body {

font-family: sans-serif;

line-height: 1.6;

margin: 20px;

}

h1, h2, h3 {

color: #333;

}

img {

max-width: 100%;

height: auto;

display: block;

margin: 20px auto;

}

Modular steel systems are revolutionizing construction, industrial design, and various other sectors. Their adaptability, speed of assembly, and cost-effectiveness make them a compelling alternative to traditional methods. This comprehensive guide delves into the key aspects of these innovative solutions, exploring their benefits, applications, and future potential.

1. The Design Flexibility of Modular Steel Systems

One of the most significant advantages of modular steel systems lies in their unparalleled design flexibility. Unlike traditional construction, where designs are often constrained by material limitations and on-site fabrication, modular steel systems offer a wide range of customization options. Pre-engineered components can be easily combined and configured to create structures of virtually any size, shape, and complexity. This flexibility extends to incorporating various features, such as windows, doors, and specialized equipment, seamlessly integrated during the manufacturing process. This pre-planning minimizes on-site errors and significantly reduces construction time. The ability to adapt to diverse site conditions and specific client requirements makes modular steel a highly attractive option for a broad spectrum of projects, from small-scale commercial buildings to large-scale industrial facilities.

2. Cost-Effectiveness and Time Savings with Modular Steel

The prefabricated nature of modular steel systems contributes significantly to their cost-effectiveness. Off-site manufacturing in controlled environments allows for efficient resource management, reduced material waste, and optimized labor costs. The streamlined production process minimizes delays and unforeseen expenses often associated with traditional on-site construction. Furthermore, the faster assembly times associated with modular systems translate directly into reduced project timelines, leading to quicker occupancy and return on investment. This efficiency extends to transportation and logistical costs, as pre-fabricated modules are easier to transport and handle than bulky conventional materials. The overall reduction in labor hours, material waste, and project duration makes modular steel a financially sound choice for many developers and businesses.

3. Sustainability and Environmental Impact of Modular Steel Solutions

Modular steel systems are increasingly recognized for their contribution to sustainable construction practices. The controlled manufacturing environment minimizes waste generation and allows for precise material usage, reducing the overall environmental footprint. Steel itself is a highly recyclable material, further enhancing the sustainability profile of these systems. Moreover, the reduced construction time and associated transportation needs translate into lower carbon emissions compared to traditional methods. Many manufacturers are also incorporating sustainable materials and practices into their modular steel production processes, such as using recycled steel and implementing energy-efficient manufacturing techniques. This commitment to sustainability is increasingly important for environmentally conscious clients and businesses looking to minimize their impact on the planet.

4. Diverse Applications of Modular Steel Systems Across Industries

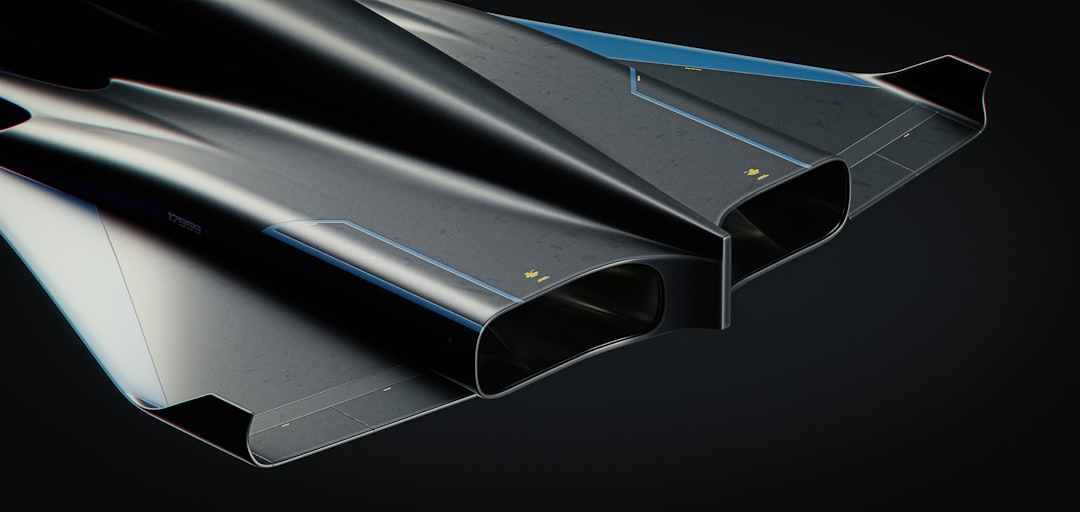

The versatility of modular steel systems extends across a wide range of industries and applications. In the construction sector, they are used for creating residential buildings, commercial structures, and industrial facilities. Their adaptability makes them ideal for temporary structures, such as event spaces and emergency shelters. The automotive and aerospace industries utilize modular steel systems for creating specialized workshops and hangars. Furthermore, the energy sector is increasingly adopting modular steel for constructing power plants and substations. The ease of transport and assembly makes them particularly suitable for remote locations and challenging terrains, where traditional construction methods might be impractical or excessively expensive. The broad applicability of these systems underscores their importance in modern construction and industrial design.

5. The Future of Modular Steel System Solutions: Innovation and Advancements

The field of modular steel system solutions is constantly evolving, driven by technological advancements and increasing demand for sustainable and efficient construction methods. Innovations in design software and manufacturing techniques are leading to more complex and sophisticated modular designs. The integration of smart technologies, such as sensors and IoT devices, is enhancing the functionality and performance of modular steel structures, enabling real-time monitoring and predictive maintenance. Research and development efforts are focused on creating even more sustainable and resilient modular systems, incorporating advanced materials and environmentally friendly manufacturing processes. The future of modular steel promises even greater efficiency, flexibility, and sustainability, solidifying its position as a leading construction and industrial design solution.

Ready to explore the potential of modular steel for your next project? Contact us today!

Tags: Modular Steel, Steel Buildings, Prefabricated Structures, Modular Construction, Sustainable Construction