete and masonry structures can be hybridized by incorporating lightweight steel or timber elements for specific components like roofs or internal partitions, enhancing design flexibility and reducing overall material weight.

3. Advantages of Embracing Hybrid Construction Techniques

Hybrid construction offers numerous advantages over traditional methods. Firstly, it significantly reduces construction time. The use of prefabricated components and efficient building systems minimizes on-site work, accelerating project completion. Secondly, it enhances sustainability. By combining materials strategically, architects can optimize resource use and reduce the environmental impact of the building’s lifecycle. For example, using timber reduces reliance on carbon-intensive concrete. Thirdly, it improves structural performance. Hybrid designs allow for optimized load distribution and increased overall strength. Finally, it offers greater design flexibility. The combination of materials allows for innovative architectural solutions that might not be achievable with traditional methods alone. This leads to more aesthetically pleasing and functional buildings.

4. Addressing the Challenges in Hybrid Construction Projects

Despite its numerous benefits, hybrid construction presents certain challenges. One key challenge is the need for specialized expertise. Successfully integrating different materials and construction techniques requires a skilled workforce with a thorough understanding of each system’s properties and interactions. Another challenge lies in coordinating different contractors and suppliers, especially when dealing with prefabricated components. Effective project management and meticulous planning are crucial to avoid delays and cost overruns. Furthermore, the design process can be more complex, requiring sophisticated software and detailed analysis to ensure structural integrity and compliance with building codes. Finally, initial costs might appear higher due to the need for specialized materials and expertise, but the long-term cost savings often outweigh these initial investments.

5. The Future of Hybrid Construction: Trends and Innovations

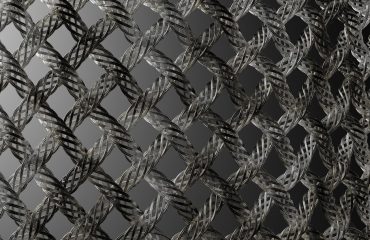

The future of hybrid construction is bright, with ongoing research and development focusing on innovative materials and techniques. The increased use of advanced materials like carbon fiber reinforced polymers (CFRP) and high-performance concrete is anticipated. These materials offer enhanced strength-to-weight ratios, leading to lighter, more sustainable structures. Furthermore, the integration of digital technologies, such as Building Information Modeling (BIM) and 3D printing, is streamlining the design and construction process. BIM allows for better coordination and collaboration among stakeholders, while 3D printing enables the creation of complex and customized components with greater precision. Finally, the development of modular and prefabricated systems is expected to further enhance efficiency and reduce construction time, leading to a more sustainable and resilient built environment.

In conclusion, hybrid construction represents a significant advancement in the building industry, offering a pathway toward more sustainable, efficient, and innovative structures. By carefully considering the advantages and challenges, and embracing technological advancements, the construction industry can unlock the full potential of this transformative approach, shaping a more sustainable and resilient future for the built environment.