In the competitive landscape of today’s manufacturing industry, delivering flawless products is no longer a luxury; it’s a necessity. The pursuit of zero-defect production goals, while seemingly unattainable, offers significant advantages, from enhanced brand reputation to reduced costs and improved customer satisfaction. This post delves into the strategies, challenges, and ultimate rewards of striving for perfection in your manufacturing process.

Understanding the Zero-Defect Philosophy

The concept of zero-defect production isn’t about achieving absolute perfection, where no defects ever occur. Instead, it represents a mindset—a relentless pursuit of excellence and continuous improvement. It’s about minimizing defects to a level that’s practically negligible, impacting neither the consumer nor the bottom line. This philosophy requires a fundamental shift in organizational culture, emphasizing proactive defect prevention rather than reactive defect detection. It necessitates a deep understanding of the production process, identifying potential failure points and implementing robust preventative measures. This approach requires buy-in from every level of the organization, fostering a culture of accountability and shared responsibility for quality.

Implementing Effective Quality Control Measures

Effective quality control is the backbone of any zero-defect strategy. This involves implementing a multi-layered approach that encompasses various stages of production. This starts with robust design and engineering processes, ensuring that the product is inherently robust and less prone to defects. Next, rigorous inspection and testing procedures throughout the manufacturing process are crucial. This might include statistical process control (SPC), which uses statistical methods to monitor and control the production process, ensuring it stays within acceptable limits. Regular audits and quality checks, both internal and external, provide valuable feedback and identify areas for improvement. Implementing advanced technologies such as automated inspection systems can enhance efficiency and accuracy in defect detection.

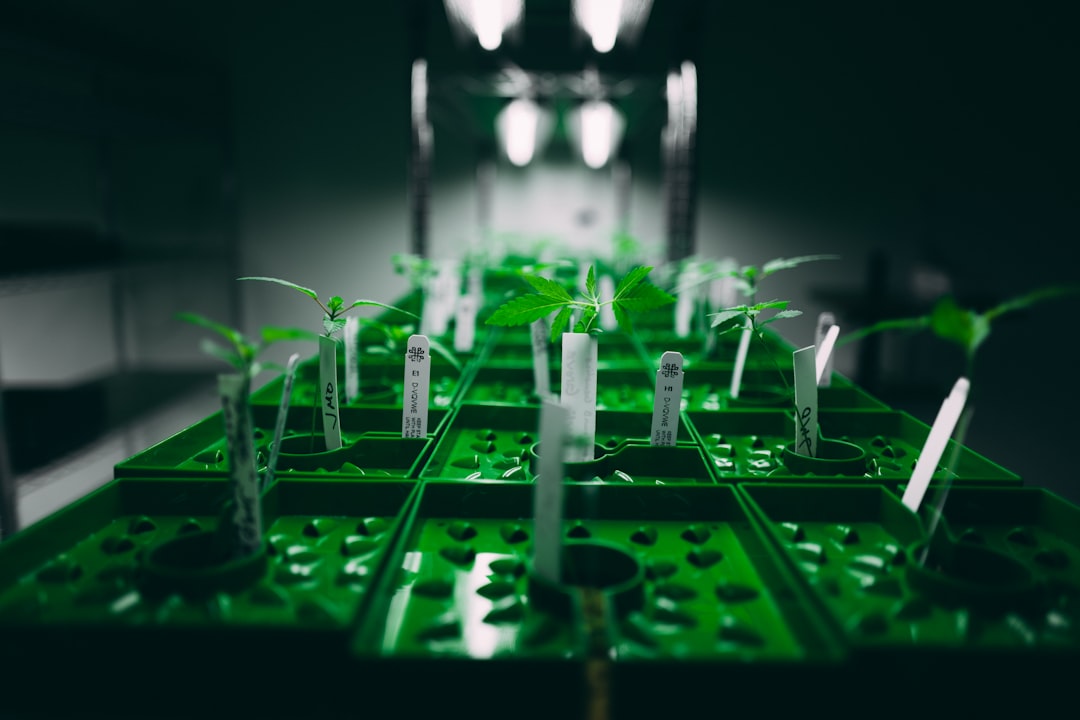

The Role of Technology in Zero-Defect Production

Technology plays a pivotal role in achieving zero-defect goals. Advanced manufacturing technologies like automation, robotics, and AI-powered systems can significantly reduce human error, a major contributor to defects. Automated inspection systems can detect even minute imperfections with higher accuracy and speed than human inspectors. Data analytics and predictive maintenance tools can analyze production data to identify potential problems before they occur, enabling proactive adjustments to prevent defects. Implementing a robust Manufacturing Execution System (MES) can provide real-time visibility into the production process, allowing for prompt identification and resolution of issues. Investing in these technologies represents a significant upfront cost, but the long-term benefits in terms of reduced defects, improved efficiency, and enhanced product quality often outweigh the initial investment.

Overcoming the Challenges of Zero-Defect Production

While the benefits are substantial, the path to zero-defect production is not without its challenges. One major hurdle is the significant investment required in advanced technologies, training, and process improvement initiatives. Resistance to change within the organization can also hinder progress, as employees may be hesitant to adopt new methods and technologies. Achieving true zero defects requires a fundamental shift in mindset, demanding a commitment to continuous improvement and a culture of proactive problem-solving. Furthermore, unforeseen circumstances, such as supply chain disruptions or material defects from external suppliers, can impact the ability to maintain zero-defect production. Effective risk management and contingency planning are essential to mitigate these challenges.

The Benefits of Achieving Zero-Defect Production

The rewards of pursuing zero-defect production goals are compelling. Reduced waste and rework significantly lower production costs. Improved product quality leads to enhanced customer satisfaction and loyalty, strengthening brand reputation. Minimizing defects reduces the need for costly recalls and warranty claims, protecting the company’s financial stability. Higher quality products command premium prices, increasing profitability. Moreover, a culture of continuous improvement fosters a more engaged and motivated workforce, boosting employee morale and productivity. Ultimately, the pursuit of zero defects translates into a competitive advantage, allowing the company to thrive in a demanding marketplace.

In conclusion, while achieving absolute zero defects may be an ideal, the journey towards it is a crucial step in achieving manufacturing excellence. By implementing the strategies outlined above and embracing a culture of continuous improvement, organizations can significantly reduce defects, enhance product quality, and reap substantial rewards.