body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

h1 {

font-size: 2.5em;

}

h2 {

font-size: 2em;

}

h3 {

font-size: 1.5em;

}

Cogeneration systems, also known as combined heat and power (CHP) systems, are marvels of energy efficiency, simultaneously producing electricity and usable heat. While the focus often lies on the technological advancements driving these systems, a crucial, often overlooked component is the steel used in their construction. The selection and proper application of steel are paramount to the system’s longevity, performance, and overall economic viability. This post delves into the vital role of steel in cogeneration systems.

Choosing the Right Steel Grade for Cogeneration Systems

The harsh operating conditions within cogeneration plants demand steel possessing exceptional properties. Factors such as high temperatures, pressure fluctuations, corrosive environments (from combustion byproducts and potential water interactions), and cyclical stress necessitate the use of specific steel grades. Common choices include:

- Carbon Steels: While cost-effective, carbon steels are often limited to lower-temperature applications due to their reduced high-temperature strength and creep resistance. They might be suitable for structural components experiencing less extreme conditions.

- Low Alloy Steels: These offer improved strength and creep resistance compared to carbon steels, making them appropriate for higher-temperature components and pressure vessels. Specific alloying elements enhance properties like yield strength and ductility.

- Stainless Steels: Crucial in environments prone to corrosion, stainless steels, particularly austenitic grades (like 304 and 316), provide excellent resistance to oxidation and chemical attack. They are frequently used in heat exchangers and components in contact with steam or water.

- Heat-Resistant Steels: For components operating at extremely high temperatures, such as boiler tubes and furnace linings, heat-resistant steels are essential. These alloys are designed to withstand oxidation, creep, and scaling at elevated temperatures.

The selection process depends on a thorough understanding of the specific operating parameters of the cogeneration system, including temperature ranges, pressures, and the chemical composition of the working fluids.

Corrosion Resistance: A Critical Factor in Steel Selection

Corrosion is a significant threat to the longevity and safety of cogeneration systems. The presence of moisture, oxygen, and various chemicals in the working fluids can lead to degradation of steel components. Therefore, selecting steel with high corrosion resistance is vital. The choice often depends on the specific corrosive agents present:

- High-Temperature Corrosion: At elevated temperatures, oxidation becomes a primary concern. Heat-resistant steels and properly applied protective coatings are essential to mitigate this.

- Chloride Corrosion: Chlorides, often present in water and some fuels, can accelerate corrosion. Stainless steels, particularly those with higher molybdenum content (like 316), offer enhanced resistance to chloride attack.

- Sulfidation Corrosion: Sulfur compounds in fuels can lead to sulfidation, which is particularly damaging at high temperatures. Specialized alloys with high chromium and nickel content are often used to combat this.

Regular inspections and preventative maintenance, including appropriate coatings and cathodic protection where necessary, are also crucial to managing corrosion and extending the lifespan of the steel components.

Steel’s Role in Key Cogeneration Components

Steel plays a vital role in various critical components within a cogeneration system:

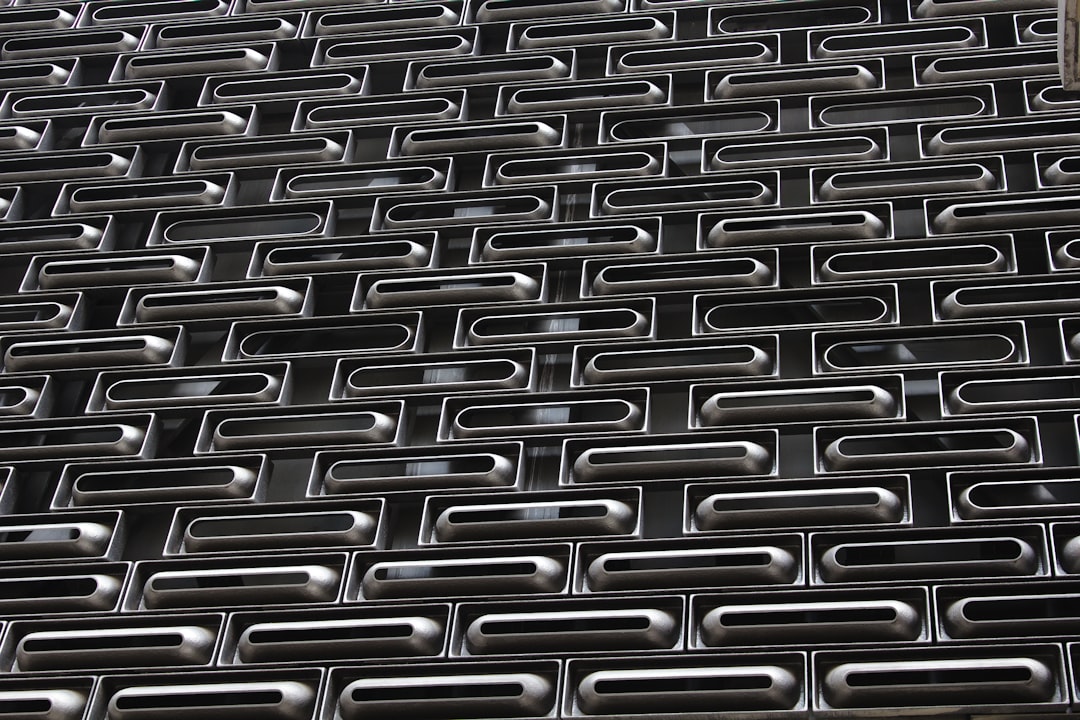

- Boilers and Heat Exchangers: These components operate under high pressure and temperature, requiring high-strength, corrosion-resistant steels. The specific grade chosen depends on the operating conditions and the type of fuel used.

- Pressure Vessels: Pressure vessels store high-pressure steam or other working fluids. The steel used must possess exceptional strength and toughness to withstand these demanding conditions. Regular inspections and testing are crucial for ensuring safety.

- Piping Systems: Steel pipes transport high-temperature steam, water, and other fluids throughout the system. The choice of steel depends on the fluid’s properties, temperature, and pressure. Proper welding and joint design are crucial for preventing leaks and failures.

- Turbines and Generators: While not entirely made of steel, turbines and generators rely heavily on steel components for structural support and critical internal parts. These components often require specialized alloys with high strength and fatigue resistance.

The integrity of these components directly impacts the efficiency, safety, and lifespan of the entire cogeneration system.

Fabrication and Welding Considerations for Steel in Cogeneration

Proper fabrication and welding techniques are crucial for ensuring the structural integrity and longevity of steel components in cogeneration systems. The specific techniques employed depend on the steel grade and the component’s geometry. Key considerations include:

- Welding Procedures: Appropriate welding processes, such as Gas Metal Arc Welding (GMAW) or Gas Tungsten Arc Welding (GTAW), must be used to ensure strong, reliable welds. Pre- and post-weld heat treatments might be necessary for certain steel grades to prevent cracking or other issues.

- Quality Control: Rigorous quality control measures, including non-destructive testing (NDT) techniques like radiography and ultrasonic testing, are essential to detect any flaws in the welds or base material.

- Material Compatibility: When different steel grades are used in a single component, careful consideration must be given to their compatibility to prevent galvanic corrosion or other issues.

Adherence to strict fabrication and welding codes and standards is paramount for ensuring the safety and reliability of the cogeneration system.

The Economic Implications of Steel Selection in Cogeneration

The initial cost of steel is only one factor in the overall economic picture. The long-term cost implications, including maintenance, repairs, and potential downtime due to component failure, are equally important. Choosing a higher-grade, more corrosion-resistant steel might increase the initial investment but can significantly reduce long-term costs by extending the lifespan of the system and minimizing maintenance needs. A thorough life-cycle cost analysis should be conducted to determine the most economically viable steel selection for a given cogeneration project.

In conclusion, the selection and application of steel are critical aspects of designing and building efficient and long-lasting cogeneration systems. Careful consideration of the operating conditions, corrosive environment, and fabrication techniques is essential for ensuring optimal performance and minimizing long-term costs.

SEO Tags:

- Cogeneration Steel

- Steel for CHP Systems

- Corrosion Resistant Steel Cogeneration

- Combined Heat and Power Steel Selection

- Heat Resistant Steel Cogeneration