The construction industry is undergoing a significant transformation, driven by the increasing demand for faster, more efficient, and sustainable building solutions. Prefabricated steel buildings are at the forefront of this revolution, offering a compelling alternative to traditional construction methods. This post delves into the exciting innovations shaping the future of prefab steel structures, highlighting their impact on various sectors.

1. Sustainable Steel: Eco-Friendly Prefab Construction

Sustainability is no longer a niche concern; it’s a core requirement for modern construction. Prefab steel buildings are inherently more sustainable than many traditional alternatives. Steel is a highly recyclable material, significantly reducing the environmental impact of demolition and waste disposal. Furthermore, advancements in steel production are continually lowering carbon emissions. Innovations like using recycled steel content in the manufacturing process and employing greener energy sources in steel mills are drastically improving the ecological footprint of these structures. Beyond the material itself, prefab construction minimizes on-site waste, reduces transportation needs (as components are pre-fabricated off-site), and often incorporates energy-efficient design features, leading to lower operational costs and a smaller carbon footprint throughout the building’s lifecycle.

2. Advanced Design & Engineering: Pushing the Boundaries of Steel

Modern software and design techniques are revolutionizing the capabilities of prefab steel buildings. Building Information Modeling (BIM) allows for precise 3D modeling, facilitating seamless integration of various building systems and components. This precision minimizes errors, reduces material waste, and ensures a smoother construction process. Advanced Finite Element Analysis (FEA) software enables engineers to optimize steel structures for strength, durability, and resistance to seismic activity and extreme weather conditions. These sophisticated tools allow for the creation of complex and aesthetically pleasing designs that were previously impossible with traditional steel construction methods. The result is stronger, safer, and more adaptable buildings.

3. Modular Construction & Rapid Deployment: Speeding Up the Build Process

The modular nature of prefab steel construction significantly accelerates the building process. Components are pre-fabricated in a controlled factory environment, minimizing weather delays and on-site disruptions. This modular approach allows for parallel construction activities, further speeding up the timeline. Once the modules are transported to the site, they are assembled quickly and efficiently, often reducing construction time by weeks or even months compared to traditional methods. This rapid deployment is particularly beneficial for projects with tight deadlines, such as temporary housing, disaster relief efforts, and commercial projects where time is money.

4. Smart Steel: Integrating Technology for Enhanced Functionality

The integration of smart technology is transforming prefab steel buildings into intelligent, responsive structures. Sensors embedded within the structure can monitor various parameters, such as temperature, humidity, and structural integrity, providing real-time data for predictive maintenance and energy management. Smart building management systems can optimize energy consumption, improve security, and enhance occupant comfort. This integration allows for greater efficiency, reduced operational costs, and enhanced safety. The ability to remotely monitor and control building systems offers unparalleled convenience and control.

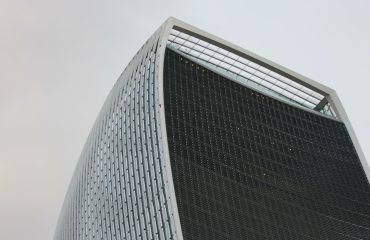

5. Customization & Design Flexibility: Beyond the Standard Steel Box

While historically associated with utilitarian designs, prefab steel buildings are now increasingly customizable. Advances in manufacturing techniques allow for greater design flexibility, enabling architects and builders to create structures that are both functional and aesthetically pleasing. From curved walls and intricate facades to unique roof designs, the possibilities are expanding. The ability to incorporate various finishes, cladding materials, and window systems allows for the creation of buildings that seamlessly blend into their surroundings or make a bold architectural statement. This flexibility caters to a wider range of applications, from residential and commercial buildings to industrial facilities and specialized structures.

The innovations discussed above demonstrate the transformative potential of prefab steel buildings. They offer a compelling solution for meeting the growing demands of a rapidly evolving construction landscape, emphasizing sustainability, efficiency, and design flexibility. As technology continues to advance, we can expect even more groundbreaking innovations in this exciting field.

SEO Tags: Prefab Steel Buildings, Steel Building Construction, Modular Construction, Sustainable Steel Buildings, Smart Buildings