body { font-family: sans-serif; line-height: 1.6; }

h1, h2, h3 { color: #333; }

img { max-width: 100%; height: auto; }

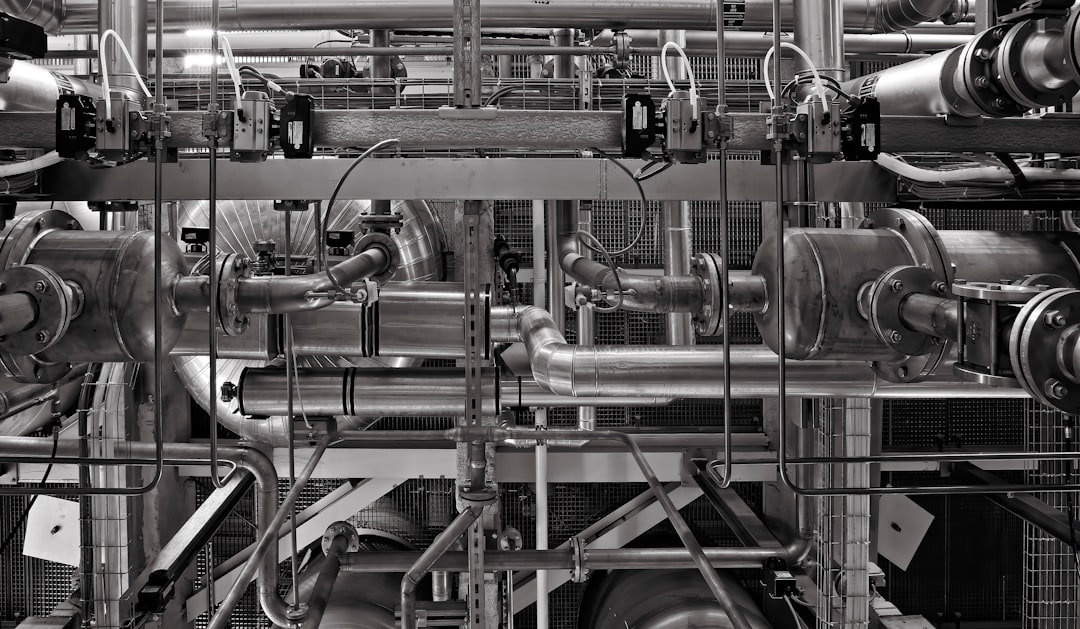

Selecting the right piping system for a chemical plant is critical. It’s not just about transporting fluids; it’s about ensuring operational safety, minimizing downtime, maximizing efficiency, and complying with stringent regulations. This comprehensive guide will walk you through the key considerations for selecting the appropriate pipes for your specific chemical processing needs.

1. Material Compatibility: The Cornerstone of Chemical Plant Piping

The most fundamental aspect of pipe selection is material compatibility. The pipe material must be inert to the chemicals it will transport, preventing corrosion, degradation, and potential leaks. This requires a thorough understanding of the chemical properties of the fluids, including their pH, temperature, pressure, and concentration. Common materials used in chemical plants include:

- Stainless Steel (304, 316, etc.): Excellent corrosion resistance, high strength, and suitable for a wide range of chemicals. The specific grade chosen depends on the aggressiveness of the chemicals.

- Carbon Steel: Cost-effective for less corrosive applications, but requires protective coatings or linings for many chemical processes. Prone to rust and degradation in the presence of moisture and certain chemicals.

- Duplex Stainless Steel: Combines the strength of carbon steel with the corrosion resistance of stainless steel, ideal for high-pressure and corrosive environments.

- PVC, CPVC, and other Plastics: Suitable for less aggressive chemicals and lower pressure applications. Offer excellent corrosion resistance but may have limitations in terms of temperature and pressure.

- Hastelloy, Monel, and other Nickel Alloys: Extremely resistant to corrosion, even in highly aggressive environments, but are significantly more expensive.

Material selection often involves consulting material compatibility charts and conducting specific tests to ensure compatibility with the intended chemicals under the operating conditions.

2. Pressure Ratings and Flow Characteristics: Optimizing Performance

Pipes must withstand the operating pressure and flow rates of the chemical process. Pressure ratings are typically expressed in pounds per square inch (psi) or bars. The selected pipe must have a pressure rating significantly higher than the maximum expected operating pressure, incorporating a safety factor. Flow characteristics are equally important. Pipe diameter, length, and internal roughness influence flow velocity, pressure drop, and overall system efficiency. Using computational fluid dynamics (CFD) simulations can optimize pipe sizing for efficient flow and minimize energy consumption.

Factors to consider include the viscosity of the fluid, the desired flow rate, and the allowable pressure drop across the piping system. Incorrect pipe sizing can lead to excessive pressure drops, reduced flow rates, and increased energy costs.

3. Corrosion Resistance: Preventing Degradation and Ensuring Longevity

Corrosion is a major concern in chemical plant piping. It can lead to leaks, equipment failure, and safety hazards. Selecting corrosion-resistant materials is crucial, but additional measures may be necessary. These include:

- Protective Coatings: Applying coatings like epoxy or polyurethane can enhance corrosion resistance, especially for carbon steel pipes.

- Linings: Internal linings made of materials like PTFE or rubber can provide a barrier between the pipe and the corrosive chemicals.

- Corrosion Inhibitors: Adding chemicals to the fluid can slow down the corrosion process.

- Cathodic Protection: This electrochemical method protects metal pipes from corrosion by supplying an external current.

Regular inspection and maintenance are essential to detect and address corrosion before it becomes a significant problem.

4. Regulatory Compliance: Meeting Industry Standards and Safety Regulations

Chemical plant piping must comply with a range of regulations and industry standards to ensure safety and environmental protection. These regulations vary depending on the location and the specific chemicals being handled. Examples include:

- ASME B31.3: Covers process piping.

- API Standards: Relevant for petroleum and gas processing.

- OSHA Regulations: Address workplace safety.

- EPA Regulations: Cover environmental protection.

Understanding and adhering to these regulations is crucial to avoid penalties and ensure the safety of workers and the environment. Proper documentation and traceability of materials are essential for compliance.

5. Cost Optimization: Balancing Performance and Budget

While material compatibility and safety are paramount, cost is also a significant factor in pipe selection. Different materials have vastly different costs, and the overall cost of the piping system depends on factors like pipe diameter, length, fittings, valves, and installation. A cost-benefit analysis should be conducted to balance performance requirements with budgetary constraints. This may involve considering a combination of materials, utilizing less expensive materials where appropriate, and optimizing pipe sizing to minimize material usage.

Life cycle costs should also be considered. A more expensive, but longer-lasting, material might be more cost-effective in the long run compared to a cheaper material that requires more frequent replacement.

Choosing the right piping system for a chemical plant is a complex process requiring careful consideration of multiple factors. By understanding material compatibility, pressure ratings, corrosion resistance, flow characteristics, and regulatory compliance, and by conducting a thorough cost-benefit analysis, you can select a piping system that ensures safety, efficiency, and longevity.

Tags:

Chemical Plant Piping, Pipe Selection, Material Compatibility, Process Piping, Chemical Engineering