body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

img {

max-width: 100%;

height: auto;

}

In the world of industrial machinery, standardized parts often fall short of meeting specific operational demands. This is where the power of customized steel machine parts comes into play. By tailoring components to precise specifications, manufacturers can optimize performance, enhance durability, and achieve unparalleled efficiency. This comprehensive guide delves into the intricacies of customized steel machine parts, exploring their design, manufacturing, applications, and the significant advantages they offer.

Designing for Precision: The Custom Steel Part Design Process

Designing a custom steel machine part begins with a thorough understanding of the application. Engineers work closely with clients to define the part’s function, operating environment, and performance requirements. This involves detailed analysis of stress points, load capacity, and potential wear and tear. Advanced computer-aided design (CAD) software is employed to create precise 3D models, allowing for virtual testing and optimization before physical production. Material selection is crucial at this stage, considering factors like strength, corrosion resistance, and cost-effectiveness. Common steel grades used include high-carbon steel, alloy steel, stainless steel, and tool steel, each offering unique properties.

Material Matters: Selecting the Right Steel for Your Custom Part

The choice of steel significantly impacts the performance and lifespan of a custom machine part. High-carbon steel offers exceptional strength and hardness, making it ideal for high-stress applications. Alloy steels, with their enhanced properties through the addition of alloying elements, provide superior toughness, wear resistance, and corrosion resistance. Stainless steel is preferred where corrosion is a major concern, such as in food processing or chemical industries. Tool steels, renowned for their exceptional hardness and wear resistance, are frequently used for cutting tools and dies. The selection process involves careful consideration of the specific demands of the application, balancing performance needs with cost and availability.

Manufacturing Methods: Shaping Steel into Precision Components

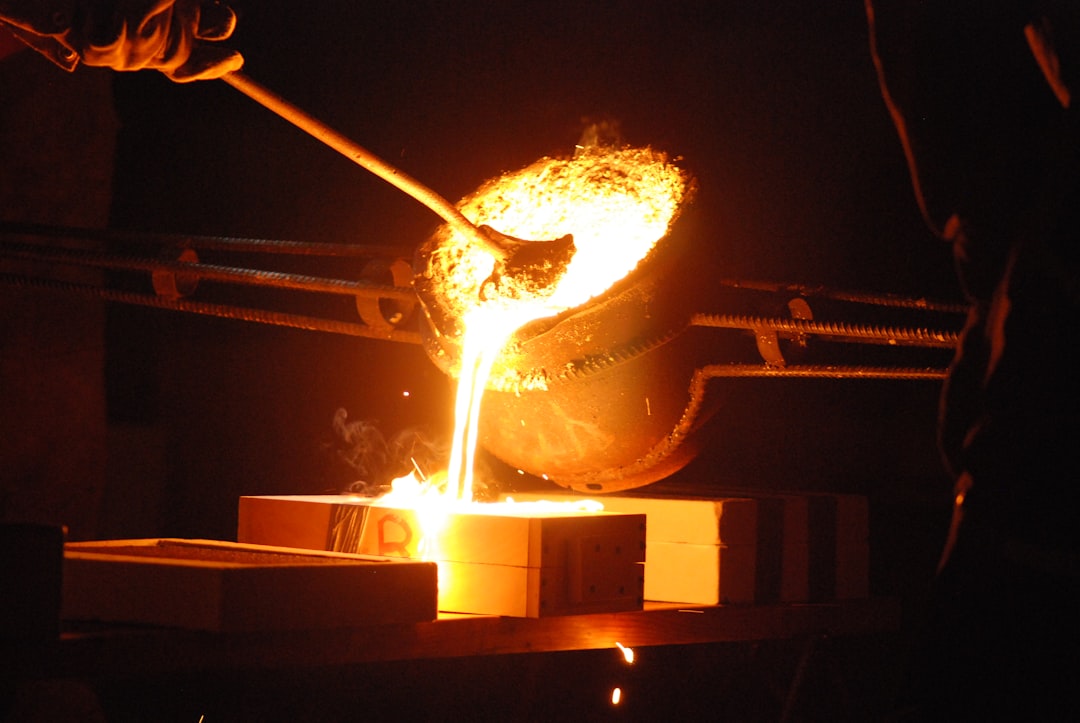

Various manufacturing processes are employed to create customized steel machine parts, each offering unique advantages. Forging, a process involving shaping metal using compressive forces, produces exceptionally strong and durable components. Machining, using tools to remove material from a workpiece, allows for precise dimensions and intricate details. Casting, pouring molten metal into a mold, is cost-effective for complex shapes, while 3D printing offers unparalleled design flexibility and rapid prototyping capabilities. The choice of manufacturing method depends on factors such as part complexity, required tolerances, material properties, and production volume. Advanced manufacturing techniques like laser cutting and waterjet cutting ensure high precision and efficient material utilization.

Applications Across Industries: Where Custom Steel Parts Shine

Customized steel machine parts find applications across a wide range of industries. In the automotive industry, they are integral to engine components, transmissions, and chassis systems. The aerospace industry relies on custom steel parts for high-strength, lightweight components in aircraft and spacecraft. Manufacturing uses custom parts for machinery, tooling, and automation systems. The energy sector utilizes them in power generation equipment and oil and gas extraction machinery. The medical device industry employs custom steel parts in surgical instruments and implants. The versatility of custom steel parts allows for tailored solutions to meet the unique requirements of diverse applications.

The Advantages of Customized Steel Machine Parts: Beyond Standardization

Choosing customized steel machine parts offers several compelling advantages over using off-the-shelf components. Firstly, it allows for precise optimization of performance, ensuring the part meets the specific demands of the application. Secondly, it enhances durability and lifespan, reducing the frequency of replacements and minimizing downtime. Thirdly, it enables the creation of innovative designs that are not possible with standardized parts, leading to improved efficiency and functionality. Fourthly, it allows for the incorporation of specialized features such as coatings or surface treatments to enhance specific properties like corrosion resistance or wear resistance. Finally, it offers the opportunity to reduce overall costs in the long run by improving efficiency and reducing maintenance needs. The investment in custom parts often translates to significant long-term savings.

In conclusion, customized steel machine parts represent a powerful solution for manufacturers seeking to optimize performance, enhance durability, and drive innovation. By carefully considering design, material selection, and manufacturing processes, engineers can create components that precisely meet the unique demands of their applications, delivering significant advantages across diverse industries. The investment in custom solutions ultimately leads to greater efficiency, reduced downtime, and a competitive edge in the marketplace.

SEO Tags:

- Custom Steel Machine Parts

- Customized Steel Components

- Precision Steel Parts Manufacturing

- Industrial Steel Parts

- Custom Metal Fabrication