The steel industry is the backbone of countless modern applications, from skyscrapers to automobiles. Ensuring the quality and reliability of steel products is paramount, and this is where ASTM International standards play a critical role. ASTM compliance in steel production isn’t just a matter of ticking boxes; it’s a commitment to safety, performance, and the integrity of the final product. This comprehensive guide delves into the significance of ASTM compliance, exploring its various facets and highlighting its impact on the steel industry.

Understanding ASTM Standards and Their Relevance to Steel

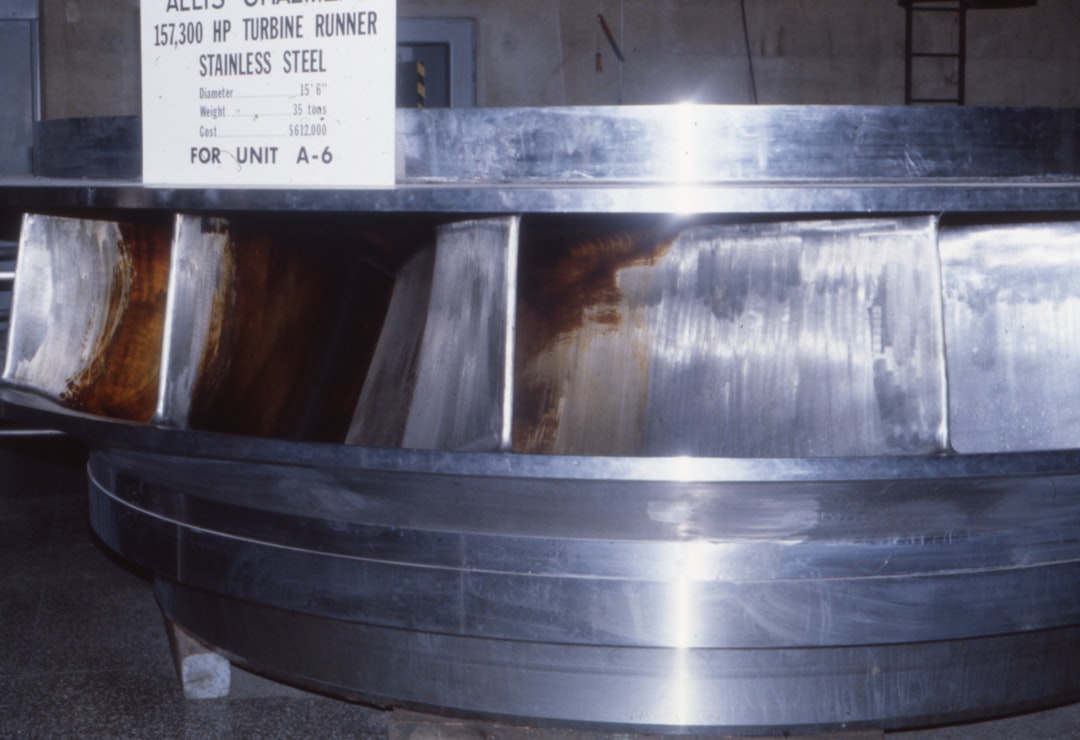

ASTM International (formerly the American Society for Testing and Materials) develops and publishes voluntary consensus standards for materials, products, systems, and services. These standards provide a common language and framework for specifying material properties, testing methods, and acceptance criteria. In the steel industry, ASTM standards are crucial for ensuring that steel products meet specific performance requirements, regardless of the manufacturer or location. These standards cover a vast range of steel types, including carbon steel, alloy steel, stainless steel, and other specialized grades. Adherence to ASTM standards ensures consistency, predictability, and reliability, fostering trust and confidence among manufacturers, suppliers, and consumers.

Key ASTM Standards Used in Steel Production

Numerous ASTM standards are directly relevant to steel production. Some of the most widely used include:

- ASTM A36: This standard specifies the requirements for structural steel for buildings. It defines chemical composition, mechanical properties (tensile strength, yield strength, elongation), and impact testing requirements.

- ASTM A572: This standard covers high-strength low-alloy structural steel, often used in bridges and other high-load applications. It provides detailed specifications for various grades, each with its own unique strength and toughness characteristics.

- ASTM A6: This covers general requirements for steel wire and rod. It outlines tests and requirements for the properties necessary for various applications.

- ASTM E8: This standard outlines the standard method for tension testing of metallic materials, a fundamental test for determining the mechanical properties of steel.

- ASTM A370: This standard details methods and practices for testing metallic materials, encompassing many techniques used in steel quality control.

These are just a few examples; many other ASTM standards address specific steel grades, testing methodologies, and other crucial aspects of steel production.

The Importance of ASTM Compliance in Quality Control

ASTM compliance is integral to a robust quality control system in steel production. By adhering to these standards, manufacturers can:

- Ensure consistent product quality: Standards provide clear specifications, minimizing variations in material properties.

- Reduce defects and waste: Proper testing and adherence to standards help identify and rectify defects early in the production process.

- Improve safety: Meeting specific strength and toughness requirements ensures the structural integrity of steel components, enhancing safety in applications ranging from buildings to bridges.

- Enhance customer confidence: Demonstrating compliance with recognized standards builds trust and confidence with customers.

- Facilitate international trade: ASTM standards are widely recognized globally, simplifying international trade and collaboration.

A comprehensive quality control program will incorporate regular testing and documentation to ensure continuous compliance.

Certification and Accreditation in Relation to ASTM Compliance

Certification and accreditation further strengthen the assurance of ASTM compliance. Independent third-party organizations can audit steel producers to verify their adherence to ASTM standards. These certifications provide an external validation of the manufacturer’s commitment to quality and compliance. Accredited testing laboratories play a crucial role by conducting the necessary tests to ensure that steel products meet the specified requirements. The results of these tests are documented and used to support certification claims.

Consequences of Non-Compliance with ASTM Standards

Failure to comply with ASTM standards can have serious consequences, including:

- Product recalls: If defects are discovered due to non-compliance, it can lead to costly product recalls and reputational damage.

- Legal liabilities: Non-compliance can result in legal action if the non-compliant product causes damage or injury.

- Loss of market share: Customers may lose confidence in a manufacturer who consistently fails to meet quality standards.

- Increased production costs: Corrective actions and rework due to non-compliance can significantly increase production costs.

- Reputational damage: Non-compliance can severely damage a company’s reputation and credibility within the industry.

Therefore, a proactive approach to ASTM compliance is crucial for the long-term success and sustainability of any steel producer.

In conclusion, ASTM compliance is not merely a regulatory requirement but a fundamental pillar of responsible and successful steel production. By embracing these standards, manufacturers can ensure the quality, safety, and reliability of their products, building a strong reputation and contributing to the safety and stability of countless structures and applications worldwide.

SEO-Friendly Tags:

- ASTM Steel Standards

- Steel Quality Control

- ASTM Compliance in Manufacturing

- Steel Material Testing

- ASTM Certification