The American Petroleum Institute (API) 5L standard is a cornerstone in the oil and gas industry, defining the specifications for line pipe used in pipelines transporting hydrocarbons. Understanding this standard is crucial for engineers, contractors, and anyone involved in the design, construction, and maintenance of pipelines. This comprehensive guide will delve into the intricacies of API 5L, providing a clear understanding of its various aspects.

Understanding API 5L Pipe Grades and Their Applications

API 5L specifies various grades of line pipe, each designed to meet specific strength, toughness, and weldability requirements. These grades are designated by letters and numbers (e.g., API 5L Grade B, API 5L Grade X42, API 5L Grade X70, etc.). The numerical designation (e.g., 42, 70) represents the minimum specified yield strength in thousands of pounds per square inch (ksi). Higher numbers indicate greater strength. Different grades are suitable for different applications based on factors like operating pressure, temperature, and environmental conditions.

For instance, lower-grade pipes like API 5L Grade B are often used in low-pressure applications, while higher-grade pipes such as API 5L Grade X80 and beyond are employed in high-pressure, long-distance pipelines transporting high-value products. The choice of grade is critical for ensuring the safety and reliability of the pipeline system.

Beyond the yield strength, other factors influencing grade selection include:

- Tensile Strength: The maximum stress a pipe can withstand before breaking.

- Elongation: The pipe’s ability to stretch before breaking, indicating ductility.

- Bend Test: Assessing the pipe’s ability to withstand bending without cracking.

- Hardness: Related to the pipe’s resistance to indentation and wear.

Detailed Specifications Covered by API 5L

The API 5L standard doesn’t just specify the material properties; it also covers a wide range of other aspects critical to the quality and performance of line pipe. These include:

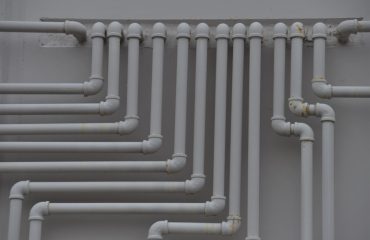

- Pipe Dimensions: Precise specifications for the outer diameter, wall thickness, and length of the pipe are provided to ensure proper fit and functionality.

- Manufacturing Processes: API 5L outlines acceptable manufacturing techniques, including seamless and welded processes. It specifies requirements for welding procedures, heat treatments, and other crucial manufacturing steps.

- Surface Finish: The standard dictates acceptable surface conditions, minimizing imperfections that could compromise the pipe’s integrity.

- Tolerances: Allowable variations in dimensions are specified to account for manufacturing processes.

- Marking and Identification: Clear marking requirements ensure traceability and proper identification of the pipe grade, manufacturer, and other relevant information.

Comprehensive Testing and Quality Control Procedures

Rigorous testing and quality control are essential to ensure that API 5L line pipe meets the specified requirements. The standard outlines various tests that must be conducted throughout the manufacturing process, including:

- Chemical Composition Analysis: To verify that the steel meets the required chemical composition.

- Tensile Testing: To determine the tensile strength, yield strength, and elongation of the pipe material.

- Hydrostatic Testing: To verify the pipe’s ability to withstand internal pressure.

- Flattening Test: To assess the pipe’s ability to withstand flattening without cracking.

- Bend Test: To evaluate the pipe’s ductility and resistance to bending.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing (UT) and radiographic testing (RT) are used to detect internal flaws without damaging the pipe.

These tests ensure that only pipes meeting the stringent quality standards are used in pipeline projects.

Ensuring API 5L Compliance: A Critical Aspect of Pipeline Safety

Compliance with API 5L is not merely a suggestion; it’s a critical requirement for ensuring the safety and reliability of pipelines. Failure to comply can lead to serious consequences, including leaks, ruptures, and environmental damage. Operators and contractors must adhere strictly to the standard’s specifications and testing procedures throughout the entire pipeline lifecycle. This includes proper procurement, inspection, installation, and maintenance.

Independent third-party inspections are often employed to verify compliance. These inspections ensure that the pipe used meets the specified requirements and that proper installation and testing procedures are followed.

The Evolution of API 5L and Future Trends

The API 5L standard is not static; it evolves to reflect advancements in materials science, manufacturing techniques, and pipeline engineering. Regular revisions and updates incorporate new technologies and best practices to enhance pipeline safety and performance. Future trends include a focus on:

- Higher Strength Grades: The development of even stronger grades of line pipe to meet the demands of increasingly complex and challenging pipeline projects.

- Improved Corrosion Resistance: The incorporation of advanced coatings and materials to enhance the pipe’s resistance to corrosion and extend its lifespan.

- Enhanced Weldability: Improvements in welding techniques and materials to ensure high-quality welds.

- Sustainable Manufacturing Practices: A growing emphasis on environmentally friendly manufacturing processes to minimize the environmental impact of pipeline construction.

Staying abreast of these developments is crucial for anyone involved in the pipeline industry.

Understanding API 5L is essential for anyone working with pipelines. This standard is a critical element in ensuring the safety, reliability, and longevity of pipeline infrastructure. By adhering to its specifications and testing requirements, the industry can minimize risks and contribute to a safer and more sustainable energy future.

Tags: API 5L, API 5L pipe, line pipe, pipeline standards, oil and gas pipeline, steel pipe specifications