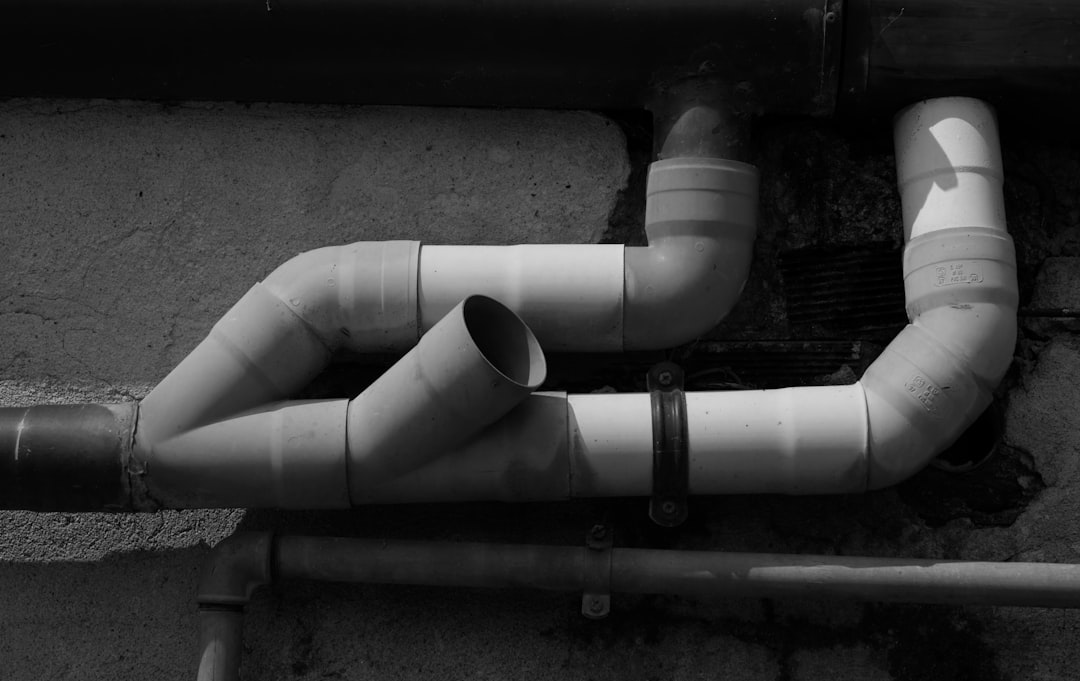

The seemingly mundane water and gas pipes hidden beneath our homes and streets are critical infrastructure, silently supporting our daily lives. Their integrity directly impacts our health, safety, and the environment. Understanding the quality standards governing these pipelines is crucial for ensuring longevity, preventing leaks, and mitigating potential hazards. This post delves into the essential aspects of these standards, exploring the materials, testing procedures, regulatory frameworks, and the consequences of substandard installations.

Material Matters: Choosing the Right Stuff for Water and Gas Pipes

The choice of material significantly influences a pipe’s lifespan, resistance to corrosion, and overall safety. For water pipes, common materials include copper, PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride), PEX (cross-linked polyethylene), and galvanized steel. Each material boasts unique properties: Copper offers excellent durability and resistance to corrosion, while PVC and CPVC are lightweight, cost-effective, and resistant to chemical degradation. PEX is flexible and easy to install, making it popular for renovations. Galvanized steel, while durable, is susceptible to corrosion over time. The selection depends on factors like water pressure, temperature, soil conditions, and budget.

Gas pipes, on the other hand, often utilize materials like black iron, galvanized steel, copper, and polyethylene. Black iron pipes are exceptionally durable but prone to rust. Galvanized steel, while offering decent strength, can corrode, potentially leading to leaks. Copper is a popular choice for its corrosion resistance, while polyethylene is favoured for its flexibility and resistance to corrosion, particularly in underground applications. Regulations often dictate the acceptable materials for gas lines depending on the pressure and location of the piping.

Rigorous Testing: Ensuring Pipeline Integrity

Before installation, water and gas pipes undergo rigorous testing to ensure they meet the required standards. These tests vary depending on the material and intended application. For water pipes, hydrostatic pressure testing is common, involving filling the pipe with water under pressure to detect leaks or weaknesses. Non-destructive testing methods, such as ultrasonic testing and radiographic testing, are employed to examine the pipe’s internal structure for flaws without damaging it. These tests are crucial for identifying defects like cracks, pinholes, or weld imperfections that could lead to future failures.

Gas pipes are also subject to stringent testing, often involving pneumatic pressure testing, which utilizes compressed air to detect leaks. Visual inspections are also carried out to check for any physical damage or signs of corrosion. Leak detection technologies, including electronic leak detection and acoustic leak detection, are increasingly used to identify subtle leaks that might be missed by traditional methods. The frequency and intensity of testing are dictated by regulations and depend on the pipe’s material, diameter, and pressure rating.

Navigating the Regulatory Landscape: Compliance and Standards

Numerous organizations and government agencies establish and enforce quality standards for water and gas pipes. In the United States, the American Society for Testing and Materials (ASTM) develops standards for pipe materials and testing procedures. The International Organization for Standardization (ISO) also publishes international standards that many countries adopt. Local building codes and plumbing codes often specify the acceptable pipe materials, installation methods, and testing requirements. Failure to comply with these regulations can lead to significant penalties, including fines and project delays.

Compliance is crucial not only for legal reasons but also for ensuring public safety. Non-compliant installations can result in leaks, which can cause water damage, gas explosions, or environmental contamination. Regular inspections and certifications by qualified professionals are essential to verify that the pipes meet the required standards.

Consequences of Substandard Pipes: Risks and Remediation

Using substandard pipes can have far-reaching consequences. Leaks in water pipes can lead to significant property damage, mold growth, and water waste. Leaks in gas pipes pose a much more serious threat, potentially causing explosions, fires, and carbon monoxide poisoning. Corrosion in pipes can reduce their lifespan, leading to premature failures and costly repairs. Environmental contamination from leaks can also have devastating consequences, affecting water sources and ecosystems.

Remediation of substandard pipes often involves replacing the affected sections or the entire pipeline. This can be a costly and disruptive process, requiring excavation, installation of new pipes, and pressure testing. Preventative maintenance, including regular inspections and timely repairs, is critical in minimizing the risk of failures and reducing the need for extensive remediation efforts.

Long-Term Strategies: Maintaining Pipeline Integrity

Maintaining the integrity of water and gas pipelines requires a proactive approach. Regular inspections are crucial for early detection of potential problems. This involves visual inspections, pressure testing, and leak detection using advanced technologies. A comprehensive maintenance plan should include a schedule for replacing aging or damaged pipes. Proper installation techniques, adherence to relevant regulations, and the use of high-quality materials are essential for ensuring the longevity and safety of pipelines. Investing in preventative maintenance is far more cost-effective than dealing with the consequences of pipe failures.

Furthermore, advancements in materials science and pipeline technology are constantly improving the durability and safety of pipelines. New materials with enhanced corrosion resistance and improved leak detection systems are continuously being developed. Staying informed about these advancements and adopting them where appropriate can contribute to a safer and more reliable pipeline infrastructure.

In conclusion, adhering to quality standards in water and gas pipes is paramount for ensuring public safety, protecting the environment, and preventing costly repairs. Understanding the materials, testing procedures, regulatory frameworks, and potential consequences of substandard installations is crucial for all stakeholders involved in the design, installation, and maintenance of these vital systems.

SEO Tags:

- Water Pipe Standards

- Gas Pipe Standards

- Pipe Material Selection

- Pipeline Safety Regulations

- Pipe Testing and Inspection